Non-power bogie for 100% low-floor vehicle

A non-power, low-floor technology, used in bogies, railway car body parts, transportation and packaging, etc., can solve the problems of poor guidance of independent wheelsets, difficult manufacturing processes, complex structures, etc., and achieve light weight and manufacturing costs. Low, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0020] Best practice:

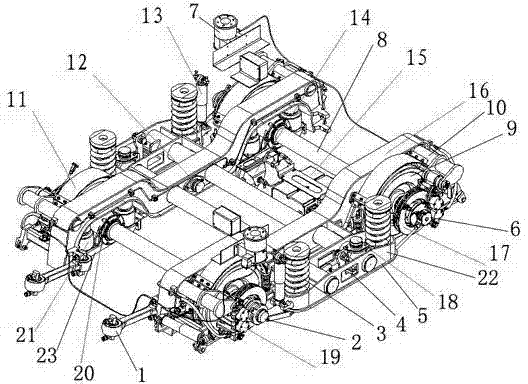

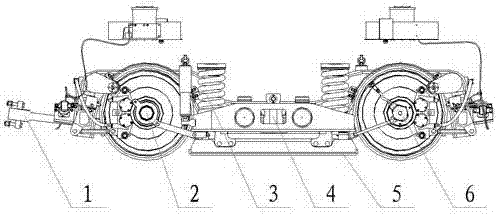

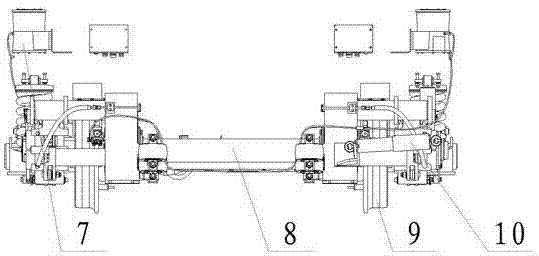

[0021] Such as figure 1 , 2 , 3, a non-powered bogie for 100% low-floor vehicles includes a frame 16 and two axles 8, and the frame 16 includes two side beams that are concave in the middle and parallel to each other and connected to two Cross members parallel to each other between the recessed portions of the side members. The side beam is a bow-shaped structure welded by weathering steel so as to reduce the height of the bottom plate; the cross beam adopts seamless steel pipe so as to reduce the overall weight of the present invention.

[0022] The two ends of the axle 8 are sequentially connected to the axle box 20, the elastic wheel 9 and the brake disc 17 from the inside to the outside, and are installed at the bottom of the side beam through the primary suspension mounts 23 and the primary suspension 21 at the front and rear ends of the axle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com