Roadbed concrete guard bar reuse construction method

A construction method and concrete technology, applied in the field of traffic safety protection, can solve the problems of insufficient anchoring force of prefabricated concrete guardrail foundation, insufficient safety protection capacity, poor protection of large vehicles, etc., to meet the needs of safety protection, easy maintenance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Figure 12 It is a flow chart of the construction method for reuse of subgrade concrete guardrails, and its specific implementation process is as follows:

[0041] (1) Production of roadbed concrete temporary guardrail:

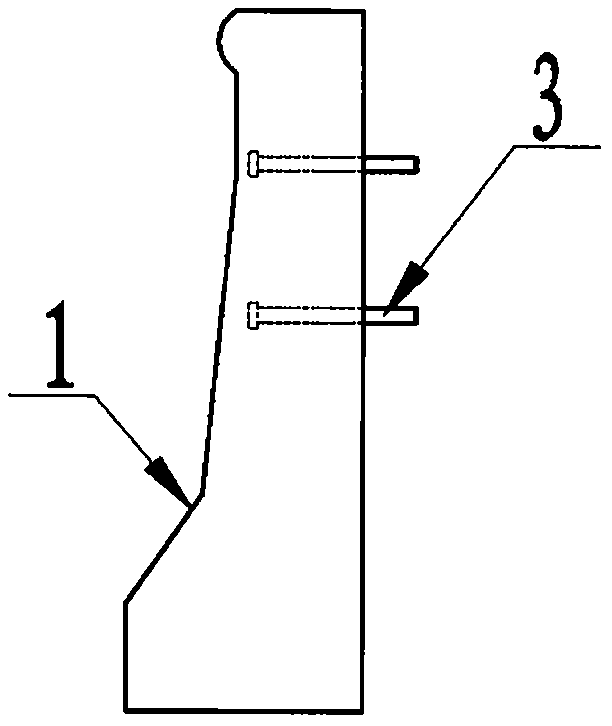

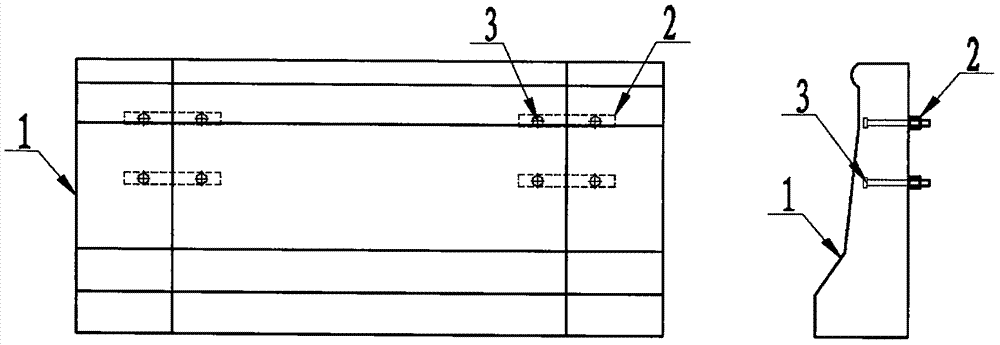

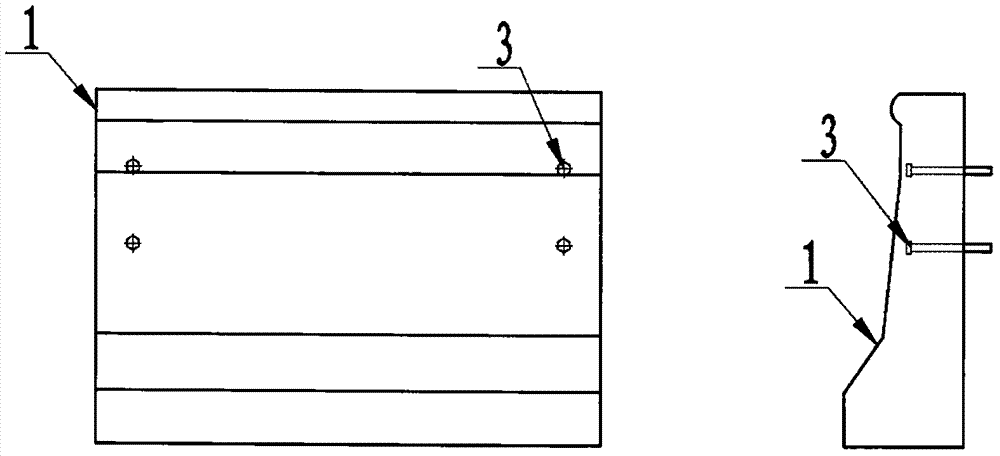

[0042] Cast concrete prefabricated block 1 with built-in guardrail reinforcement in concrete prefabricated block 1 and pre-embedded component 3 of longitudinal connection 2. When the positions of the two conflict, the position of pre-embedded component 3 should be kept unchanged and the position of the reinforcement should be adjusted appropriately. The pouring of the prefabricated concrete block 1 must be strictly controlled, and the construction requirements of the drawings must be strictly followed, and the pre-embedded components 3 of the longitudinal connection 2 should be accurately positioned. Get concrete prefabricated block 1 structure such as figure 1 .

[0043] (2) Installation of roadbed concrete temporary guardrail:

[0044] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com