Permeable brick paving ground and construction method

A construction method and ground technology, applied to pavement details, roads, roads, etc., can solve the problems of single rainwater discharge, lack of water permeability, and affect the effect of rainwater infiltration, so as to avoid the effect of water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

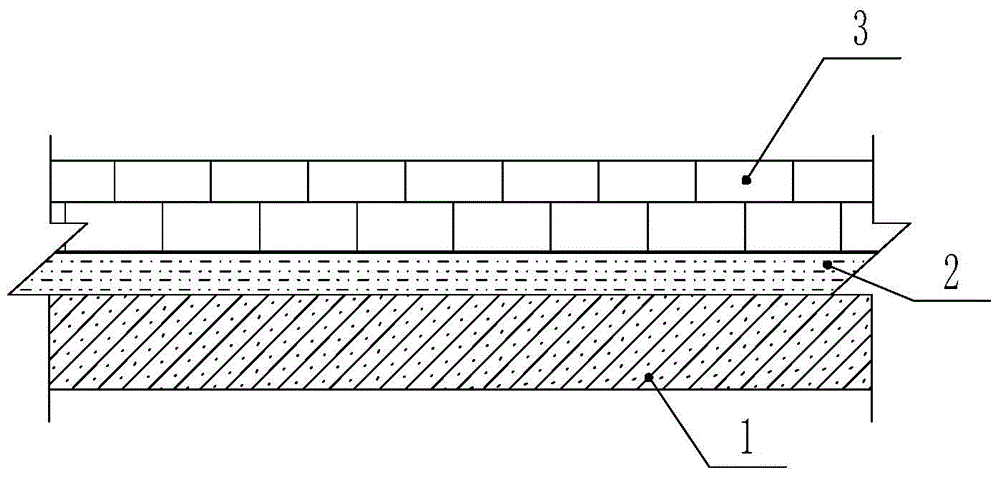

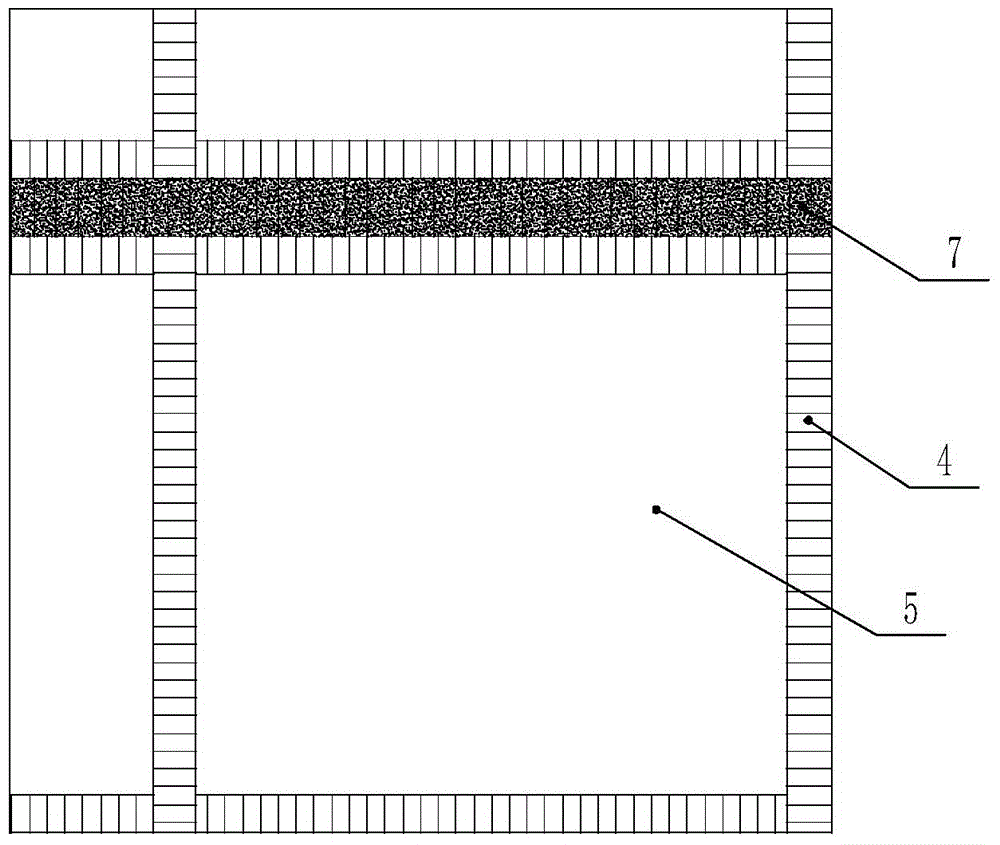

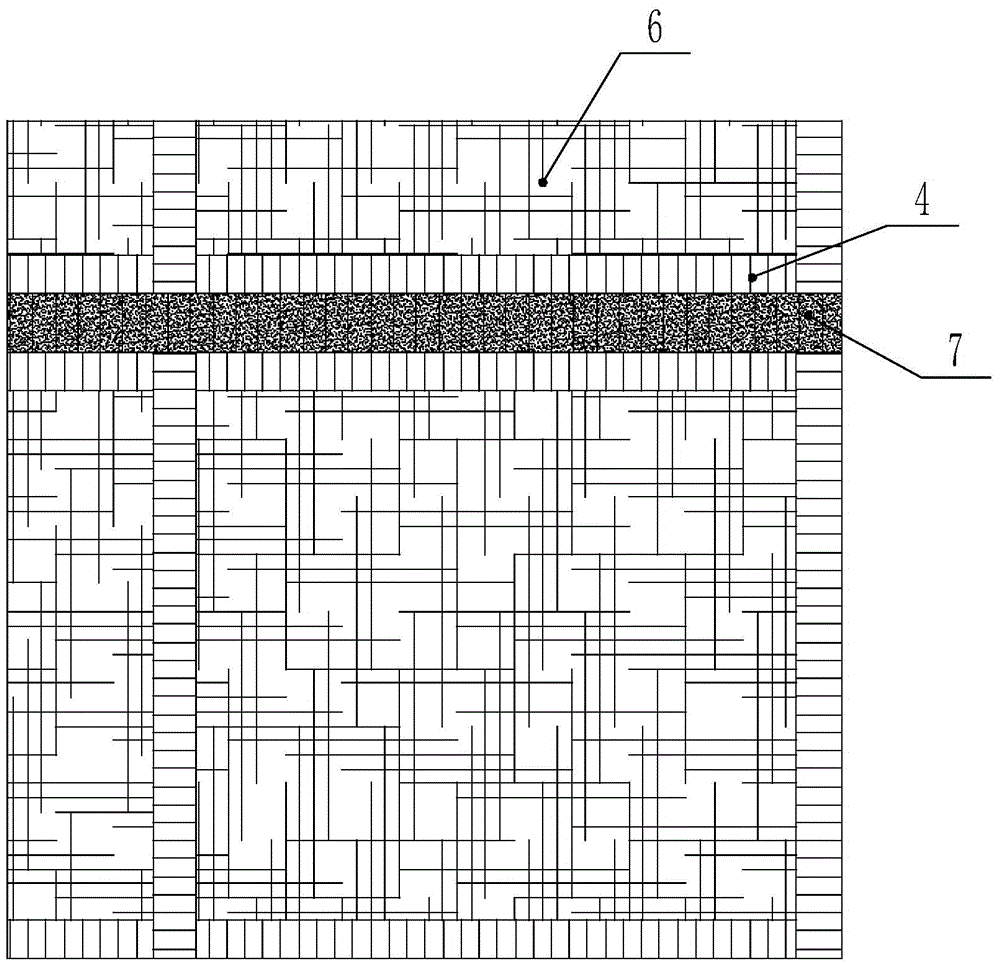

[0025] A permeable paved floor such as figure 1 and figure 2 As shown, starting from the original soil road foundation from bottom to top, there are sandless permeable concrete cushion 1, dry sand leveling layer 2 and surface layer 3; the dry sand leveling layer 2 is a coarse sand layer; the surface layer 3 includes Grid bricks 4 and permeable bricks 6 in each grid unit 5 surrounded by grid bricks 4 .

[0026] It should be noted that gray bricks are preferred for grid face brick 4, and antique green bricks with a specification of 280x140x75 can be used as the permeable bricks on the surface layer, and they are built vertically, so that the rainwater penetration effect is better. In addition, the size of the grid unit 5 is usually designed to be 5mx5m. The grid unit 5 divided by the subdivided surface bricks 4 can effectively control the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com