Thick plate high-efficiency gas-slag combined protection welding method

A protective welding and high-efficiency technology, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve problems such as aggravating the structural safety risks of welded joints, increasing welding material consumption and energy consumption, and reducing weld performance, etc. To avoid excessive softening and embrittlement, improve performance, and reduce welding fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A thick plate high-efficiency gas slag joint protection welding method, the steps:

[0037] 1) Base metal properties: tensile strength Rm is 490MPa, thickness is 10mm; equal thickness butt vertical vertical welding;

[0038] 2) Groove form: U-shaped groove, the arc radius R at the bottom of the groove is 5mm, the groove angle is 15°, the blunt edge is 2mm, and the gap between the two U-shaped grooves of the butt welding plate is 3mm; before welding The surface of the butt joint is cleaned to a smooth state, and the cleaning and grinding width is 50mm;

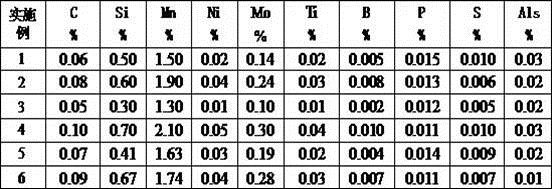

[0039] 3) Welding matching material: use non-copper-coated flux-cored wire with a diameter of Φ1.6mm; the components and contents of the welding wire used in this example are the corresponding examples in Table 1;

[0040] 4) Welding process

[0041] A. Welding process conditions: the volume percentage of shielding gas is: 80% CO 2 +20%O 2 Mixed gas; DC power supply positive connection method is adopted, the welding cu...

Embodiment 2

[0047] A thick plate high-efficiency gas slag joint protection welding method, the steps:

[0048] 1) Base metal properties: tensile strength Rm is 550MPa, thickness is 25mm; equal thickness butt vertical vertical welding;

[0049] 2) Groove form: U-shaped groove, the arc radius R at the bottom of the groove is 4mm, the groove angle is 12°, the blunt edge is 1mm, and the gap between the two U-shaped grooves of the butt welding plate is 3mm; before welding The surface of the butt joint is cleaned to a smooth state, and the cleaning and grinding width is 50mm;

[0050] 3) Welding matching material: use non-copper-coated flux-cored wire with a diameter of Φ1.6mm; the components and contents of the welding wire used in this example are the corresponding examples in Table 1;

[0051] 4) Welding process

[0052] A. Welding process conditions: the volume percentage of shielding gas is: 80% CO 2 +20%O 2 Mixed gas; DC power supply positive connection method is adopted, the welding ...

Embodiment 3

[0058] A thick plate high-efficiency gas slag joint protection welding method, the steps:

[0059] 1) Base metal properties: tensile strength Rm is 450MPa, thickness is 32mm; equal thickness butt vertical vertical welding;

[0060] 2) Groove form: U-shaped groove, the arc radius R at the bottom of the groove is 4mm, the groove angle is 10°, the blunt edge is 1mm, and the gap between the two U-shaped grooves of the butt welding plate is 1mm; before welding The surface of the butt joint is cleaned to a smooth state, and the cleaning and grinding width is 50mm;

[0061] 3) Welding matching material: use non-copper-coated flux-cored wire with a diameter of Φ1.6mm; the components and contents of the welding wire used in this example are the corresponding examples in Table 1;

[0062] 4) Welding process

[0063] A. Welding process conditions: the volume percentage of shielding gas is: 80% CO 2 +20%O 2 Mixed gas; DC power supply positive connection method is adopted, the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com