Metal roof structure

A metal roof and structure technology, applied in building roofs, roof insulation materials, roof coverings, etc., can solve the problems of reducing thermal insulation performance, water vapor penetration, deterioration, etc., and achieve the effect of solving moisture-proof problems and ensuring durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

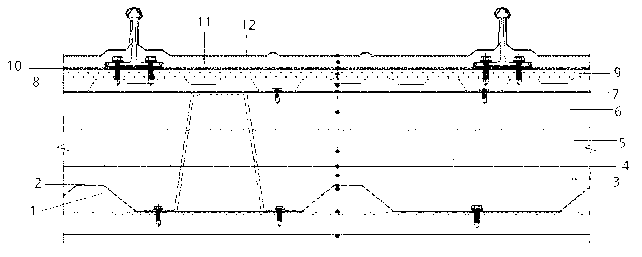

[0027] Combine below figure 1 Specifically illustrate the metal roof structure of the present invention, the bottom layer of the roof structure is a steel inner lining board 1, the uppermost layer of the roof structure is an aluminum-magnesium-manganese alloy roofing board 12, and an aluminum-magnesian-manganese alloy roofing board and the inner lining board are also arranged There are supporting steel plates 8 and gypsum fiberboards 9, wherein the supporting steel plates are supported at the bottom of the gypsum fiberboards, and an anti-noise layer 11 of ultra-fine glass wool is filled between the aluminum-magnesium-manganese alloy roof panel and the gypsum fiberboards, and a bracket is provided at the bottom of the supporting steel plates Supported by purlins 7, the inner lining board 1 is laid with a non-woven dust-proof layer 2, and the non-woven dust-proof layer is provided with a glass wool sound-absorbing layer 3, and the glass wool sound-absorbing layer and the bracket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com