Patents

Literature

44results about How to "The process method is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

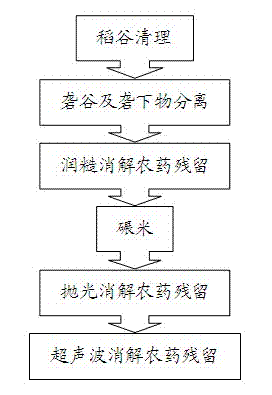

Paddy rice producing production technology for removing pesticide residue

ActiveCN102824934ASolve the problem of pesticide residuesChange qualityGrain huskingGrain polishingFlavorPesticide residue

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

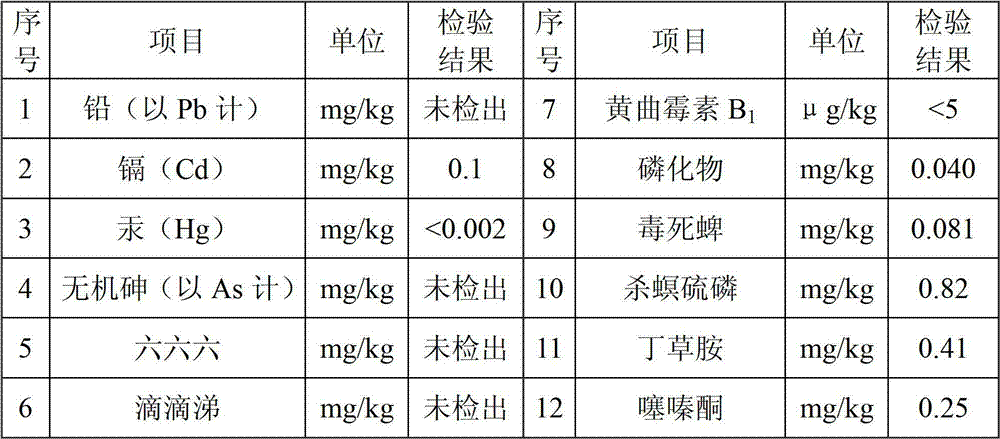

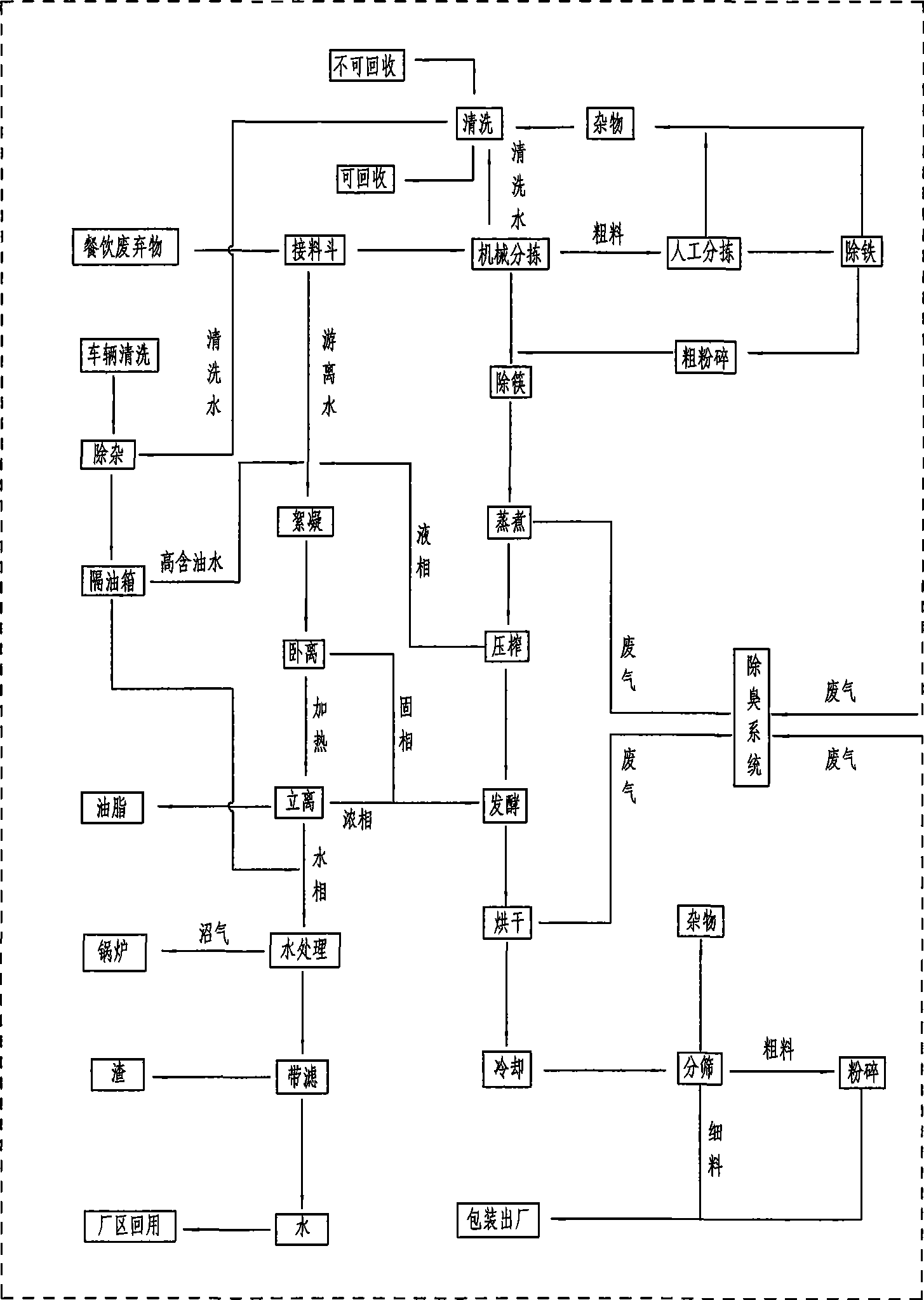

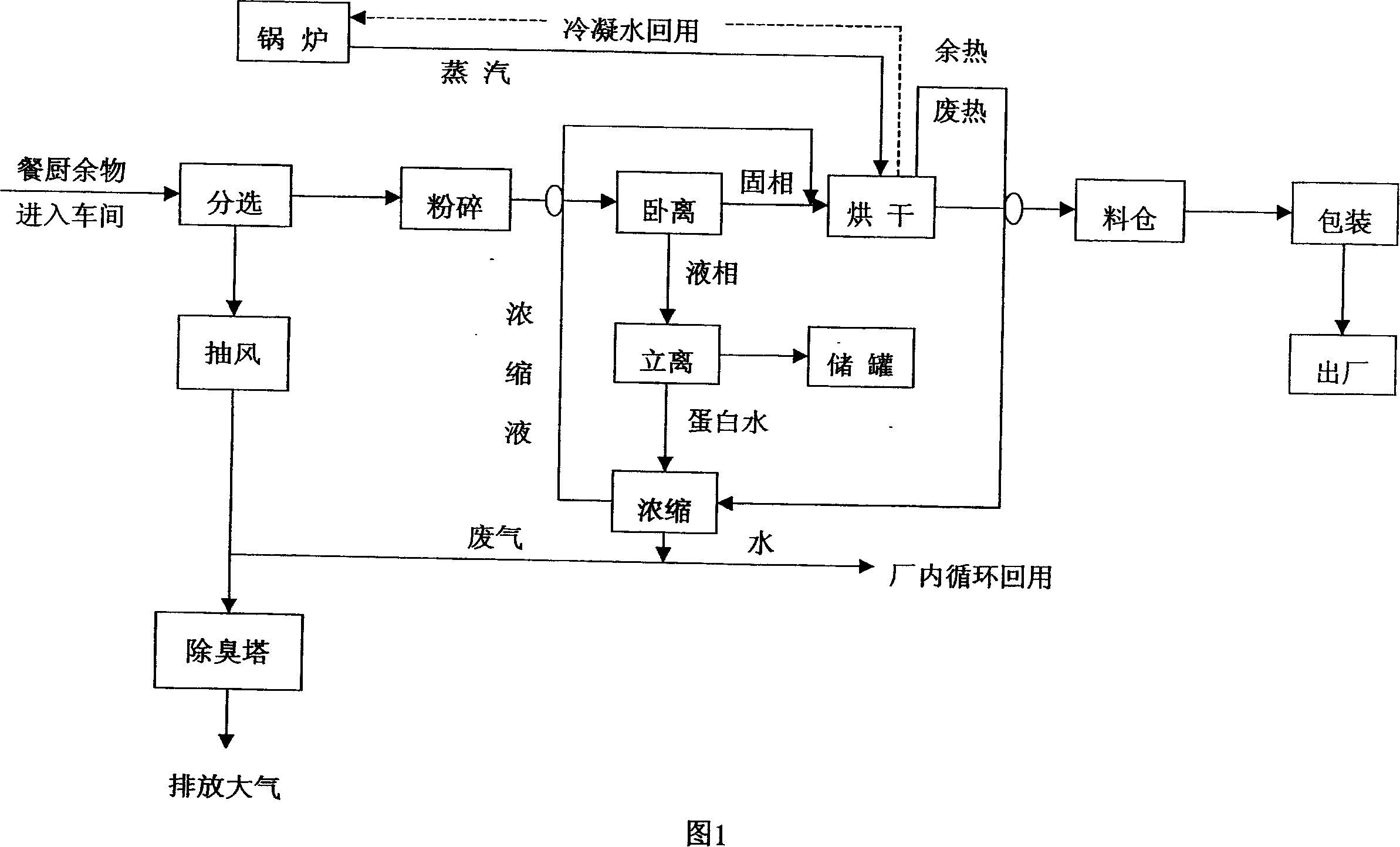

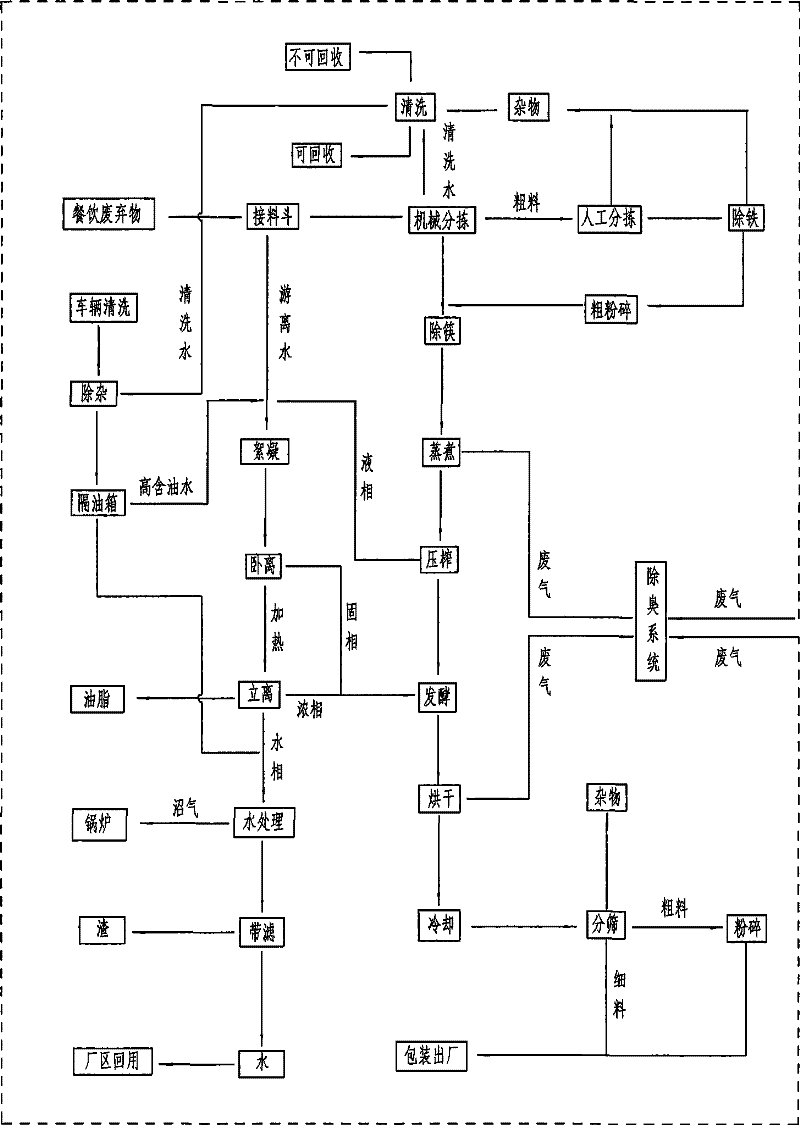

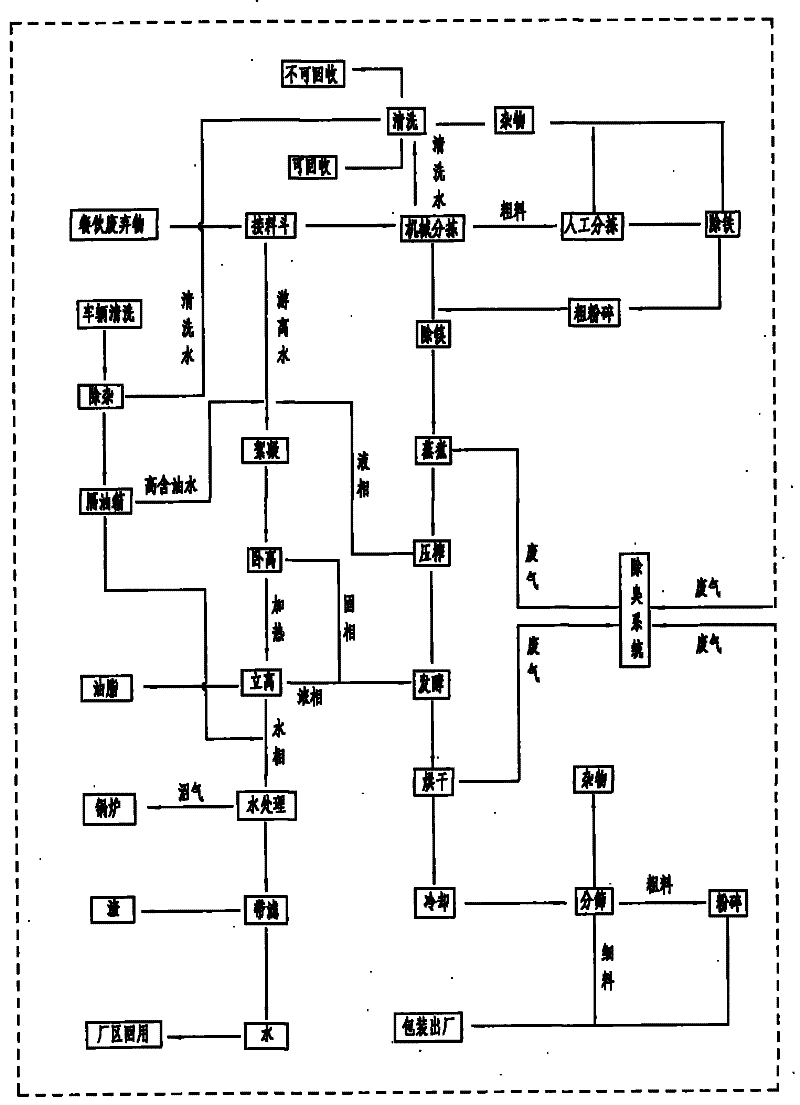

Method for preparing feedstuff with fermentation of food and drink castoff

ActiveCN101366446AAvoid churnPreserve nutrientsFood processingAnimal feeding stuffFodderFermentation

The invention provides a method for producing feed by fermenting dining waste. The method is characterized in that the method sequentially comprises the steps of separating, boiling, pressing, fermenting, drying and separating screen packaging, wherein in the boiling step, the dining waste undergoing the separating step is boiled at a temperature of between 35 and 55 DEG C for 10 to 30 minutes. The technological method is more reasonable, and can fully utilize nutrient compositions of the dinning waste, avoid the loss of liquid phase after filter pressing, simultaneously avoid and reduce environmental pollution and lower production cost.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

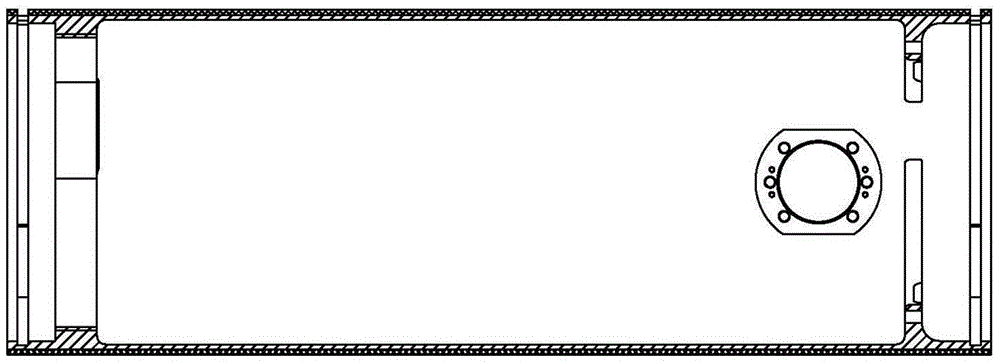

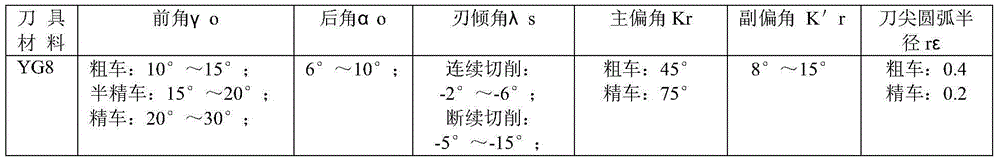

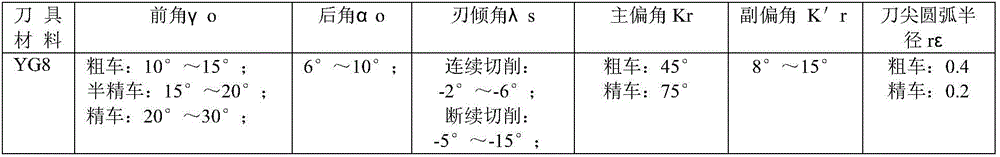

Turning method of long thin wall composite shell body formed by metal and glass fiber reinforced plastics

ActiveCN104588682AExtend your lifeImprove processing efficiencyAircraft componentsAmmunitionGlass fiberCold air

The invention discloses a turning method of a long thin wall composite shell body formed by metal and glass fiber reinforced plastics. The method comprises the steps that (1) glass fiber reinforced plastics outer circle rough turning is carried out; (2) the two end faces of the shell body are subjected to rough turning; (3) glass fiber reinforced plastics outer circle fine turning is carried out; and (4) the two end faces of the shell body, an inner hole and an annular groove are subjected to fine turning. Rough-fine machining processes are used, technology allowance is distributed reasonably, deforming amount is controlled, metal shell inner hole accuracy is controlled and is used as the machining standard of a structure piece after recombination, an end cap and a soft claw are used for clamping, clamping deforming is lowered, through a low-temperature cold air cooling mode, a cutting environment is improved, a tool and cutting parameters during cutting machining are stipulated, product tool service life is prolonged, and machining efficiency is improved. The technology method is reasonable and reliable, product deforming is small, and the machining quality of the composite shell body can be effectively guaranteed.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Method for producing feedstuff coarse albumen powder by kitchen waste

ActiveCN101138386AAvoid churnPreserve nutrientsFood processingAnimal feeding stuffFiltrationOil water

A production method fro preparing the feed of crude protein powder with the residues in kitchen is characterized by the steps which comprise selection; smashing; separation; the smashed solid and liquid residue pastes from the kitchen are separated in a centrifugal machine and the oil and water of the separated liquid are separated by a separator; the oil is delivered to an oil tank and the water containing protein is implemented with the step of concentration; concentration; a concentrator is used for concentrating the water containing protein; drying; the concentrated water containing protein is sprayed on the solid paste through a pipe and a nozzle and dried on a drier; the water content is controlled under 15 percent and the feed of crude protein powder is obtained. The processing method is more rational and with the method, the nutrition in residues in kitchen can be fully used and the liquid loss after press filtration is prevented; at the same time, the environmental pollution is prevented or reduced and the production cost is decreased.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

Preparation method of sodium carboxymethyl starch with superhigh viscosity

The preparation method of ultra-high viscosity sodium carboxymethyl starch belongs to the modified starch technology; the method steps are: starch and ethanol solution are made into starch milk in a reactor, and the starch milk is processed by using NaOH twice put into the reactor. Alkalinization, then put the cross-linking agent into the reactor for cross-linking reaction, put chloroacetic acid into the reactor twice to react for 2-3h, after the reaction, neutralize the pH=7 with HCl, centrifuge and wash with ethanol solution , centrifugal separation, and drying to obtain the product; the method is novel and reasonable, and the obtained sodium carboxymethyl starch has high viscosity, good transparency, strong stability and wide application range.

Owner:吴也平 +1

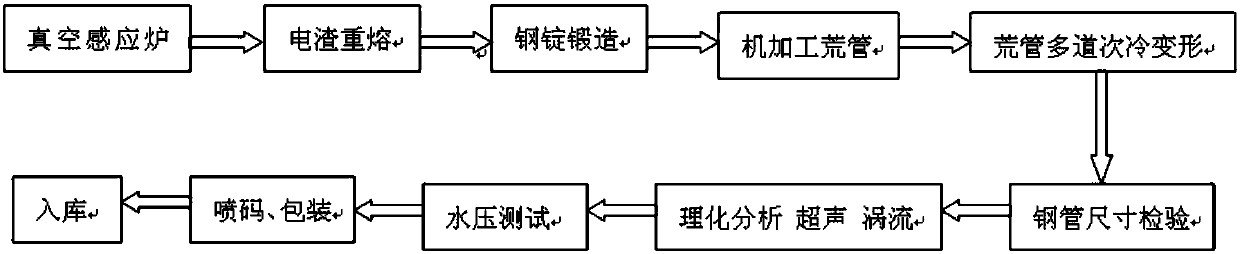

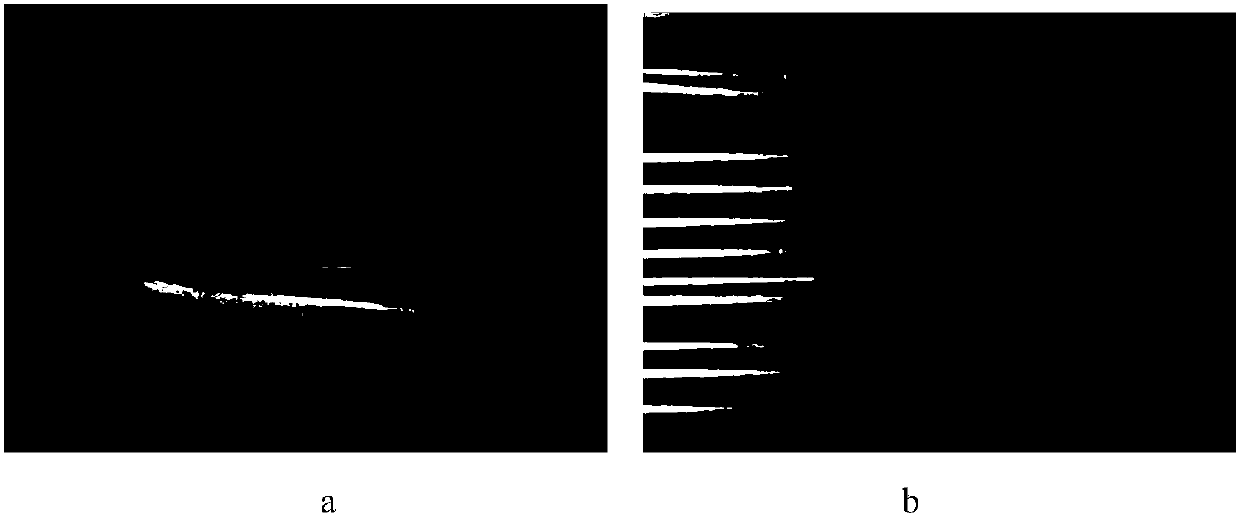

Processing technology for corrosion-resistant stainless steel seamless steel tube

The invention relates to a processing technology for a steel tube, particularly relates to a processing technology for a corrosion-resistant stainless steel seamless steel tube, and belongs to the technical field of tube processing. The processing technology for the corrosion-resistant stainless steel seamless steel tube comprises the following steps: (1) tube blank smelting, (2) tube blank forging, (3) machining of a pierced billet, and (4) steel tube deforming. A tube blank is subjected to repeated chambering and cold rolling treatment, and is processed by a multi-pass small deformation; andaccording to the final cold drawing procedure, processing of the seamless steel tube is finished by cold drawing, oil removal, annealing, straightening, fixed cutting, acid pickling and inspection toobtain the product. In a cold rolling process, the processing deformation of the seamless steel tube does not exceed 55%; in a chamfering process, the processing deformation of the seamless steel tube does not exceed 10%; in a cold drawing process, the processing deformation of the seamless steel tube does not exceed 15%; and an annealing process in the chamfering, cold rolling and cold drawing processes meets the conditions of solution annealing at the temperature of 1,052-1,093 DEG C and rapid cooling or water cooling.

Owner:BAOFENG STEEL GRP

Production technology of nuts

The invention discloses a production technology of nuts. The technology comprises the steps of A raw material selection; B, annealing; C, pickling and phosphatizing; D, drawing; E, cold heading forming; F, tapping; G, surface finishing: a finished product nut is placed into a cleaning pond which contains a cleaning solution to be cleaned and remove rust, and then drying and spraying process are conducted on the finished product nut; H, packaging and outbound delivery. The technology has the advantages that the method is simple and reasonable, the production speed is fast, the production efficiency is effectively improved, the production cost is reduced, the processing sequences of the nut is simplified by adopting the cold heating forming method, the processing cost is reduced, and the processing speed and accuracy are improved.

Owner:嘉兴市兆丰五金科技股份有限公司

Chinese traditional medicine moist dressing for treating diabetes foot and the preparing method

InactiveCN101041086AMaterial selection scienceReasonable formulaMetabolism disorderUnknown materialsPolyvinyl alcoholDiabetic foot

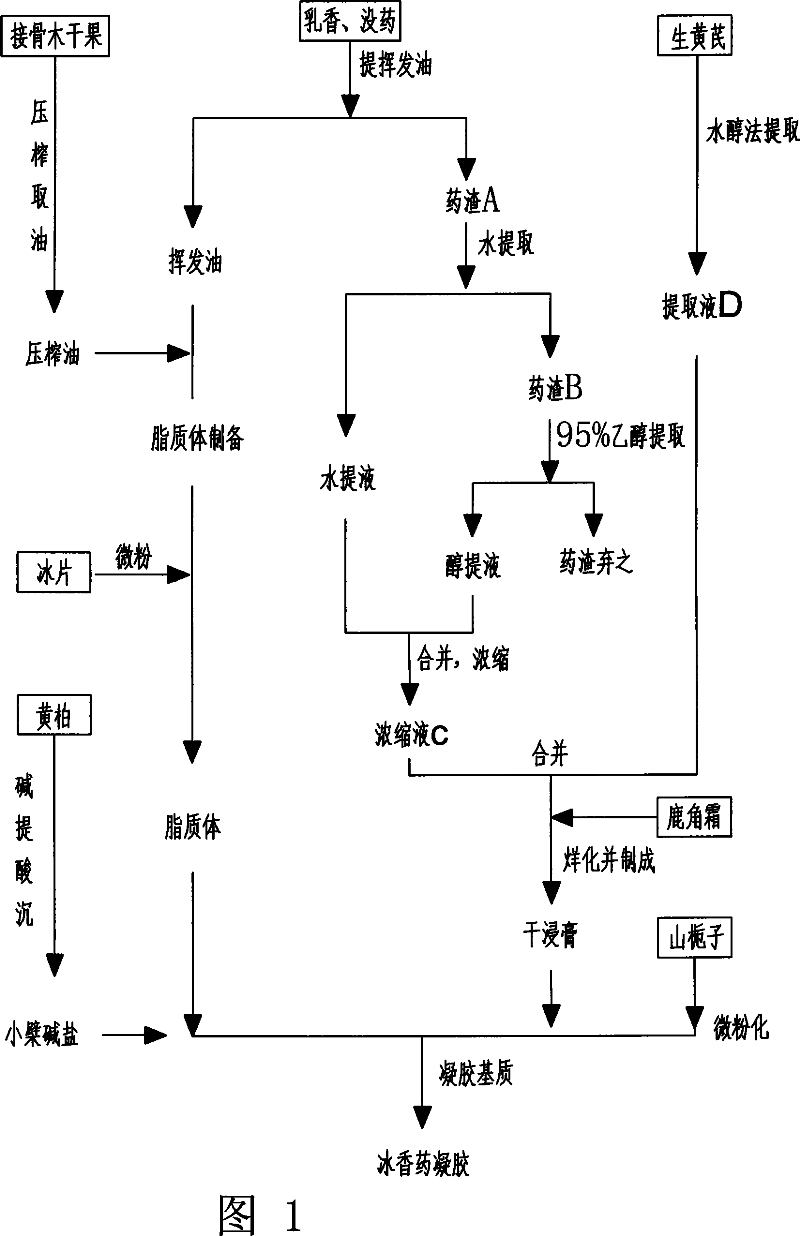

The invention relates to a Chinese pharmaceutical wet dressing for treating diabetes and process for preparation, wherein the dressing comprises the following constituents (by weight portions): yellow corktree bark 13-19%, astragalus root 13-19%, frankincense 8-14%, myrrh 8-14%, Sambucus williamsii. 3-7%, deglued antler powder 13-19%, cape jasmine 13-19%, borneol 3-7%, polyvinyl alcohol 124 0.5-2%, macromolecular auxiliary material 0.5-2% and trehalose 0.05-0.1%.

Owner:YANGZHOU UNIV

Medicine for treating senile dementia and its preparing process

InactiveCN100515486CAcute toxicity safetyThe process method is reasonableNervous disorderInanimate material medical ingredientsCodonopsisBULK ACTIVE INGREDIENT

The invention discloses a new medicine for treating senile dementia, which is composed of Codonopsis pilosula, Guizhi, Radix Paeoniae Alba, Poria cocos and licorice as main raw materials and / or pharmaceutically acceptable carriers. The medicine of the present invention is also effective for vascular dementia. The invention also discloses a preparation method of the medicine.

Owner:SHANDONG WOHUA PHARMACEUTICALS CO LTD

Fresh-keeping method of fresh melon and fruit

InactiveCN101467547AKeep it originalKeep the original colorFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingUltraviolet irradiationMelon (food)

The invention provides a fresh-keeping method for fresh melon and fruit. The fresh fruit, which enters the red ripe stage and is still hard, is placed into a container after disinfection through ultraviolet irradiation; then the container is vacuumed, placed into an ice house and preserved away from light; the preservation period can be several months or above; the preserved melon and fruit have primary taste and color, and the method is reasonable and satisfies the environment protection requirements.

Owner:TIANJIN ZHONGYING HEALTH FOOD

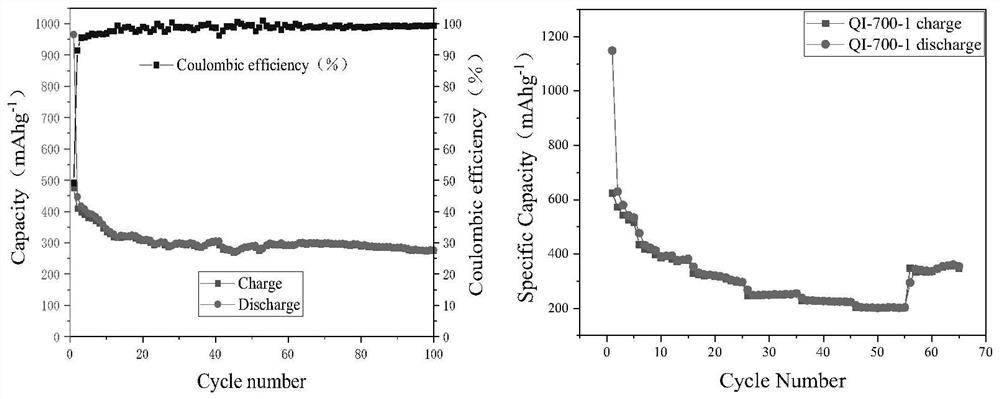

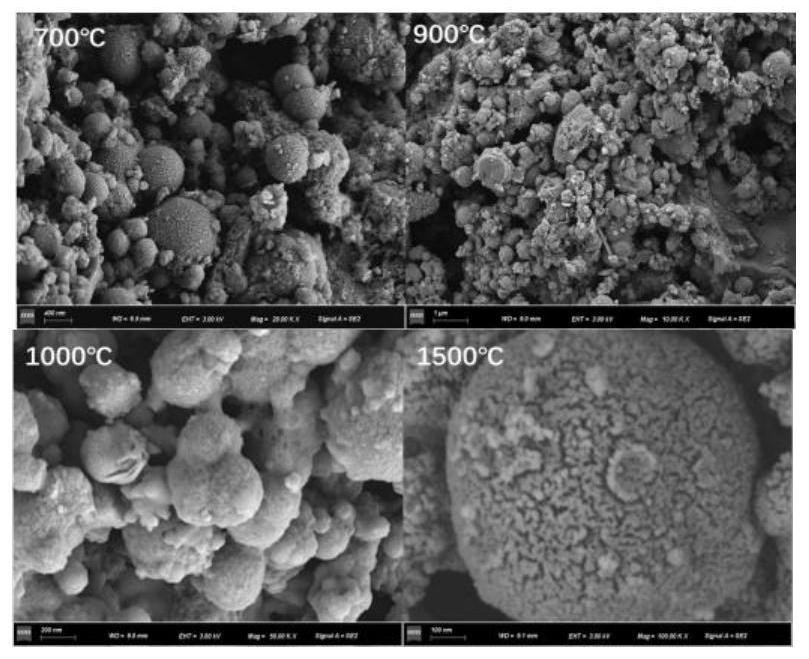

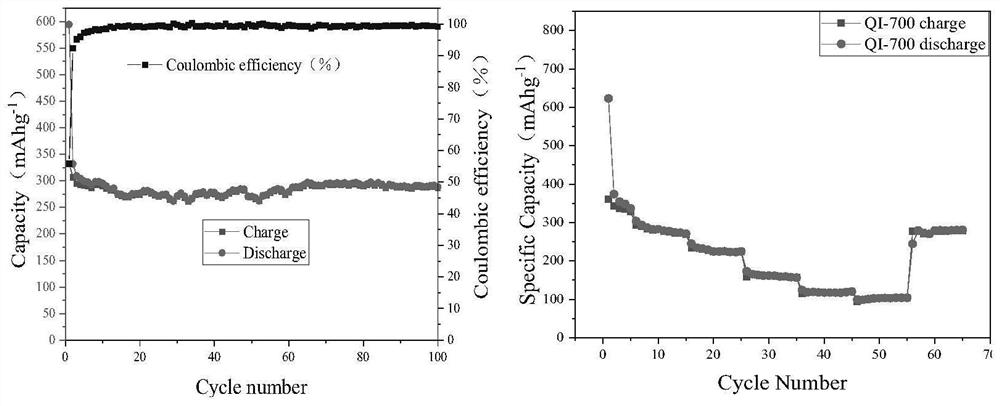

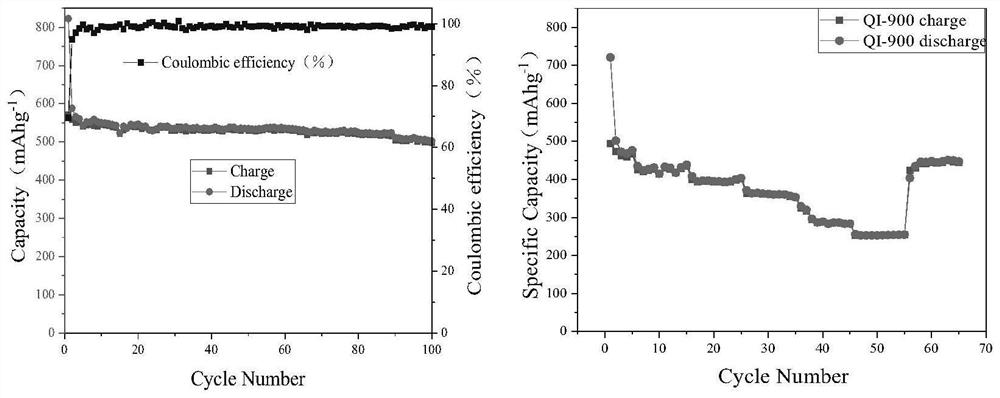

Lithium ion battery negative electrode material and preparation method thereof

ActiveCN113830768AImprove conductivityImprove performanceCarbon compoundsCell electrodesElectrical batteryQuinoline

The invention provides a lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: mixing coal tar pitch with a solvent which is a mixed solvent consisting of kerosene, absorber oil or anthracene oil in a certain proportion, conducting stirring at a certain temperature and pressure, and conducting standing and settling to obtain a coal tar pitch quinoline insoluble substance; mixing the coal tar pitch quinoline insoluble substances with a quinoline solution, performing centrifugal separation, and collecting solids; sequentially washing the solid with a quinoline solution and a toluene solution which are heated to 70 DEG C, and conducting drying; mixing the dried solid with KOH according to a certain proportion, conducting grinding, and conducting activating in a furnace under the protection of inert gas; and washing the activated product with an acid solution and water until the product is neutral, and conducting drying to obtain the lithium ion battery negative electrode material. The preparation method has the advantages of environmental friendliness, no pollution, simplicity in operation, low raw material price and excellent property of the battery negative electrode material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

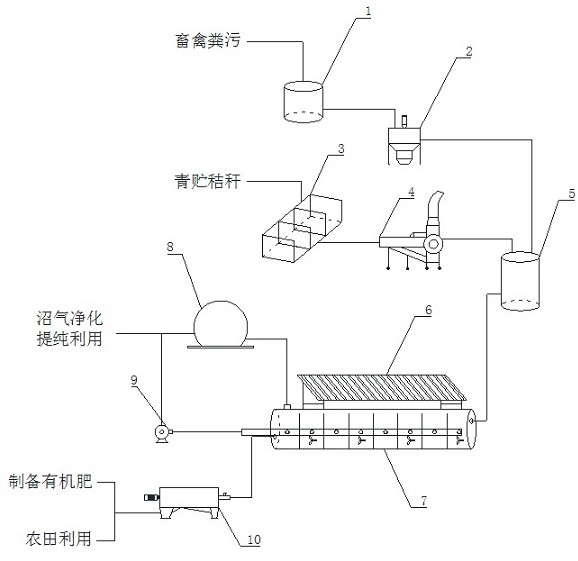

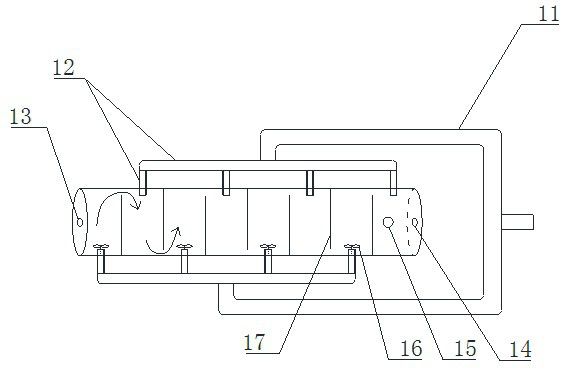

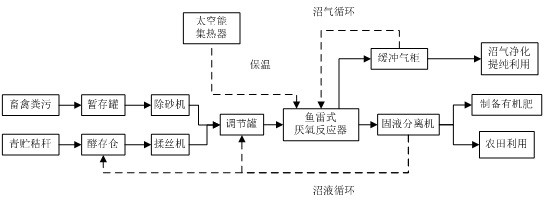

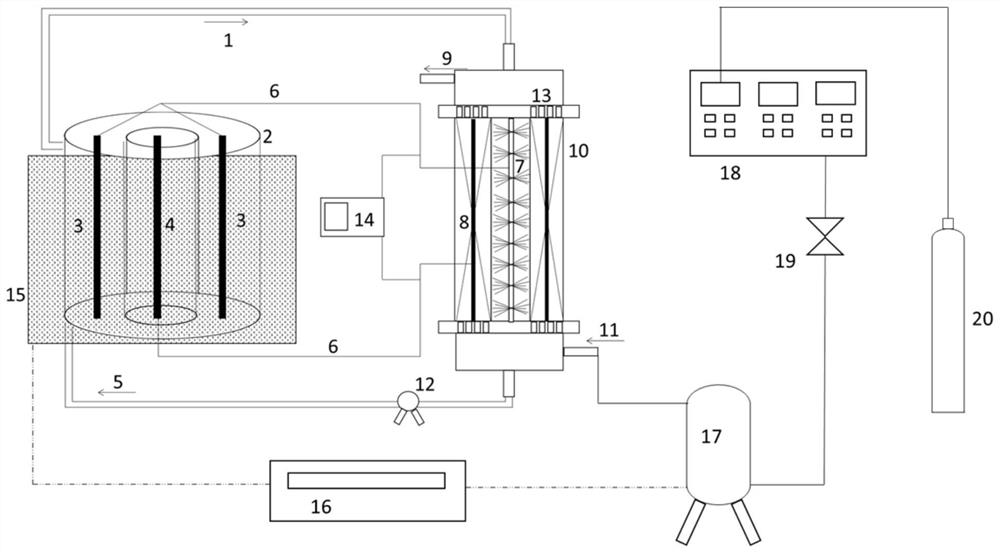

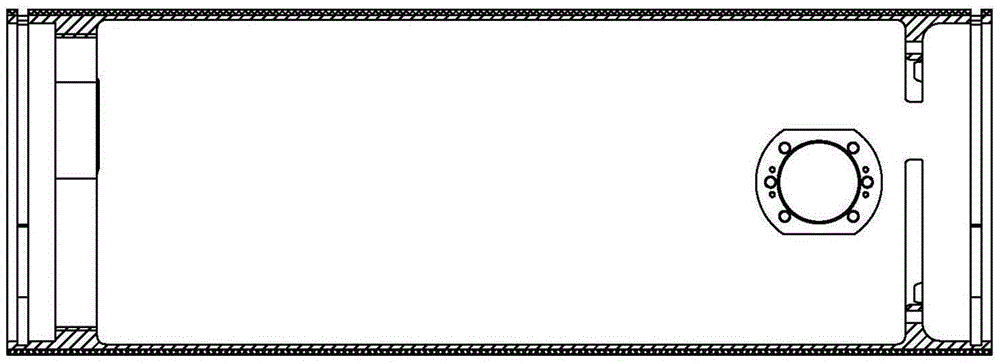

Efficient synergistic resource utilization method for livestock and poultry manure and silage straw

PendingCN113430101ASolve the problem of low gas production in resource utilizationPromote decompositionBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural scienceAgricultural engineering

The invention discloses an efficient synergistic resource utilization method for livestock and poultry manure and silage straw. The livestock and poultry manure and the silage straw are blended into a mixed material in an adjusting tank (5); the mixed material enters an anaerobic fermentation tank (7), the anaerobic fermentation tank (7) is a torpedo type anaerobic reactor, and partition plates (17) are arranged in a cylinder body at intervals; a rotary spraying stirrer (16) is mounted between every two adjacent partition plates (17) on one side of the lower part of the cylinder body; every two partition plates (17) form a material reaction bin, and after the material enters the anaerobic fermentation tank (7), the rotary spraying stirrer (16) and an air blower (9) are started to carry out gas-liquid stirring on the material; after discharged slurry passes through a solid-liquid separator (10), biogas residues are subjected to aerobic composting to prepare organic fertilizer, and part of biogas slurry is treated and then returned to the field for utilization; and the other part of biogas slurry flows back to the adjusting tank (5) and a fermentation storage bin (3). According to the efficient synergistic resource utilization method for the livestock and poultry manure and the silage straw, through efficient cooperative treatment of feces and crops, and the gas production rate of biogas is increased.

Owner:中钢集团天澄环保科技股份有限公司

Method and device for preventing oxidation in synthesis of anode material of lithium-ion battery

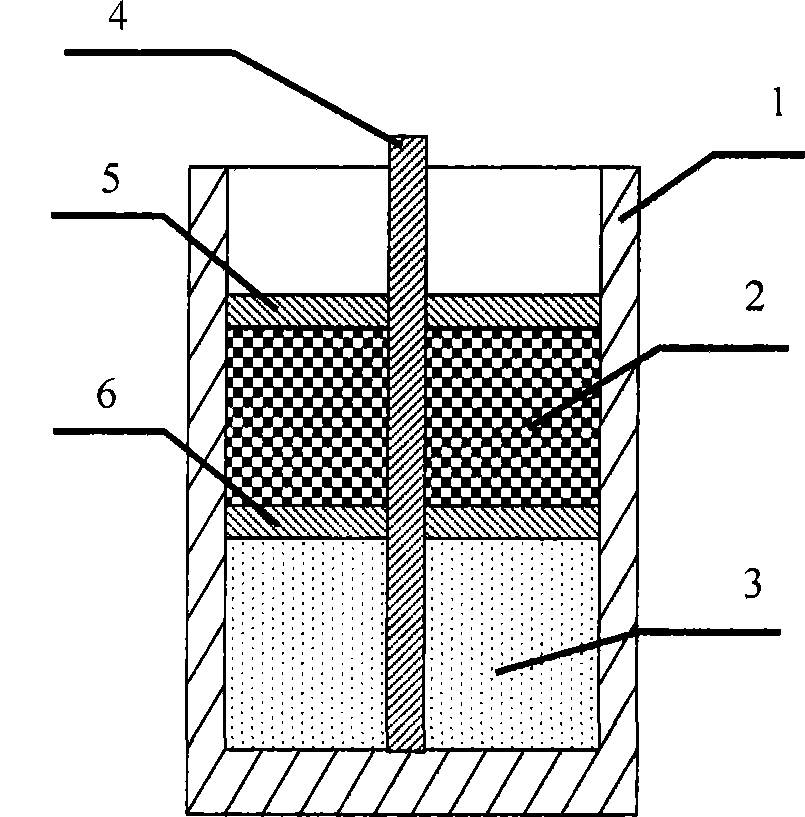

ActiveCN101626073BQuality improvementReduce manufacturing costElectrode manufacturing processesLithium compoundsChemical reactionMetallurgy

The invention discloses a method and a device for preventing oxidation in synthesis of an anode material of a lithium-ion battery. The method comprises the following steps of: filling raw materials needed for synthesizing the anode material of the lithium-ion battery in a bottom part of a reactor, wherein the region is called a material loading region; filling a reducing agent or an inert material which does not participate in chemical reactions at a high temperature in a region above the material loading region, wherein the region is called an isolation region; placing the filled reactor into an electric furnace for sintering at a high temperature; and maintaining an oxygen content of 0.5 to 30 percent of the air in the reaction region in the electric furnace; and thus obtaining the needed anode material of a lithium-ion battery. The process is technical method, convenient in operation and reasonable in structure, can effectively reduce the production cost for synthesizing the anode material of the lithium-ion battery, greatly decreases requirements on the equipment and the purity of protective atmosphere, and can realize massive production and replace the prior synthesizing process of the anode material of the lithium-ion battery.

Owner:CENT SOUTH UNIV +1

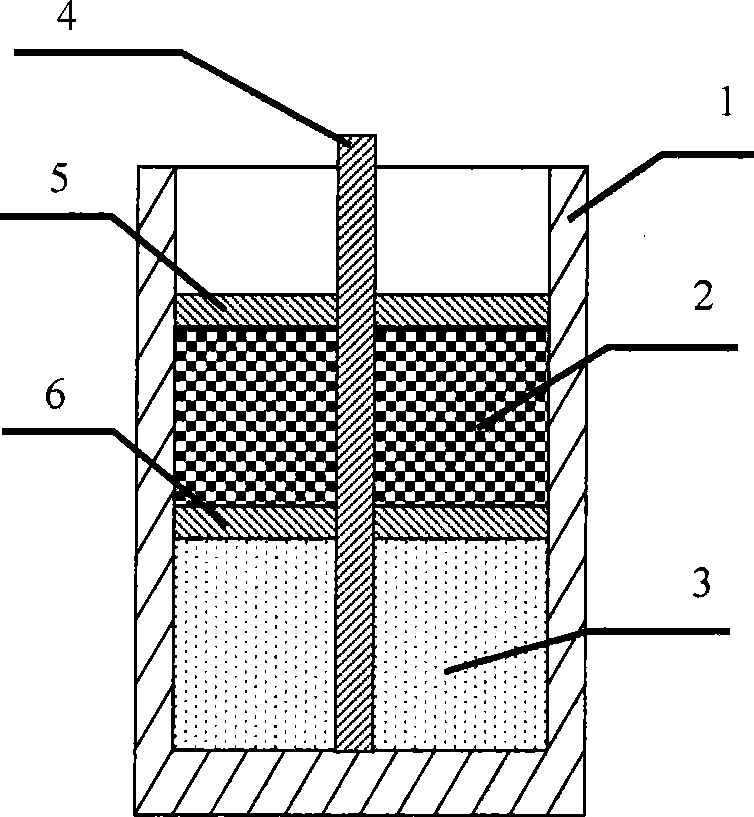

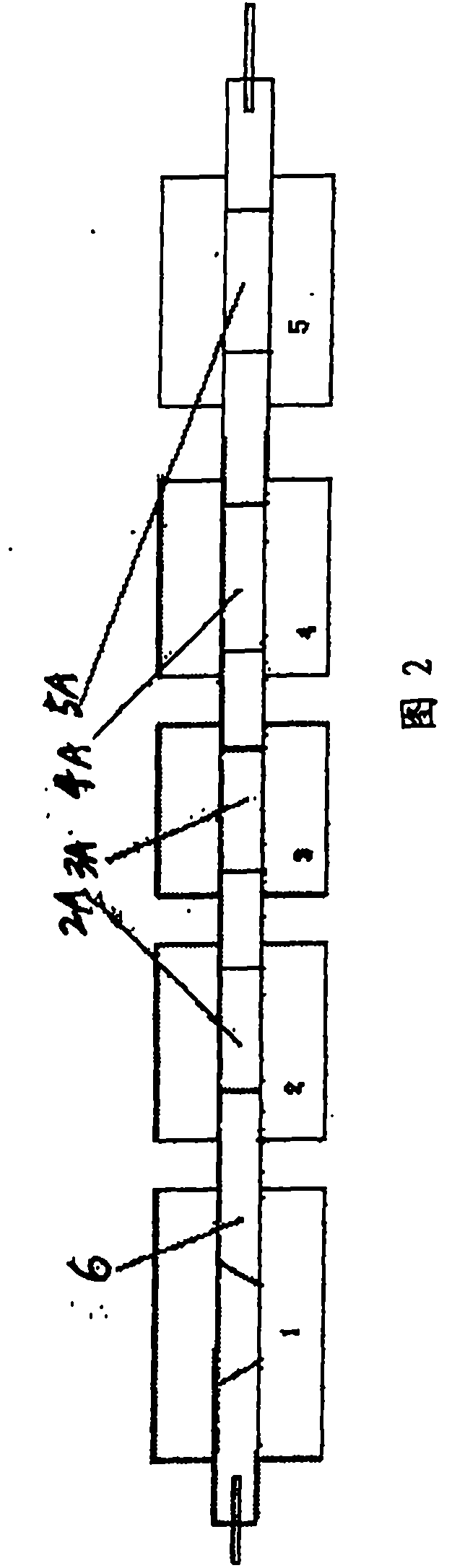

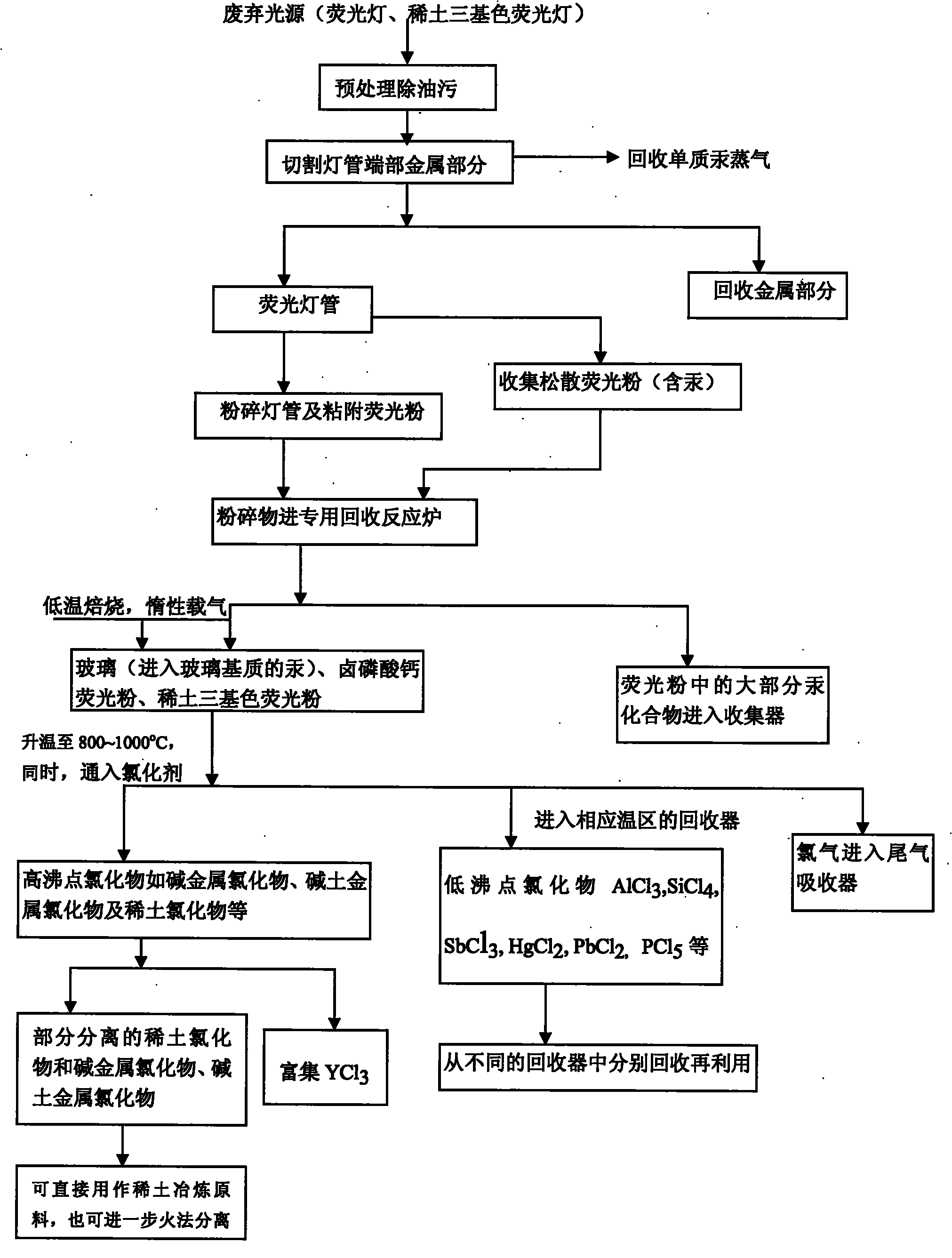

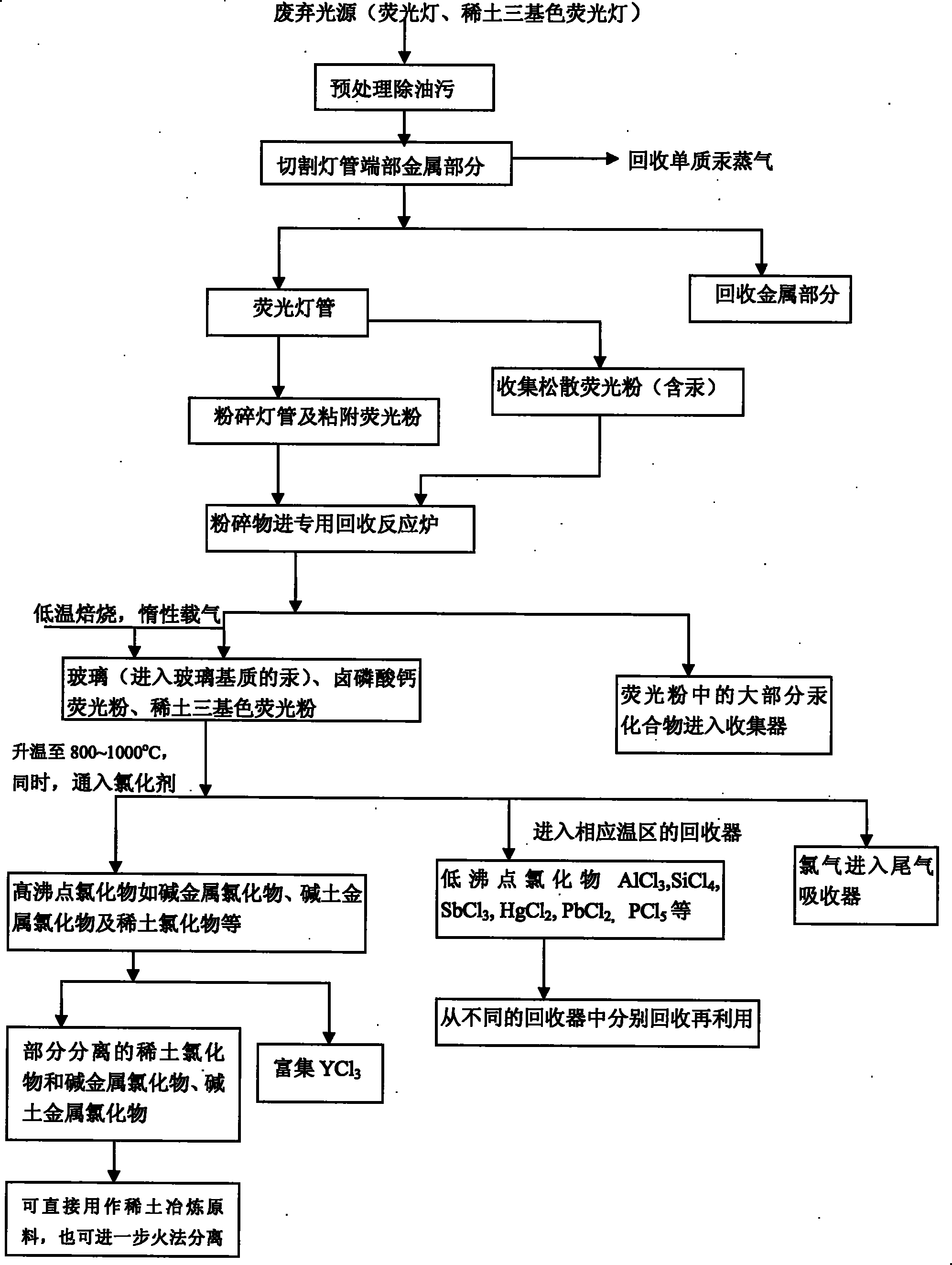

Method for recovering and processing discarded fluorescent lamp

InactiveCN101150032BTo achieve the purpose of recycling rare earthReduce processingGlass recyclingElectronic waste recyclingRare-earth elementAdhesive

This invention relates to a method for recovering and processing waste fluorescent lamps of straight fluorescent lamps, energy-saving lamps and rare earth three-basic color lamps including: safely cutting a waste fluorescent lamp to recover gas Hg, recovering Al caps, brass bolts, filament metals and adhesive Hg, recovering Hg in relaxed fluorescent powder and separating and recovering rare earthelements and other valuable elements from fluorescent powder by fire and recovering Hg and rare earth elements in the glass and adhered powder by a fire method, which applies one time of fire method to recover and separate Hg, rare earth and other valuable elements in fluorescent powder and the special recovery reaction bake oven includes a master reaction oven and several ovens controlling temperature independently.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Tin plating method

The invention relates to a tin plating process which is characterized by comprising the following steps of 1. removing dust and oil; 2. pickling and phosphating; 3. washing with water; 4. passivating; 5. plating tin, that is, putting a cleaned product processed by passivation in a tin plating solution with a certain temperature, controlling a conveying speed at 1-3 m / s and a current density at 2-5 a / dm<2>; 6. washing with water; and 7. packaging. The tin plating method is reasonable in process, and a product produced by the method has high quality and is not easy to blacken and grow crystal whiskers.

Owner:赵春美

Heat-clearing oral liquid for children and preparation method thereof

InactiveCN103041123AIncreased heat-clearing and detoxifying effectsDouble the effectSenses disorderPharmaceutical delivery mechanismFormularyAsparagus cochinchinensis

The invention relates to a heat-clearing oral liquid for children and a preparation method thereof. In a formula of the preparation method of the heat-clearing oral liquid for the children, honeysuckle, cape jasmine and taraxacum are taken as main drugs, and radix paeoniae alba, aloes, sophora flowers and radix asparagi are taken as adjuvants; the selected traditional Chinese medicinal material prescription is reasonable; the heat-clearing oral liquid has obvious efficacies of preventing and treating heat toxin and damp toxin, clearing heat, moistening dryness and the like; a technique is reasonable; raw materials are saved; the production cost is lowered greatly; and the heat-clearing oral liquid is convenient to take and carry, unique in flavor, and more suitable for the children to take.

Owner:洛阳本草生物制药股份有限公司

Gasoline saving additive and preparation method thereof

The invention relates to a gasoline saving additive and a preparation method thereof, in particular discloses a high-efficient and environment-friendly gasoline saving additive capable of effectively improving the gasoline quality and the fuel value and reducing harmful substance emission, and belongs to the technical field of petrochemical industry. The gasoline saving additive comprises the following components by weight: 10 to 30 percent of methanol, 1 to 10 percent of copper sulphate, 2 to 10 percent of acetone, 3 to 15 percent of hexamethylene tetramine, 0.2 to 5 percent of span 85, 5 to 20 percent of normal propyl alcohol, and 10 to 30 percent of isopropyl alcohol. The gasoline saving additive has the advantages of having reasonable compound design, effectively improving the gasoline quality, improving the gasoline octane number, improving the fuel value, increasing power, eliminating carbon deposit, cleaning a fuel system, having obvious gasoline saving effect, reducing the emission of automobile off gas pollutants, reinforcing the lubrication of a machine, prolonging the service life of the machine, and reducing the operating cost of an automobile.

Owner:杭州桐庐洪风新技术新燃料开发有限公司

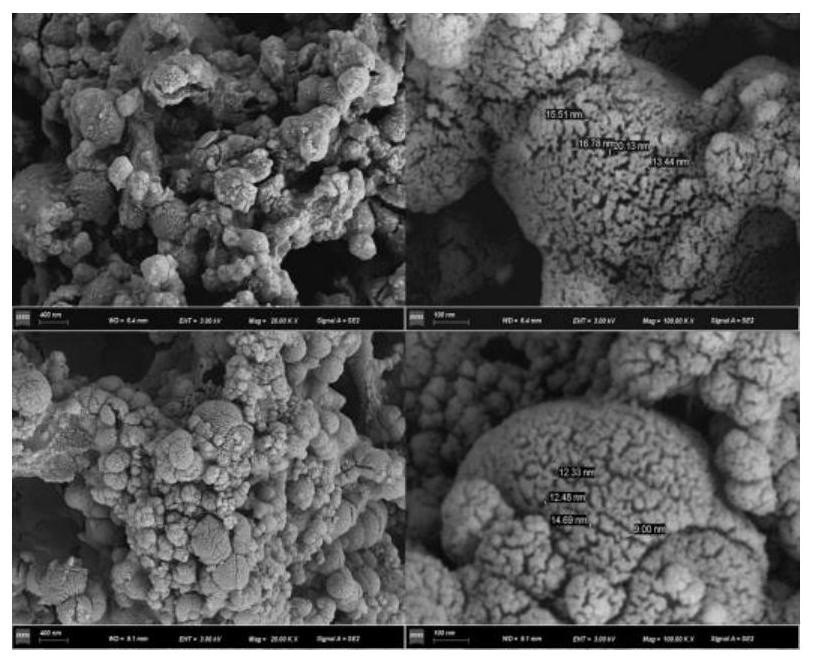

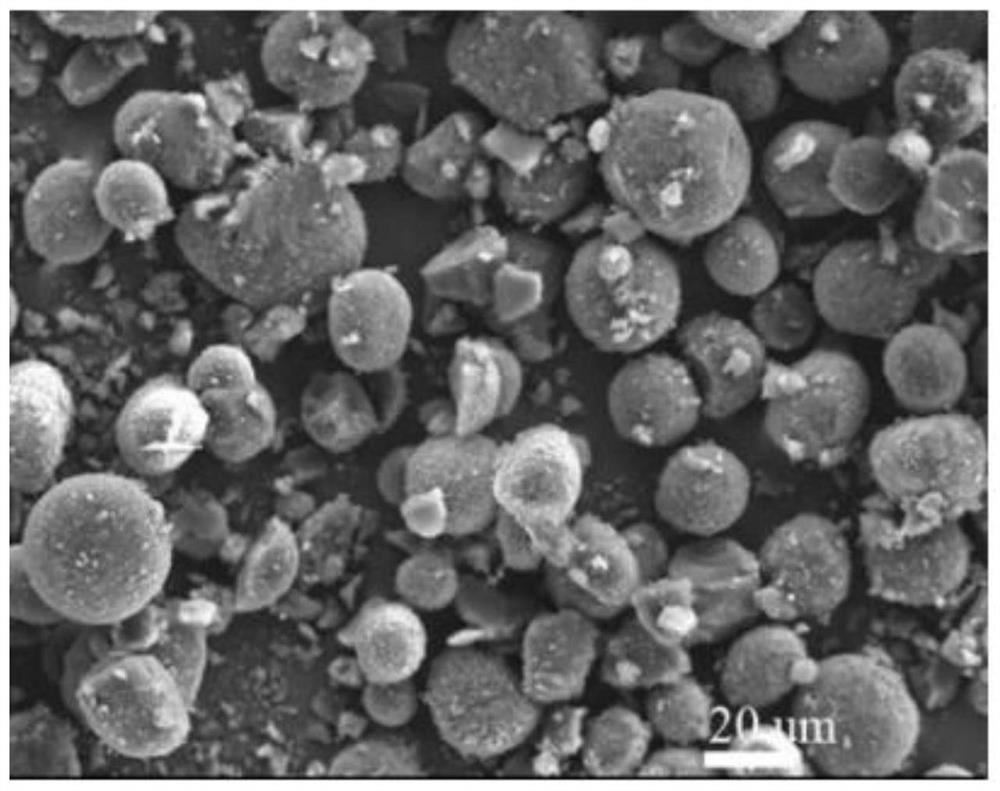

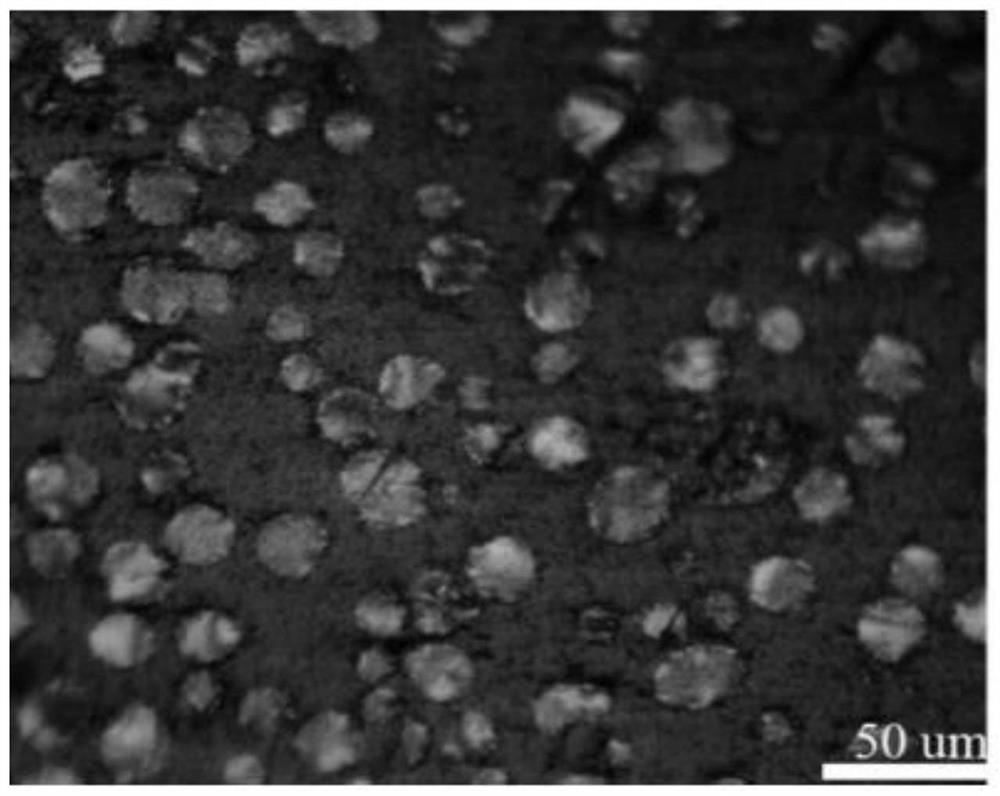

Mesocarbon microbeads and preparation method thereof

The invention provides mesocarbon microbeads and a preparation method thereof. The method comprises the following steps: putting coal tar pitch and biomass pitch into a reaction kettle, purging with inert gas, performing heating to 90-110 DEG C, and performing uniform stirring; continuously raising the temperature to 400-420 DEG C, keeping the temperature, and then performing cooling to room temperature in an inert gas atmosphere; extracting by using quinoline until the solution is colorless, washing the residual solid by using methylbenzene, and then performing drying; putting the dried solid into a furnace, and performing heating and carbonizing to obtain the mesocarbon microbeads. The process method is reasonable and environment-friendly, and the obtained mesocarbon microbeads are in the shape of uniform spheres and have large interlayer spacing and defect points.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

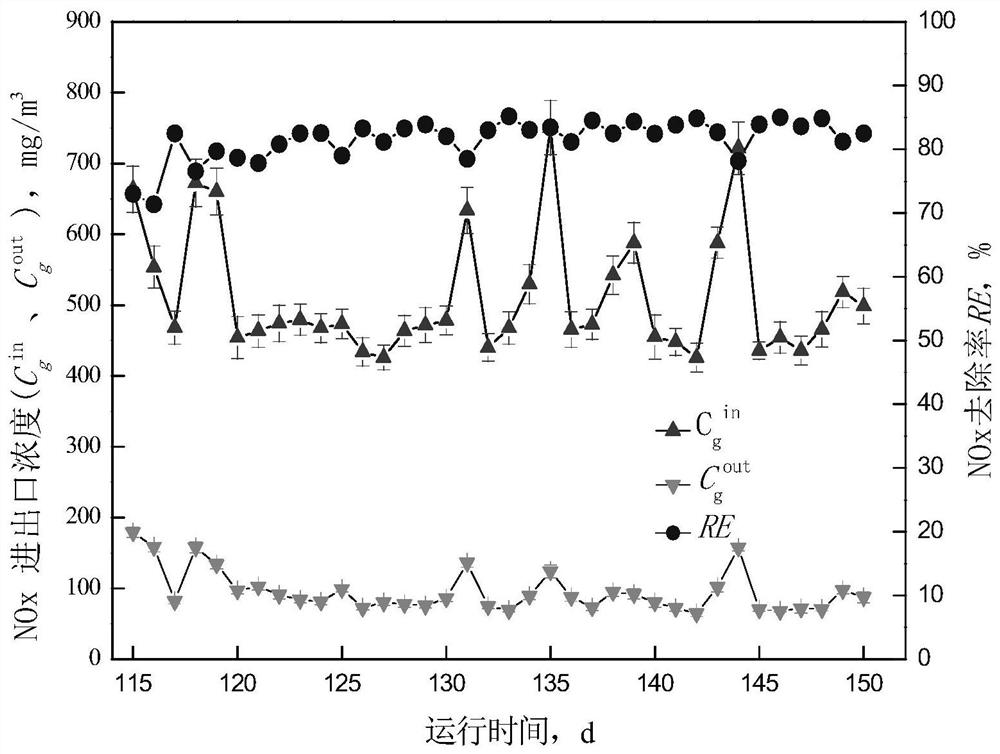

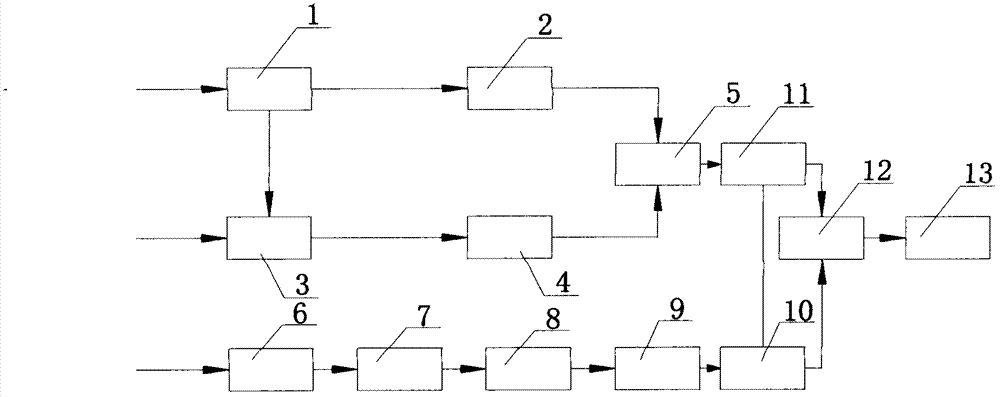

A device and method for flue gas denitrification using a microbial fuel cell combined with a microbial electrolytic cell

ActiveCN111530267BEasy to useIn line with the law of growthGas treatmentTreatment by combined electrochemical biological processesFuel cellsFluid phase

The invention discloses a device and method for flue gas denitrification using a microbial fuel cell combined with a microbial electrolytic cell. The cathode of the MFC is connected to the anode of the MEC through a wire, the anode of the MFC is connected to the cathode of the MEC through a wire, and the anode chamber of the MFC and the MEC and The cathode chambers are separated by a proton exchange membrane; the bottom of the MFC cathode is provided with a flue gas inlet and a nutrient solution outlet, and the top of the MFC cathode is provided with a flue gas outlet and a nutrient solution inlet. The cathode chamber of the MFC and the cathode chamber of the MEC are There is a nutrient solution circulation loop between them; the electrons generated by the MFC are used as a power source to act on the MEC, and under the double strengthening of the MEC and the MFC, the flue gas denitrification is realized. The invention has low cost and low energy consumption, and the NOx in the flue gas is transferred to the liquid phase through the chemical absorbent, and the pollutants are removed and the absorbent is activated through the MFC-MEC joint technology, so that the high-efficiency and greenness of the medium-temperature flue gas can be realized Denitrification.

Owner:SOUTH CHINA UNIV OF TECH

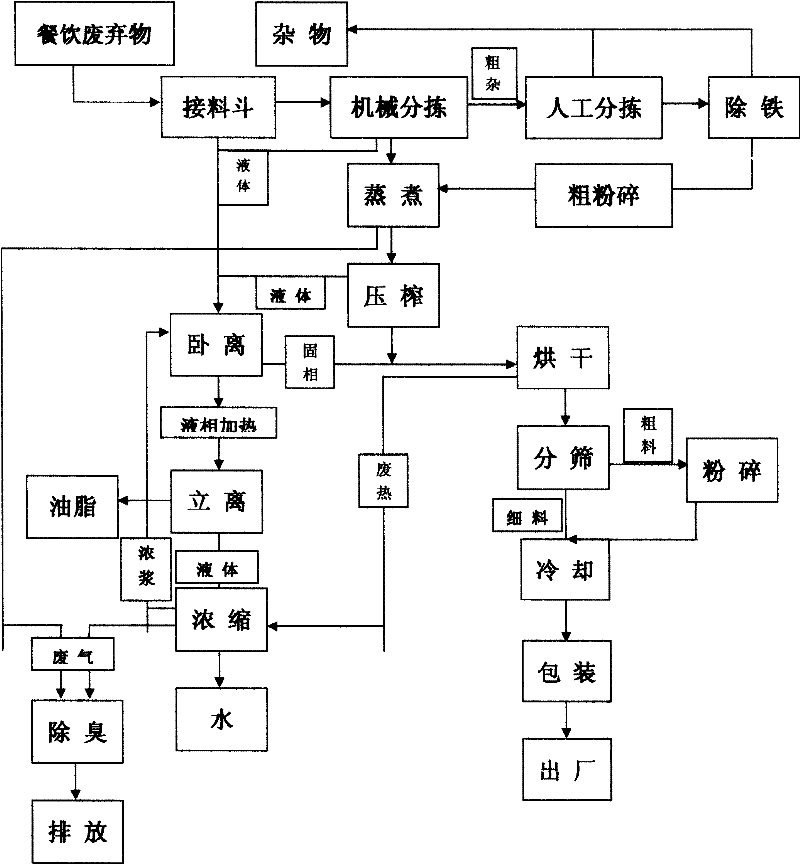

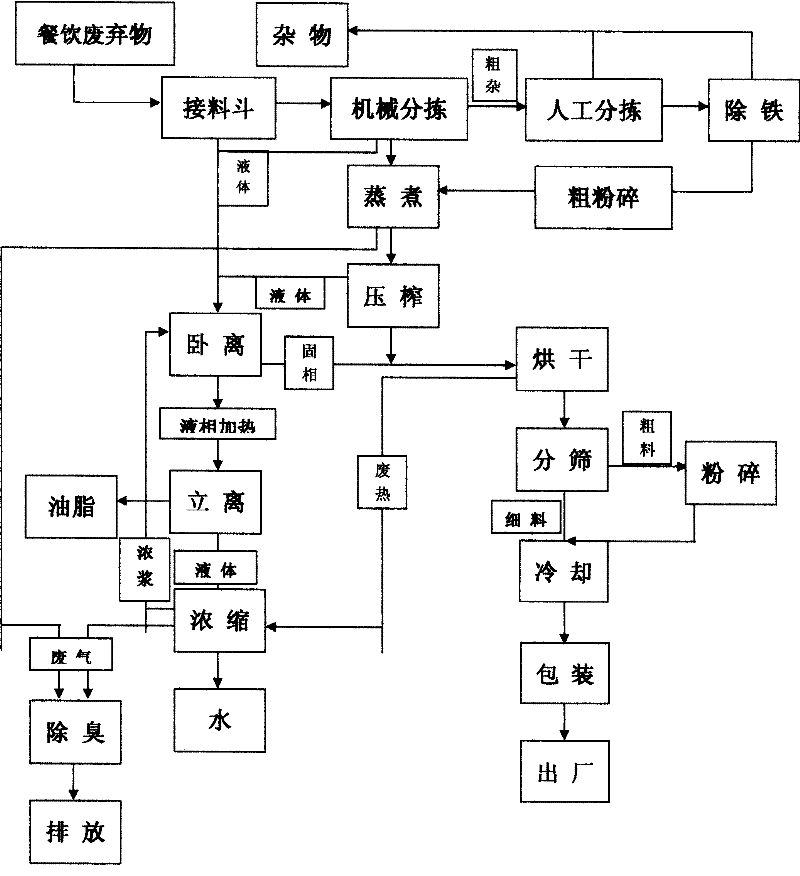

Processing method for castoff of food and drink

ActiveCN101268803BAvoid churnPreserve nutrientsFood processingAnimal feeding stuffWaste materialCentrifuge

The invention relates to a processing method of food and beverage waste material, which is characterized in that steps are as follows in sequence: a sorting step, a braising and boiling step, a squeezing step, a drying step, a screening and packing step, wherein, in the braising and boiling step, the food and beverage waste material after the sorting step is braised and boiled for 10 to 30 minutes at the temperature of 35 to 55 DEG C. Partial liquid separated from the squeezing step is separated by a horizontal centrifuge, a separated solid or solid-liquid mixture steps in the drying step, the separated liquid utilizes waste heat in the dry step to concentrate, partial condensed water and exhaust gas are discharged, and then the concentrated liquid is sent to the horizontal centrifuge for circular separation. The technique method is more reasonable, the nutritious substance of food giblets can be fully utilized, and the liquid loss after being squeezed and filtered is prevented, at the same time, environmental pollution is avoided and reduced, and the production cost is lowered.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

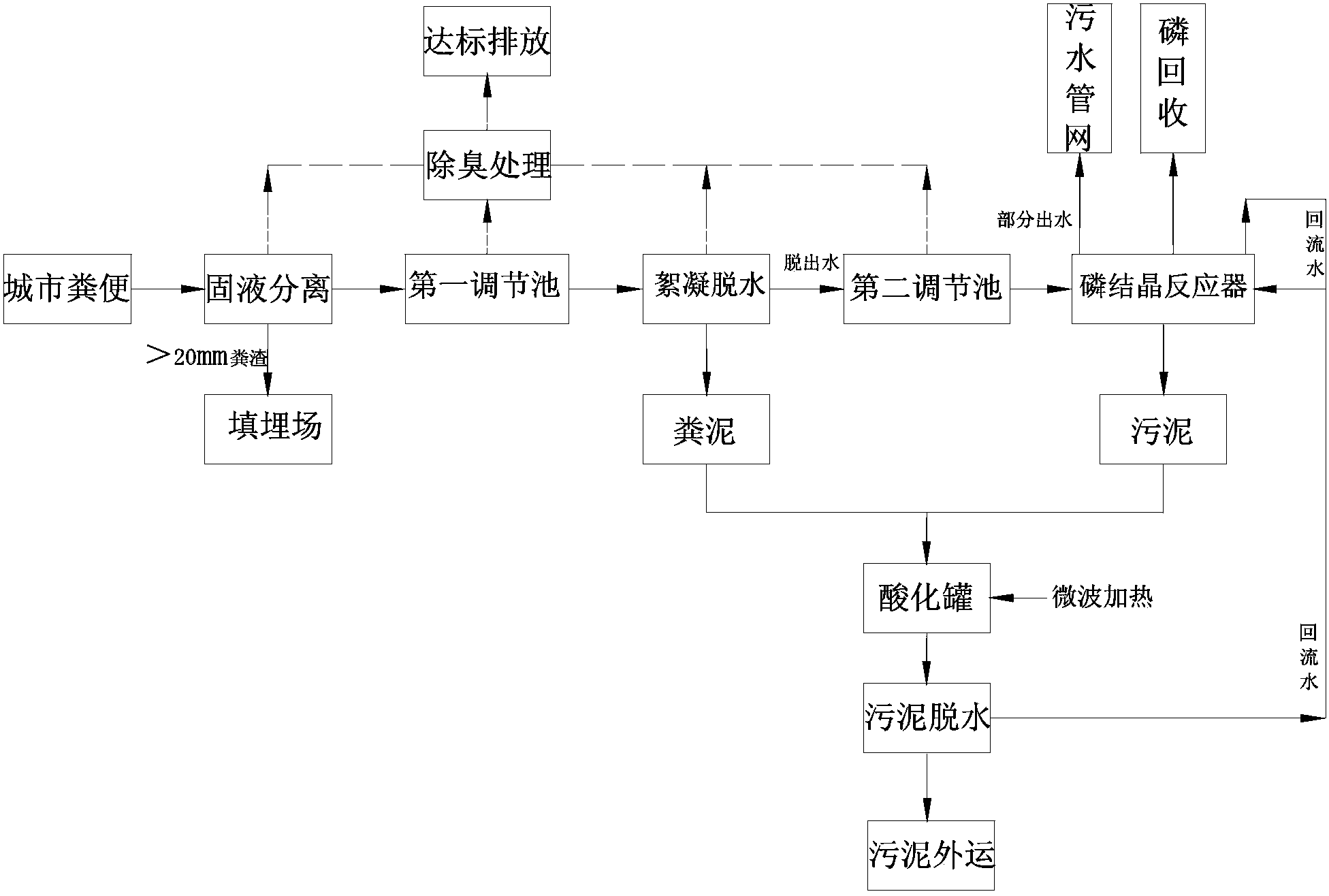

Method for extracting phosphorus from urban excrement

ActiveCN102815824BPrevent eutrophicationImprove qualitySludge treatmentPhosphatesFlocculationResource utilization

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +2

Heat-clearing oral liquid for children and preparation method thereof

InactiveCN103041123BIncreased heat-clearing and detoxifying effectsDouble the effectSenses disorderPharmaceutical delivery mechanismFormularyAsparagus cochinchinensis

The invention relates to a children's heat-clearing oral liquid and a preparation method thereof. The formula of the children's heat-clearing oral liquid of the present invention uses honeysuckle, gardenia and dandelion as the main ingredients, and white peony root, aloe, Sophora japonica and Asparagus as supplements. The selected Chinese herbal medicines are reasonable in composition and have obvious effects such as prevention and treatment of heat-toxin, damp-toxin, heat-clearing and moistening dryness, etc. The process method is reasonable, raw materials are saved, the production cost is greatly reduced, the product is easy to take and carry, and the taste is unique. For use in children.

Owner:洛阳本草生物制药股份有限公司

Production method of red mud filler

ActiveCN103483880BIncrease profitReduce pollutionPigment treatment with organosilicon compoundsPigment physical treatmentRed mudSlurry

The invention discloses a production method of red mud filler. The method includes the steps of: (1) wet levigation: sending a coarse red mud slurry from a red mud grading process into a grinding machine, conducting wet levigation to obtain a fine red mud slurry; (2) dehydration: bringing the fine red mud slurry into plate-and-frame filter press to press it into a red mud filter cake with a water content of less than 25%; (3) drying: sending the filter cake into a flash dryer to carry out crushing and drying so as to obtain powder with a water content of less than 0.5%; (4) grinding: subjecting the powder to superfine grinding in an impact type superfine powder mill to obtain 1250-6000 mesh superfine powder; (5) grading: grading the superfine ground material by a grader to obtain fine powder; and (6) modification: putting the fine powder into a modification machine, adding a modifier by spraying, and carrying out heat preservation reaction for 20-30min. The method provided in the invention realizes integration of material superfine processing and surface modification, simplifies the process, and no leakage exists in the production process. The method has the advantages of less environmental pollution, fast speed, high efficiency, environmental protection and energy saving, and no secondary pollution.

Owner:山东绿生洁环保科技有限公司

Method for preparing feedstuff with fermentation of food and drink castoff

ActiveCN101366446BAvoid churnPreserve nutrientsFood processingAnimal feeding stuffFermentationNutrient

The invention provides a method for producing feed by fermenting dining waste. The method is characterized in that the method sequentially comprises the steps of separating, boiling, pressing, fermenting, drying and separating screen packaging, wherein in the boiling step, the dining waste undergoing the separating step is boiled at a temperature of between 35 and 55 DEG C for 10 to 30 minutes. The technological method is more reasonable, and can fully utilize nutrient compositions of the dinning waste, avoid the loss of liquid phase after filter pressing, simultaneously avoid and reduce environmental pollution and lower production cost.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

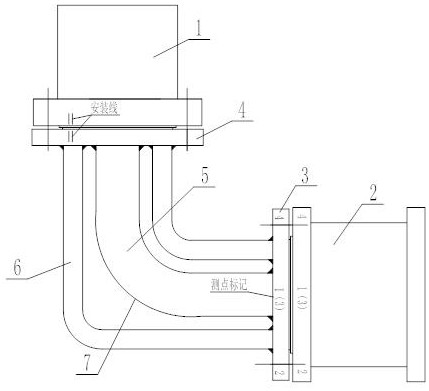

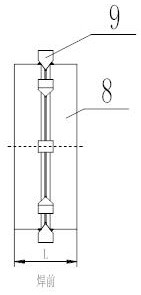

Method for controlling mounting size of DN650 metal flexible connecting pipe

ActiveCN113600976AHigh precisionScientific methodMetal working apparatusTubular articlesExperimental researchSS - Stainless steel

The invention provides a method for controlling the mounting size of a DN650 metal flexible connecting pipe. The method is suitable for controlling the mounting precision of an ultra-large-diameter metal flexible connecting pipe, and the mounting quality of the metal flexible connecting pipe is ensured. According to the method, the advantages of a traditional method are absorbed, a DN650 mounting precision control process method is provided through scientific analysis and experimental research, so that the pipeline mounting quality of a circulating water system is effectively improved, a scientific, reasonable and efficient process method is provided through experimental research, each construction link is precisely controlled, the construction efficiency and the construction quality are improved, the welding shortening amount of a stainless steel pipeline is obtained through a welding test, and the pipeline manufacturing precision is effectively improved. The method is suitable for being popularized and applied as the method for controlling the mounting size of the DN650 metal flexible connecting pipe.

Owner:中国船舶集团渤海造船有限公司

Intelligent defrosting method for air conditioner

ActiveCN100587369CDoes not affect the heating effectThe process method is reasonableSpace heating and ventilation safety systemsSpace heating and ventilation control systemsTransducerEngineering

The invention relates to an intelligent defrosting method of an air conditioner. The air conditioner judges whether one of the seven conditions is satisfied according to a series of integral elementssuch as indoor coil pipe temperature transducer variable quantity, environment temperature variable quantity, indoor wind velocity variable quantity, heat-production runtime accumulation quantity, andwhether an outdoor fan and a compressor are overcurrent protected, to determine whether an outdoor set is defrosted or whether defrosting is needed or not, so that intelligent defrosting is performedwithout using an outdoor coil pipe temperature transducer. The outdoor coil pipe temperature transducer and related signal lines are saved on the base of traditional air conditioners. Intelligent defrosting can be performed without human interference and only operation according to a preset program is needed. Clean outdoor defrosting is provided, heat quantity is not affected, and international specified requirements are satisfied.

Owner:安徽奥克斯智能电气有限公司

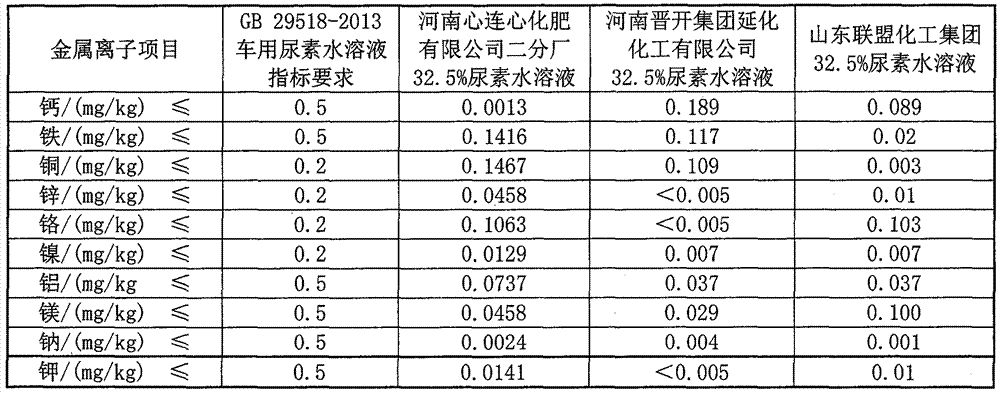

Device for directly producing urea solution for vehicles and production method thereof

ActiveCN104772031BSolve the problem of excessive formaldehyde contentSimple structureDispersed particle separationFluid phaseReverse osmosis

Owner:河南心连心蓝色环保科技有限公司 +1

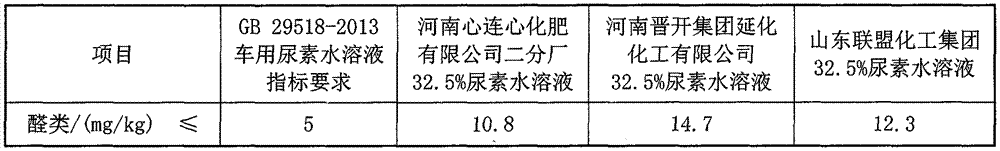

Method of using tremolite minerals to prepare jade building materials

The invention belongs to the field of building decorative material artificial synthesized stones, and particularly relates to a method of using tremolite minerals to prepare jade building materials, which mainly solves the problem of serious waste of tremolite and diopside minerals. The technical scheme includes that the method of using the tremolite minerals to prepare the jade building materials uses, by weight, 50-98 parts of base materials, 1-20 parts of polymers and 0-1 part of filler to prepare jade building material products by means of a base material shaping procedure, a material combination and arrangement procedure, a vacuum vibration procedure, a saw cutting procedure, a filling procedure and a grinding and polishing procedure. The method adopts various peculiar materials to combine and prepare the jade building materials, is reasonable in process, provides an approach of transforming precious minerals such as tremolite and the like to high-end building materials and furniture products, and provides a feasible scheme for upgrade of artificial synthesized stone industry and products.

Owner:STATE GRID CORP OF CHINA +1

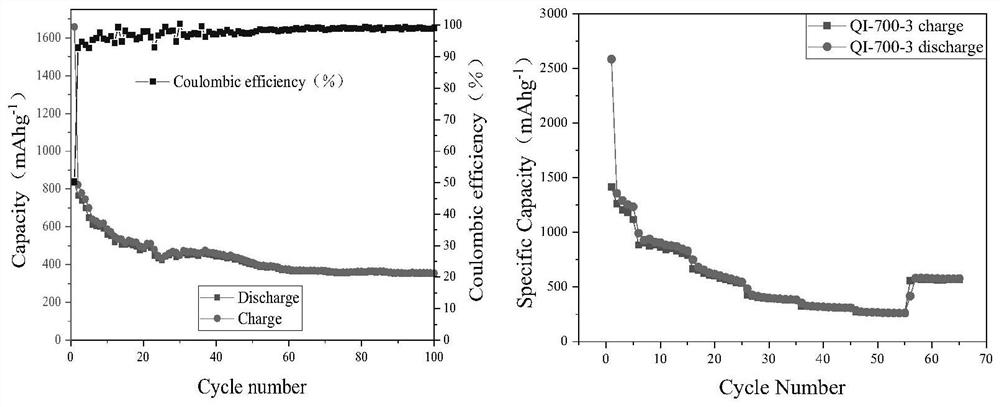

Battery negative electrode material and preparation method thereof

PendingCN114455565AImprove conductivityUniform polymerizationNegative electrodesSecondary cellsElectrical batteryQuinoline

The invention provides a battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: mixing coal tar pitch with a solvent which is a mixed solvent of kerosene, absorber oil or anthracene oil in a certain proportion, stirring at a certain temperature and pressure, standing and settling to obtain a coal tar pitch quinoline insoluble; the method comprises the following steps: adding coal tar pitch quinoline insolubles into a quinoline solution, performing centrifugal separation, and collecting solids; sequentially washing the solid with a quinoline solution and a toluene solution which are heated to 70 DEG C, and drying; and putting the dried solid into a furnace, and carbonizing under the protection of inert gas to obtain the battery negative electrode material. The preparation method has the advantages of environmental friendliness, no pollution, simplicity in operation, low raw material price and excellent property of the battery negative electrode material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Turning method of long and thin-wall composite shell formed by metal and FRP

ActiveCN104588682BExtend your lifeImprove processing efficiencyAircraft componentsAmmunitionCold airGlass fiber

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com