Thick plate vertical butt joint welding method

A welding method and automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of poor welding quality, heavy equipment, complicated operation, etc., and achieve improved weld quality, high degree of automation, and weld seam Evenly shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

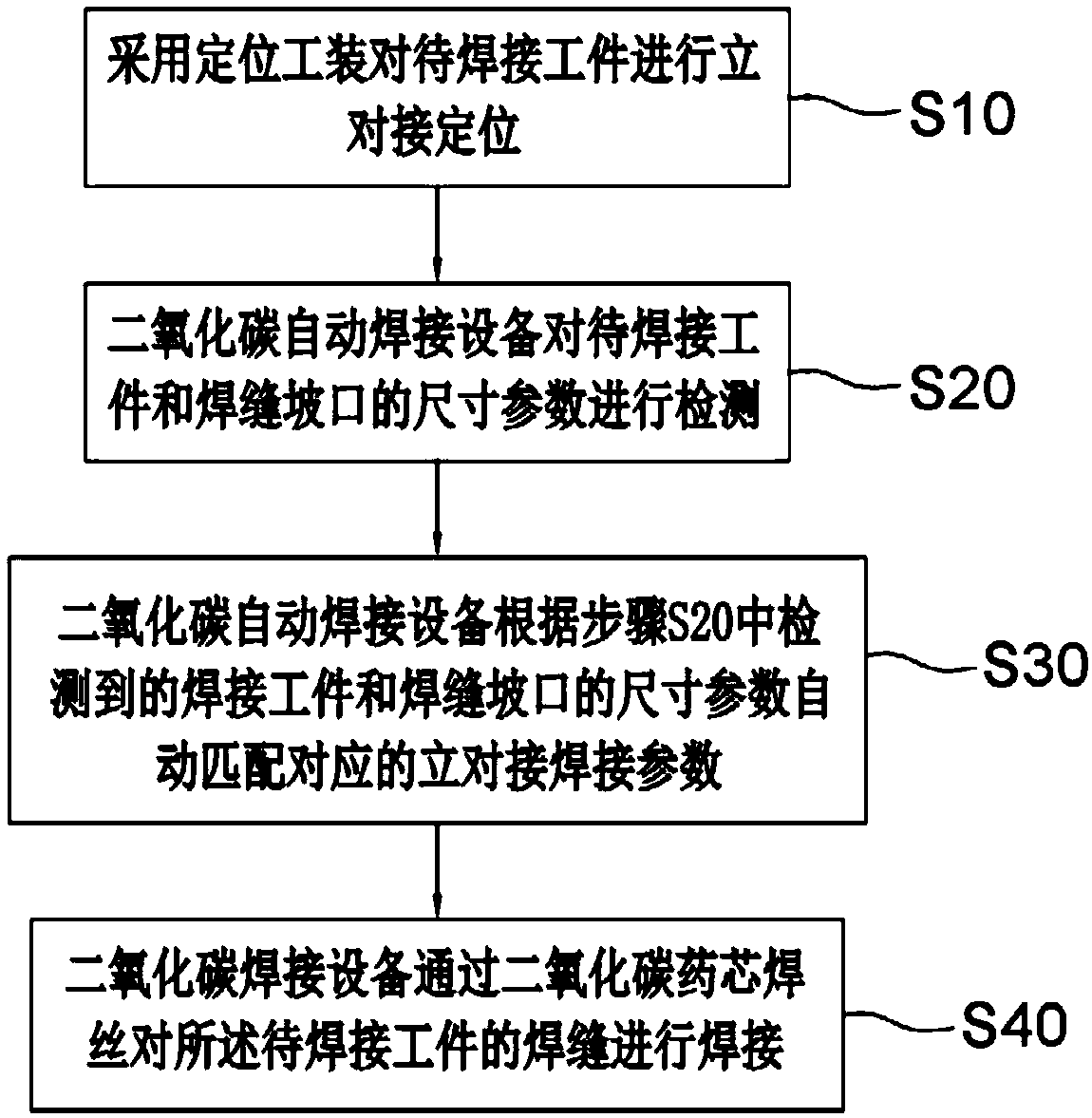

[0039] This embodiment provides a vertical butt welding method for thick plates, which is used for vertical butt welding of thick plates. In this embodiment, the thick plate is a workpiece to be welded with a thickness of 10mm-60mm, and the vertical butt joint of the thick plate is such that the angle between the workpiece to be welded and the horizontal plane is greater than 15° and less than or equal to 90°. The vertical butt welding method of thick plate is as follows: figure 1 shown, including the following steps:

[0040] S10, using a positioning tool to perform vertical butt joint positioning of the workpiece to be welded.

[0041] The workpiece to be welded is vertically docked and positioned by the positioning tool. Specifically, the positioning tool includes a first positioning tool and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com