A Concrete Construction Method for Slope Roof

A construction method and large-slope technology, applied to roofs, roof coverings, roofs using sealed aggregates, etc., can solve problems such as difficulty in pouring and molding, restrictions on popularization and application, and leakage, so as to reduce maintenance costs, avoid damage, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

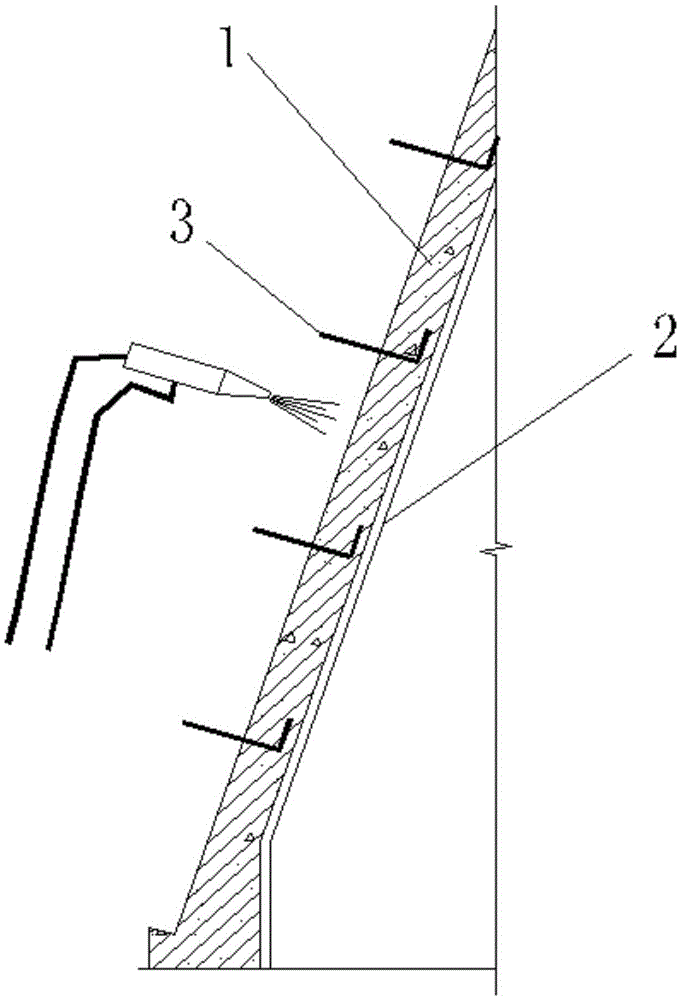

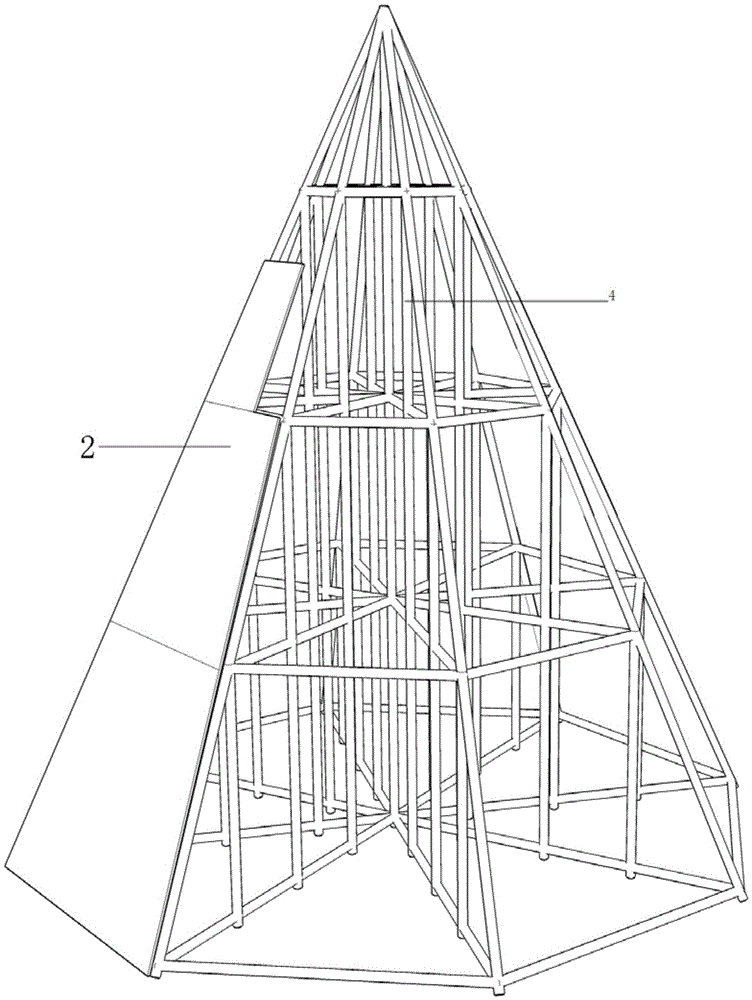

[0017] see figure 1 : A concrete construction method for a steep slope roof. First, install the bottom formwork module 2 of the steep slope roof according to the requirements. The sloping roof panel 1 includes the sloping roof formwork module 2 and the pre-embedded "L-shaped" tie bars 3. The formwork module 2 is processed and shaped in advance and lifted to the full hall support frame 4. According to the plane control line and the slope and elevation of the sloping roof, it automatically Lay formwork modules 2 block by block from bottom to top, and pre-embed "L-shaped" tie bars 3 after the roof panel reinforcement is bound.

[0018] Marking steel bars shall be set reasonably along the ridge line and sloping roof surface.

[0019] The concrete pouring of the roof slab adopts shotcrete construction, which combines the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com