Laser and arc composite welding method of martensite precipitation-hardening stainless steel

A precipitation hardening, laser arc technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient precision and uneven bottom weld formation, and achieve the effect of uniform forming, small deformation, and avoiding peroxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

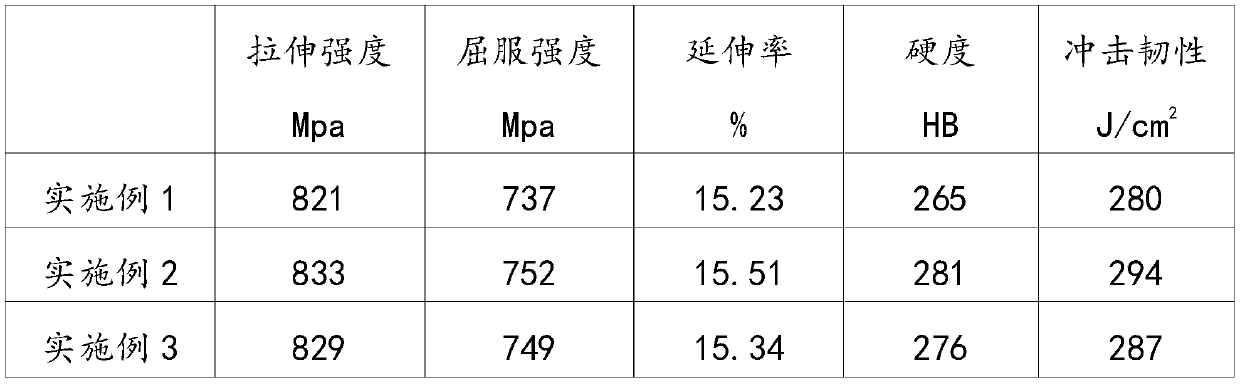

Embodiment 1

[0041] The laser arc hybrid welding method of the martensitic precipitation hardening stainless steel of the present embodiment is realized according to the following steps:

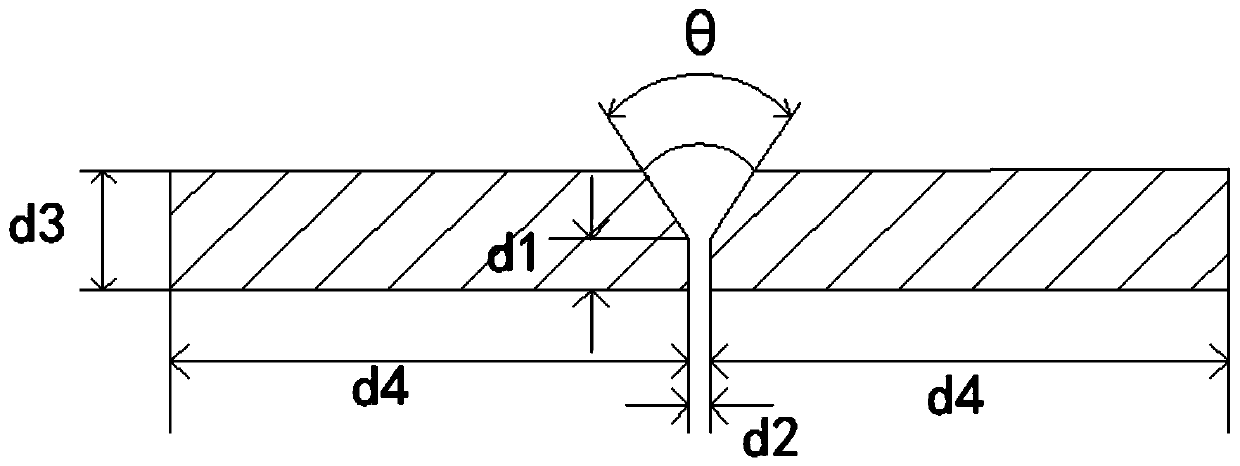

[0042] S1: Process the butt joints of the two workpieces to be welded into a Y shape, the groove angle θ is 65 degrees, and the blunt edge thickness d1 is 3mm;

[0043] S2: Grind the processed groove and side walls on both sides, and use a cleaning agent (acetone, alcohol or isopropanol solution of analytically pure grade) to clean up oil, metal powder, etc. that affect the welding quality, and dry it with compressed air ;

[0044] S3: Assemble and fix the two workpieces to be welded so that the gap d2 between them is 0.2mm;

[0045] S4: Pass the protective gas into the groove position 5000ms before the laser rooting welding, so as to isolate the groove position from the outside air during the rooting welding. The pressure of the protective gas is 0.25Mpa, and the protective gas The air flow rate is 9L...

Embodiment 2

[0052] The laser arc hybrid welding method of the martensitic precipitation hardening stainless steel of the present embodiment is realized according to the following steps:

[0053] S1: Process the butt joints of the two workpieces to be welded into a Y shape, the groove angle θ is 70 degrees, and the blunt edge thickness d1 is 3.5mm;

[0054] S2: Grind the processed groove and side walls on both sides, and use a cleaning agent (acetone, alcohol or isopropanol solution of analytically pure grade) to clean up oil, metal powder, etc. that affect the welding quality, and dry it with compressed air ;

[0055] S3: Assemble and fix the two workpieces to be welded so that the gap d2 between them is 0.3 mm;

[0056] S4: Pass the protective gas (nitrogen or argon) into the groove position 6000ms before the laser rooting welding, so as to separate the groove position from the outside air during rooting welding and filler wire cap welding Insulation, the pressure of the protective gas...

Embodiment 3

[0063] The laser arc hybrid welding method of the martensitic precipitation hardening stainless steel of the present embodiment is realized according to the following steps:

[0064] S1: Process the butt joints of the two workpieces to be welded into a Y shape, the groove angle θ is 60 degrees, and the blunt edge thickness d1 is 3mm;

[0065] S2: Grind the processed groove and side walls on both sides, and use a cleaning agent (acetone, alcohol or isopropanol solution of analytically pure grade) to clean up oil, metal powder, etc. that affect the welding quality, and dry it with compressed air ;

[0066] S3: Assemble and fix the two workpieces to be welded so that the gap d2 between them is 0.25mm;

[0067] S4: 5000ms before the laser root welding, the protective gas is introduced into the groove position, so as to isolate the groove position from the outside air during the root welding and the filler wire cover welding, and the air pressure of the protective gas 0.2Mpa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com