Motor vehicle front end and method for its production

A technology for automobile bodies and automobiles, applied to motor vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of increasing the weight of the overall structure, and achieve the effect of reducing the deceleration pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

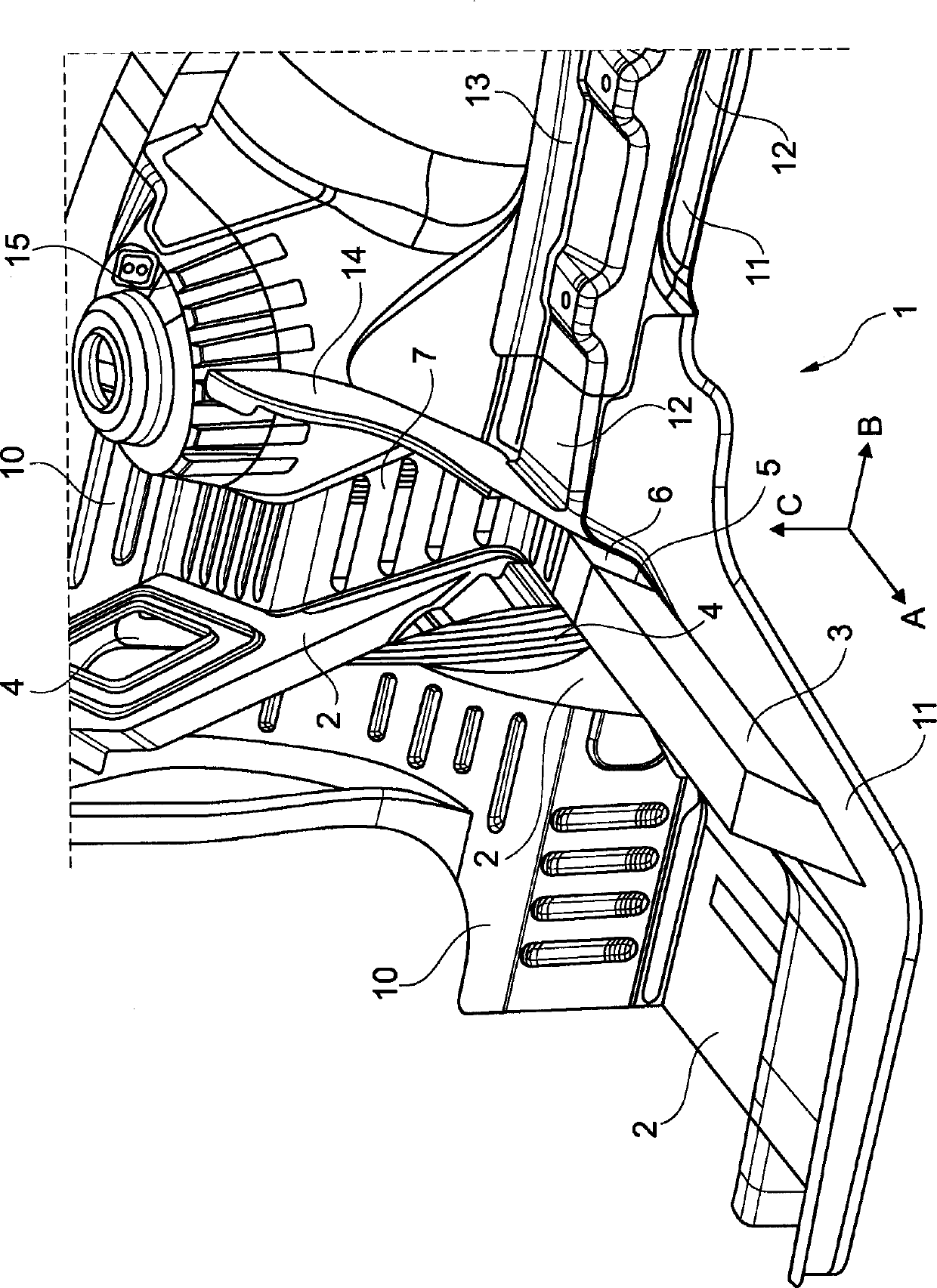

[0023] The front end 1 of the motor vehicle has a front wall 2 . Furthermore, the vehicle body front end 1 has a front wall cross member 3 which is arranged substantially in the direction of the vehicle transverse axis indicated by the direction of the arrow A. As shown in FIG. Furthermore, the motor vehicle front end 1 has a first front wall strut 4 which is designed as a hinge pillar in the embodiment shown. The first front wall strut 4 is here arranged essentially in the direction of the vertical axis of the vehicle indicated by the direction of the arrow C. As shown in FIG. Furthermore, the first front wall strut 4 is supported on the front wall cross member 3 in a first region 5 of the front wall cross member 3 .

[0024] A reinforcing element 6 is arranged in the first region 5 of the front wall cross member 3 . In the embodiment shown, the reinforcement element 6 is designed as a bulkhead. The stiffness of the stiffening element 6 is adapted to the requirements regar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com