Method for producing organic attapulgite by dry process

An attapulgite and organic technology, applied in the production field of organic attapulgite, can solve the problems of increased production cost, large consumption, and large energy, and achieve the effects of strong environmental protection, low production cost, and scientific process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

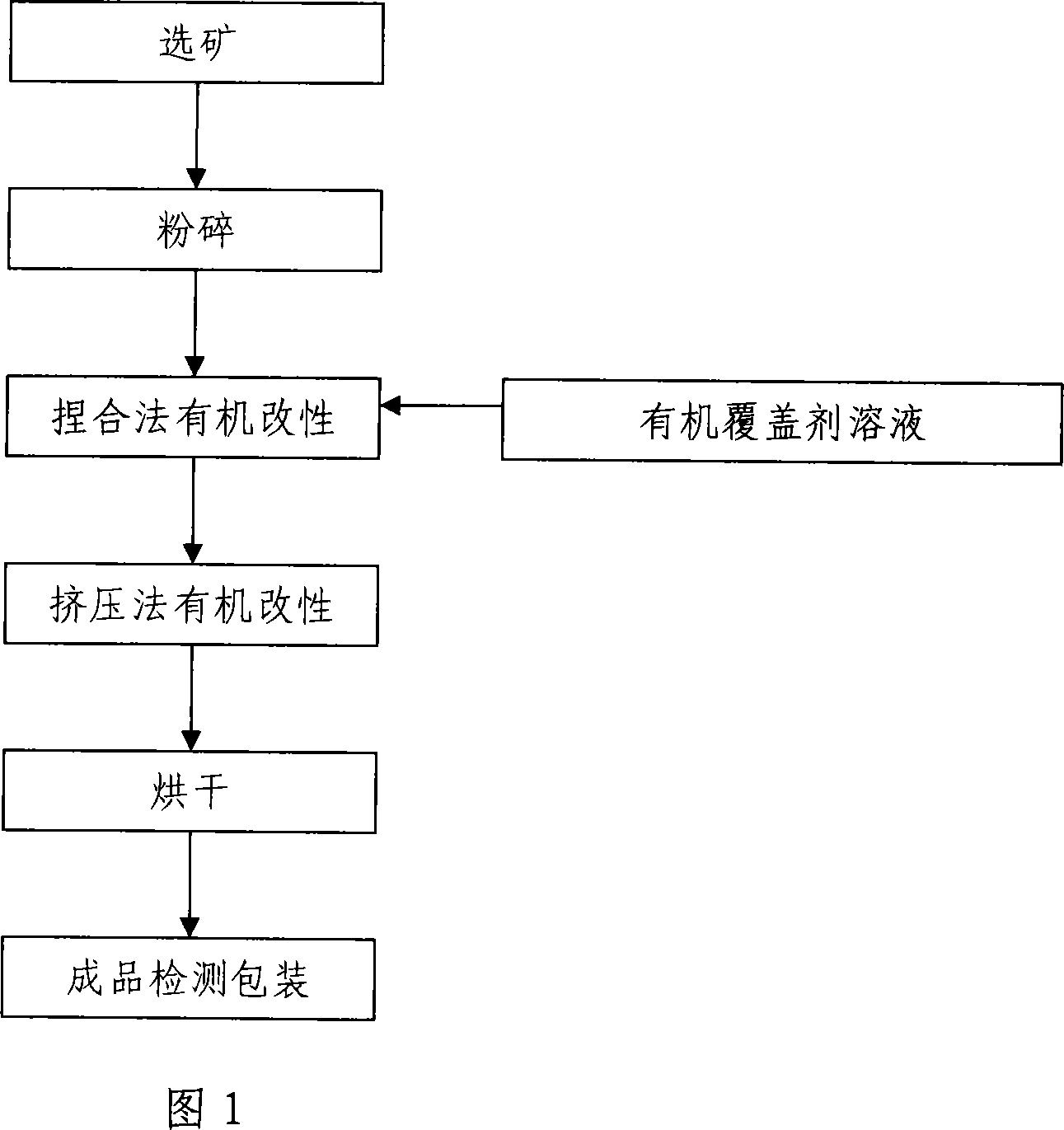

Image

Examples

Embodiment 2

[0037] Embodiment 2 of the present invention, a kind of dry method of producing organic attapulgite comprises the following steps:

[0038] Mineral processing step: choose colloidal high-viscosity attapulgite as raw material.

[0039] Pulverization step: use grinding equipment to mechanically pulverize the selected attapulgite raw materials, and then screen and purify the attapulgite materials after pulverization.

[0040] The general milling equipment is Raymond mill; the screen accuracy of the screen equipment ranges from 250 mesh to 400 mesh, and 325 mesh is generally selected.

[0041] Kneading organic modification step: adding an organic covering agent solution to the pulverized and purified attapulgite material, and performing kneading organic modification on the pulverized and purified attapulgite material by kneader equipment.

[0042] The organic covering agent at least includes a dodecyl quaternary ammonium salt covering agent and an octadecyl quaternary ammonium sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com