Patents

Literature

60results about How to "Comply with protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tung oil-modified water-based insulating paint

ActiveCN101724335AImprove electrical insulation strengthIncrease added valuePolyester coatingsWater basedElectrical conductor

The invention discloses a method for preparing a tung oil-modified water-based insulating paint. The method comprises the following steps that: firstly, 100 parts of polyalcohol reacts with 20 to 40 parts of poly-acid and 10 to 20 parts of maleic anhydride at the temperature of between 160 and 200 DEG C for 1 to 2 hours under the protection of the nitrogen gas to give an esterified liquid; secondly, 25 to 35 parts of the tung oil and 50 to 60 parts of maleic anhydride are added into the esterified liquid to react 2 to 6 hours at the temperature of between 190 and 210 DEG C under the protection of the nitrogen gas to form the esterified liquid, 15 to 25 percent of organic solvent by weight is added into the obtained esterified liquid and the mixture is neutralized by organic amine until the pH value is between 7.0 and 8.5 to form a polyester resin liquid modified by the tung oil; and finally, 10 to 30 weight percent of etherified amino resin and 0.1 to 0.3 weight percent of peroxide are added into the tung oil-modified polyester resin liquid and the obtained product is stirred and blended the for half an hour to 1 hour at room temperature to form the tung oil-modified water-based insulating paint. When the insulating paint is used, water is added in the insulating paint, the mixture is stirred and diluted to form a product with a solid content of 30 to 40 weight percent and the pH value of between 7 and 8, and the product is coated on a conductor to be solidified into a paint film at the temperature of between 120 and 130 DEG C.

Owner:合肥英索莱特新材料科技有限公司

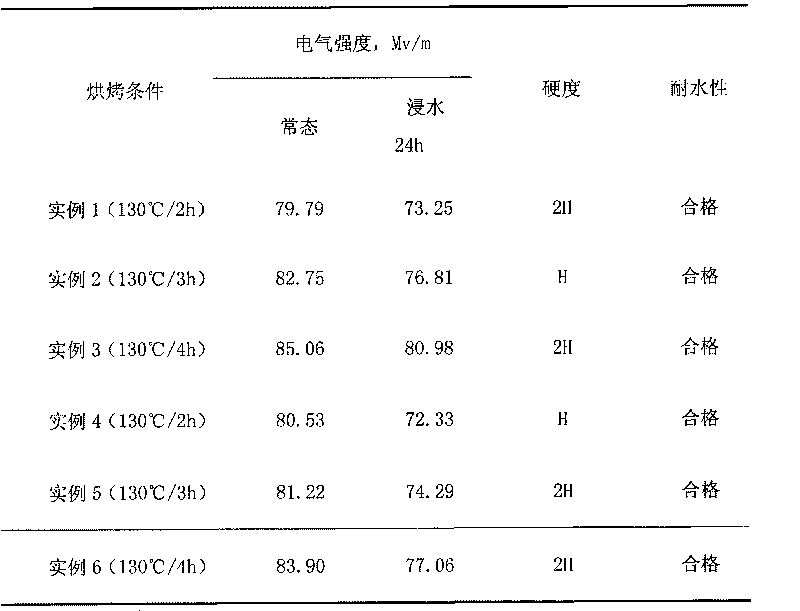

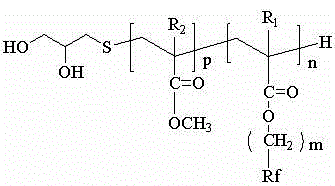

UV-curing side-chain fluorine-containing water-based polyurethane paint and preparation method thereof

ActiveCN103333285AFast curingComply with protectionPolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention relates to the technical field of paints, particularly to a UV-curing side-chain fluorine-containing water-based polyurethane paint and a preparation method thereof. The preparation method comprises the following steps: by using handy fluorine-containing acrylate monomer and / or fluorine-free acrylic monomer and chain transfer diol as raw materials, carrying out free-radical polymerization to obtain fluorine-containing alkyl diol; polymerizing side-chain fluorine-containing alkyl diol monomer to a water-based polyurethane hard section, and meanwhile, introducing photosensitive reactive group to the tail end of the polyurethane chain to prepare a UV-curing side-chain fluorine-containing water-based polyurethane resin; and blending with assistants to obtain the UV-curing water-based paint. The water-based paint provided by the invention has the characteristics of environmental protection and UV quick curing, has the advantages of excellent solvent property, excellent weatherability, high glossiness, excellent anti-staining property, excellent self-cleaning property and the like, can be used as a waterproof anticorrosive paint for building external walls, automobiles, ships and the like.

Owner:GUANGDONG UNIV OF TECH

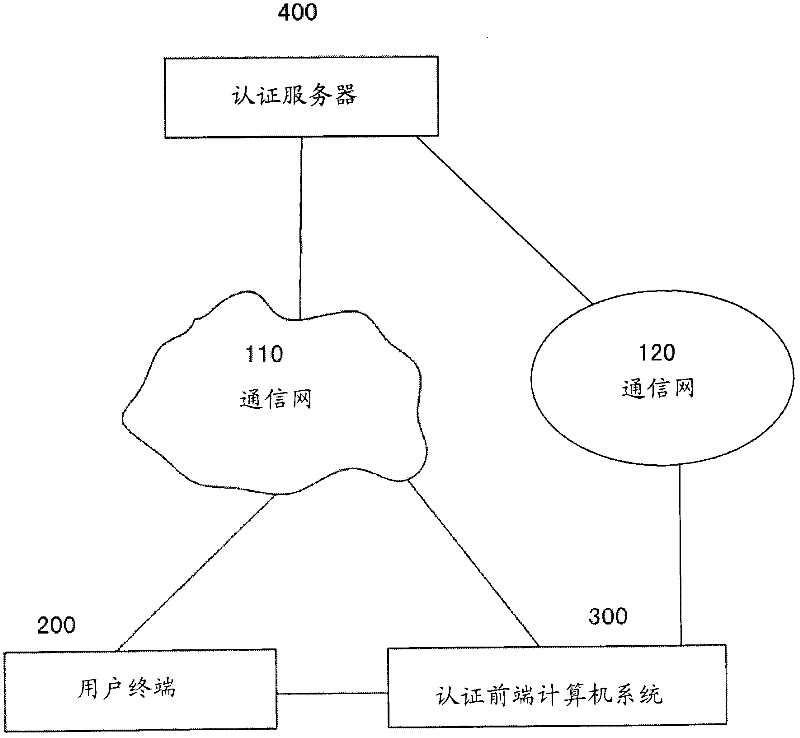

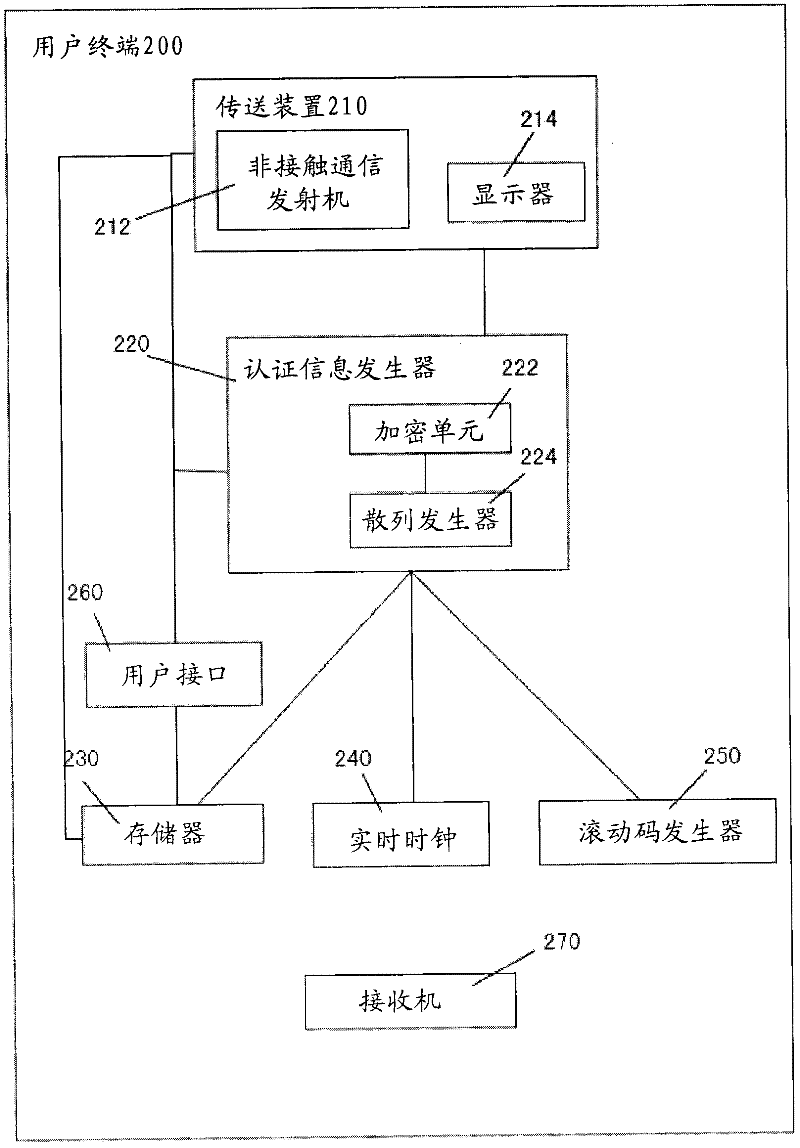

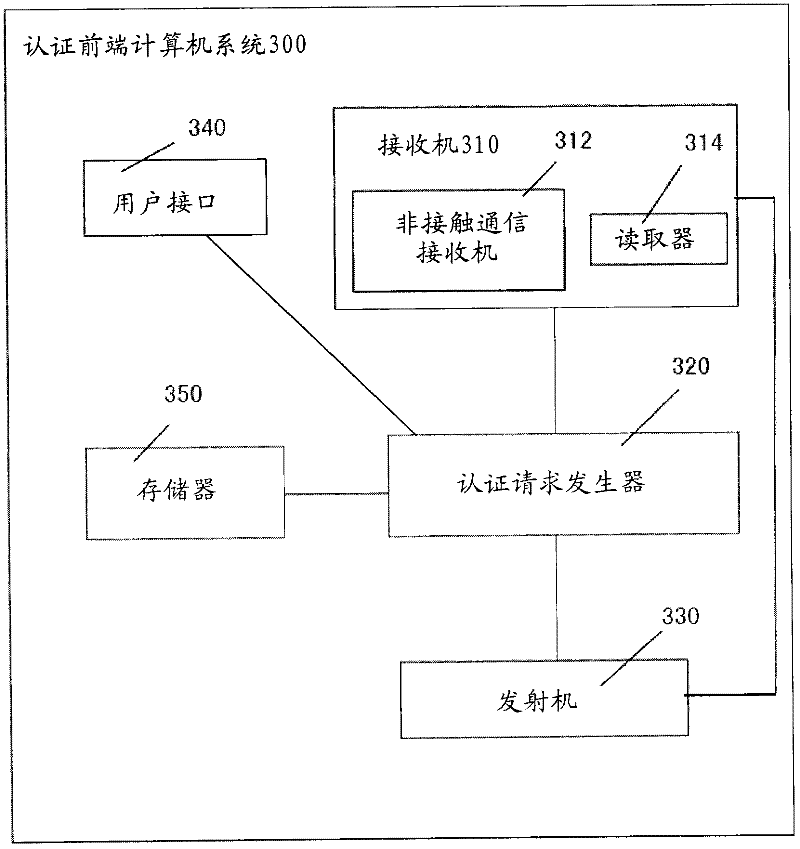

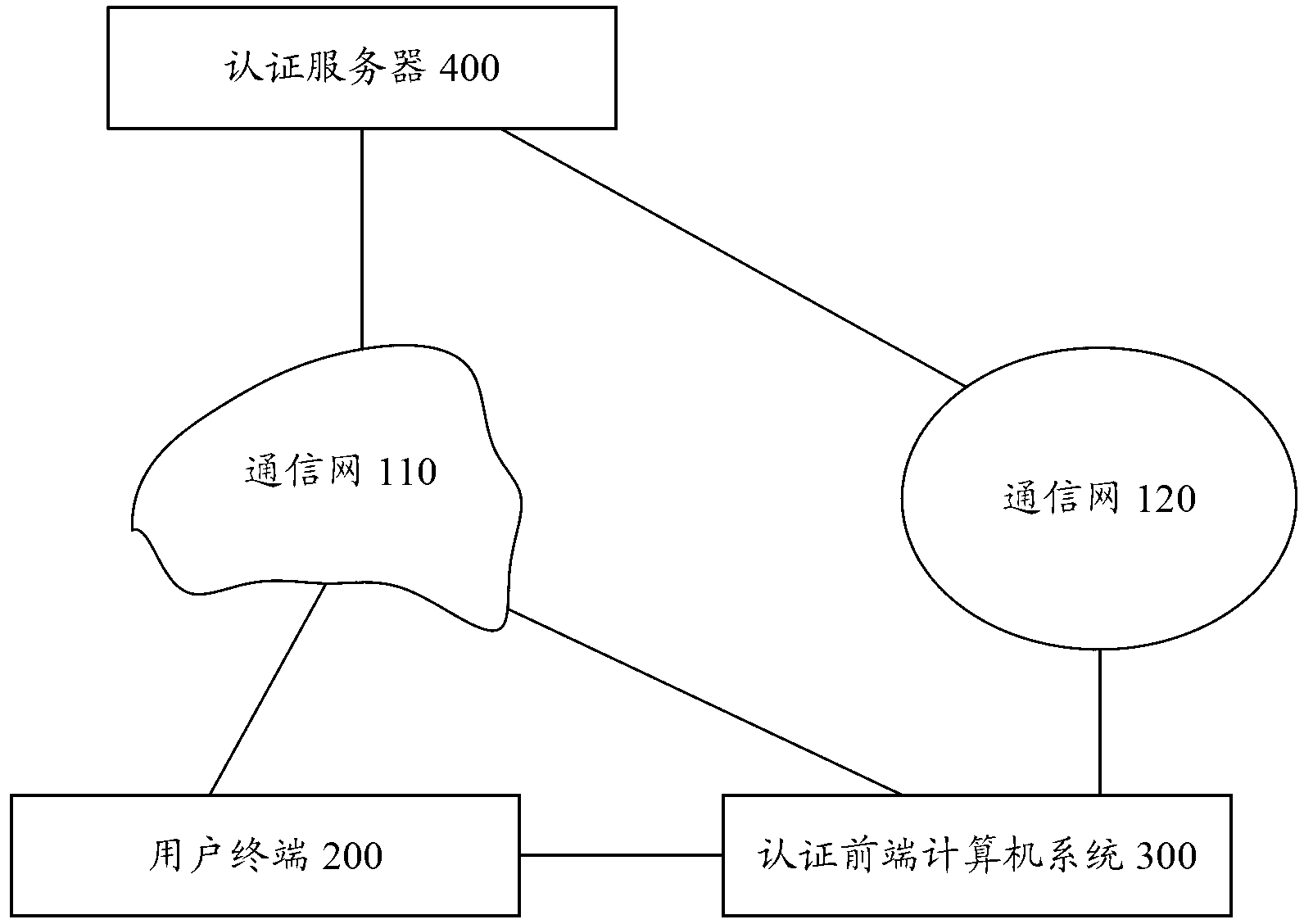

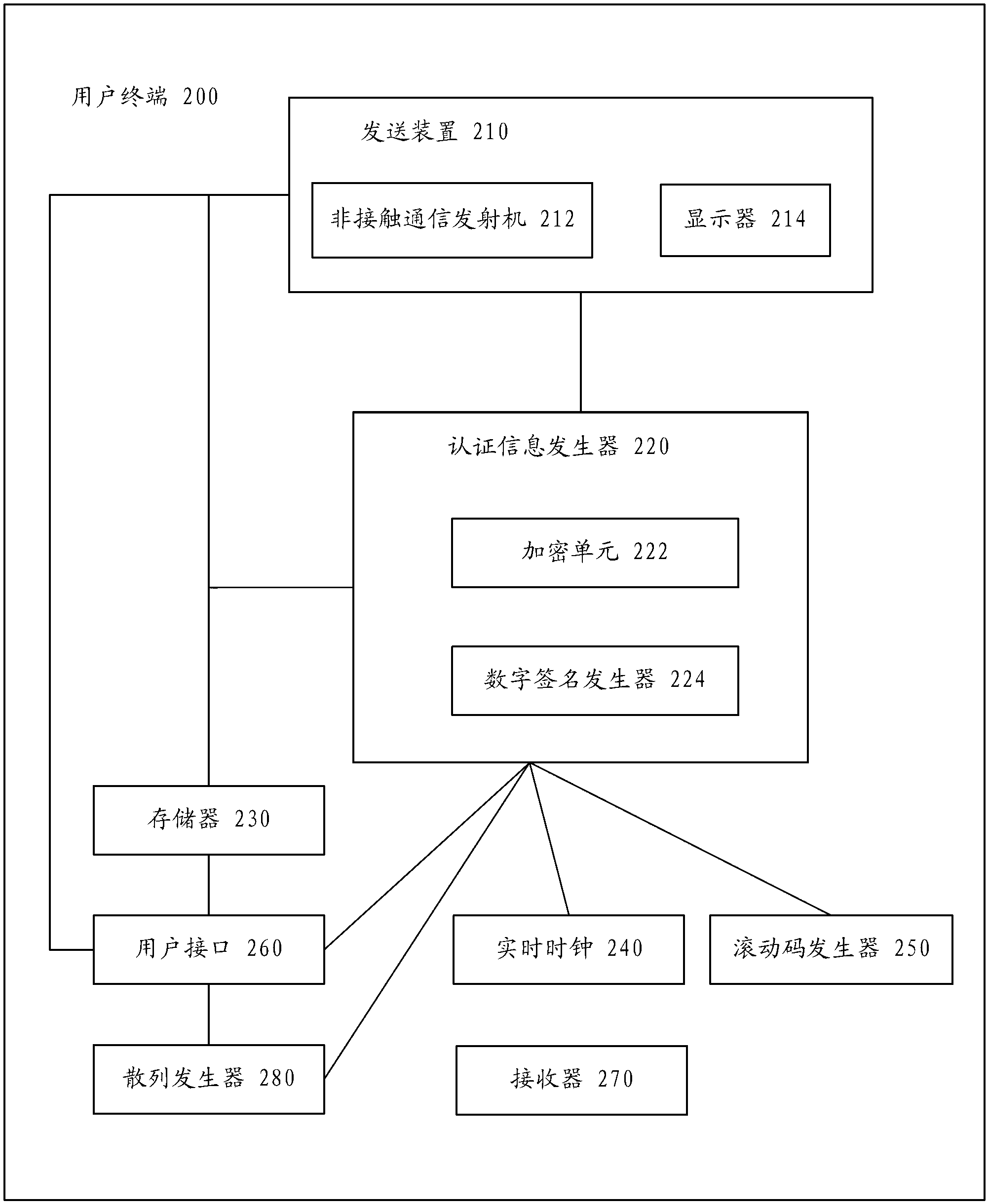

Method, system and device for identifying user's identity

InactiveCN102497354AEnsure safetyEasy to installUser identity/authority verificationEngineeringData mining

The invention relates to a method and a system for identifying a user's identity, as well as a user terminal, an identification front end computer system and an identification server. According to the invention, the user terminal transmits identification indication containing identification information to the identification front end computer system; the identification front end computer system sends an identification request containing the identification information to a specific identification server; after receiving the identification request, the identification server identifies a user's identity according to the identification information; and preferably, the identification server sends an identification result to the identification front end computer system. When the user pays a certain amount of money to an operator, and after successful identification, the identification server pays a certain amount of money to a specific operator's account from a specific user's payment account.

Owner:陈嘉贤

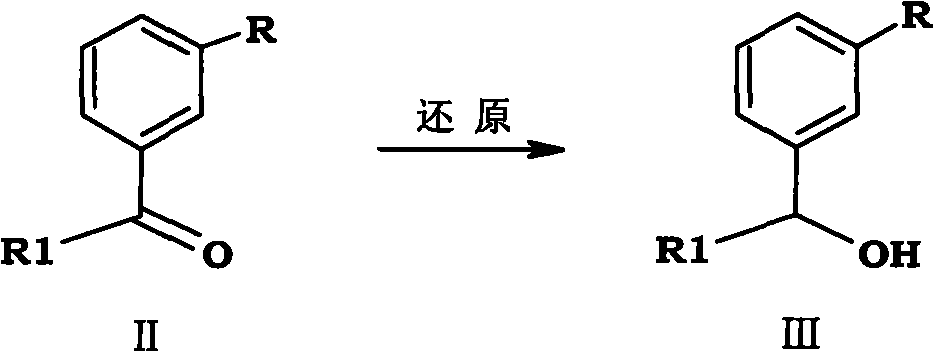

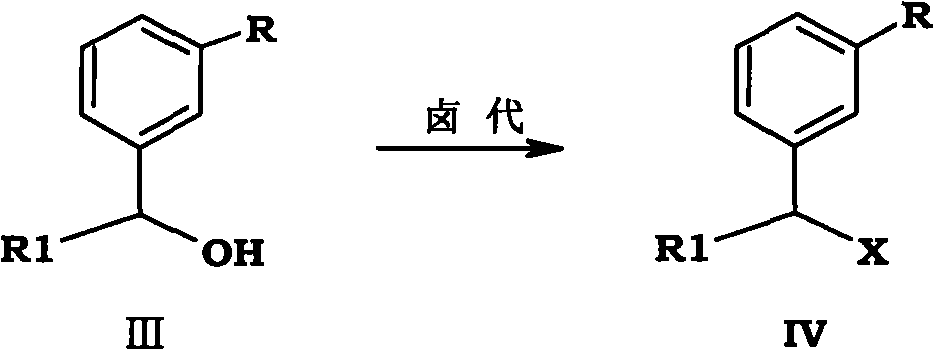

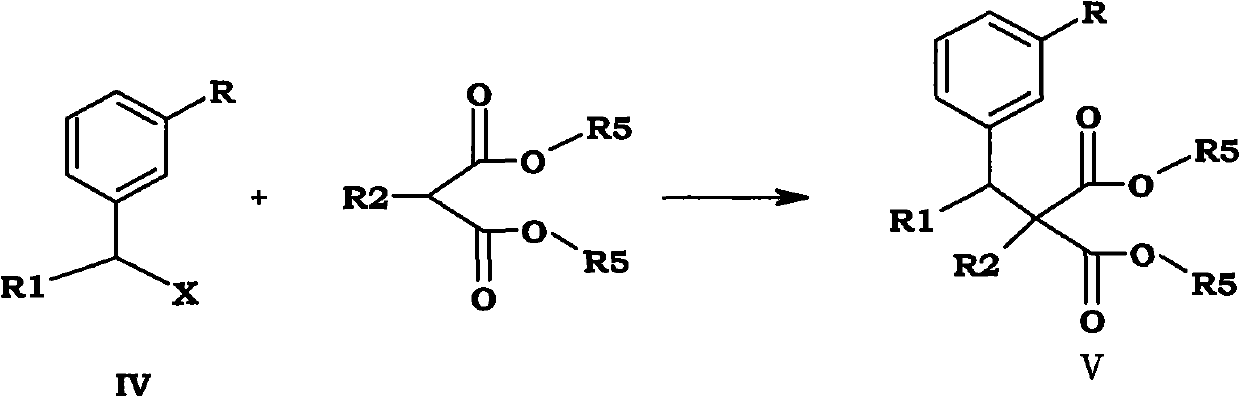

New method for synthesizing tapentadol hydrochloride and analogue of tapentadol hydrochloride

ActiveCN102557851AReduce processing costsEasy to industrializeOrganic compound preparationOptically-active compound separationKetoneChemistry

The invention provides a new method for synthesizing tapentadol hydrochloride and analogue of the tapentadol hydrochloride, and particularly provides a method for synthesizing a compound with the formula shown as a formula (1). Groups of the compound are defined in the specification. The invention also particularly provides a method for synthesizing the tapentadol hydrochloride and the analogue compound of the tapentadol hydrochloride by using 1-(3-substituted phenyl)-1-ketone compound as an initial raw material. According to the method, the raw materials are easy to obtain, and reaction conditions are mild; and the method is easy to control and operate, reduces production cost and is particularly suitable for industrial production.

Owner:ANHUI NEW STAR PHARMA DEV

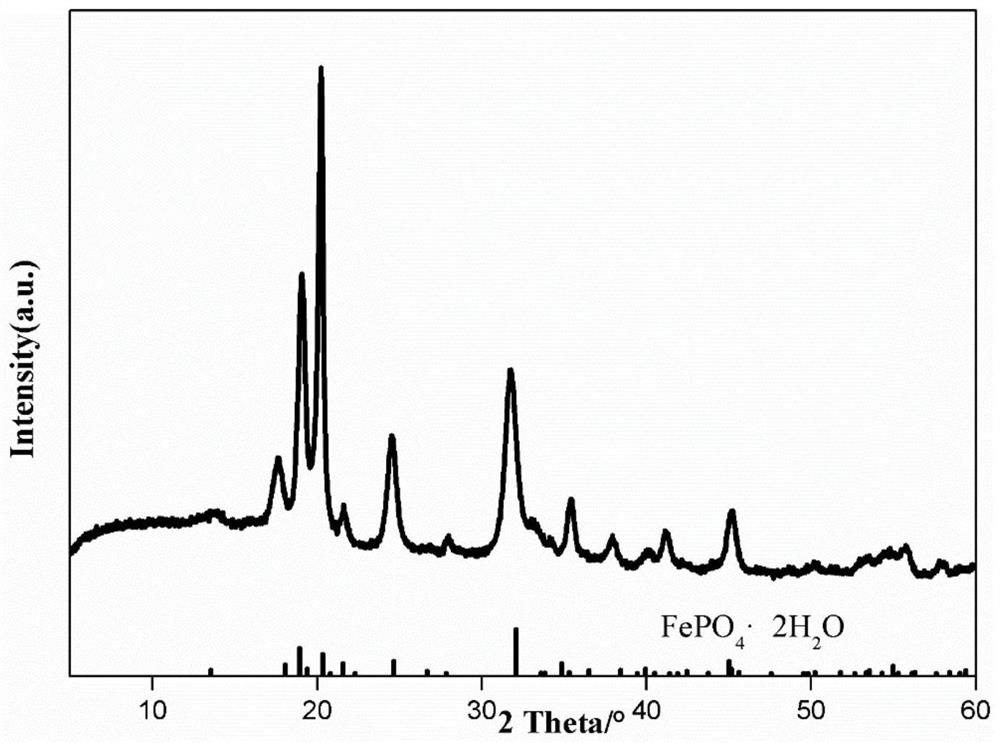

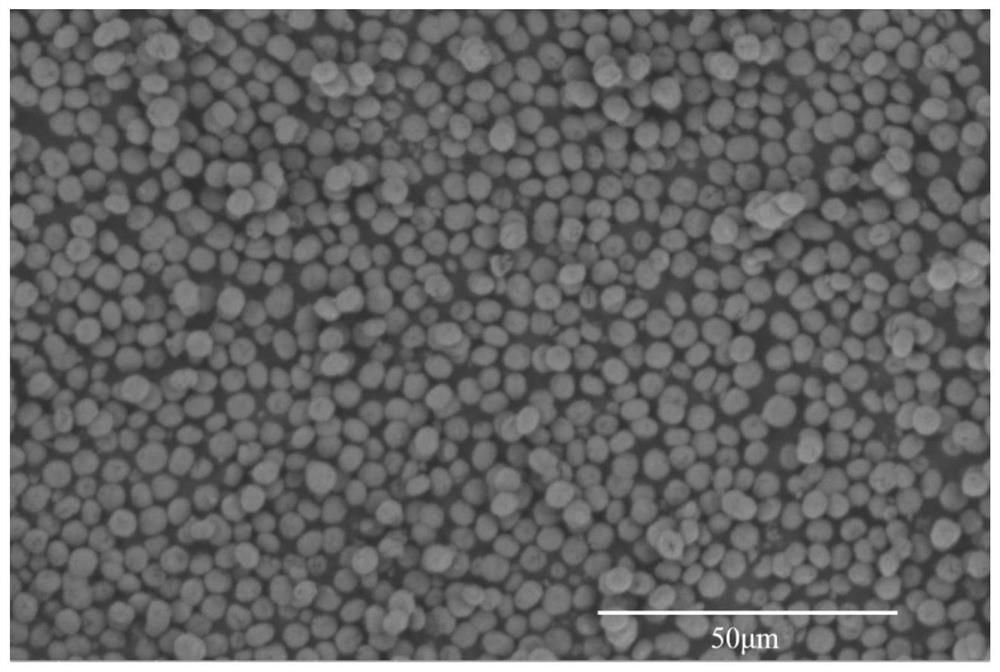

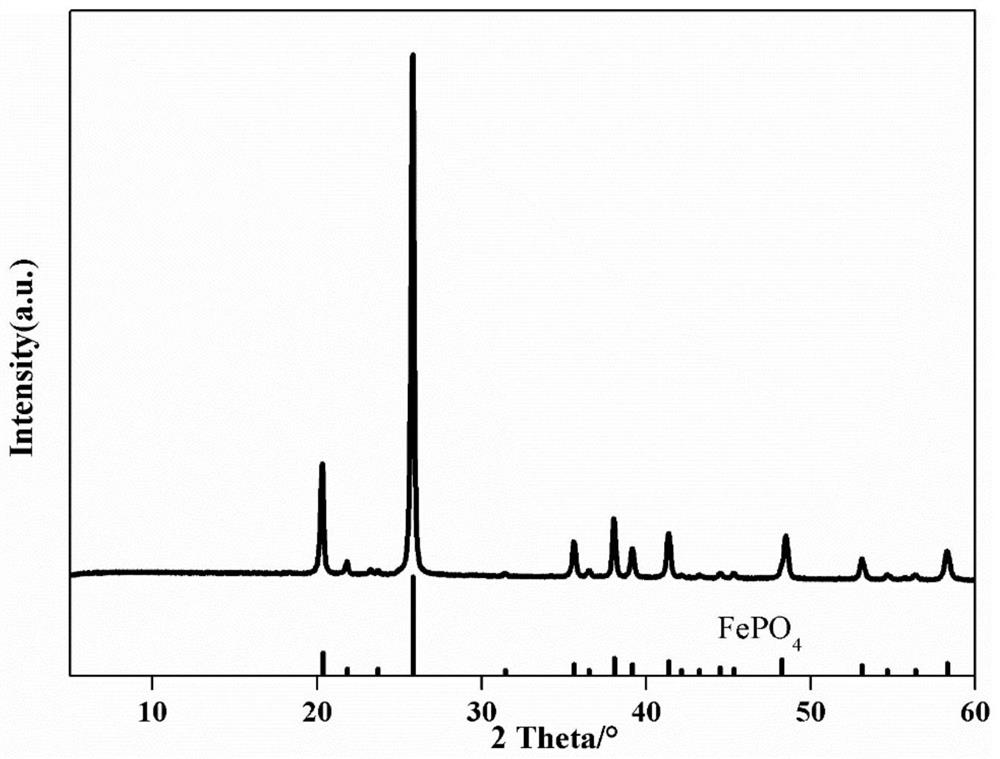

Battery-grade iron phosphate, preparation method and application thereof

PendingCN112624077ALow impurity contentStable qualityCell electrodesPhosphorus compoundsElectrical batteryIron phosphate

The invention belongs to the field of battery materials, and discloses battery-grade iron phosphate, a preparation method and application thereof. The preparation method comprises the following steps: roasting iron phosphate waste, adding into acid liquor, dissolving, and filtering to obtain a solution A containing an iron element and a phosphorus element; stirring the solution A and alkali liquor, adjusting the pH value to be acidic, and reacting to obtain iron phosphate slurry; heating the iron phosphate slurry, adding phosphoric acid, stirring for aging reaction, washing and filtering to obtain an iron phosphate dihydrate filter cake, and drying to obtain iron phosphate dihydrate powder; and roasting, dehydrating and cooling the iron phosphate dihydrate powder to obtain the battery-grade iron phosphate. According to the invention, recovered ferrophosphorus waste is used as a raw material, NaOH is used for precipitating amorphous iron phosphate, phosphoric acid is used as an aging agent under the high-temperature stirring condition, and battery-grade iron phosphate with the impurity content smaller than or equal to 1.0% is prepared through a one-step method.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Production technology for heat shrinkable polyester film

ActiveCN103640237AEasy to recycleImprove mechanical propertiesFlat articlesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a production technology for a heat shrinkable polyester film and relates to the package material field. The production technology comprises the following technologies: slicing, vacuum drying, melt extrusion, quenching slice casting, biaxial tension, cooling and rolling slitting. Amorphous polyethylene glycol terephthalate is selected as a raw material, amorphous polyethylene glycol terephthalate is easy to recycle, nontoxic and odourless, has good mechanical properties, and meets environment protection requirements. Heat is transferred to materials to be dried through a drier shell under the vacuum environment, and therefore the purpose of drying reinforcement is achieved. The softening point of polymers is raised effectively, adhesion and agglomeration of resin particles are avoided during the drying and melt extrusion processes, moisture in resins can be removed, and hydrolytic degradation and bubble generation of polymers containing ester groups are prevented during the melt extrusion process. The ways of segmented heating and segmented processing are beneficial for fusion of molecules, and avoid material deterioration caused by too fast heating. the intensity of the produced shrinkable film is raised, and the shrinkable film has impact resistance.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

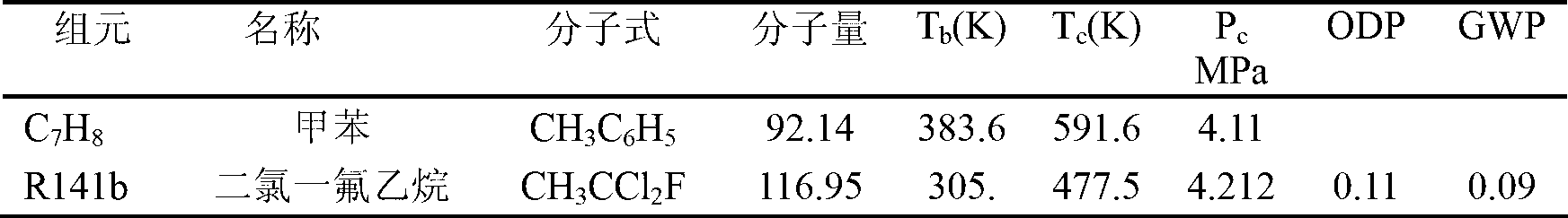

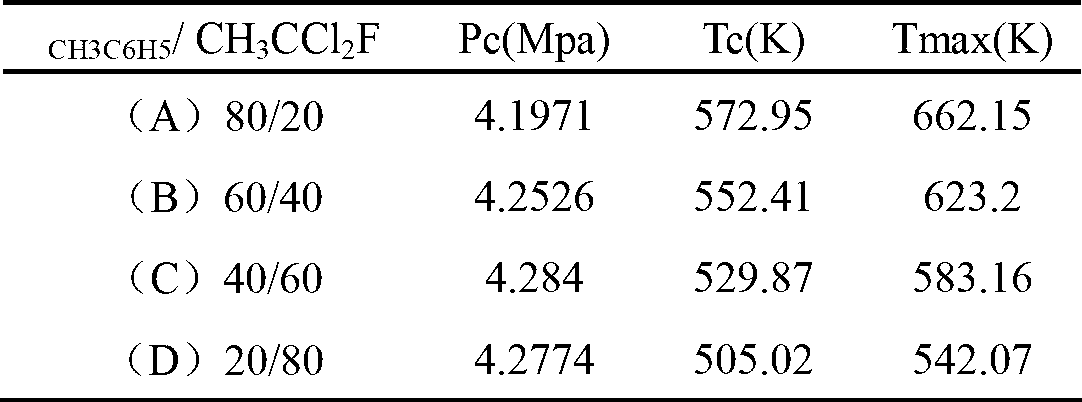

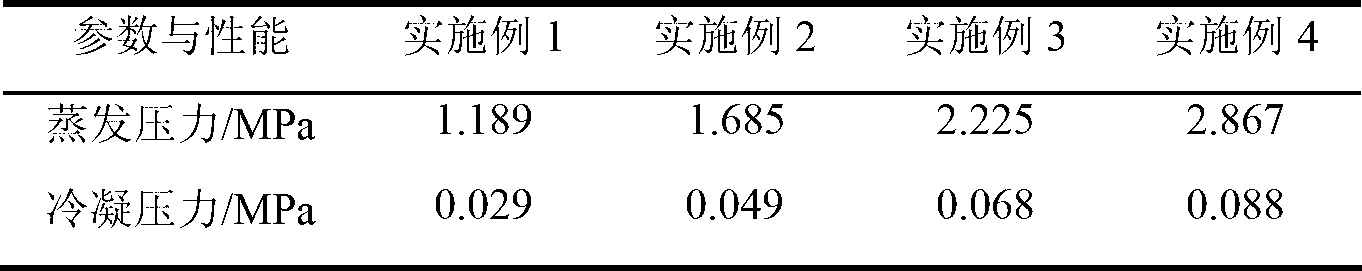

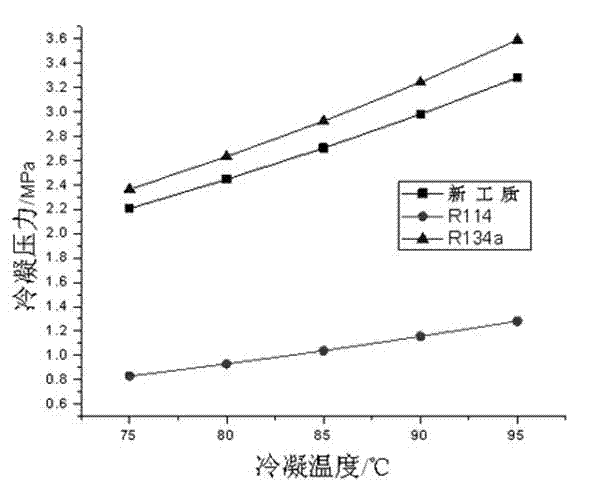

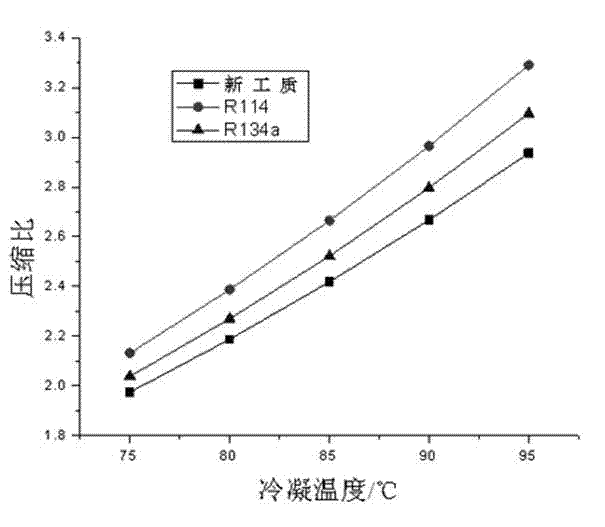

Organic Rankine cycle mixed working medium containing toluene

InactiveCN103013450AComply with protectionLow ODPHeat-exchange elementsOrganic Rankine cycleEngineering

The invention discloses an organic Rankine cycle mixed working medium containing toluene, which is applied to an engine waste heat system. The working medium is a two-component mixture composed of toluene and dichloro-fluoroethane in different mass percentages, and is suitable for being used as a working medium of a high-temperature ORC system in which the temperature of a heat source is 400 DEG C to 700 DEG C. The preparation method is as follows: performing physical mixing on the components according to designated matching at normal temperature, so as to obtain the corresponding mixed working medium. The ODP of the working medium is almost zero and the GWP is lower. The working medium has a good environmental property, conforms to the requirements for protecting the ozone layer and reducing the greenhouse effect, and can be directly applied to the high-temperature exhaust waste heat ORC system of an engine.

Owner:TIANJIN UNIV

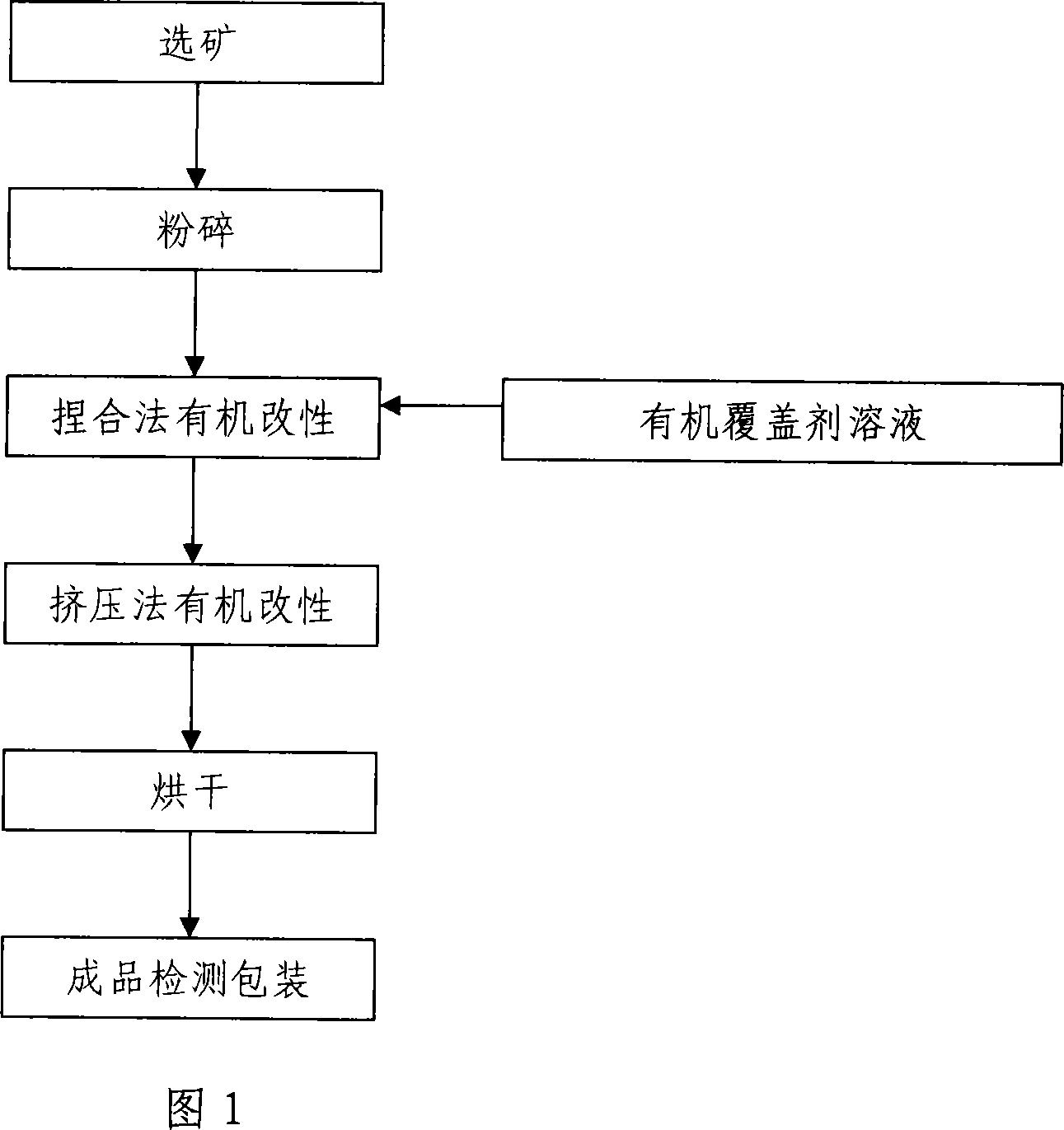

Method for producing organic attapulgite by dry process

InactiveCN101224891AComply with protectionImprove performanceSilicon compoundsWater resourcesChemistry

The invention discloses a method for producing organic attapulgite clay by adopting dry process, which includes the following steps: mineral selection: select attapulgite clay as raw material; crushing step: crush the selected raw material and then screen and purify the granules by using a piece of screen mesh equipment; an organic modification step by adopting a kneading method: add an organic covering agent solution and utilizes a piece of kneader equipment to carry out organic modification on the crushed and purified attapulgite clay material; an organic modification step by adopting an extrusion method: adopt a piece of extruder equipment to carry out further organic modification by extrusion; a drying step: dry until the finished product is obtained; the inspection and packing step of the finished product: carry out quality inspection on the finished product and pack the qualified product; the invention adopts a dry process to modify the attapulgite clay material into an organic attapulgite clay material, the process flow design is scientific, thus considerably saving energy and water resources; the production cost is low, the performance and various technical criteria are comparatively high; the production process is environment-friendly which can meet present regulation on environment protection.

Owner:赵溶

High strength cement and production method thereof

The invention provides a high-strength cement and a production method thereof. Raw materials of the high-strength cement comprise 10-20 parts of Portland cement, 10-30 parts of carbide slurry, 10-20 parts of lime mud, 20-25 parts of mine mud, 25-35 parts of red mud, 5-11 parts of diatomaceous earth, 5-25 parts of fly ash, 1-3 parts of pyrite slag powder, 1-5 parts of polypropylene fibers, 2-6 parts of a naphthalene series water reducer, 11-14 parts of desulfurized gypsum, 5-7 parts of dicyandiamide residues, 4-5 parts of metal magnesium reduction powder, 10-20 parts of quartz sands, 15-30 parts of quicklime, 12-30 parts of a stone breaker, 2-6 parts an inhibitor and 5-15 parts of a water reducer. The cement has the high-efficiency waterproofing, moisture proofing, expanding, crack preventing and permeation preventing functions, and is worth promoting and applying.

Owner:合肥市一片叶装饰工程有限公司

Organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of internal combustion engine

InactiveCN105062426AGood environmental characteristicsComply with protectionHeat-exchange elementsEnvironmental resistanceOrganic Rankine cycle

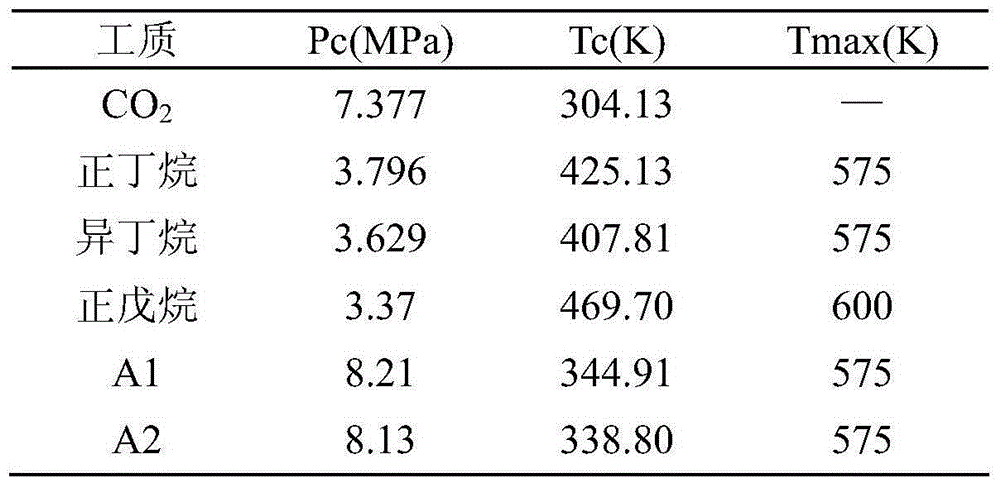

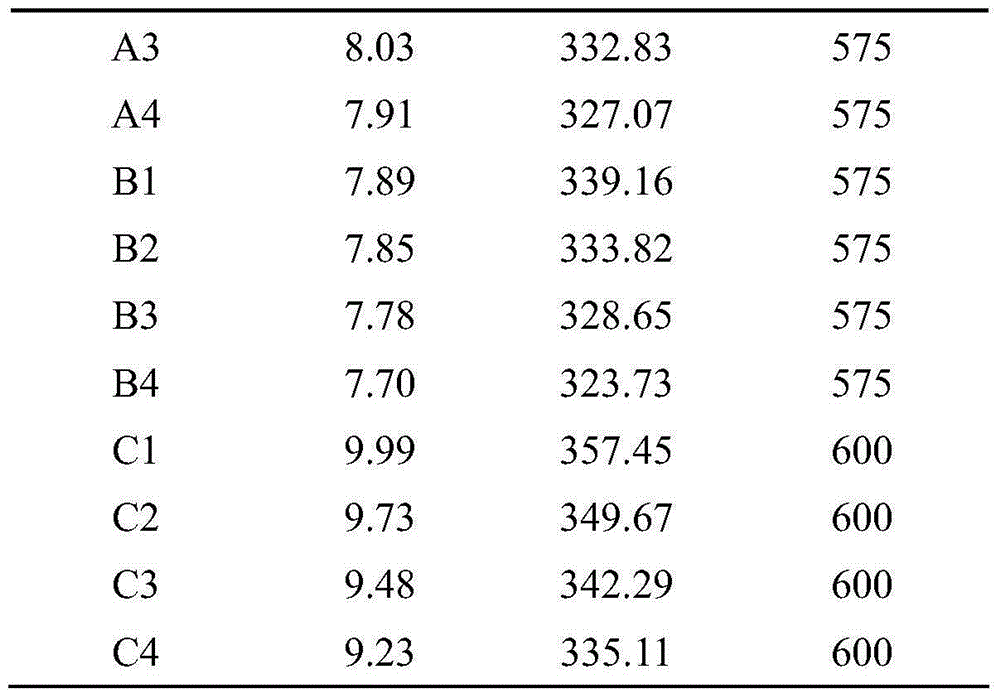

The invention discloses a group of organic Rankine cycle mixed working media applicable to recovery of waste heat of high-temperature exhaust gas of an internal combustion engine. The organic Rankine cycle mixed working media comprise components in percentage by mass as follows: 20%-32% / 68%-80% of n-butane / CO2, 20%-32% / 68%-80% of iso-butane / CO2 and 15%-27% / 73%-85% of n-pentane / CO2. The mixed working media are physically mixed at the normal temperature and then subjected to systematical filling. The mixed working media belong to natural working media, the ODP (ozone depletion potential) value is zero, the GWP (global warming potential) value is very small, and the organic Rankine cycle mixed working media have good environment protection performance; besides, the organic Rankine cycle mixed working media can meet the ISO 817-2010 standard and the A2-class safety working medium standard of the ASHRAE 34-2010 standard and have higher safety. The critical pressure and the critical temperature of the mixed working media are appropriate, the heat efficiency under the working condition of organic Rankine cycle design is higher than 14%, and the thermal performance is excellent.

Owner:TIANJIN UNIV

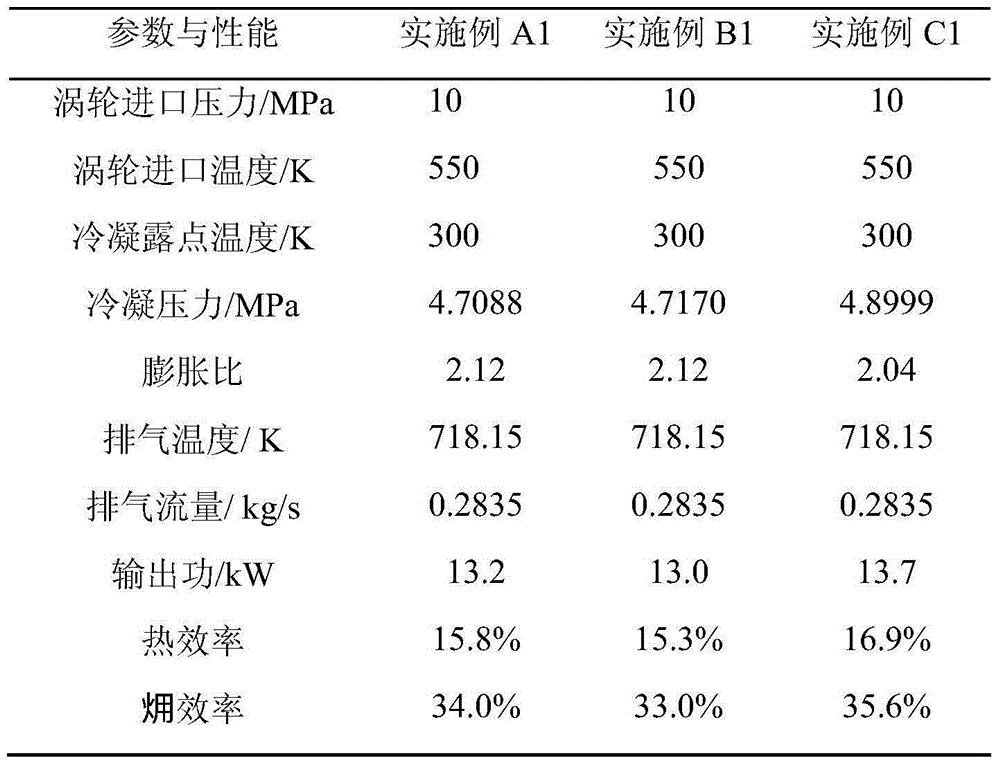

A group of mixed working media, containing HFCs and HCs for heat pump at mid and high temperature

InactiveCN1563256AComply with protectionMeet environmental protection requirementsHeat-exchange elementsMass ratioEngineering

A group of mixed working media suitable to be used as refrigerant for heat pump with condensing temperature of 60-120 deg.c cotnains eight component materials of HFC134a, HFC152a, R1311, HFC143, HFC 236fa, HFC 245fa, HC600 and HC600a. The eight component materials can be prepared to be binary and ternary mixture as per different mass ratio and its preparing process is to carry out physical mixing of abovesaid component materials as per appointed ratio at ordinary temperature for forming relevant mixed working media.

Owner:TIANJIN UNIV

Environment-friendly medium-high temperature heat pump working medium containing dimethyl ether and iodotrifluoromethane

InactiveCN103045174AComply with protectionImprove protectionHeat-exchange elementsDifluoroethyneThermodynamics

The invention relates to an environment-friendly mixing working medium suitable for compression type medium-high temperature heat pump unit. The working medium comprises three components in percentage by weight as follows: 25%-75% of DME (dimethyl ether), 15%-45% of R13I1 (iodotrifluoromethane) and 10%-50% of R152a (difluoroethane). A preparation method comprises the step that the components are subjected to fluent physical mixing at the normal temperature in a designated proportion. The working medium has the advantages that the ODP (ozone depletion potential) of the working medium is zero, the GWP (global warming potential) is very low, and the mixing working medium is environment-friendly; the cycle performance is excellent, the performance of the medium-high temperature variable working condition is better, and the slippage temperature is very low; and the working medium can be directly used in the R134a heat pump unit, so that the compressor and main parts in the system are not required to be changed. The heat pump unit employing the mixing working medium can provide a medium-high temperature heat source in a range from 70 DEG C to 90 DEG C.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Natural wild fruit health care wine and its production method

InactiveCN1534090AEnhance immune functionRefreshing and mellow tasteAlcoholic beverage preparationRose hipSugar

A health-care wine is prepared from rice wine, crystal sugar, granular white sugar and 6 natural wild fruits including cherokee rose-hip-fruit, wild jujube, red bayberry carambola, etc through respectively sterilizing, proportionally mixing, sealing in earth jar to obtain raw wine, and mingling. Its advantages are agreeable taste, and sure health-care function.

Owner:何国武

Zero zone destruction and mixed working medium suitable for compression type heat pump

InactiveCN1757695AZero Ozone Depletion PotentialReduce the greenhouse effectHeat-exchange elementsEngineeringButane

A mixed working medium for the high-temp compression-type heat pump features no damage to ozone contains 1,1,1,2-tetrafluoroethane, 1,1,1,2,3,3,3-heptafluoropropane, and 1,1,1,3,3-pentafluoropropane. It is possible to add butane to it. Its advantages are no poison, incombustible, and high thermodynamic performance.

Owner:TSINGHUA UNIV +1

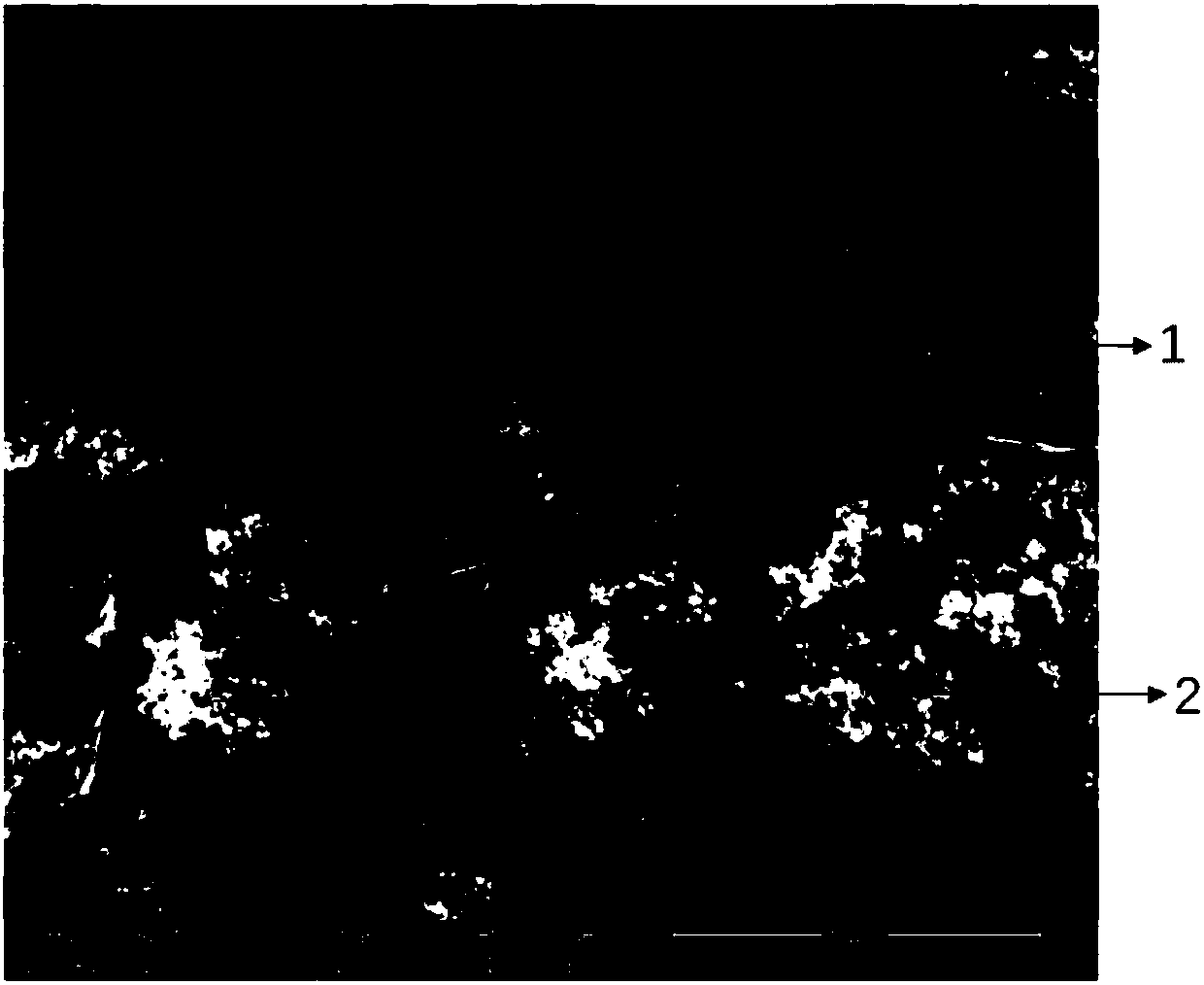

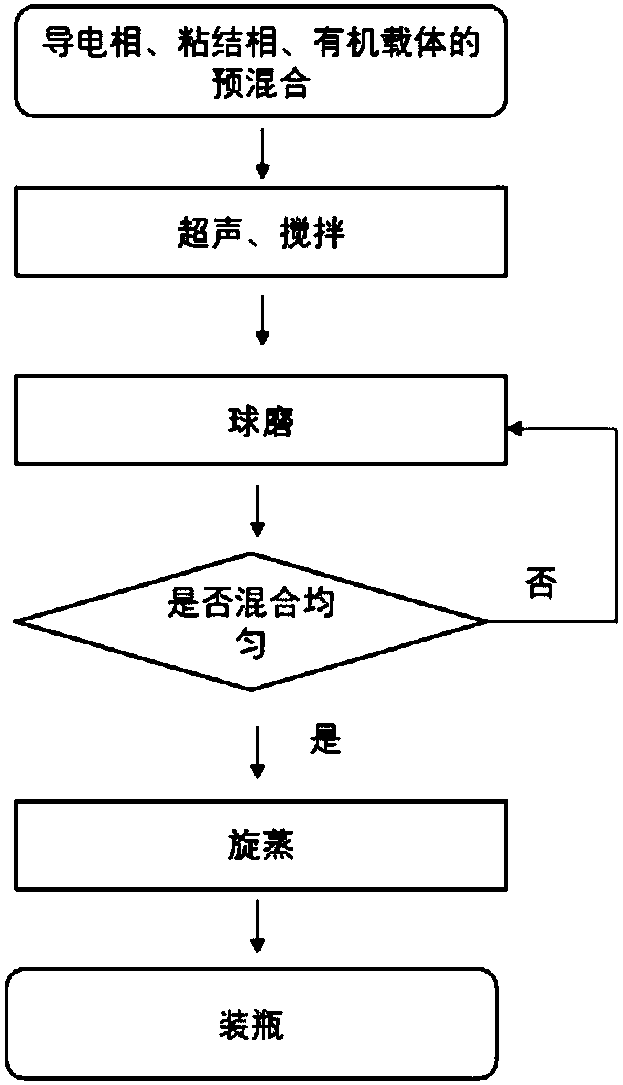

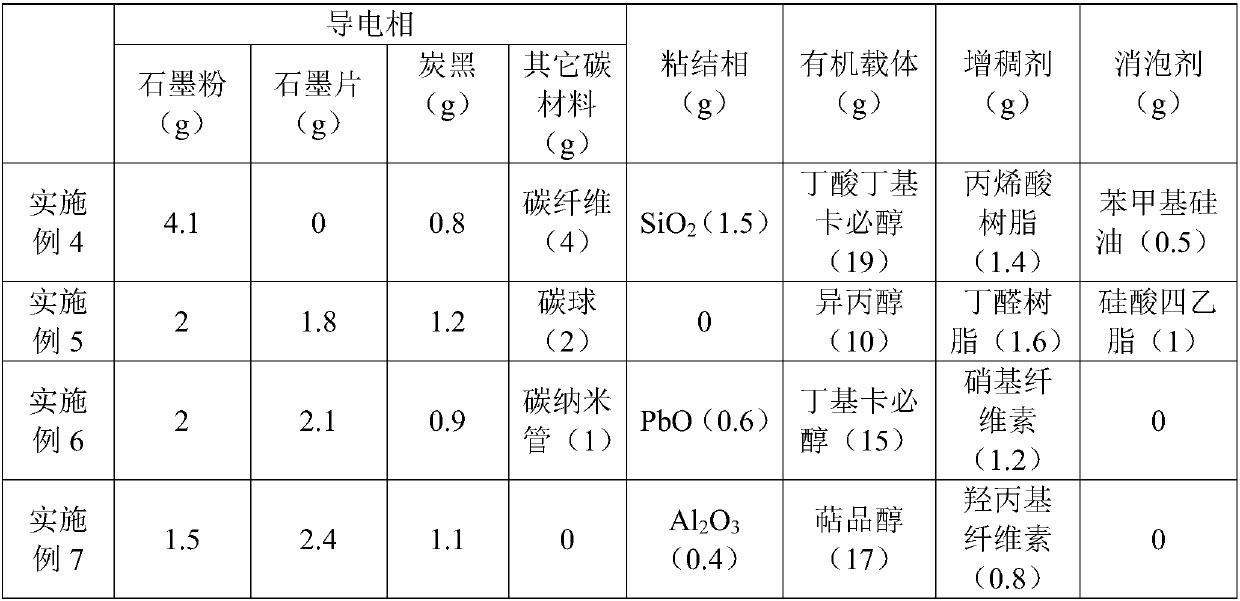

Carbon electronic paste and preparation method thereof

InactiveCN107705878AImprove performanceLow costNon-conductive material with dispersed conductive materialCable/conductor manufactureScreen printingRotary evaporator

The invention discloses a carbon electronic paste. The carbon electronic paste comprises the following components in parts by weight: 30-90 parts of a conductive phase, 0-20 parts of a binding phase,100-190 parts of an organic carrier, 0-16 parts of a thickening agent and 0-10 parts of a defoaming agent. The invention further provides a preparation method of the carbon electronic paste. The preparation method comprises the following steps of adding the conductive phase, the binding phase and the organic carrier into a solvent for pre-mixing the conductive phase, the binding phase and the organic carrier, adding the thickening agent and the defoaming agent during the pre-mixing process, carrying out mechanical stirring and ultrasonic crushing, transferring materials into a ball milling instrument to conduct the ball milling treatment on the materials, taking out the materials, rapidly evaporating the solvent by using a rotary evaporator, adding the materials into a bottle and obtainingthe carbon electronic paste. Compared with a metal electronic paste in the prior art, the above carbon electronic paste is high in performance, low in cost and lead-free, and the idea of protecting the environment is met. The competitive capacity of carbon electronic paste products is greatly improved. The carbon electronic paste prepared by the preparation method disclosed in the invention can be used subsequently by adopting the simple silk-screen printing or the blade scraping method. Meanwhile, the preparation method is convenient and simple.

Owner:武汉配斯特科技有限公司

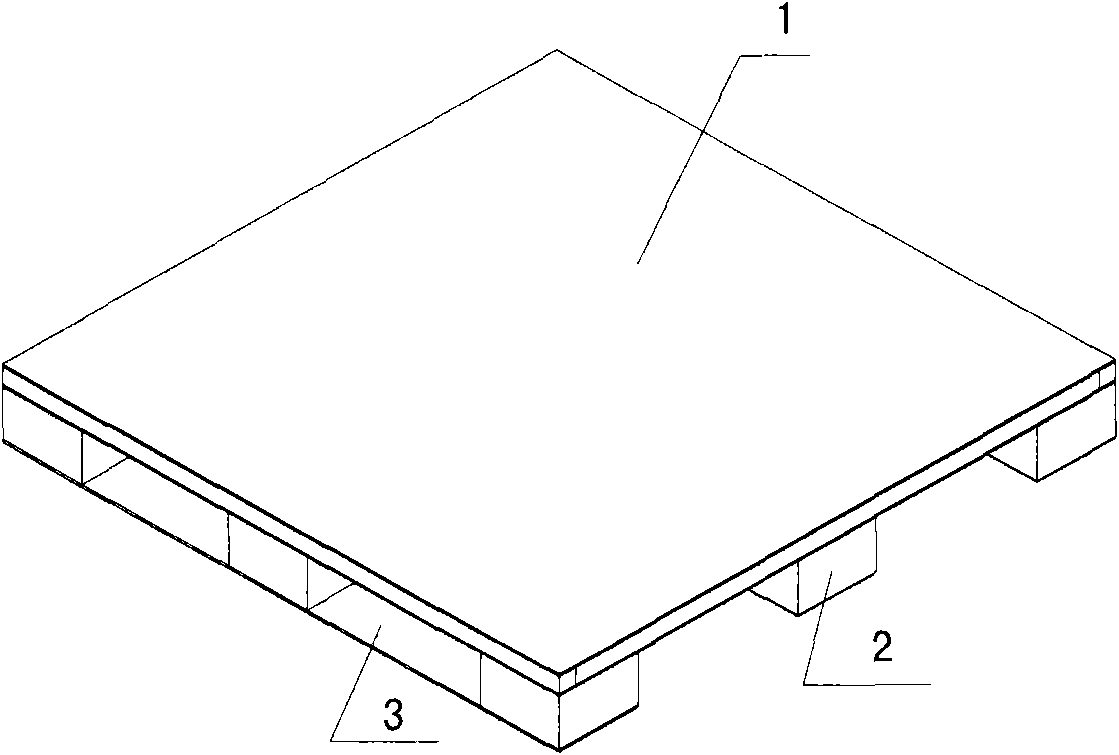

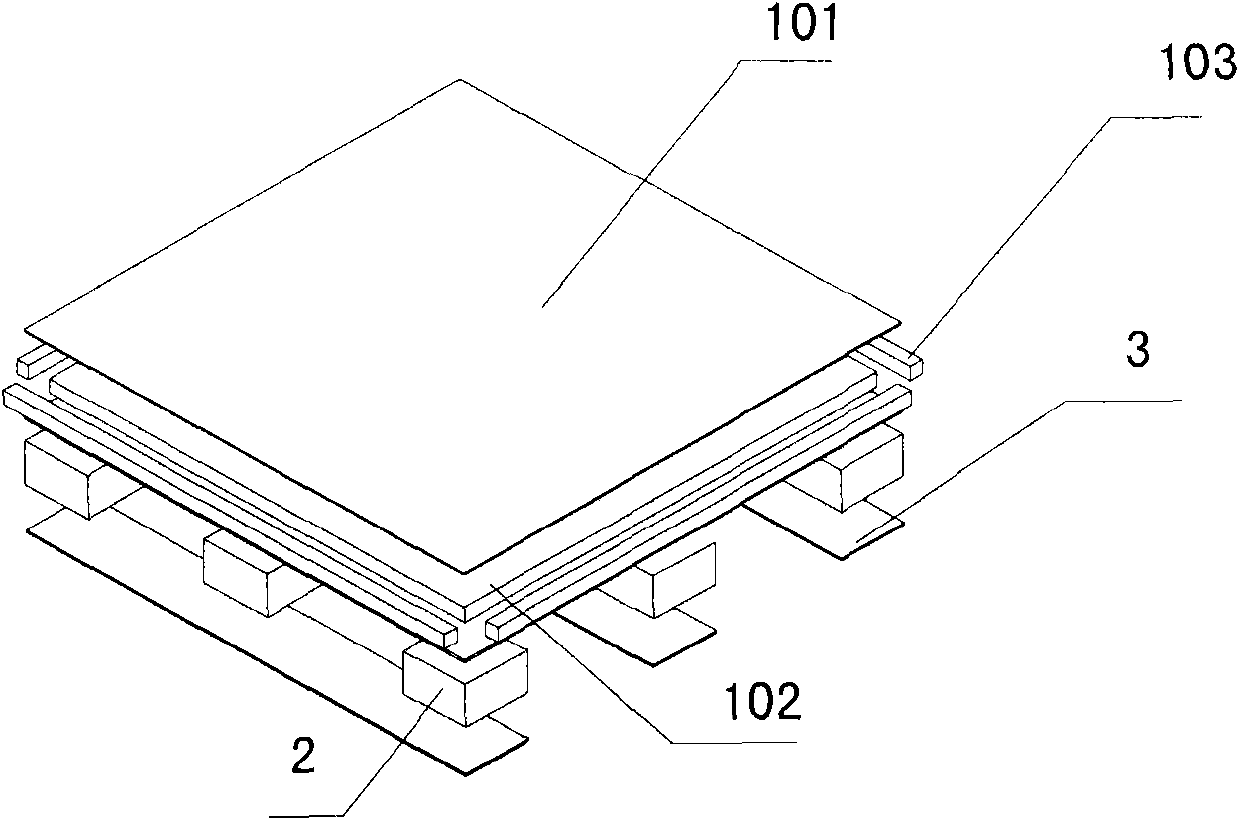

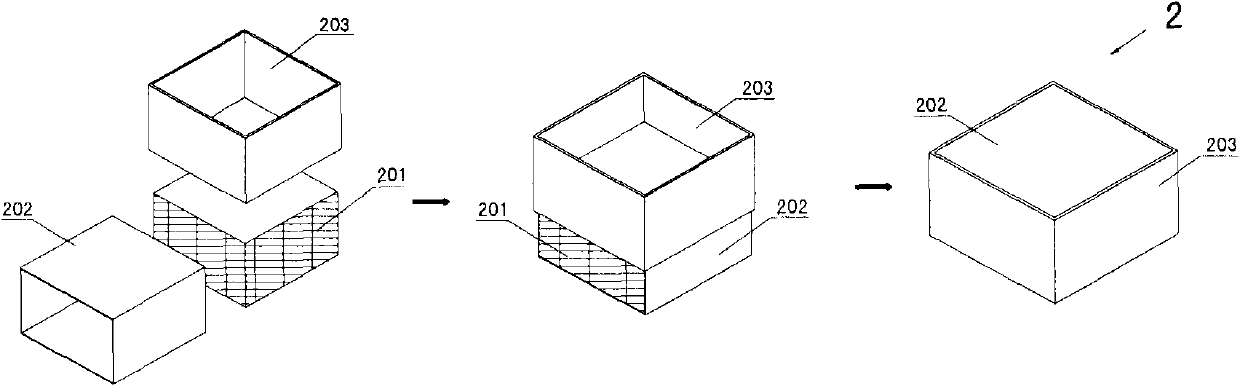

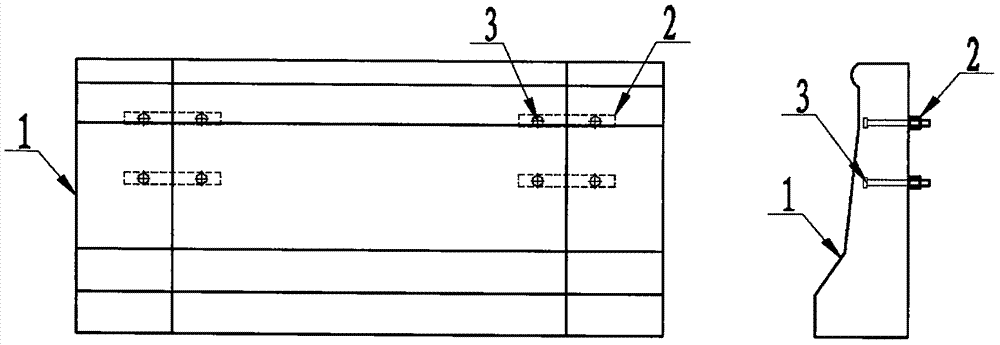

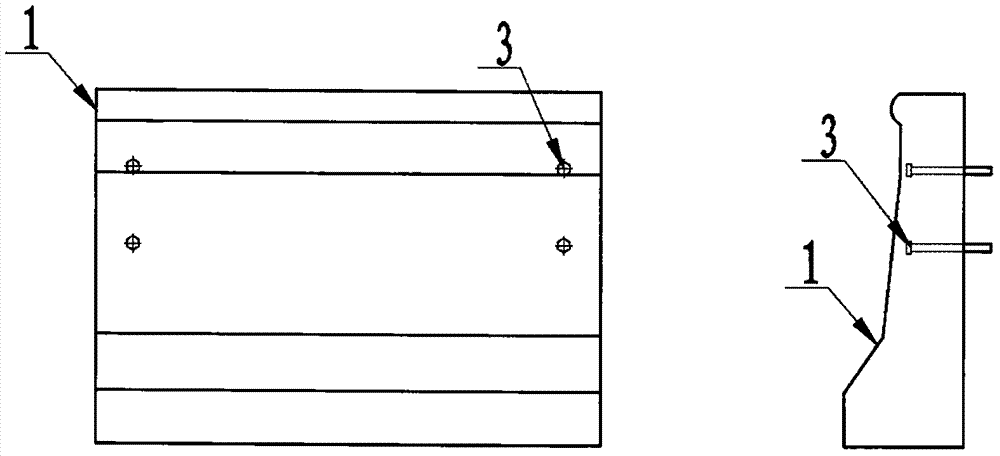

Honeycomb paperboard all-paper tray and manufacturing method thereof

InactiveCN102085939AWith strengthQuite strongPaper/cardboard articlesRigid containersEnvironmental resistanceCardboard

The invention discloses a honeycomb paperboard all-paper tray and a manufacturing method thereof. The honeycomb paperboard all-paper tray comprises a top board, bottom piers and a bottom belt, wherein the top board comprises a honeycomb paperboard base material, paper cardboards compounded on upper and lower surfaces of the honeycomb paperboard base material, and paper square tubes which are compounded at the periphery of the honeycomb paperboard base material; each bottom pier comprises a honeycomb paperboard filled block, an inner sleeve of the paper square tube and an outer sleeve of the paper square tube; the inner sleeve of the paper square tube is sleeved outside the honeycomb paperboard filled block; and the outer sleeve of the paper square tube is sleeved outside the honeycomb paperboard filled block and the inner sleeve of the paper square tube along a direction vertical to the direction of sleeving the inner sleeve of the paper square tube. The manufacturing method comprises the following steps of: manufacturing the top board; manufacturing the bottom piers; manufacturing the bottom belt; and adhering various bottom piers on the same bottom belt at intervals to form a bottom pier assembly, and parallelly adhering one end of each of the various bottom piers which is not adhered with the bottom belt to the lower surface of the top board. The honeycomb paperboard all-paper tray meets the requirement on environment friendliness, and has the advantages of low cost and high compressive strength and bending resistance.

Owner:青岛众和恒业蜂窝纸板制品有限公司

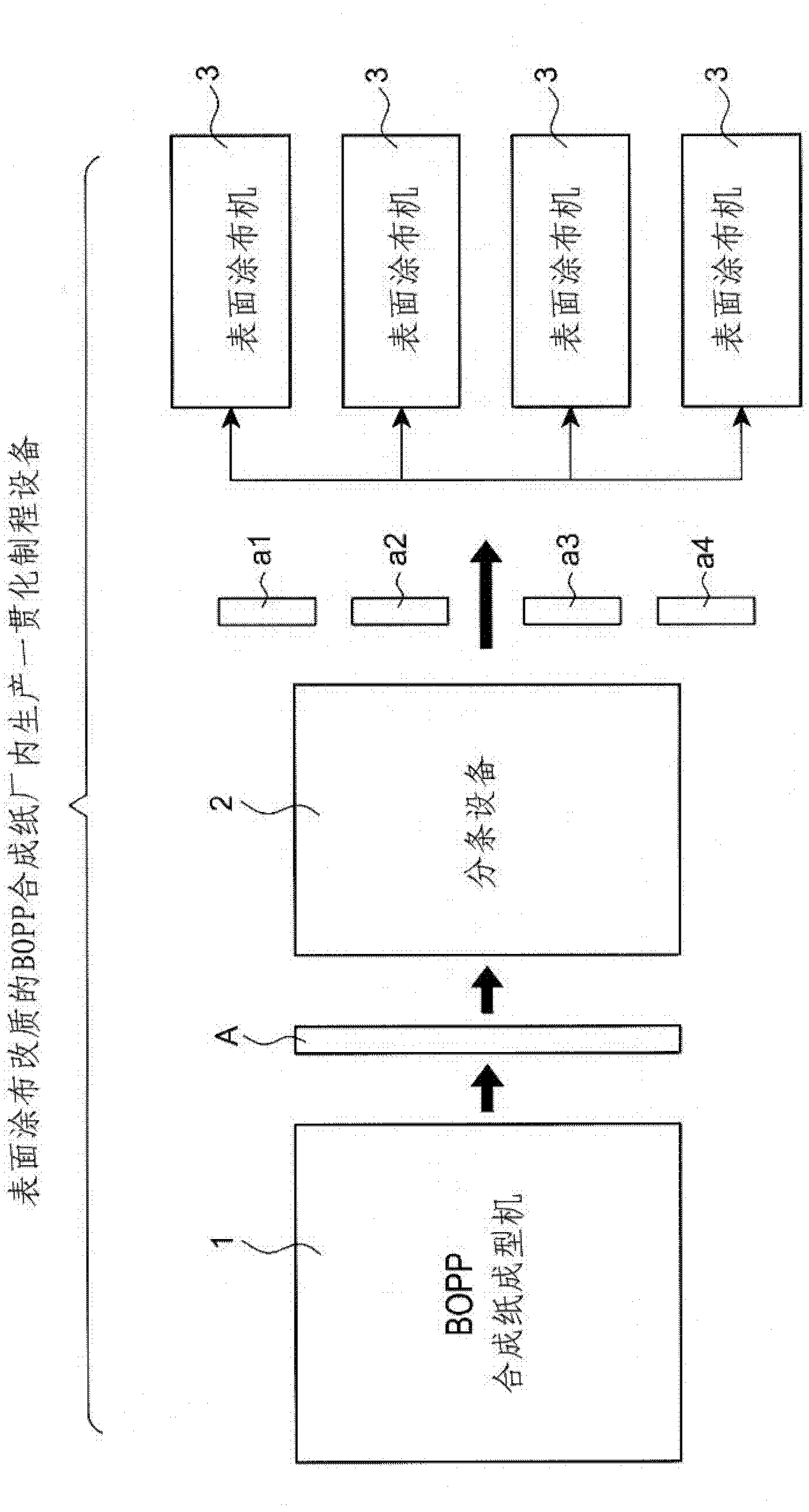

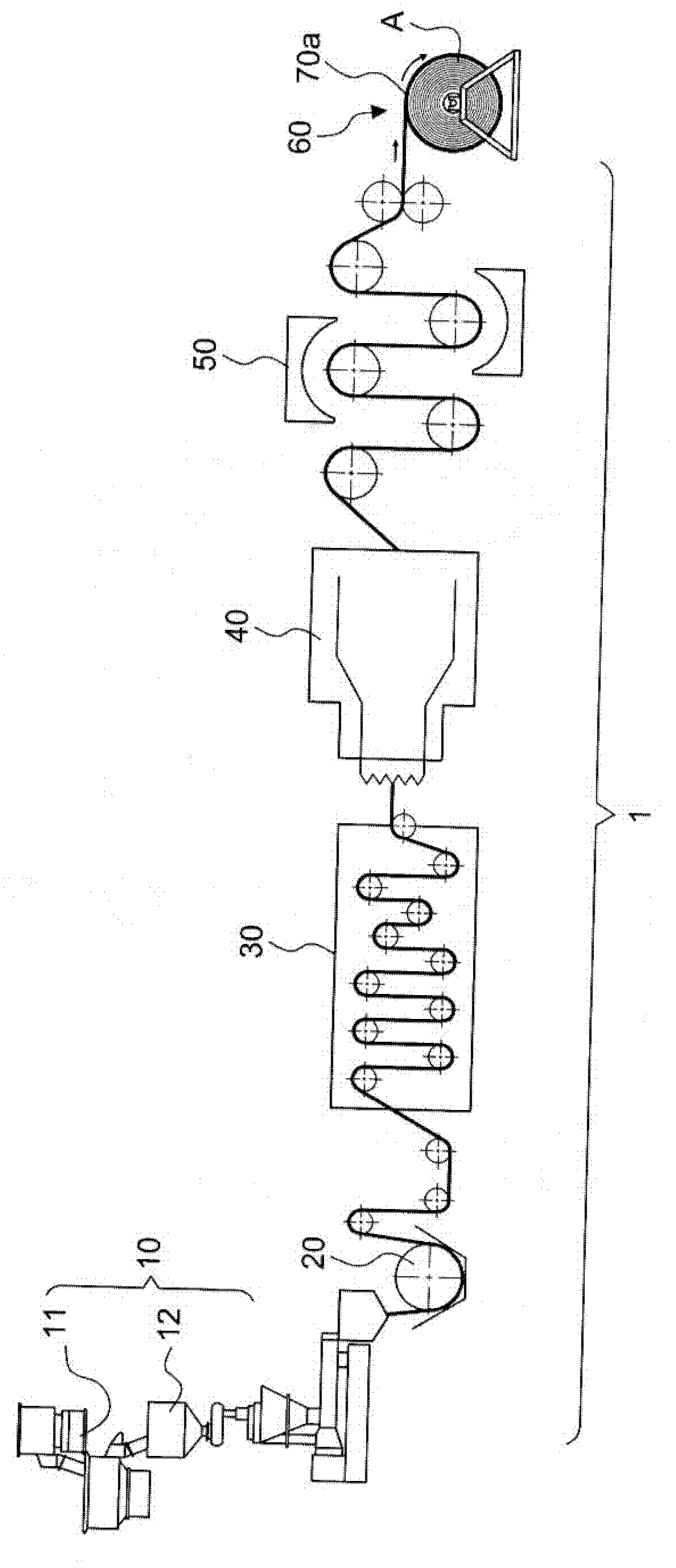

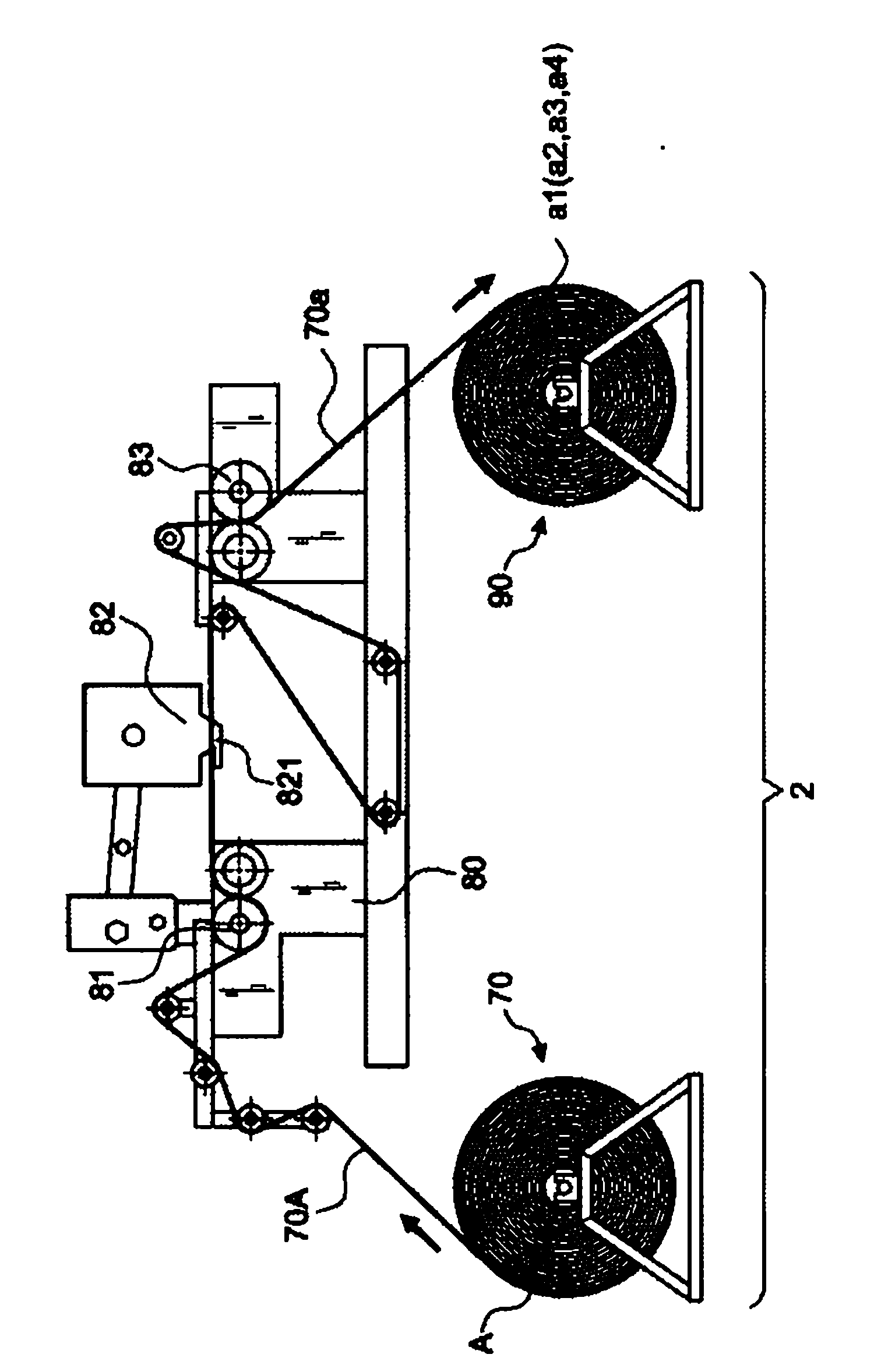

Integrated processing device of in-plant production of surface-coated and modified BOPP (Biaxially Oriented Polypropylene) synthetic paper

InactiveCN103009647AMonitor qualityReduce labor costsFlat articlesCoatingsSurface layerPulp and paper industry

The invention relates to an integrated processing device of in-plant production of a surface-coated and modified BOPP (Biaxially Oriented Polypropylene) synthetic paper. The integrated processing device comprises a BOPP synthetic paper forming machine, a stripping device and at least one surface coating machine, wherein the BOPP synthetic paper forming machine is used for machining compositions mainly comprising polypropylene to finish primary blank synthetic paper and reeling the primary-blank synthetic paper to a long paper roll with the width of eight meters; then the stripping device is used for cutting the long paper roll with the width of eight meters into multiple segments of short paper rolls by a cutting tool; and the at least one surface coating machine is used for carrying out surface coating and modifying on stripped short paper roll primary blanks to form a paper surface layer having multiple superfine air hole volumes and an air hole series connection degree similar to the natural paper. According to the integrative processing device of the in-plant production of the surface-coated and modified BOPP synthetic paper, the in-plant integrative production is realized, the cultural paper or the packaging paper can be produced with the lowest cost and production process, and the target of protecting environmental resources is accorded.

Owner:陈博彦

Middle and high temperature heat pump mixed working medium containing HFC245fa

InactiveCN1782016AComply with protectionMeet environmental protection requirementsHeat-exchange elementsOzone layerGreenhouse

The mixed middle and high temperature heat pump working medium containing HFC245FA is suitable for use as refrigerant in middle and high temperature heat pump system of condensing temperature 60-120 deg.c. The mixed working medium contains four kinds of matter, R13I1, HFC245fa, HFC134a and HFC152a in different mass proportions to constitute binary and ternary mixtures. The mixed working medium is prepared through mixing the components in designated proportion physically at normal temperature. The present invention has no damage on ozone layer, very low green house effect potential, proper thermotechnical parameters and excellent circulation performance, and may be used in middle and high temperature heat pump system of new and available HCFC22 air conditioner compressor.

Owner:TIANJIN UNIV

Substitute refrigerant for freon-12 centrifugal cold water machine set

InactiveCN1330122ANot brokenReduce the impact of the greenhouse effectHeat-exchange elementsCentrifugal chillerFreon

A substitute refrigerant for freon-12 centrifugal cold water machine set is prepared from monochlorodifluoromethane, 1,1,1,2,3,3,3-heptafluoropropane, 1-monochloro-1,1-difluoroethane, and optional isobutane through proportionally physical mixing. Its advantages include environmental protection, high safety and refrigerating efficiency, and no need of reforming existing equipment.

Owner:TSINGHUA UNIV +1

Refrigerating medium for heat pump of high-temp water source

InactiveCN1330121ALow damage potentialComply with protectionHeat-exchange elementsRefrigerantEngineering

Arefrigerant for heat pump of high-temp water source is prepared from monochloroe-1,2,2,2-tetrafluoroethane (HCFC-124), 1-monochloro-1,1-diffluoroethane (HCFC-1426) and optional isobutyane (HC-600a) through proportional pysical mixing. Its advantages include no damage to ozonosphere, no poison, imbustible nature, and high thermodynamic performance. It can directly use freon-22 refrigerating system and need not to change the compressor and main parts in the system.

Owner:TSINGHUA UNIV

Modified phenolic resin and rigid foamed plastic and preparation method thereof

The invention disclose a modified phenolic resin, prepared from phenol, formaldehyde, sodium hydroxide, oxalic acid catalyst and grease assistant. A rigid foamed plastic prepared by using the modified phenolic resin is prepared from phenolic resin, silicone oil surfactant, water, chlorinated hydrocarbon foaming agent and hydrochloric acid catalyst. The preparation method of the above materials comprises the steps of charging, comprehensive reaction, neutralization, dehydration, mixing, foaming, molding, and curing. Compared with polyurethane materials, the rigid foamed plastic has the characteristics of no toxicity and pollutant, non-flammable property, low cost, and good heat preservation and cold preservation performances, and is suitable for heat preservation of various pipelines, cold preservation of cold storage, indoor sound insulation, and moisture-proof engineering and the like.

Owner:王福伟

A group of mixed working media containing HFCs and HPCs for mid-high temperature heat pump

InactiveCN1563255AExcellent environmental characteristicsProtect the ozone layerHeat-exchange elementsRefrigerantProcess engineering

A grou of mixed working media being used suitable as refrigerant for heat pump with condensing temperature of 60-120 deg.c contains eight component materials of R1311, 1,1,2-HFC 134a, CHF2OCHF2(HFE134), CH2FOCHF2(HFE143), 1,1-HF(152a, 1,1,2,2,3-HF (245ca, 1,1,2,2-HFC254cb and 1,1,1,2,3,3-HFC 236ea for forming binary and ternary mixture as per different mass ratio.

Owner:TIANJIN UNIV

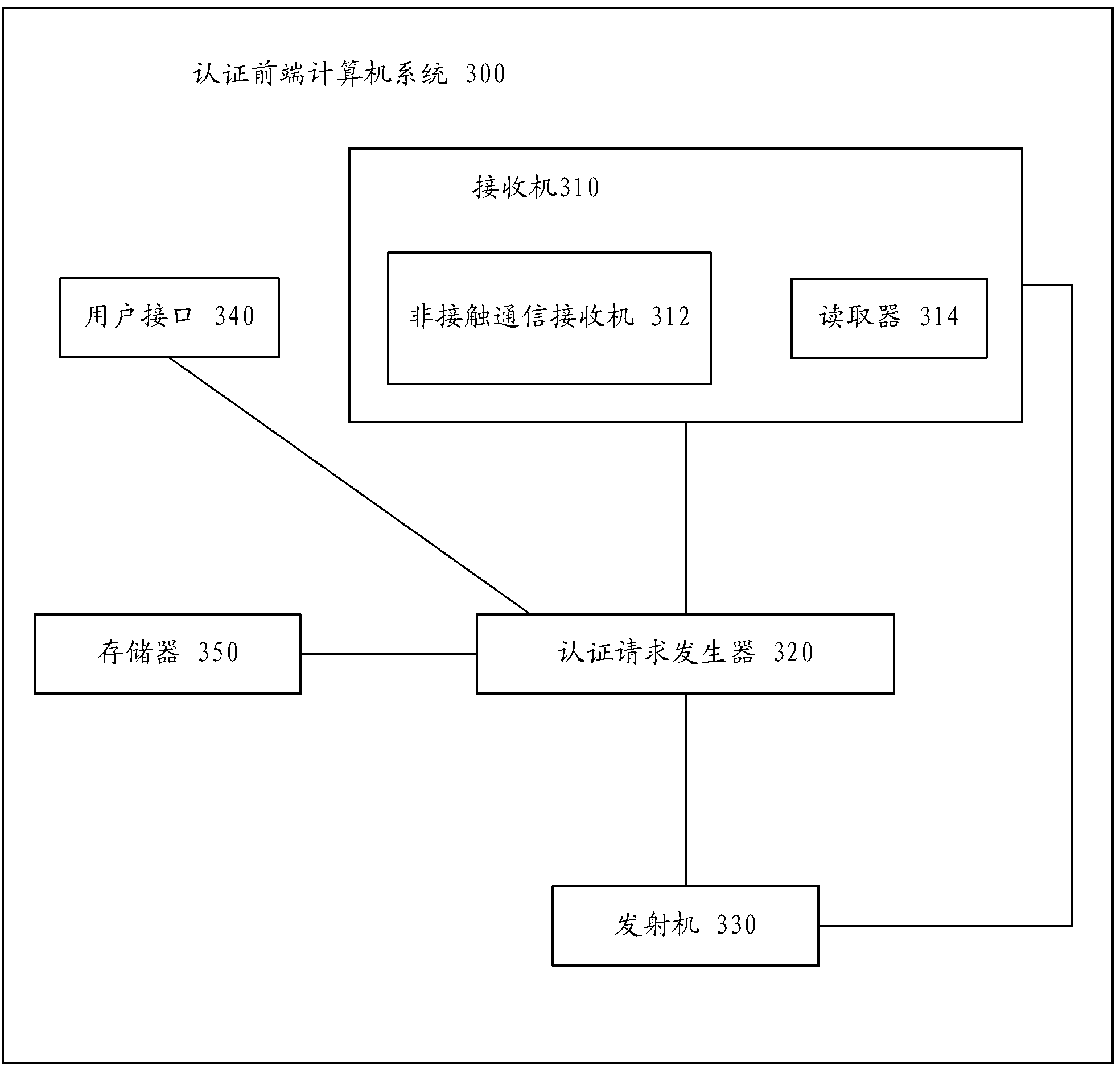

Method and system for user authentication and devices used in system

InactiveCN102984130AGuaranteed operational safetyEasy to installUser identity/authority verificationInternet privacyEngineering

The invention relates to a method and a system for user authentication and a user terminal, an authentication front-end computer system and an authentication server, wherein the user terminal, the authentication front-end computer system and the authentication server are used in the system for the user authentication. One implementation mode is that the user terminal sends an authentication instruction containing authentication information to the authentication front-end computer system, and then the authentication front-end computer system sends an authentication request containing the authentication information to the specific authentication server. Another implementation mode is that the user terminal sends the authentication request containing the authentication information to the specific authentication server. Based on either of the two implementation modes, after the authentication server receives the authentication request, the authentication server authenticates the user identity according to the authentication information. At last, preferably, the authentication server sends authentication results to the authentication front-end computer system. When a user needs to pay a certain amount of money to an operator, after successful authentication, the authentication server transfers the specific amount of money from a specific payment account of the user to a specific account of the operator.

Owner:陈嘉贤

Mixed substance containing HCFC-142b(chloro-1,1-difluoroethane) for moderate and high temperature heat pump

InactiveCN1654588AComply with protectionEnvironmentally friendlyHeat-exchange elementsRefrigerantEngineering

The mixed work medium containing HCFC-142b(-chloro-1, 1-difluroethane) for high and medium temperature heat pump is suitable for use as the refrigerant of high and medium temperature heat pump system of condensation temperature of 60-120 deg.c. The mixed work medium is ternary or quarternary mixture of 10 kinds of components, including HCFC-124, HCFC-142b, HFE-134, HFC-143, HFC-236ca, HFC-245fa, HFC-236fa, HC-600a, HFC-134a and HCFC-123, in certain mass proportion; and various components are mixed physically at normal temperature. The present invention has no damage on ozone layer, low greenhouse effect potential, proper thermal parameters and excellent circulation performance, and may be used in both optimally designed HCFC22 air conditioner compressor and available HCFC22 air conditioner compressor to convert the air conditioner compressor into high and medium temperature heat pump set with the new work medium.

Owner:TIANJIN UNIV

Acid pumping method for small lead-acid batteries

InactiveCN102290558AHigh acid consistencyIncreased consistency of acid pumpingCell component detailsMotor speedElectrical battery

The invention provides a method for extracting acid from a small lead-acid battery. A plurality of batteries are balancedly fixed on a rotating frame, and the rotation speed of the motor is controlled at 10-1000 rpm for 0.1-10 minutes to drive the battery to rotate. Surplus acid is thrown out, and the acid thrown out is recycled for reuse. The method is used for acid pumping of small lead-acid batteries after formation, and is easy to operate, standardized, and high in efficiency. During mass production, the acid pumping consistency of batteries is good, which can improve the consistency of batteries, increase battery capacity and life, and protect the environment. ,save resources.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

A group of mixed working media containing HFCs for high temperature heat pump

InactiveCN1563253AComply with protectionGuaranteed matchHeat-exchange elementsThermodynamicsRefrigerant

A group of mixed working media being used suitably as refrigerant of heat pump system with condensing temperature of 100-140 deg.C, contains six component materials of HFC 134a, HFC 152a, R1311, HFC 143, HFC 236 fa and HFC 245 fa. The six compound materials can be formed to be binary and ternary mixture according to different mass ratio and its preparing process is to carry out physical mixing of abovesaid component materials as per appointed ratio at ordinary temp to forming relevant mixed working media.

Owner:TIANJIN UNIV

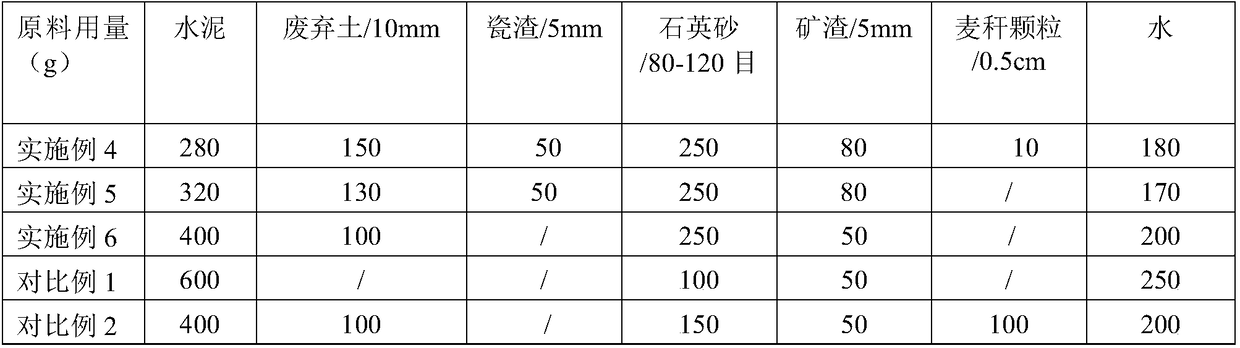

Pumice decoration plate and preparation method thereof

InactiveCN108751822AComply with protectionReduce loadOrnamental structuresSpecial ornamental structuresAdhesiveWaste material

The invention discloses a pumice decoration plate. The pumice decoration plate is prepared from cement, quartz sand, urban construction abandoned building waste, slag, wheat straw particles and coal ash; the urban construction abandoned building waste is prepared from abandoned soil, abandoned cement blocks, ceramic slag and stone powder; the slag is prepared from silicate and aluminosilicate slag, the grain size of the urban construction abandoned building waste is 5-15mm, the grain size of the slag is 1-10mm, the grain size of the wheat straw particles is 0.1-1cm, and the grain size of the coal ash is 0.1micron-350microns. The pumice decoration plate which is light and has the flame retardant performance adopts the raw materials such as the urban construction abandoned building waste, the wheat straw and the coal ash, meanwhile, no organic adhesives is added, the production cost is lowered, and the problem of pollution generated by the waste materials is solved.

Owner:上海赛冠新材料科技有限公司

Mixed heat pump work substance with zero ozone layer destroying potential

InactiveCN100347265CComply with protectionReduce protection requirementsHeat-exchange elementsWater source heat pumpOzone layer

The mixed heat pump work substance with zero ozone layer destroying potential is one kind of mixed refrigerating work substance for use in medium and high temperature water source heat pump set. The work substance contains three substances of 1, 1, 1, 2-tetrafluoro ethane, 1, 1, 1, 2, 3, 3, 3-heptafluoro propane and 1, 1, 1, 2, 3, 3-hexafluoro propane, or may have butane added to constitute quaternary mixed work substance. The preparation process is physical mixing of the liquid components in certain proportion. The present invention has the advantages of no destruction on ozone layer, no toxicity, being inflammable and high thermal performance, and may be used directly in HFC-134a heat pump set, with the heat pump set being able to provide hot water of about 80 deg.c.

Owner:TSINGHUA UNIV +1

Technology of producing high strength cement by utilizing industrial waste residue

ActiveCN104193204BComply with protectionReduce disposal costsCement productionSocial effectsToxic industrial waste

Owner:崇左南方水泥有限公司

Roadbed concrete guard bar reuse construction method

InactiveCN107513963AAchieve reuseExtended service lifeRoadway safety arrangementsResource savingSubgrade

The invention relates to a roadbed concrete guard bar reuse construction method, and belongs to the field of traffic safety protection. The roadbed concrete guard bar reuse construction method includes the following steps: (1) producing concrete precast blocks; (2) assembling the concrete precast blocks, and forming a temporary guard bar; (3) longitudinally disconnecting the concrete precast blocks while demounting the guard bar, and then transferring the concrete precast blocks for use; and (4) arranging the concrete precast blocks as a roadbed guard bar for reuse. The roadbed concrete guard bar reuse construction method is simple and reasonable, is short in construction period, can effectively allow reuse of the roadbed concrete guard bar, can reduce the cost and simplify the construction for reconstruction and extension projects, can simplify a construction manner, and satisfies the project construction idea of resource saving and environment protection.

Owner:BEIJING HUALUAN TRAFFIC TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com