An oil-based emulsified drilling fluid with an ultra-low oil-water ratio of 40:60

A technology of emulsified drilling fluid and oil-water ratio, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as poor stability, achieve wide application range, significant economic benefits, and improve stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

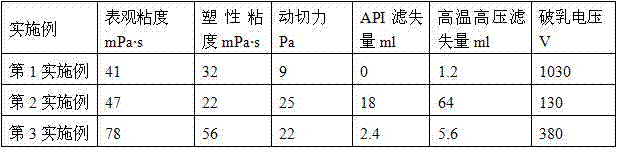

Examples

Embodiment 1

[0036] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0037] 40 parts of 3# white oil,

[0038] 60 parts of 30% calcium chloride brine,

[0039] 3 parts of high-efficiency emulsifier, composed of cetyl trimethyl ammonium chloride, didodecyl dimethyl ammonium chloride, lauryl amidopropyl amine oxide, cetyl polyethylene glycol / polypropylene glycol-10 / 1 Dimethylsiloxane is prepared by mixing and stirring for 20 minutes at a temperature of 80°C and a stirring speed of 3000 rpm; hexadecyl trimethyl ammonium chloride: didodecyl dimethyl ammonium chloride : Lauramidopropylamine Oxide: Cetyl Polyethylene Glycol / Polypropylene Glycol-10 / 1 Dimethicone The ratio is 1.5︰1︰3︰4;

[0040] 2 parts of emulsion stabilizer, prepared by mixing polystyrene, fatty alcohol polyoxyethylene ether sodium sulfate AES, octanol, and ethylene glycol monobutyl ether at a temperature of 80°C a...

Embodiment 2

[0046] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0047] 40 parts of 3# white oil,

[0048] 60 parts of 30% calcium chloride brine,

[0049] 2 parts of high-efficiency emulsifier, consisting of cetyl trimethyl ammonium chloride, didodecyl dimethyl ammonium chloride, lauryl amidopropyl amine oxide, cetyl polyethylene glycol / polypropylene glycol ~10 / 1 Dimethylsiloxane is prepared by mixing and stirring for 20 minutes at a temperature of 80°C and a stirring speed of 3000 rpm; hexadecyl trimethyl ammonium chloride: didodecyl dimethyl ammonium chloride : Lauramidopropylamine Oxide: The ratio of Cetyl Polyethylene Glycol / Polypropylene Glycol-10 / 1 Dimethicone is 0.5︰0.5︰2.0︰3.0;

[0050] 1 part of emulsification stabilizer, prepared by mixing polystyrene, fatty alcohol polyoxyethylene ether sodium sulfate AES, octanol, and ethylene glycol monobutyl ether at a temp...

Embodiment 3

[0056] First determine the weight of each part according to the preparation requirements, and then weigh the raw materials according to the following parts by weight.

[0057] 40 parts of 3# white oil,

[0058] 60 parts of 30% calcium chloride brine,

[0059] 5 parts of high-efficiency emulsifier, composed of cetyl trimethyl ammonium chloride, didodecyl dimethyl ammonium chloride, lauryl amidopropyl amine oxide, cetyl polyethylene glycol / polypropylene glycol ~10 / 1 Dimethylsiloxane is prepared by mixing and stirring for 20 minutes at a temperature of 80°C and a stirring speed of 3000 rpm; hexadecyl trimethyl ammonium chloride: didodecyl dimethyl ammonium chloride : Lauramidopropylamine Oxide: Cetyl Polyethylene Glycol / Polypropylene Glycol ~ 10 / 1 Dimethicone The ratio is 2: 1.5: 4: 5;

[0060] 3 parts of emulsion stabilizer, prepared by mixing polystyrene, fatty alcohol polyoxyethylene ether sodium sulfate AES, octanol, and ethylene glycol monobutyl ether at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com