Inorganic heat-insulating mortar exterior wall heat insulation construction method

An inorganic thermal insulation mortar and construction method technology, applied in thermal insulation, building components, covering/lining, etc., can solve problems such as cracking and water seepage of the thermal insulation layer, affecting project quality, and damage to the thermal insulation system, so as to improve work efficiency, facilitate construction, and project quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] In this embodiment, the inorganic thermal insulation mortar adopts vitrified bead thermal insulation mortar (JCTA-950), which has Class A fireproof performance and can meet the fireproof design requirements of high-rise buildings.

[0026] Vitrified microbead thermal insulation mortar (JCTA-950) not only has excellent and long-lasting thermal insulation performance, but at the same time, due to the use of vitrified microbead inorganic material as the main material, it overcomes the large water absorption of expanded perlite, easy pulverization, and The large volume loss rate during slurry mixing can easily lead to the reduction of thermal insulation performance and hollowing and cracking of the product in the later stage. It has defects such as high resilience and easy to be eaten by insects and ants. Its anti-aging and weather resistance are unmatched by other wall insulation materials.

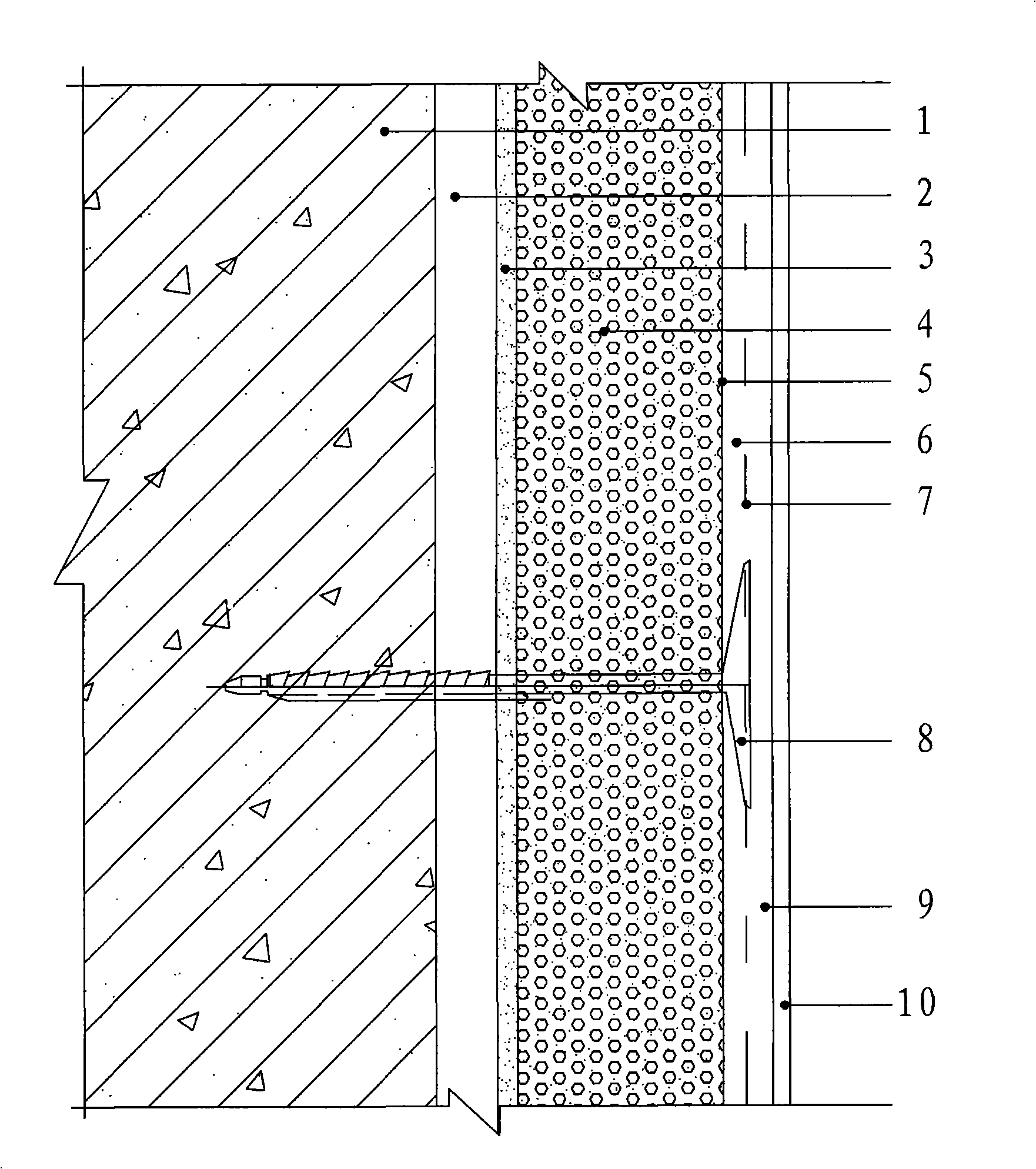

[0027] refer to figure 1 , describe this construction method in detail:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com