Patents

Literature

31results about How to "Process Design Science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

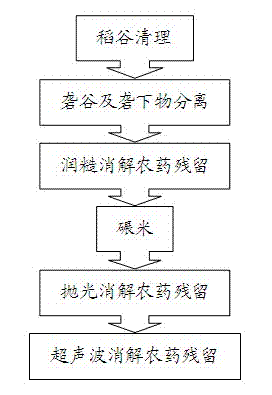

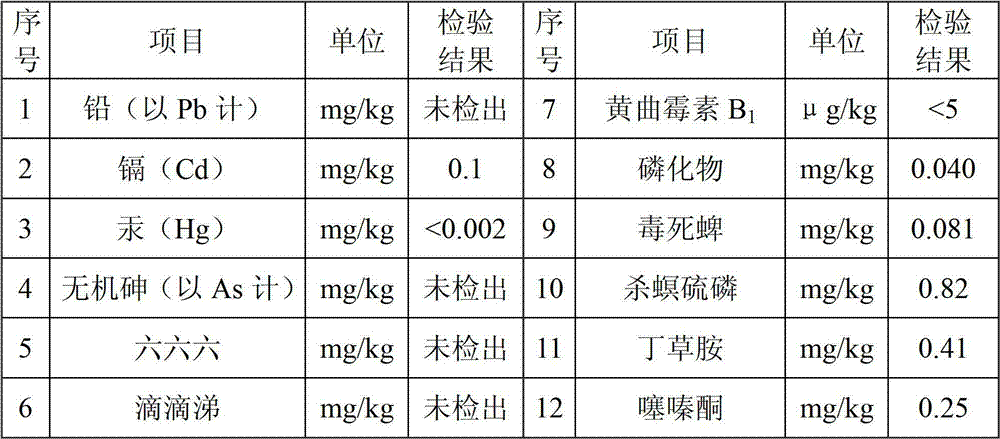

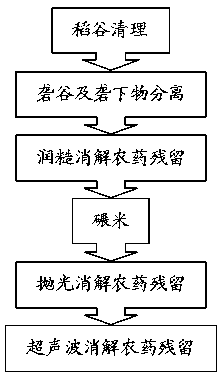

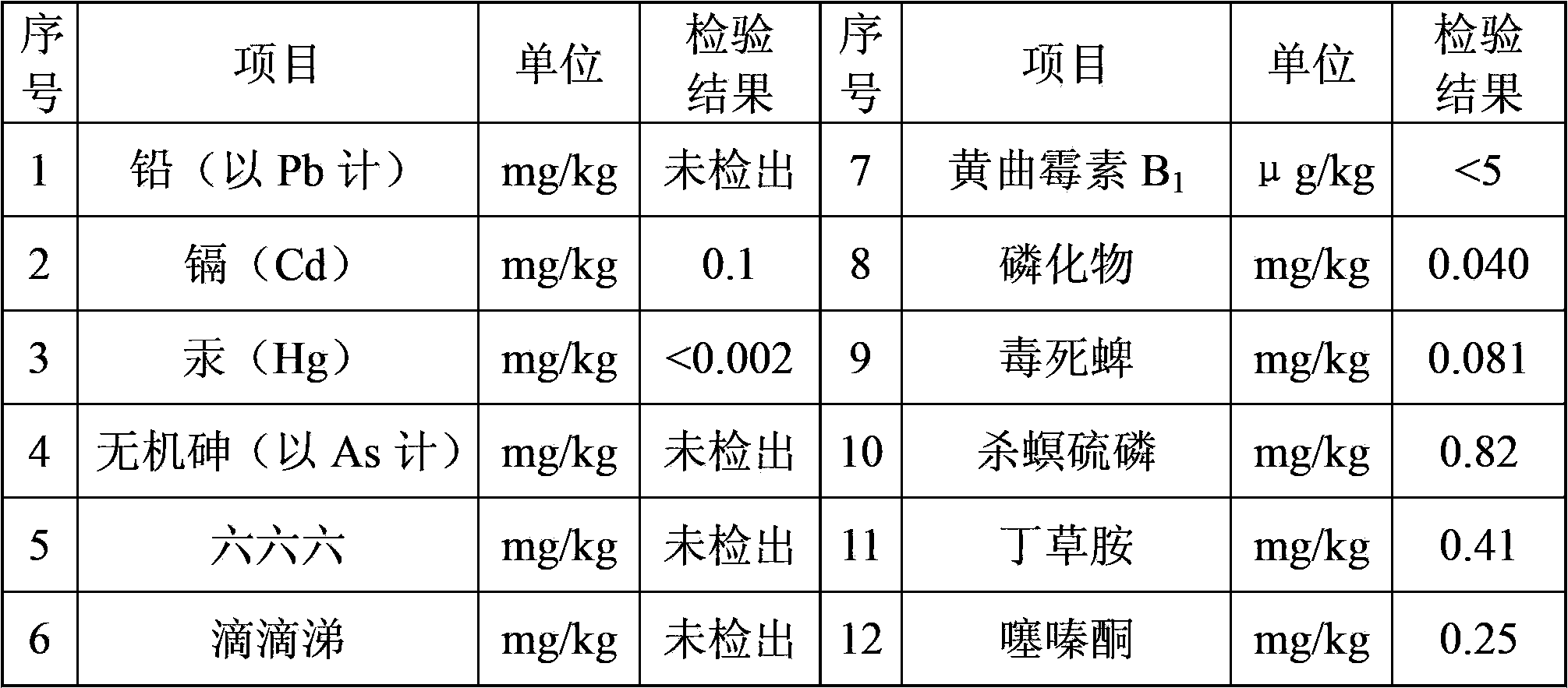

Paddy rice producing production technology for removing pesticide residue

ActiveCN102824934ASolve the problem of pesticide residuesChange qualityGrain huskingGrain polishingFlavorPesticide residue

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

Low-protein daily ration for growing pig under net energy system and application thereof

ActiveCN103110013ALow costControl energy depositionAnimal feeding stuffResearch councilResearch Object

The invention discloses low-protein daily ration for a growing pig under a net energy system and an application thereof, and belongs to the field of feed processing. The method comprises the steps of: taking the growing pig with the weight being 20-50kg as a research object, utilizing corn-bean pulp daily ration, reducing the protein content of the daily ration by 2% on the basis of the standard recommended by the National Research Council, simultaneously supplying lysine, methionine, threonine and tryptophan; adding mannan oligosaccharide, multivitamins, complex phosphoesterasum, probiotics and the like to form the low-protein daily ration for the growing pig under the net energy system; crushing, mixing, pelletizing then dosing, and packaging the pelletized feed and a probiotic component in a mixing manner to obtain the product disclosed by the invention. The animal feed utilization rate can be improved; the use quantity of antibiotic medicines in the feeding of animals is effectively reduced; the immunity of fed animals is improved; the security of animal meat products is improved; and the raise efficiency is also improved. The low-protein daily ration is scientific in process design, high in production efficiency, low in cost, and suitable for multi-variety and small-scale production.

Owner:LIAONING WELLHOPE AGRI TECH

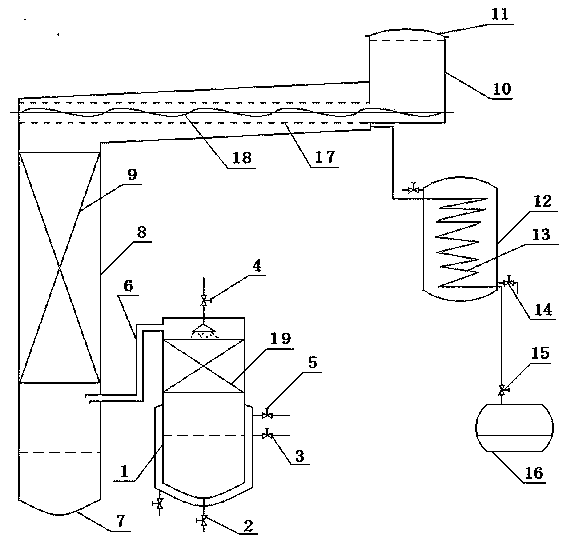

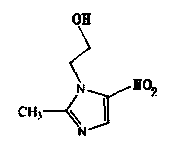

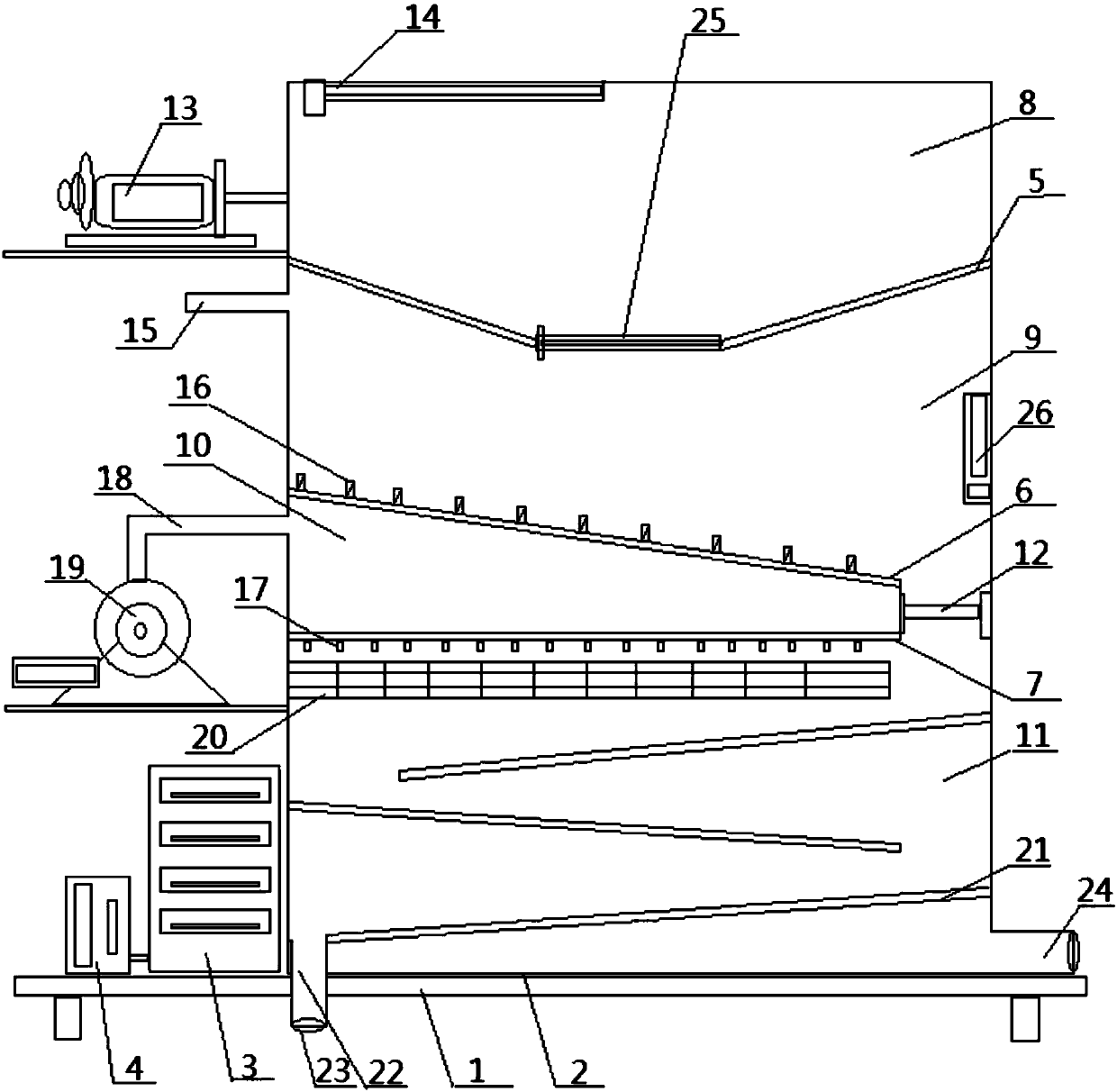

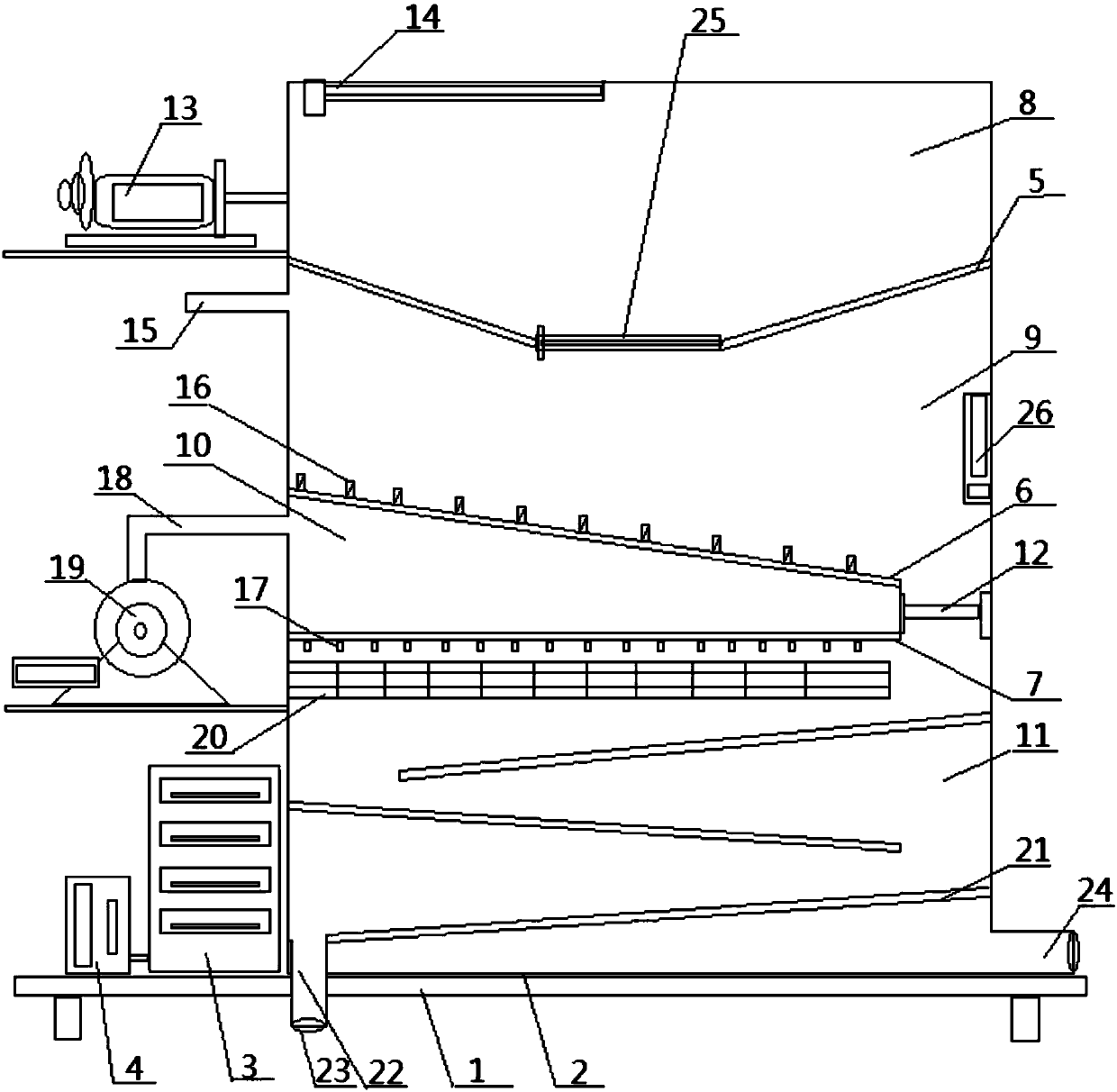

Recovery method and device for formic acid solvent during metronidazole production

InactiveCN103408082AQuality improvementProcess Design ScienceNature of treatment waterWater/sewage treatment by heatingHigh concentrationIndustrial waste water

The invention discloses a recovery method and device for a formic acid solvent during metronidazole production, which solves the problems that in the prior art, the cost of waste water recovery is large, the environment is polluted due to the direct emission of the waste water, and the like, and is characterized in that the recovery device formed by an evaporator (1), a storage kettle (7), a water absorption tower (8), filling materials (9 and 19), a high position feeding tank(10), a condenser (12), a storage tank (16), a perforated pipe (17), a screw (18) and the like performs recovery treatment on industrial waste water; the particular technological processes are as follows: the hydroxylation solution is evaporated through adopting the evaporator so as to obtain dilute formic acid vapor with the mass concentration of 30-70%; the formic acid vapor firstly passes through the cold material filling layer at the upper part of the evaporator to remove entrainment substances, such as metronidazole, of the formic acid vapor; part of water in the formic acid vapor is removed through the water absorption tower of the material filling layer with sticky polyphosphoric acid and high concentration phosphoric acid both flowing downwards; water in the formic acid vapor is further removed through a pipeline with phosphorus pentoxide; the concentrated formic acid vapor is condensed into high concentration formic acid liquid. The method and the device can be widely applied to a production enterprise for recycling a great deal of produced dilute formic acid waste water in chemical engineering production enterprises.

Owner:HUANGGANG NORMAL UNIV

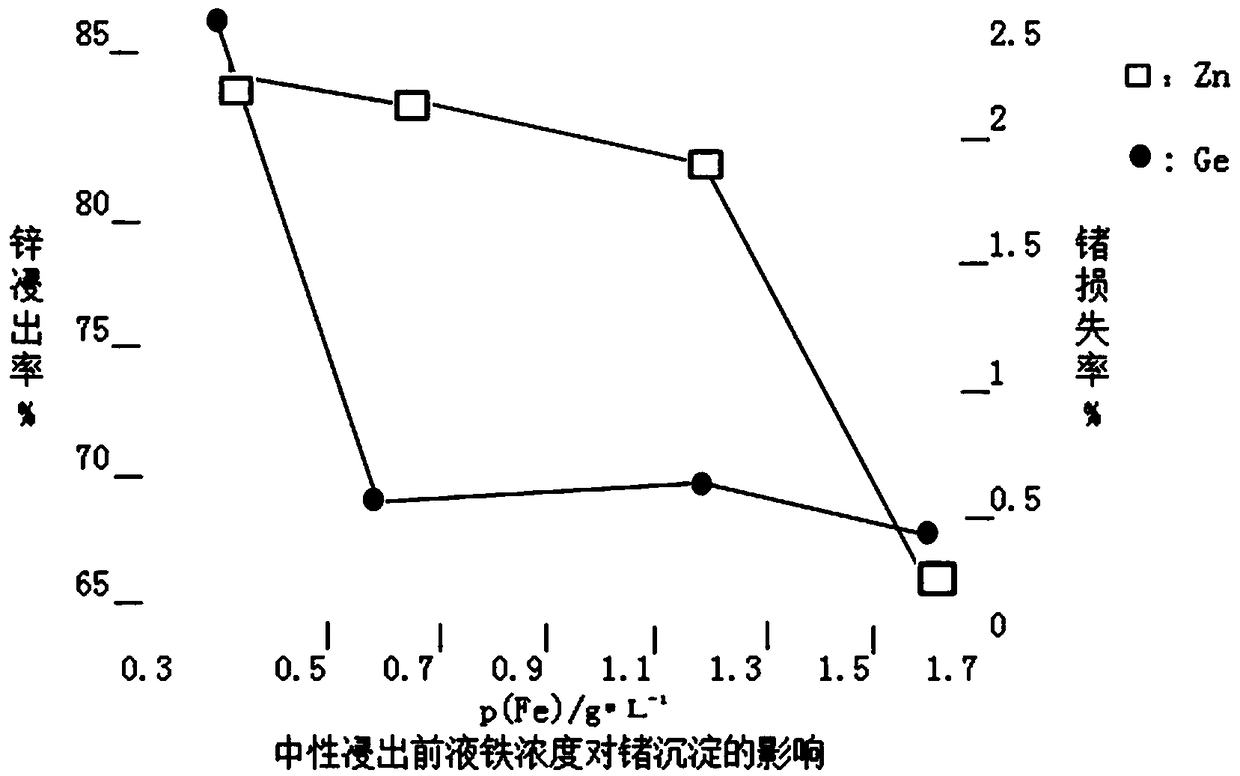

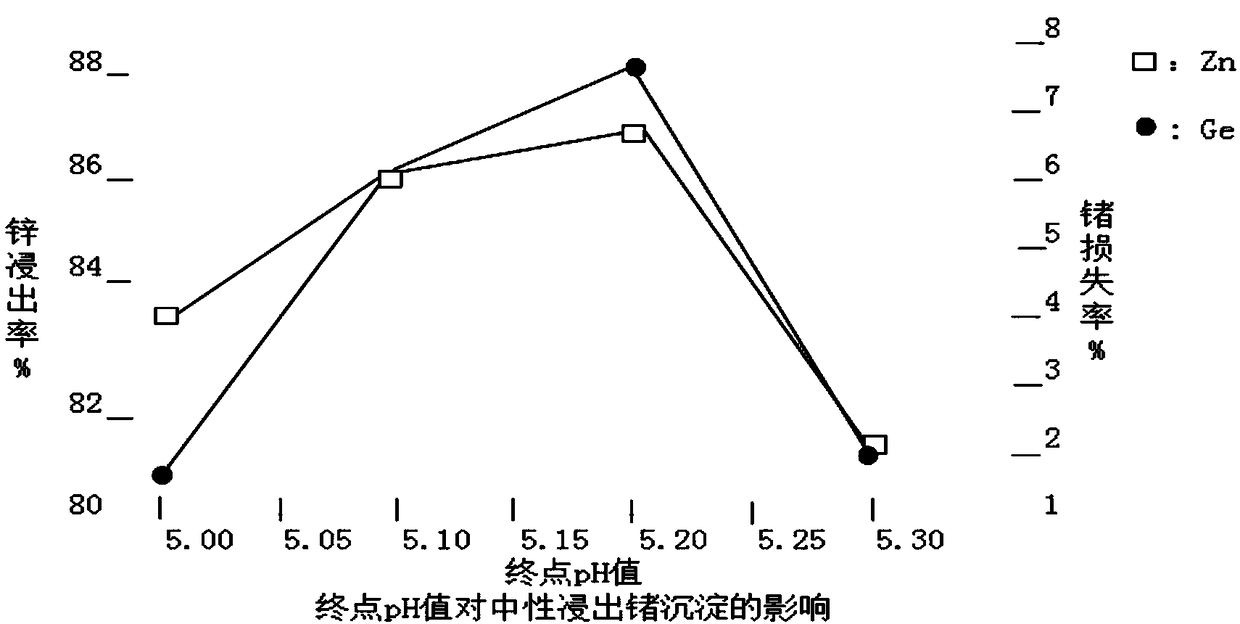

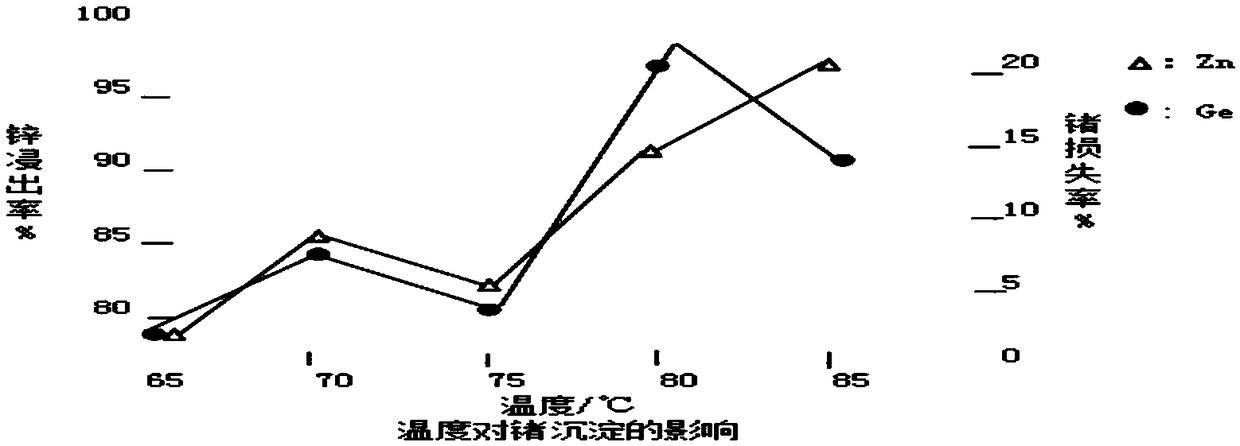

Process for improving germanium recovery rate of electro-zinc system

InactiveCN108715938AHigh recovery rateRaise the gradeProcess efficiency improvementPregnant leach solutionIron powder

The invention belongs to the technical field of zinc smelting germanium recovery, and provides a process for improving the germanium recovery rate of an electro-zinc system. The process comprises thefollowing steps that (1) a reducing agent and zinc leaching slag are introduced into a rotary kiln, and rotary treatment is carried out to obtain germanium-containing zinc oxide smoke dust; (2) neutral leaching is carried out on the germanium-containing zinc oxide smoke dust to obtain a leaching solution; (3) iron powder is added into the leaching solution, and filtering is carried out to obtain high-germanium slag; (4) low-leaching is carried out on the high-germanium slag to obtain a low-leaching solution; (5) germanium precipitation is carried out on the low-leaching solution and tannic acid so as to obtain crude tannin germanium; and (6) the crude tannin germanium is washed to obtain a washing solution and a refined tannin germanium, the washing solution is fed back to the low-leachingsolution, and desulfurization and decarbonization are carried out on the refined tannin germanium to obtain germanium concentrate. The process is scientific in design, capable of conveniently realizing large-scale industrial production and capable of remarkably improving the recovery rate and the grade of germanium.

Owner:四川四环锌锗科技有限公司

Method for manufacturing vacuum glass in vacuum heating furnace by using temperature and pressure control method

ActiveCN102503096AProcess Design ScienceSolve the problem of air leakageGlass reforming apparatusVacuum pumpingQuality level

The invention relates to a method for manufacturing vacuum glass in a vacuum heating furnace by using a temperature and pressure control method. Firstly sides are sealed by heating under normal pressure and controlled temperature of 380-500 DEG C, requirements are met by vacuum pumping after side sealing powder is cooled and solidified, bleeder hole sealing is carried out on high temperature inorganic glass powder on a 420-900 DEG C melting bleeder hole, sealing is all continuously completed in the same vacuum heating furnace independently, so that the whole process design is scientific. The method adopts side sealing under the normal pressure and rising temperature before the vacuum heating furnace is pumped to be vacuum, vacuum pumping is carried out at the temperature lower than the side sealing temperature after the side sealing powder to be carried out side sealing is cooled and solidified after the sides are sealed, after vacuum degree meets requirements, the heat resisting inorganic sealing powder is partially heated to more than 400 DEG C to melt, and the bleeder hole is sealed. The method can effectively guarantee edge sealing quality of the vacuum glass and the vacuum degree of the vacuum glass, avoids air leakage and moisture problems of the vacuum glass, and effectively improves quality level of the vacuum glass.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

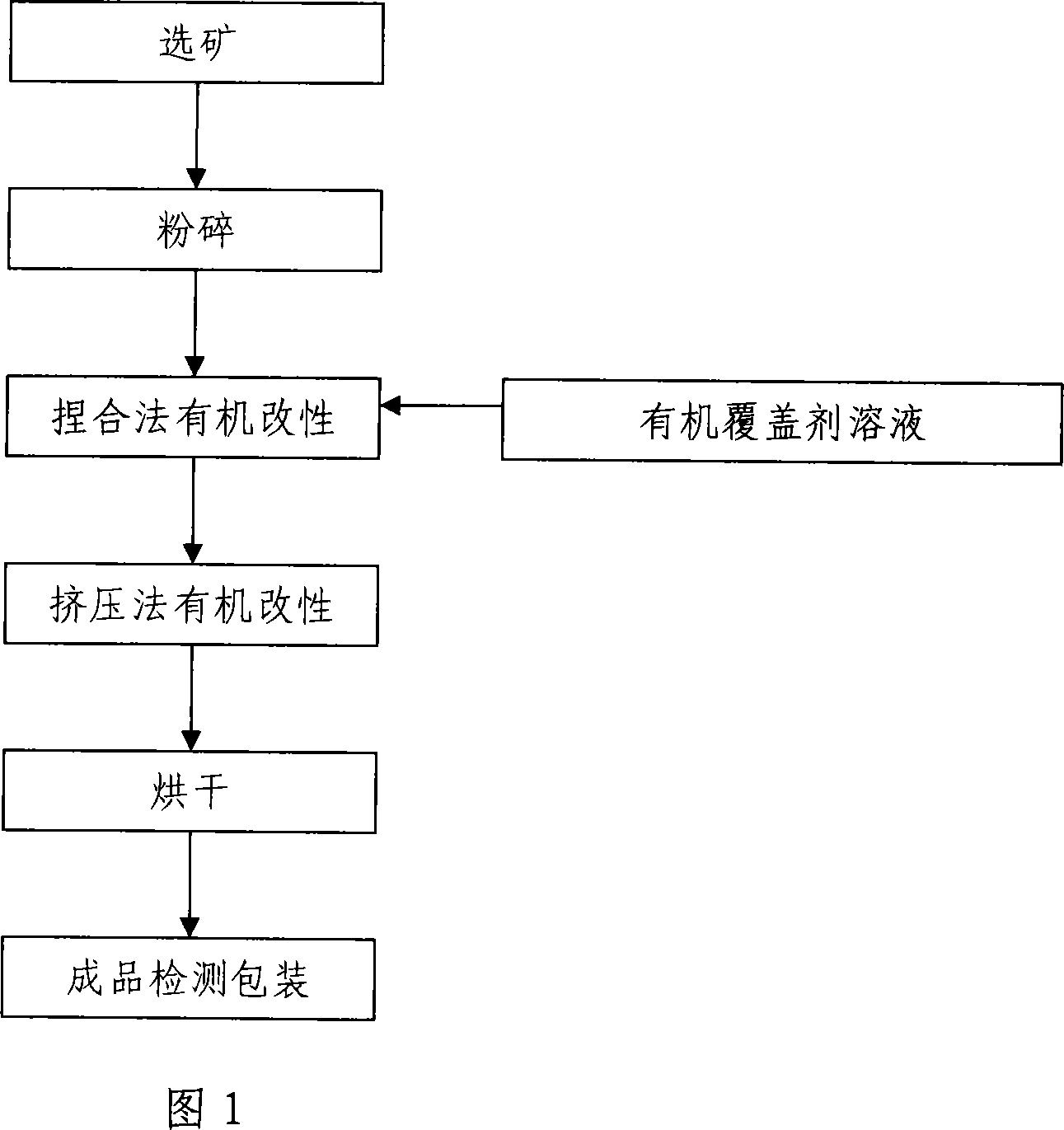

Method for producing organic attapulgite by dry process

InactiveCN101224891AComply with protectionImprove performanceSilicon compoundsWater resourcesChemistry

The invention discloses a method for producing organic attapulgite clay by adopting dry process, which includes the following steps: mineral selection: select attapulgite clay as raw material; crushing step: crush the selected raw material and then screen and purify the granules by using a piece of screen mesh equipment; an organic modification step by adopting a kneading method: add an organic covering agent solution and utilizes a piece of kneader equipment to carry out organic modification on the crushed and purified attapulgite clay material; an organic modification step by adopting an extrusion method: adopt a piece of extruder equipment to carry out further organic modification by extrusion; a drying step: dry until the finished product is obtained; the inspection and packing step of the finished product: carry out quality inspection on the finished product and pack the qualified product; the invention adopts a dry process to modify the attapulgite clay material into an organic attapulgite clay material, the process flow design is scientific, thus considerably saving energy and water resources; the production cost is low, the performance and various technical criteria are comparatively high; the production process is environment-friendly which can meet present regulation on environment protection.

Owner:赵溶

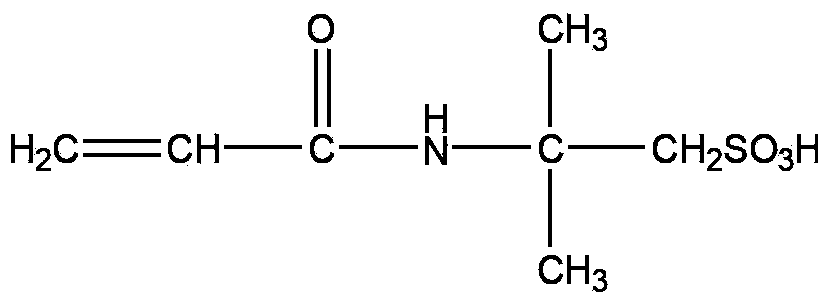

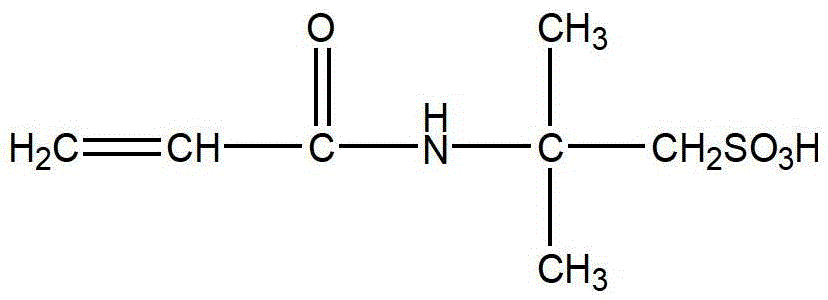

Method for continuous production of 2-acryloylamino-2-methyl propanesulfonic acid

ActiveCN104211622AMeet the use requirementsStrong reaction stabilitySulfonic acid preparationAcrylonitrileSulfur trioxide

The invention provides a method for continuous production of 2-acryloylamino-2-methyl propanesulfonic acid. The method comprises the steps: acrylonitrile and sulfur trioxide are continuously mixed, the mixed liquid flows into a first-level reactor and is subjected to a first-level reaction with isobutene simultaneously introduced into the first-level reactor, the reaction liquid of the first-level reactor enters a second-level reactor and is subjected to a second-level reaction with isobutene and sulfur trioxide simultaneously introduced into the second-level reactor, then the reaction liquid of the second-level reactor is subjected to solid-liquid separation, and the obtained solid is dried to obtain the 2-acryloylamino-2-methyl propanesulfonic acid product. The occurrence of side reactions can be effectively reduced by adopting sulfur trioxide as a sulphonating agent, and the molecular weight of a polymer obtained from polymerization of the obtained 2-acryloylamino-2-methyl propanesulfonic acid as a monomer is relatively high. In addition, the continuous synthesis mode can effectively reduce possibly produced adverse effects on the stability of the product quality in the operation process, so as to further improve the product yield and quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of ceramic substrate lacquerware

InactiveCN110893737AColorful and reservedSolve the problem of easy falling offOrnamental structuresSpecial ornamental structuresLacquerwareVarnish

The invention discloses a manufacturing method of a ceramic substrate lacquerware. The method comprises the following steps of (1) manufacturing a ceramic substrate green body; (2) polishing; (3) coating a raw lacquer; (4) baking a varnish; (5) coating colored paint; (6) carrying out graining modification on a surface; (7) grinding: a, coating a first black refined Chinese lacquer; b, grinding paint; (8) brightening; and (9) wiping. In the invention, a problem that the raw lacquer is easy to fall off when be coated on a ceramic surface is solved. The raw lacquer can be firmly attached to the surface of a ceramic substrate through a scientific baking process, preferably baking is performed at a temperature of 130 DEG C for 40-45 min, and a bright color of the raw lacquer is still kept. Crafts ceramics and arts and crafts are ingeniously combined, a novel and unique ceramic utensil which is not easy to damage, is resistant to a high temperature and moisture, and is easy to store is manufactured, gloss is natural, a texture is clear, soft and beautiful, transparency and brightness are achieved, an artistic ornamental value and a collection value are achieved too, and the manufacturingmethod is scientific in procedure design and is practical.

Owner:程凌云

Method for manufacturing color paint coated artistic bottle

InactiveCN101407152ANot easy to saveEasy to storeDecorative surface effectsSpecial ornamental structuresLacquerMetallurgy

The invention provides a method for manufacturing a lacquer-casting handicraft bottle, which comprises the following steps: the outer surface of a real blank of the handicraft bottle is subjected to polishing treatment; base color layer lacquer is cast on the outer surface of the polished handicraft bottle to prepare a base color layer of the handicraft bottle; an artistic handicraft is adhered to the base color layer of the handicraft bottle; the handicraft bottle and the artistic handicraft are subjected to spray painting and sealing to prepare a transparent paint layer of the handicraft bottle; UV lacquer is sprayed on the transparent paint layer of the handicraft bottle, and ultraviolet rays between 2,000 and 3,000 watts are used for illumination and solidification when the UV lacquer is sprayed simultaneously; and the lacquer-casting handicraft bottle is formed after cooling and waxy luster packaging. The method aims to the technical blank of the lacquer-casting handicraft bottle and skillfully combines the handicraft bottle and the artistic handicraft to manufacture the novel handicraft bottle having the advantages of novelty and specialty, difficult damage, high-temperature resistance, moisture resistance and easy storage. The handicraft bottle has natural luster, clear grain, soft texture and artistic aesthetic feeling, and is transparent and bright; and the manufacturing method has scientific process design and is suitable for practicality.

Owner:张洪帆

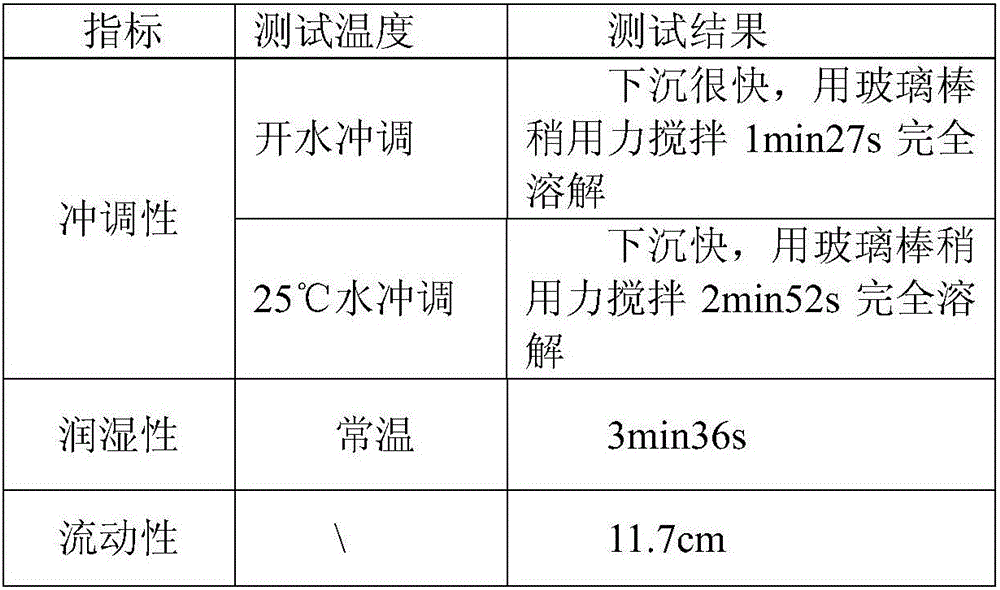

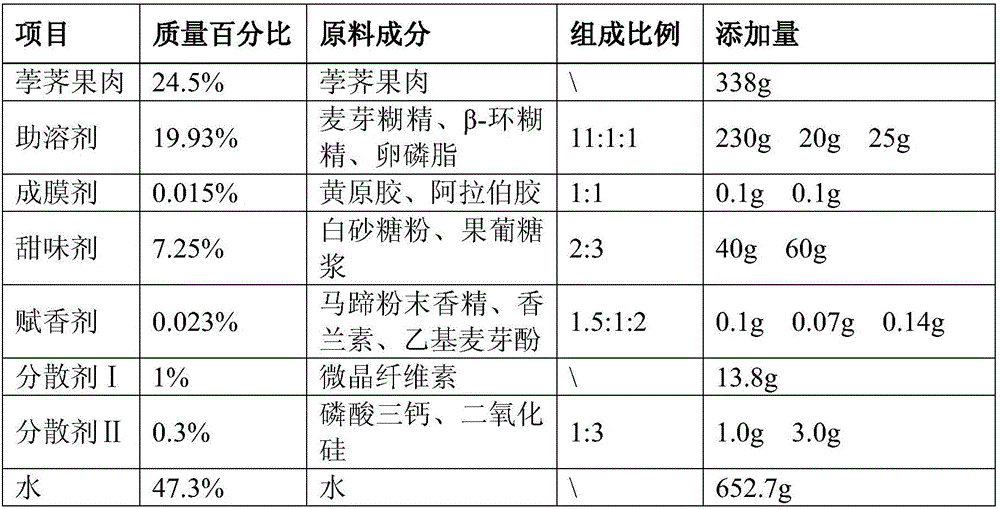

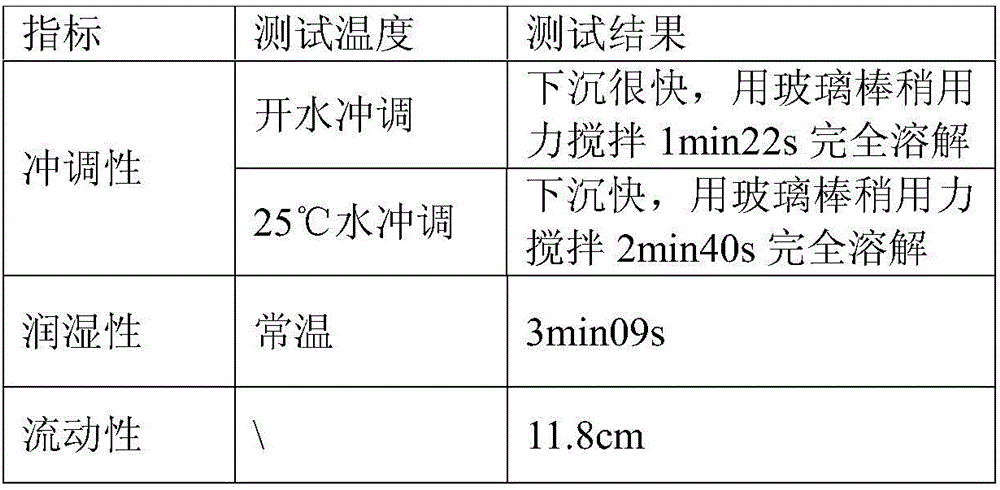

Water chestnut-flavor solid beverage

The invention relates to a water chestnut-flavor solid beverage. The water chestnut-flavor solid beverage is characterized by containing the following components in parts by weight: 94-97 parts of water chestnut microcapsule powder, 2-4 parts of powdered sugar, 0.5-1.5 parts of microcrystalline cellulose, 0.05-0.1 part of tricalcium phosphate, 0.15-0.3 parts of silicon dioxide and 0.01-0.02 part of water-chestnut powder essence. The water chestnut-flavor solid beverage has the beneficial effects that the formula and the process design are scientific and reasonable, the control is easy, the cost is low, and the product cost is good. The water chestnut-flavor solid beverage has the characteristics that the water chestnut fragrance is strong, the taste is good, the added value is high, the carrying and the eating are convenient, and the like. The water chestnut-flavor solid beverage is a good leisure travel product.

Owner:HEZHOU UNIV

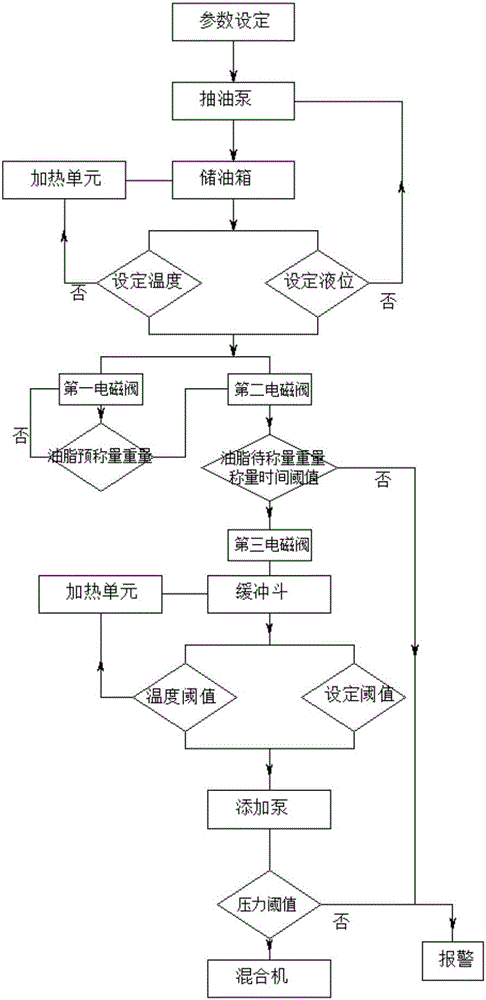

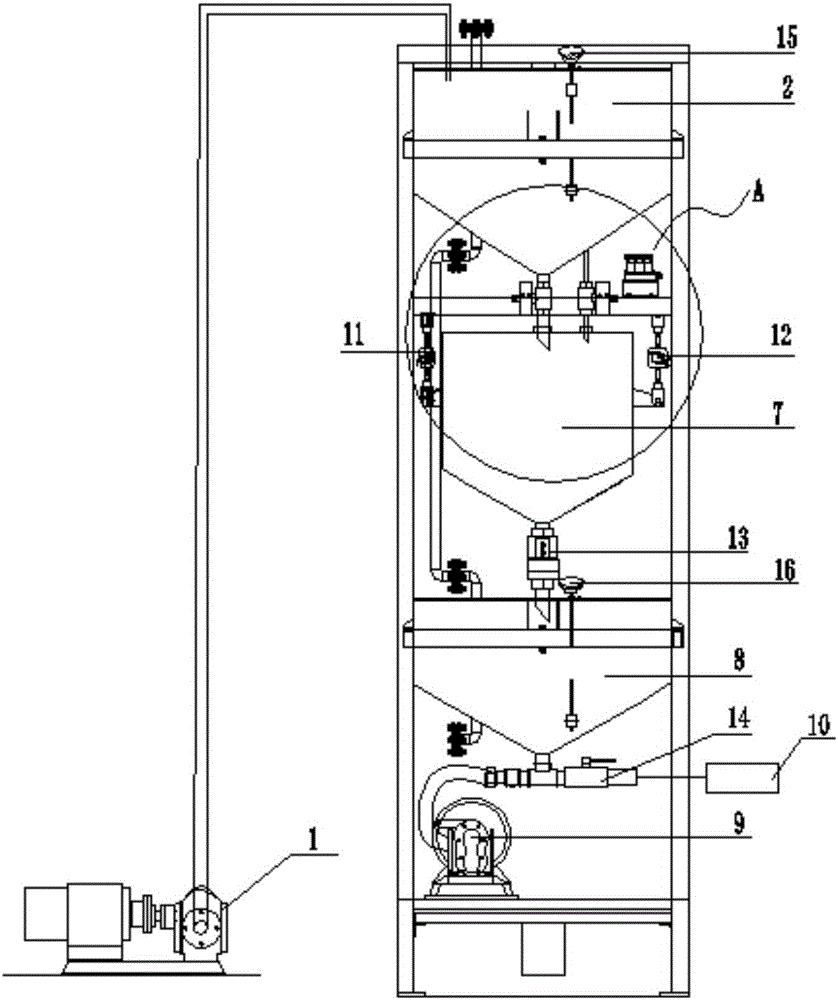

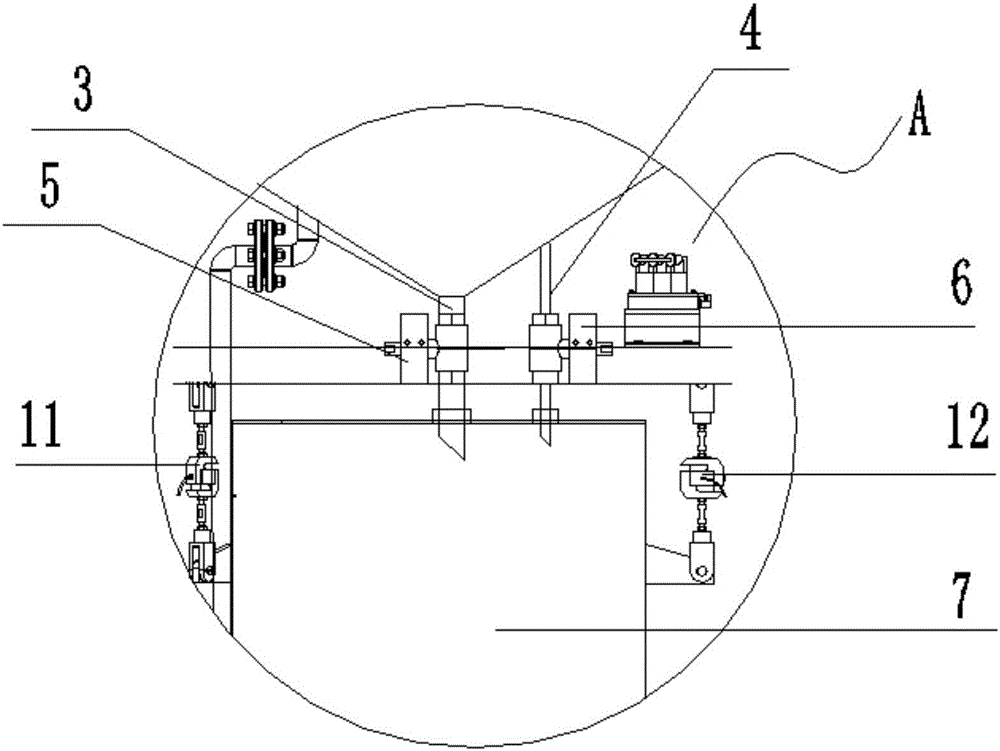

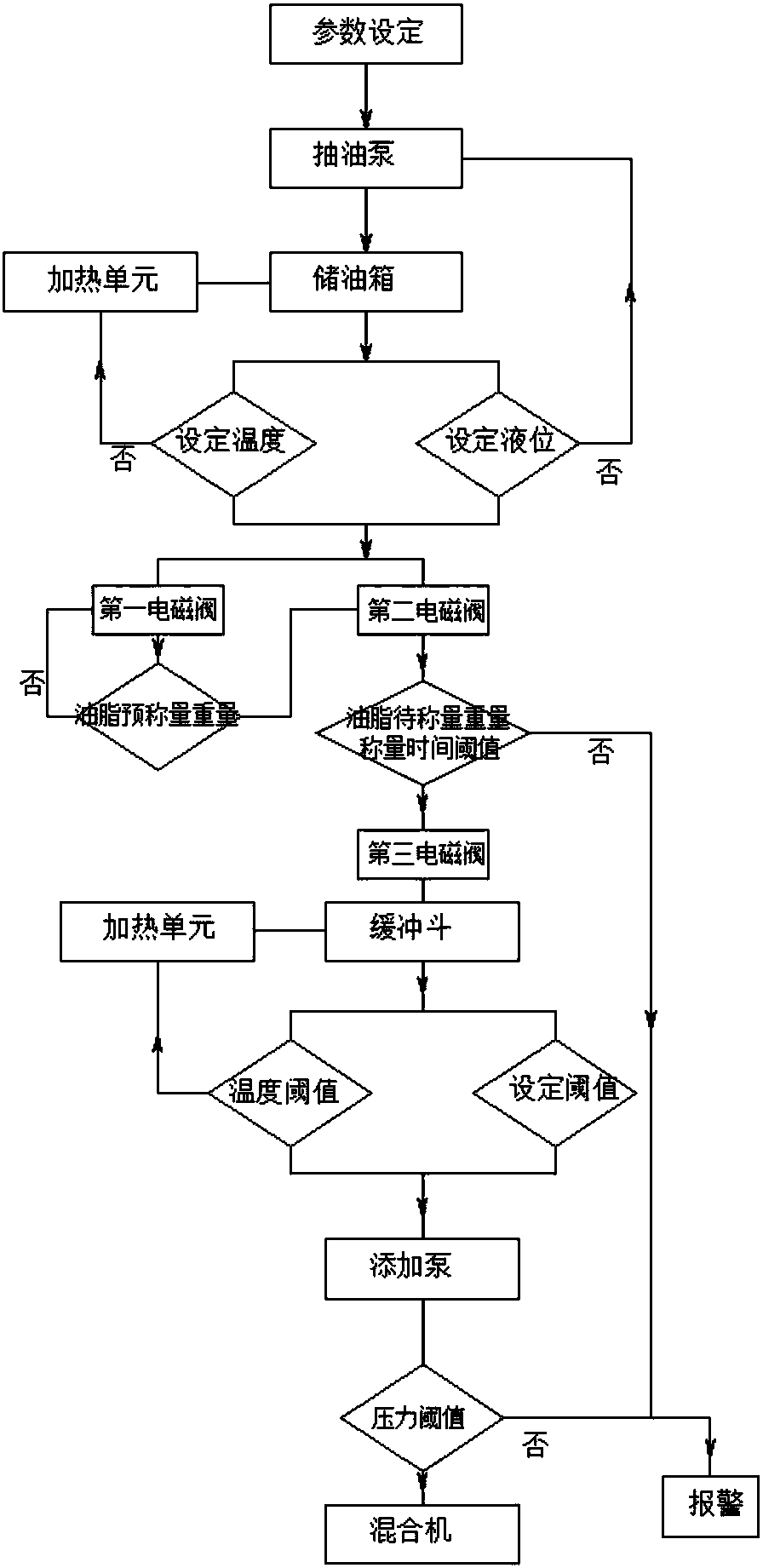

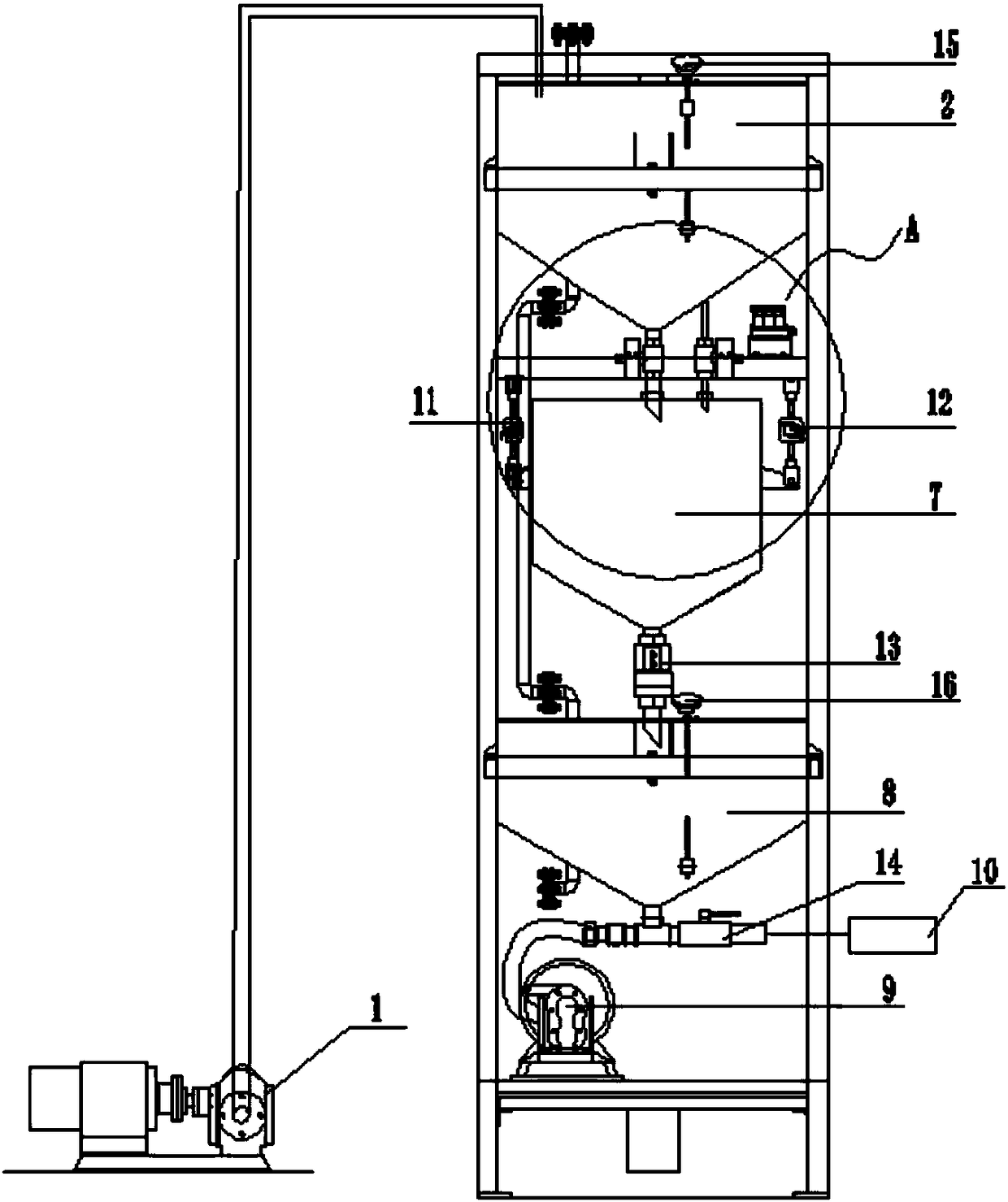

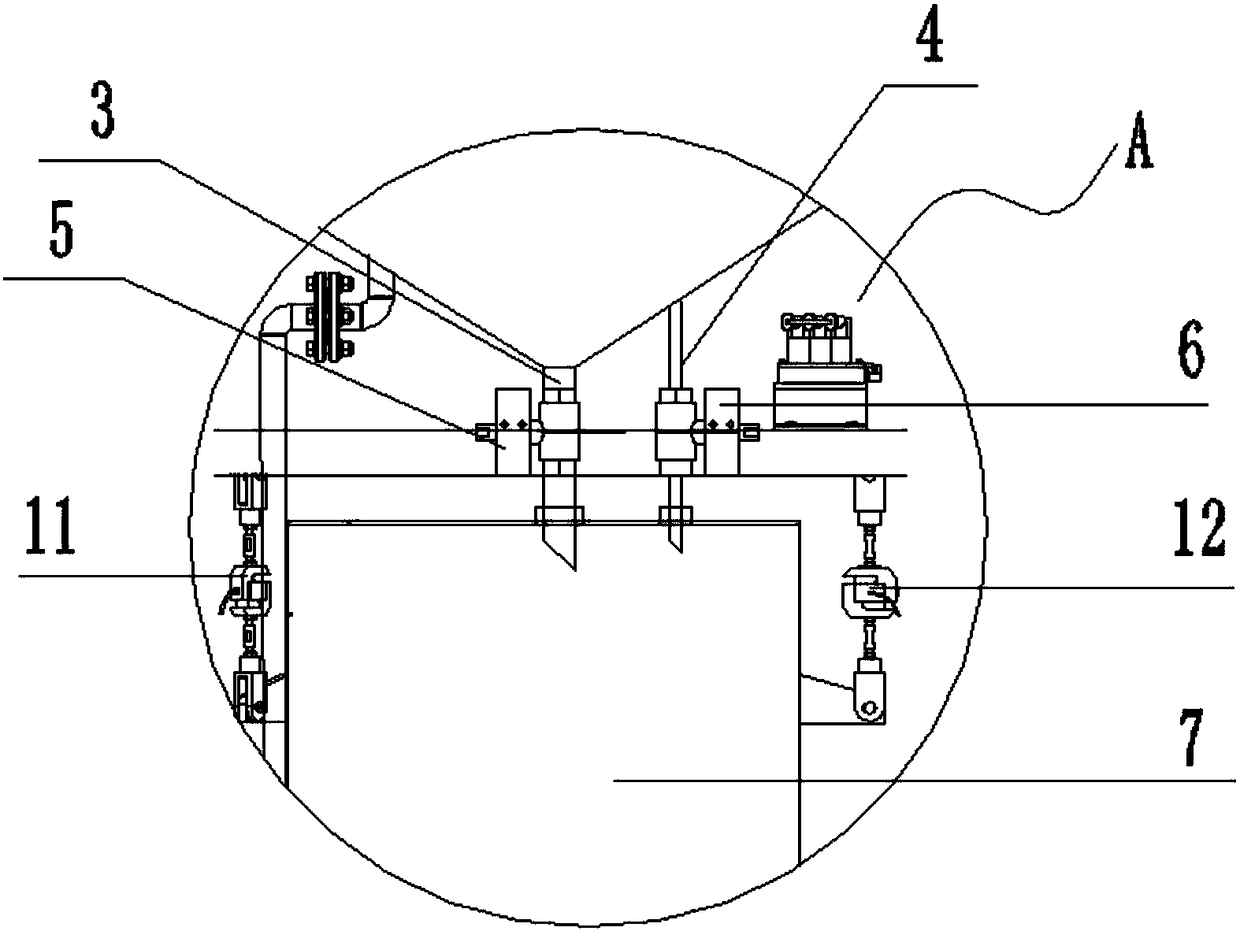

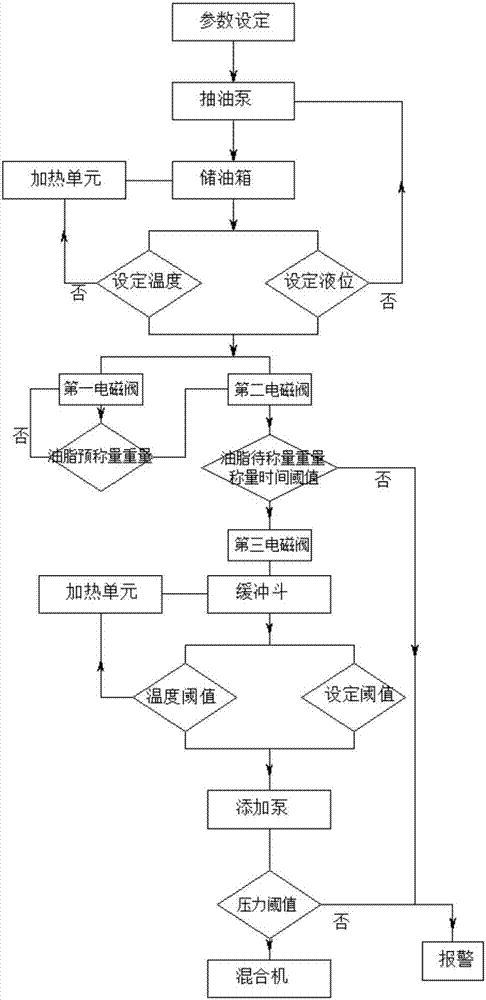

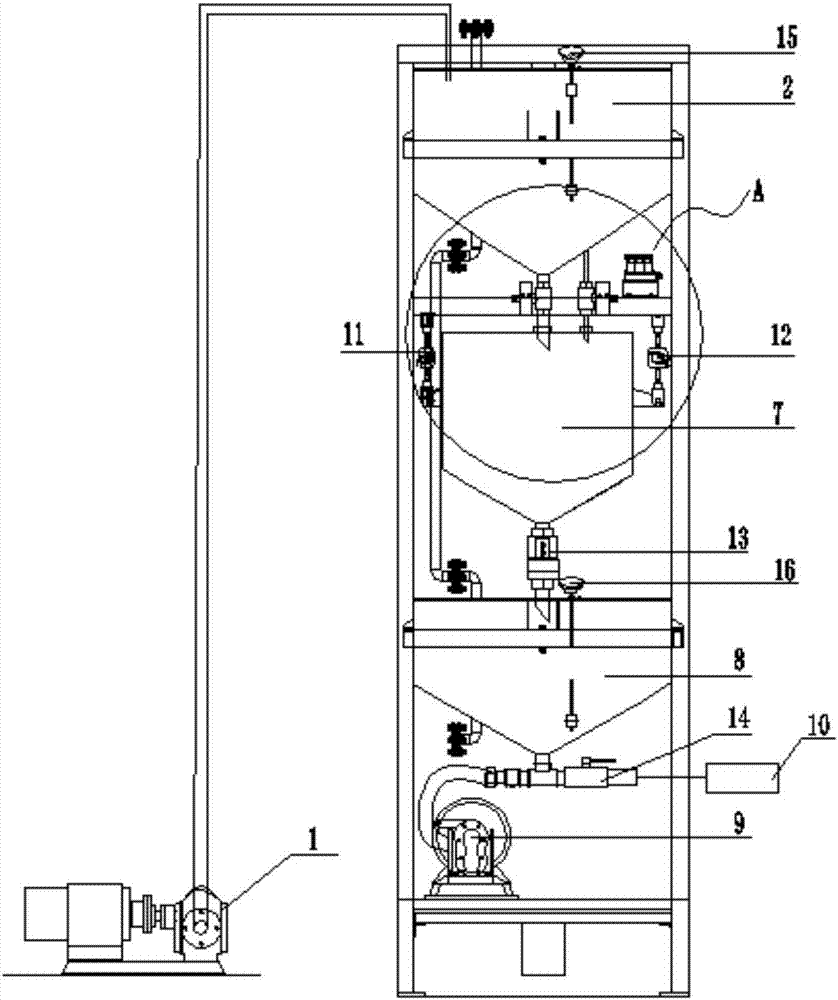

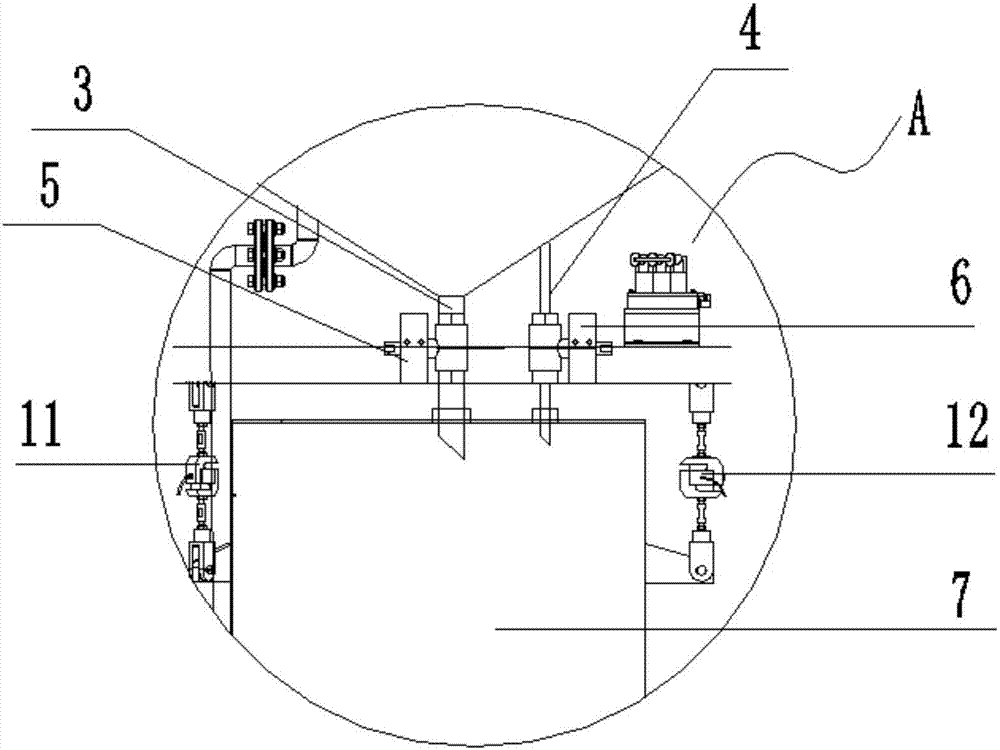

Feed oil adding device

ActiveCN105901754AAutomatically and accurately addedTemperature controlFeeding-stuffAutomatic controlSolenoid valve

The invention discloses a feed oil adding device. The feed oil adding device comprises an oil pump, an oil storage tank, a thick oil drain pipe, a thin oil drain pipe, a first solenoid valve, a second solenoid valve, a weighing hopper, a buffer head, an oiling pump, a mixer, a timeout controller, a weighing sensor, a third solenoid valve, a pressure sensor and and an external control center; an oil inlet of the oil storage tank is connected with the oil pump through a pipeline, the oil storage tank is communicated with the weighing hopper through the thick oil drain pipe and the thin oil drain pipe, and the thick oil drain pipe and the thin oil drain pipe are provided with the first solenoid valve and the second solenoid valve respectively. The feed oil adding device is scientific and reasonable in structure, safe and reliable in operation, good in automatic control and good in practicability.

Owner:济南天惠饲料有限公司

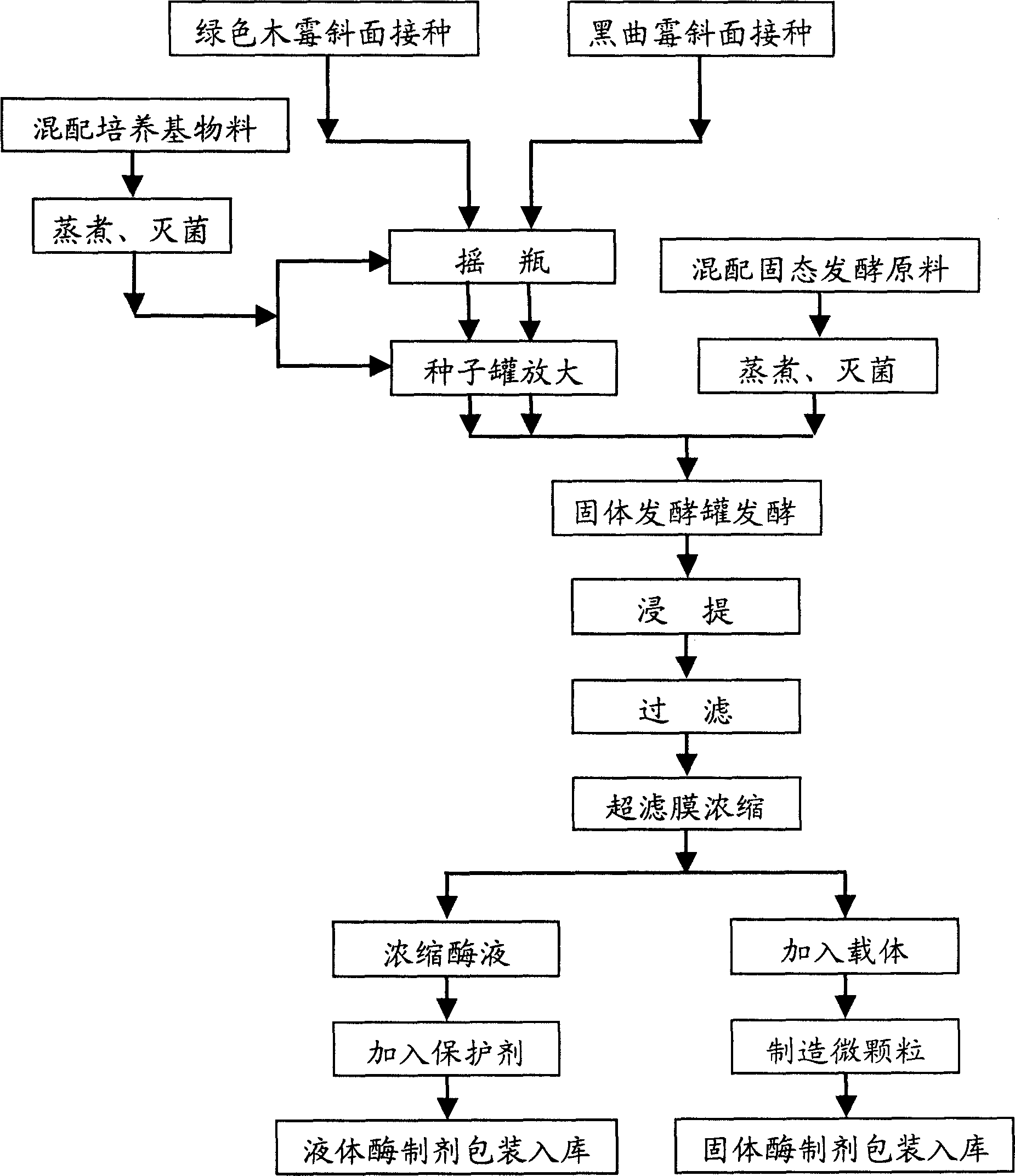

Composite microorganism beta-dextranase and beta-glucosaccharase production method

InactiveCN1884506ACompatibility scienceCompatibility is reasonableFungiHydrolasesFiltrationDigestion

The invention relates to a method for making composite microbio beta-glucanase and beta-glucosidase. The invention includes mixed fermentation of trichoviridin and aspergillus niger to prepare composite microbio beta-glucanase and beta-glucosidase, preparation of solid enzyme preparation and liquid enzyme preparation, and inclined-plane bacterial, shake flask shake culture, liquid seed tank enrichment culture of the trichoviridin and aspergillus niger, mixed input of the trichoviridin and aspergillus niger after enrichment culture into solid fermentation tank to perform fermentation, after fermentation, by digestion, filtration and ultrafilter membrane concentration, obtaining liquid enzyme preparation after adding protecting agent; obtaining solid enzyme preparation by adding British gum in concentrated enzymatic solution with dehumidification and granulation. The inventiom is of scientific and fair industrial design, the trichoviridin and aspergillus niger obtained by mixed culture and screening of strains of fungus can perform paragenetic mixed culture and mutually have no antagonistic reaction, the cost is low, the energy consumption is small, and the invention is of no devil liquor and waste slag discharge, which has a wide applicability of an invention and fills up our zymin breed margin, and has large market foreground.

Owner:天津科建科技发展有限公司

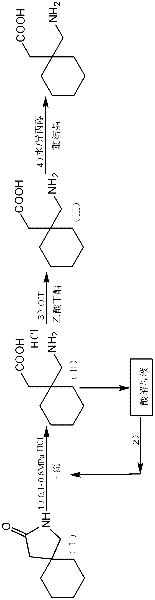

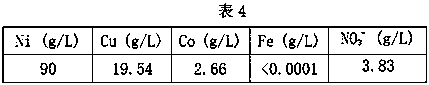

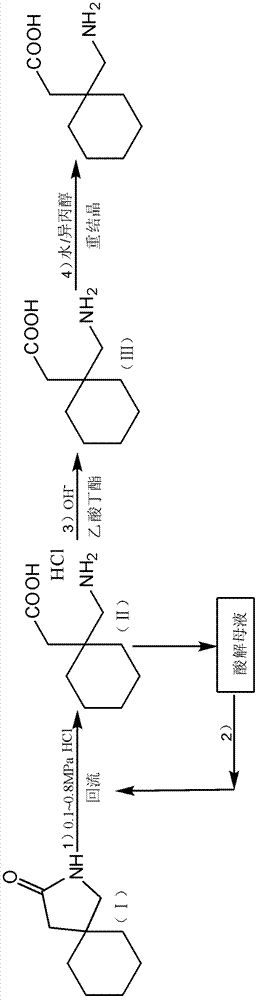

Method for preparing high-purity gabapentin

ActiveCN102363598AEasy to operateShort timeOrganic compound preparationAmino-carboxyl compound preparationGabapentinStrong acids

The invention discloses a method for preparing high-purity gabapentin, which comprises the following steps: 1) subjecting 2-aza-spiro[4,5]-3-decanone to reflux acidolysis in strong acid or aqueous solution of strong acid under pressure and obtaining gabapentin strong acid salt and acidolysis mother solution; 2) recycling the obtained acidolysis mother solution for preparing gabapentin strong acid salt; 3) repeating the step 2); 4) obtaining gabapentin strong acid salt obtained by the two steps and preparing coarse gabapentin; and 5) dissolving the coarse gabapentin in aqueous solution of lower alcohol, distilling under reduced pressure and recrystallizing. The high-purity gabapentin can be obtained by using the method, and the method has the characteristics of high yield, low cost and the like.

Owner:浙江精进药业有限公司

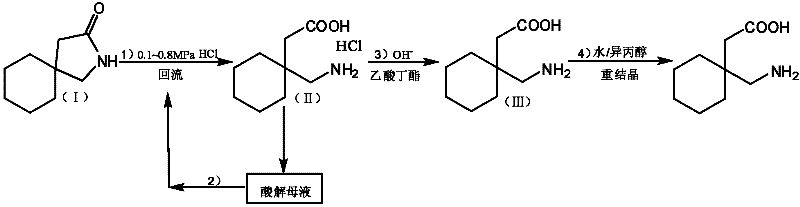

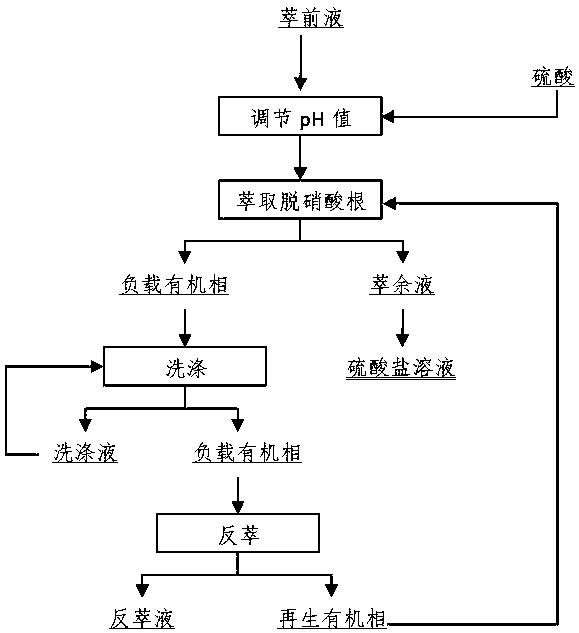

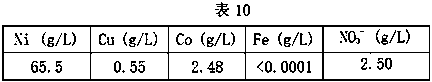

Method for removing nitrate from nickel copper cobalt sulfate solution

InactiveCN109911948ARealize selective extraction and separationSolve the problem of removing nitrateNickel sulfatesHydrometallurgyCopper

The invention discloses a method for removing nitrate from a nickel copper cobalt sulfate solution, belongs to the technical field of nickel copper cobalt hydrometallurgy, and solves the problem thatthe nitrate in the nickel copper cobalt sulfate solution is difficult to remove. The method comprises the following steps: A, adjusting the pH value: adding a sulfuric acid solution for adjusting thepH value of the nickel copper cobalt sulfate solution to 1.0-2.0; B, extracting for removing nitrate ions: extracting by using an extracting organic phase to obtain a nitrate ion-containing supportedorganic phase and a sulfate-containing raffinate respectively, wherein an extractant in the extracting organic phase is N235. Selective extraction separation of the nitrate is achieved by using the N235, so that the nitrate ion removing rate is high, and the purity of the sulfate solution and the metal ion concentration can be maintained in the technological process.

Owner:JINCHUAN GROUP LIMITED

A feed oil adding device

ActiveCN105901754BAutomatically and accurately addedTemperature controlFeeding-stuffOil and greaseAutomatic control

The invention discloses a feed oil adding device. The feed oil adding device comprises an oil pump, an oil storage tank, a thick oil drain pipe, a thin oil drain pipe, a first solenoid valve, a second solenoid valve, a weighing hopper, a buffer head, an oiling pump, a mixer, a timeout controller, a weighing sensor, a third solenoid valve, a pressure sensor and and an external control center; an oil inlet of the oil storage tank is connected with the oil pump through a pipeline, the oil storage tank is communicated with the weighing hopper through the thick oil drain pipe and the thin oil drain pipe, and the thick oil drain pipe and the thin oil drain pipe are provided with the first solenoid valve and the second solenoid valve respectively. The feed oil adding device is scientific and reasonable in structure, safe and reliable in operation, good in automatic control and good in practicability.

Owner:济南天惠饲料有限公司

Yacon bifidobacteria rabbit sausage and preparation method thereof

The invention discloses a yacon bifidobacteria rabbit sausage and a preparation method thereof. The yacon bifidobacteria rabbit sausage is prepared by salting and baking the following raw materials: rabbit meat, pork lean, fat pork, yacon, edible salt, white granulated sugar, monosodium glutamate, cooking wine, phosphate, D-sodium erythorbate, spices and seasonings. The preparation method comprises the following steps of: mincing the pork lean and the rabbit meat, salting the pork lean and the rabbit meat with the edible salt, the phosphate, the D-sodium erythorbate and sodium nitrite; adding the white granulated sugar, the monosodium glutamate, the cooking wine, the spices and seasonings, the fat pork and the yacon into the salted pork lean and the rabbit meat to be uniformly stirred to obtain a salted raw material; casing the salted raw material to obtain a prefabricated sausage; and baking, sealing, packaging and sterilizing the prefabricated sausage to obtain the sausage. The yacon bifidobacteria rabbit sausage is not only unique in flavor, fresh and tender to taste, crispy and tasty, not greasy after being eaten for a long time, rich in color, easy to preserve and convenient to carry and eat. The preparation method is short in flow, easy to operate and capable of realizing the industrialized production.

Owner:张恒华

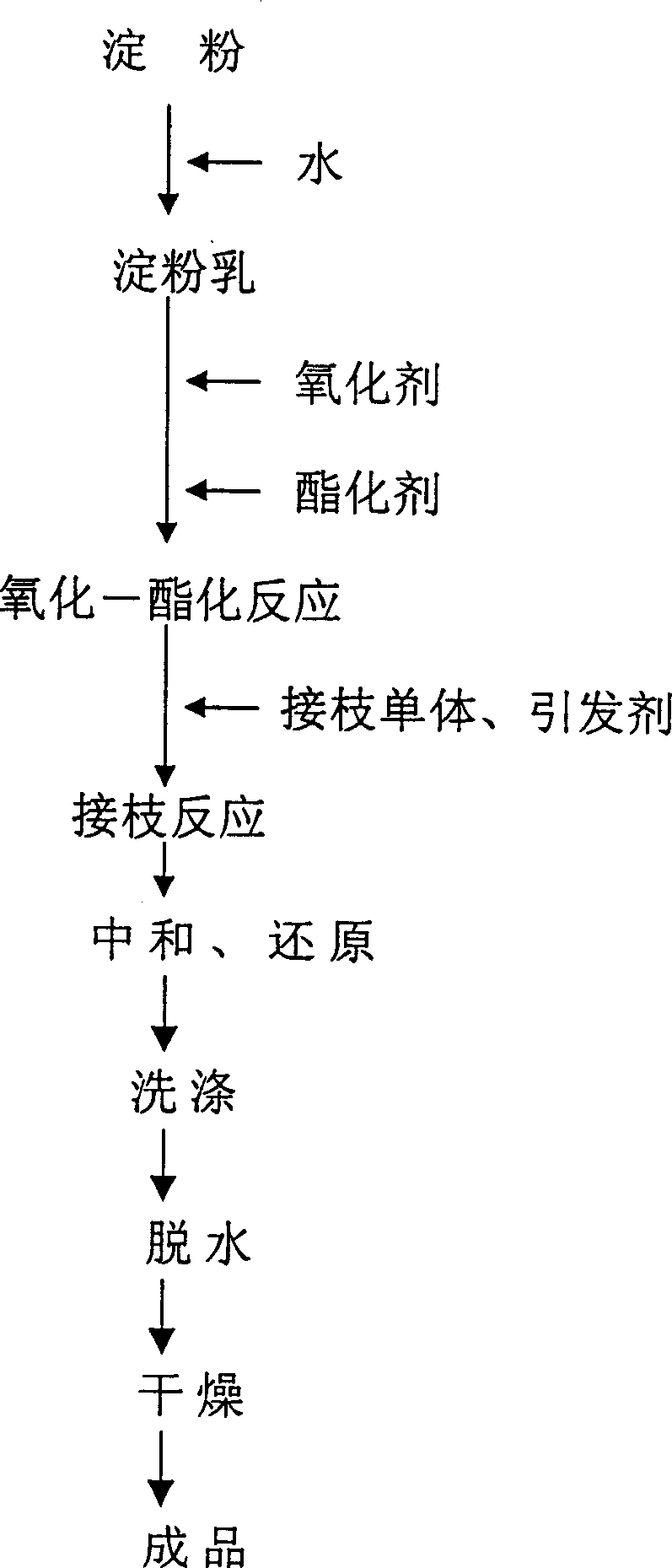

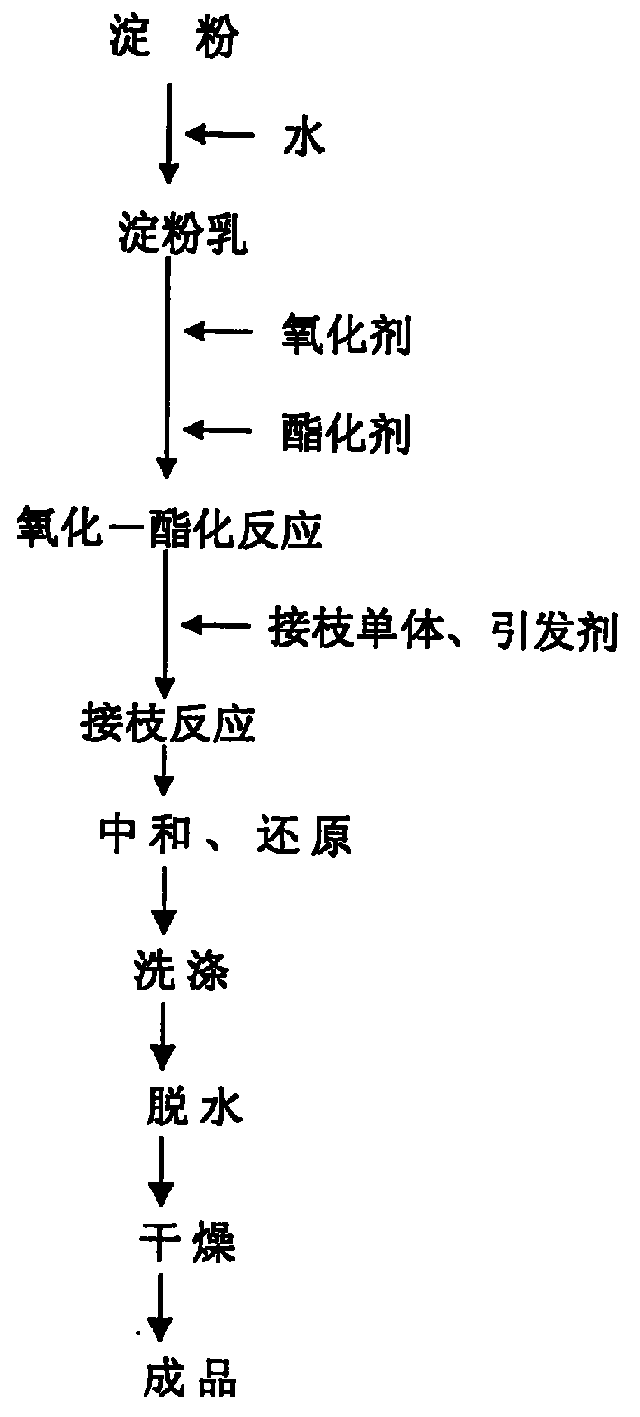

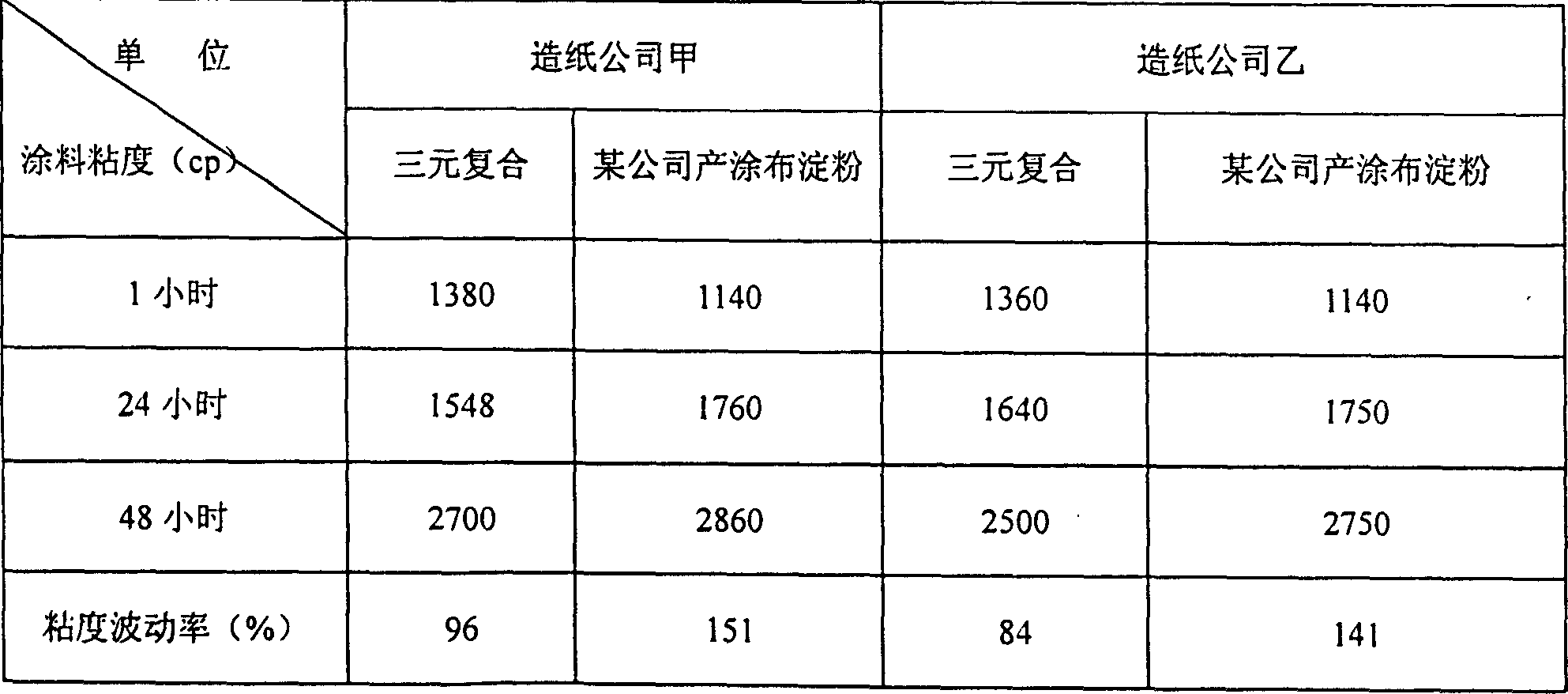

Oxidation-esterification-grafting three element complex denatured starch and its preparation method and application

InactiveCN1257189CProcess Design SciencePractical process designStarch dervative coatingsStarch derivtive adhesivesTernary complexProcess design

An oxidation-esterification-grafting ternary composite modified starch and its preparation method and application belong to the technical field of starch modification. The product of the present invention is prepared by applying a preparation method of simultaneously oxidizing, esterifying, and grafting modification of starch, so that it has the characteristics of oxidation, esterification, and grafting modified starch at the same time. The products are used as coating agents and sizing agents in the paper industry. The advantage of the present invention is that the three modification methods of oxidation, esterification and grafting are organically combined with almost no additional equipment, and are completed in one step in the oxidized starch production process and equipment. The process design is scientific and practical. The product performance is better than the modified starch varieties currently widely used in the paper industry, and it is easy to promote and apply.

Owner:JIANGNAN UNIV

A kind of continuous production method of 2-acrylamido-2-methylpropanesulfonic acid

ActiveCN104211622BMeet the use requirementsStrong reaction stabilitySulfonic acid preparationAcrylonitrileSulfur trioxide

The invention provides a continuous production method of 2-acrylamido-2-methylpropanesulfonic acid, which comprises continuous mixing of acrylonitrile and sulfur trioxide, and the mixed liquid flows into the first-stage reactor and simultaneously passes into the The isobutene in the primary reactor is subjected to the primary reaction, and the reaction liquid of the primary reactor enters the secondary reactor to carry out the secondary reaction with the isobutylene and sulfur trioxide which are simultaneously passed into the secondary reactor, and then the secondary reaction The reaction liquid in the device is subjected to solid-liquid separation, and the obtained solid is dried to obtain 2-acrylamido-2-methylpropanesulfonic acid product. The use of sulfur trioxide as a sulfonating agent can effectively reduce the occurrence of side reactions, and the polymer obtained by polymerizing the obtained 2-acrylamido-2-methylpropanesulfonic acid as a monomer has a relatively high molecular weight. In addition, the continuous synthesis method can effectively reduce the adverse impact on the stability of product quality that may occur during the operation process, thereby further improving the yield and quality of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

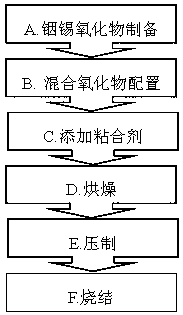

ITO coating film target material and preparation method thereof

InactiveCN108642458AProcess Design ScienceAppropriate target densityVacuum evaporation coatingSputtering coatingAdhesiveRadiation

The invention discloses a preparation method of an ITO coating film target material, and relates to the technical field of coating film. The method comprises the steps of preparing an indium tin oxide, mixing oxide formula, adding an adhesive, sintering, etc. The method is scientific and reasonable in technology design; the density of the target material is proper, and the uniformity of the targetmaterial is high; the preparation is convenient; the production efficiency is high; the cost is saved; the action is safe and reliable; the method is applicable to coating film of a lens, and cracking is avoided; the performance is stable; the adhesion performance is high; a formed coating film is high in uniformity, conductivity and transparence; electronic radiation, UV and blue rays which areharmful to human bodies can be effectively cut off, and thus the product quality is ensured.

Owner:JIANGSU RARE OPTICS CO LTD

Method for manufacturing vacuum glass in vacuum heating furnace by using temperature and pressure control method

ActiveCN102503096BProcess Design ScienceSolve the problem of air leakageGlass reforming apparatusVacuum pumpingQuality level

Owner:左树森

Efficient quick non-damaged cleaning equipment of fresh tea leaves

InactiveCN109954720AQuality impactGreat tastePre-extraction tea treatmentDrying gas arrangementsFlavorAdditive ingredient

The invention provides efficient quick non-damaged cleaning equipment of fresh tea leaves. An important fresh leaf cleaning step is added, thus contains surface adhesive materials such as pesticides and dust which can be contained in fresh leaves are removed, taste and quality of the tea leaves are improved, influence of pesticide residue on human health is reduced, edible safety of tea leaf beverages is guaranteed, severe food safety incidents caused by tea leaf pollution are prevented, the equipment special for cleaning the tea leaves is arranged and developed, a special low temperature pre-cooling technology is adopted, the tea leaves are cleaned after low temperature pre-cooling, flavor of the tea leaves can be greatly improved, loss of nutritional ingredients in the tea leaves is alsosmall, an ultrasonic cleaning technology is applied, thus the fresh quality of the tea leaves can be maintained, meanwhile cleaning is completed, the whole technology process is carried out integrally, the advantages of the automatic production equipment are exploited to the utmost extent, the production efficiency is high, and quality of the treated tea leaves is good.

Owner:高小翎

Low-protein daily ration for growing pig under net energy system and application thereof

ActiveCN103110013BLow costControl energy depositionAnimal feeding stuffResearch councilResearch Object

The invention discloses low-protein daily ration for a growing pig under a net energy system and an application thereof, and belongs to the field of feed processing. The method comprises the steps of: taking the growing pig with the weight being 20-50kg as a research object, utilizing corn-bean pulp daily ration, reducing the protein content of the daily ration by 2% on the basis of the standard recommended by the National Research Council, simultaneously supplying lysine, methionine, threonine and tryptophan; adding mannan oligosaccharide, multivitamins, complex phosphoesterasum, probiotics and the like to form the low-protein daily ration for the growing pig under the net energy system; crushing, mixing, pelletizing then dosing, and packaging the pelletized feed and a probiotic component in a mixing manner to obtain the product disclosed by the invention. The animal feed utilization rate can be improved; the use quantity of antibiotic medicines in the feeding of animals is effectively reduced; the immunity of fed animals is improved; the security of animal meat products is improved; and the raise efficiency is also improved. The low-protein daily ration is scientific in process design, high in production efficiency, low in cost, and suitable for multi-variety and small-scale production.

Owner:LIAONING WELLHOPE AGRI TECH

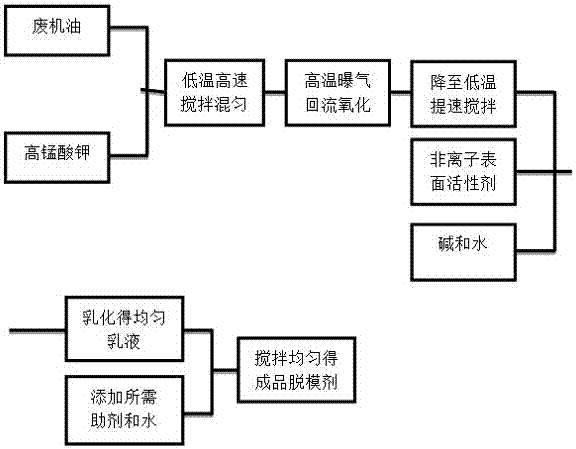

Method for preparing mold lubricant through oxidation modification of waste engine oil

InactiveCN107365620ASmall particle sizeHigh temperature resistant and smoothLubricant compositionSodium bicarbonateAeration rate

The invention discloses a method for preparing a mold lubricant through oxidation modification of waste engine oil. The method comprises the following steps: adding 100 parts by weight of the waste engine oil and 0.3-0.5 part by weight of nanometer manganese dioxide or potassium permanganate into a reaction kettle, heating the obtained mixture to 100-120 DEG C, stirring and emulsifying the heated mixture to evaporate water, reducing the stirring rate and heating the emulsified mixture to 180-200 DEG C, carrying out full aeration with the aeration rate every minute being 2-3 times the volume of the reaction kettle, carrying out a reaction for 5 h, determining the acid value of the obtained reaction product to obtain 210-220 KOH mg / g, cooling the reaction product to 80 DEG C, adding triethanolamine or an aqueous solution of sodium bicarbonate to adjust the pH value of the reaction product to 9, adding a hydrophilic nonionic surfactant accounting for 1-5% of the total weight of the reaction product, adding deionized water with the weight 2-3 times the weight of the waste engine oil, and keeping the temperature at 70-80 DEG C to obtain the mold lubricant. The method has the advantages of simple process, environmental protection, good economic benefit, and good market competition advantage.

Owner:ZHEJIANG NORMAL UNIVERSITY

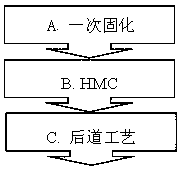

Resin glasses free of secondary curing and preparation method thereof

InactiveCN108859191AProcess Design ScienceReasonable process designOptical articlesOptical partsProcess designInternal quality

The invention discloses resin glasses free of secondary curing and a preparation method thereof, and relates to the technical field of glasses. The preparation method comprises the following steps that a primary curing of the glasses is carried out, HMC (hardening and anti-ultraviolet coating) is conducted, and a packaging process step. According to the resin glasses free of secondary curing and the preparation method thereof, process design is scientific, reasonable and novel, a process step of secondary curing can be omitted boldly in the production process of substrate, the production process, time and production cost are reduced, the production efficiency is improved, the qualified rate is increased, and good internal quality, and stable and reliable performance of products are guaranteed.

Owner:JIANGSU WANXIN OPTICAL

Hole site design and calculation method applied to modular product processing of panel furniture

PendingCN114282974AAchieve standardizationEasy to calculateDesign optimisation/simulationBuying/selling/leasing transactionsModular productDimension measurement

The invention discloses a hole site design and calculation method applied to panel furniture modular product processing, and the method comprises the following specific steps: 1, a design technology principal carries out the review of a hole site design scheme, puts forward questions and answers, a technician compiles a special hole site design scheme and pays attention to details, and the design technology principal carries out the design of the hole site design scheme; technical disclosure is carried out to workers; 2, dimension measurement is carried out on a panel furniture hole site design drawing prepared in advance, and the length value of each side is marked; and 3, according to the formula 2100 = (9) + (32 * 62) + (98 + 9), the first number 9 is a structural hole, the middle of the plate with the thickness of 18 mm is 9, and the 62-bit multiple of 32 grouped in the middle is a system hole site. An existing hole site design and calculation mode applied to panel furniture modular product machining is easy to operate and calculate, the process design can be more scientific and standardized, the production efficiency can be improved, and the method is suitable for wide application and popularization.

Owner:深圳比目鱼平方科技有限公司

Method for preparing relay-like ionic conversion controlled-release fertilizer

InactiveCN102303999AReduce pollutionImprove overall utilizationFertilizer mixturesPolymer scienceMixing ratio

The invention relates to a method for preparing a relay-like ionic conversion controlled-release fertilizer, which comprises the following steps: (1) adding water and polyacrylamide into a reaction kettle according to a weight mixing ratio, and uniformly stirring; (2) cooling the reaction kettle to 80 DEG C, adding corn starch according to a weight mixing ratio, and uniformly stirring; (3) rising the temperature of the reaction kettle to 95 DEG C, adding rosin according to a weight mixing ratio and uniformly stirring; (4) adding liquid paraffin into the reaction kettle according to a weight mixing ratio, uniformly stirring, and keep stirring and keeping the temperature for 1 hour; and (5) cooling the reaction kettle to 80 DEG C, adding bentonite according to the weight mixing ratio, uniformly stirring and discharging. The fertilizer prepared by the method overcomes the common problems of low utilization rate and serious environment pollution of quick-acting chemical fertilizers widely used at home and abroad and has the characteristics of excellent fertilizer effect, little environment pollution, high economic benefit, simple and easy manufacturing, low cost and high nutrient utilization rate which is up to 65 percent.

Owner:TIANJIN SHIYIDE FERTILIZER

Method for preparing high-purity gabapentin

ActiveCN102363598BEasy to operateHigh reaction yieldOrganic compound preparationAmino-carboxyl compound preparationGabapentinAlcohol

The invention discloses a method for preparing high-purity gabapentin, which comprises the following steps: 1) subjecting 2-aza-spiro[4,5]-3-decanone to reflux acidolysis in strong acid or aqueous solution of strong acid under pressure and obtaining gabapentin strong acid salt and acidolysis mother solution; 2) recycling the obtained acidolysis mother solution for preparing gabapentin strong acid salt; 3) repeating the step 2); 4) obtaining gabapentin strong acid salt obtained by the two steps and preparing coarse gabapentin; and 5) dissolving the coarse gabapentin in aqueous solution of lower alcohol, distilling under reduced pressure and recrystallizing. The high-purity gabapentin can be obtained by using the method, and the method has the characteristics of high yield, low cost and the like.

Owner:浙江精进药业有限公司

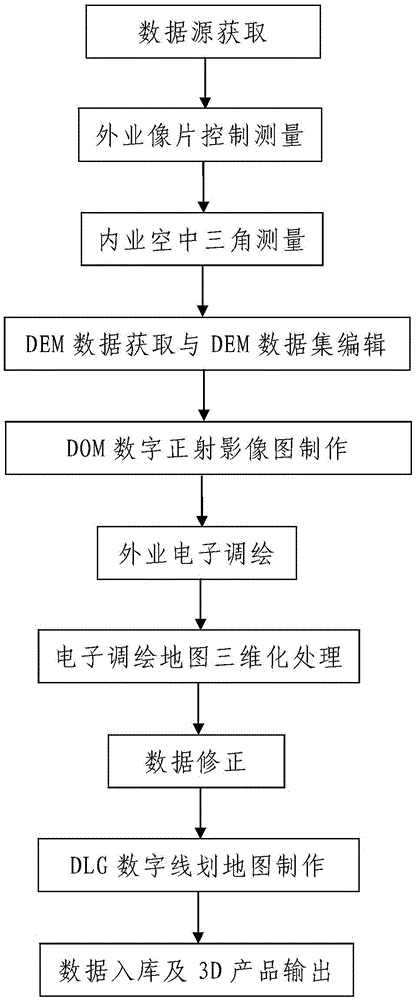

A Mapping Technology of Remote Sensing Image

InactiveCN103884321BThe method steps are simpleReasonable designPicture interpretationElectromagnetic wave reradiationGraphicsData set

Owner:AERIAL PHOTOGRAMMETRY & REMOTE SENSING CO LTD

A paddy rice production process for digesting pesticide residues

ActiveCN102824934BSolve the problem of pesticide residuesNo change in qualityGrain huskingGrain polishingPesticide residueFood flavor

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

A kind of feed oil adding method

ActiveCN106036961BAutomatically and accurately addedTemperature controlFeeding-stuffSimultaneous control of multiple variablesControl systemFuel tank

The invention discloses an addition method of feed fat, and belongs to the technical field of processing of feeds. The addition method comprises the following steps of (1) setting parameters: according to actual demands, setting technological parameters, such as a temperature threshold, a liquid level threshold, fat pre-weighting weight, fat to-be-weigh weight, a weighing time threshold and a pressure threshold, in an external control center; (2) charging fat: conveying the fat to an oil storage tank, and setting and controlling opening and closing of a thick oil drain pipe and a thin oil drain pipe so as to realize the charging manner that the firstly, the fat is rapidly charged, and then the fat is slowly charged; (3) charging oil for a mixing machine: after weighing, conveying fat in a weighing hopper to a buffer hopper, and measuring pressure of the fat before the fat enters the mixing machine; and (4) performing controlling and warning, wherein the external control center monitors a liquid level, temperature and pressure in real time, and a control system normally runs. According to the addition method disclosed by the invention, automatic and accurate addition of the feed fat can be realized, accuracy in the weighing process is double guaranteed, and failure in the process is timely eliminated.

Owner:青岛环山生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com