Pumice decoration plate and preparation method thereof

A decorative board and pumice technology, applied in the field of building materials, can solve problems such as unqualified production processes, peeling of decorative layers, wall leakage, etc., and achieve the effect of saving space and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

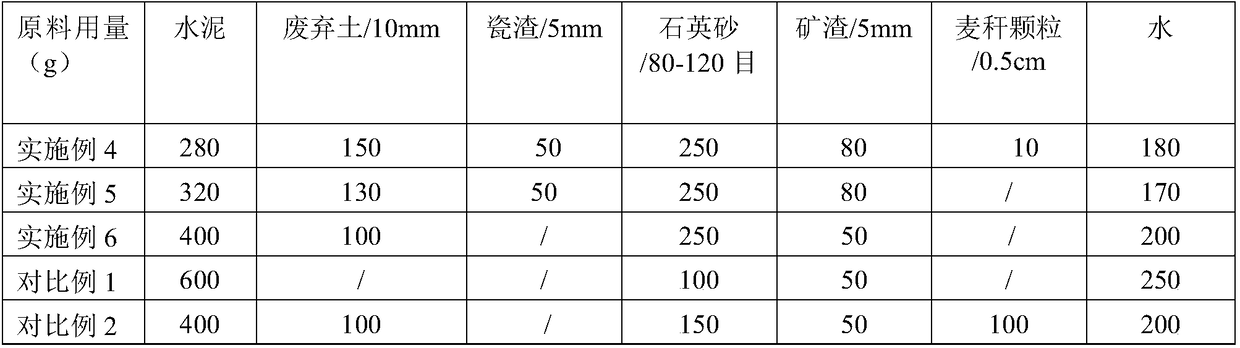

Examples

Embodiment 1

[0031] (1) Weigh 350g of cement, 50g of fly ash, 100g of porcelain slag, and 300g of quartz sand according to the formula and put them into the mixer for mixing. The particle size of each raw material is 100um of fly ash, 10mm of porcelain slag, and 80-120 mesh of quartz sand. , mixed evenly to obtain inorganic powder;

[0032] (2) Add 200g of water to step (1), stir evenly with a disperser, and adjust the viscosity to 10000-12000mpa.s concrete mortar with water;

[0033] (3) Pour the concrete mortar prepared in step (2) into the mold, put it into the drying room, and control the curing temperature of the concrete mortar at 20°C. A layer of mesh cloth with a mesh size of 8mm×8mm is placed in the mold in advance, and press Level the vested light stone slabs;

[0034] (4) After the pumice board prepared in step (3) is dried for 2 hours, the water content is 6%, and the imitation stone pattern is made on the surface through the 5D technology transfer process; wherein the thermal...

Embodiment 2

[0037] (1) Take by weighing 400g of cement, 100g of waste soil, 30g of wheat straw particles, and 250g of quartz sand in a mixer for mixing according to the formula, wherein the particle diameter of each raw material is 100um of waste soil, 0.2cm of wheat straw particles, and 80-120 mesh of quartz sand. Uniform vested inorganic powder;

[0038] (2) Add 220g of water to step (1), stir evenly with a disperser, and adjust the viscosity to 10000-12000mpa.s concrete mortar with water;

[0039] (3) Pour the concrete mortar prepared in step (2) into the mould, put it into a drying room and control the curing temperature of the concrete mortar at 20°C, and place two layers of grid cloth with meshes of 8mm×8mm in advance in the mold, Press and level the acquired light stone slab;

[0040] (4) After drying the pumice board prepared in step (3) for 2.5 hours, after the water content is 5%, a stone-like pattern is made on its surface through a 5D technology transfer process, wherein the ...

Embodiment 3

[0043] (1) Weigh 300g of cement, 100g of waste soil, 120g of stone powder, and 300g of quartz sand in a mixer according to the formula. The particle size of each raw material is 100um of waste soil, 10mm of stone powder, and 80-120 mesh of quartz sand. Powder;

[0044] (2) Add 180g of water to step (1), stir evenly with a disperser, and adjust the viscosity to 10000-12000mpa.s concrete mortar with water;

[0045] (3) Pour the concrete mortar prepared in step (2) into the mold, put it into the drying room, and control the curing temperature of the concrete mortar at 25°C. A layer of mesh cloth with a mesh size of 10mm×10mm is placed in the mold in advance, and press Level the vested light stone slabs;

[0046] (4) The pumice board prepared in step (3) is dried for 1.5 hours, and after the water content is 7%, a stone-like pattern is made on its surface through a 5D technology transfer process, wherein the thermal printing head controls the printing and dyeing temperature at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com