Patents

Literature

79results about How to "No change in quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

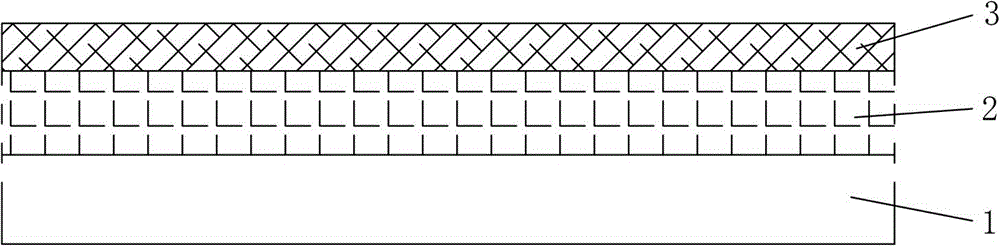

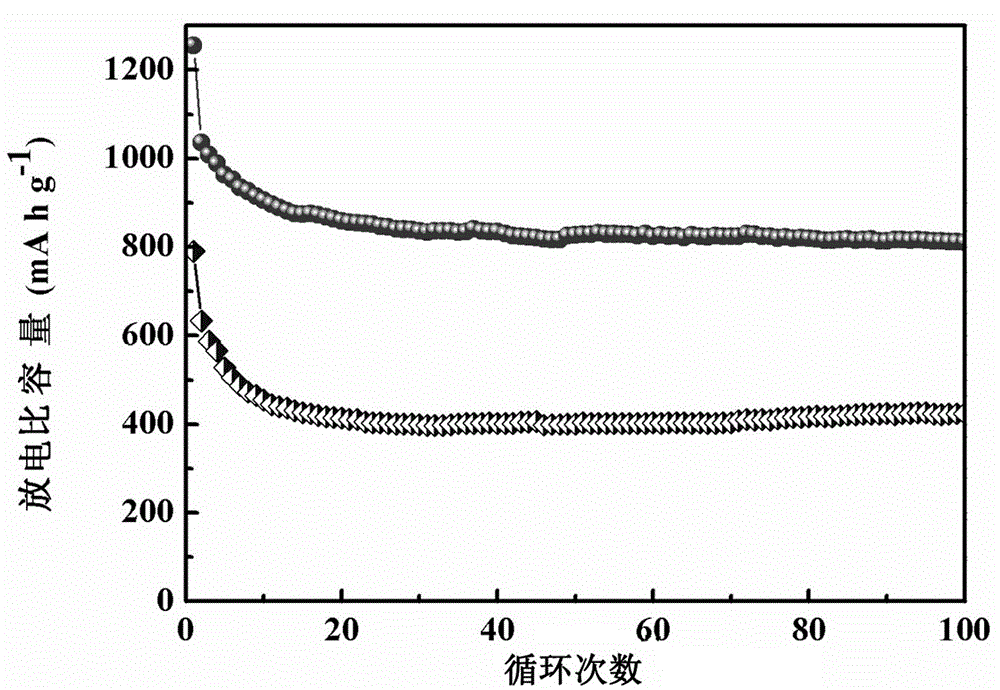

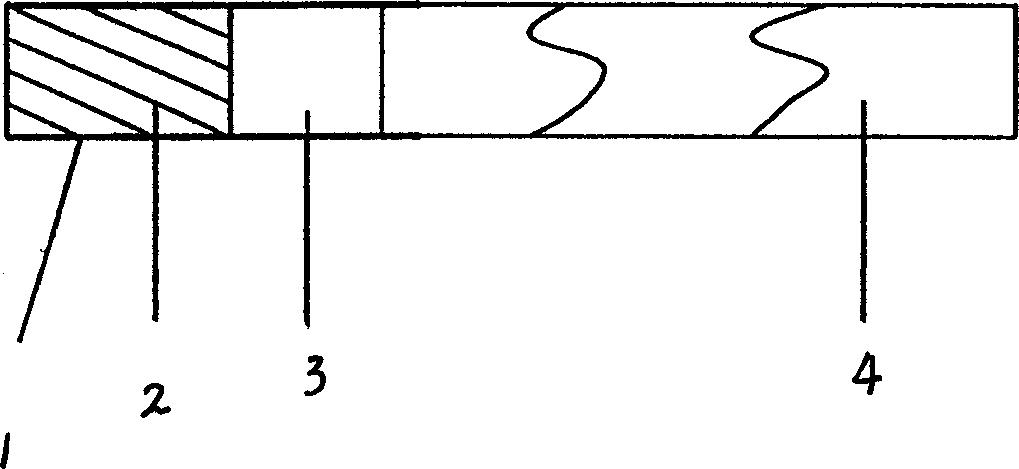

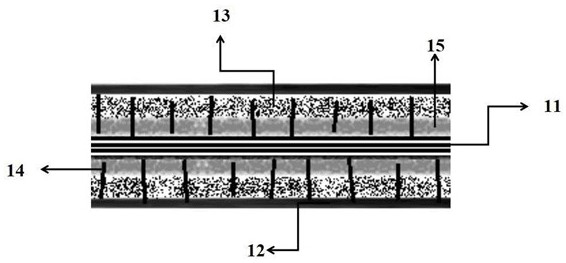

Lithium-sulfur battery positive electrode and preparation method thereof

InactiveCN104600251AIncrease capacityRaise the ratioElectrode collector coatingLi-accumulatorsLithium–sulfur batterySizing

The invention discloses a lithium-sulfur battery positive electrode and a preparation method thereof. The preparation method comprises the steps of uniformly mixing a positive active substance, a conducting agent and a bonding agent to obtain a mixture, smearing the mixture on a current collector as an active substance layer, and drying the current collector to obtain a positive substrate; uniformly mixing a conducting agent, a bonding agent and a dispersing agent to obtain a conducting sizing agent, smearing the conducting sizing agent on the outer surface of the positive substrate as a protective layer, and drying the positive substrate to obtain the lithium-sulfur battery positive electrode. The preparation method is simple and easy to operate, easy to control and suitable for industrialized production; in the prepared lithium-sulfur battery positive electrode, the protective layer plays a role of a conducting, sulfur intercepting and electrode stabilizing structure, so that the capacity, multiplying power and cycling stability of a lithium-sulfur battery can be effectively improved, the thickness of the protective layer is easy to control, and the influence on the sulfur content of the positive electrode can be reduced as far as possible.

Owner:CENT SOUTH UNIV

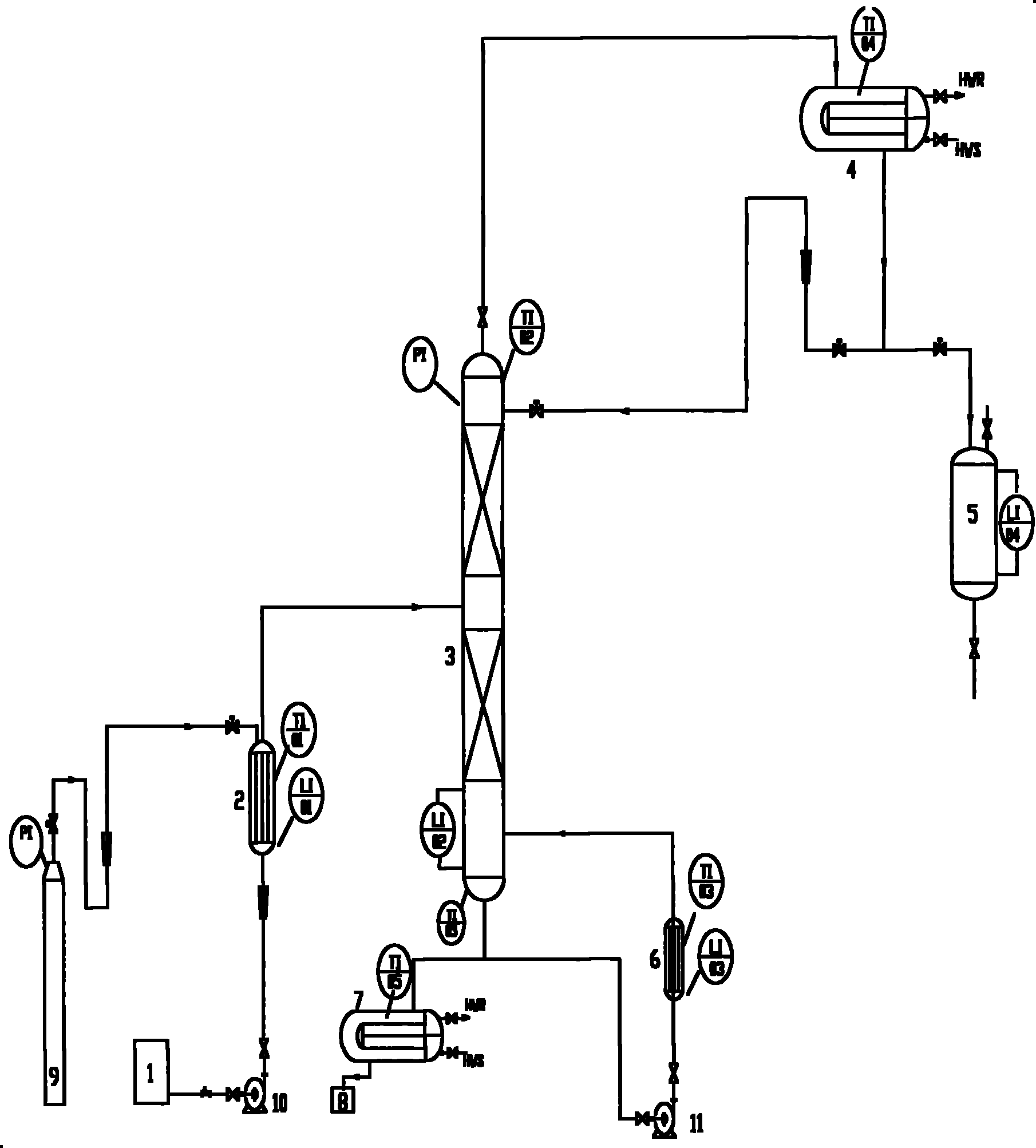

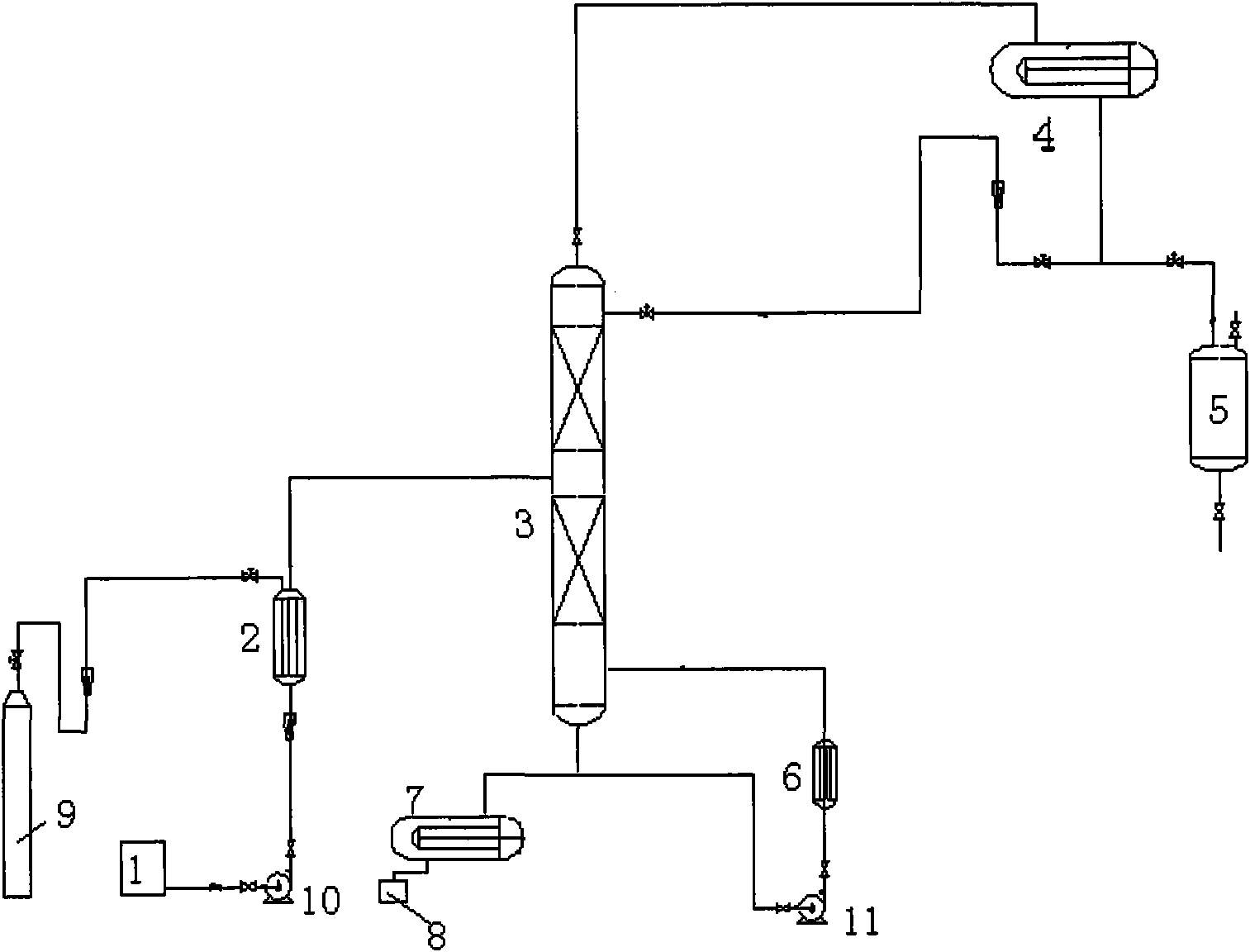

Method for preparing high-purity cyclopentadiene

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

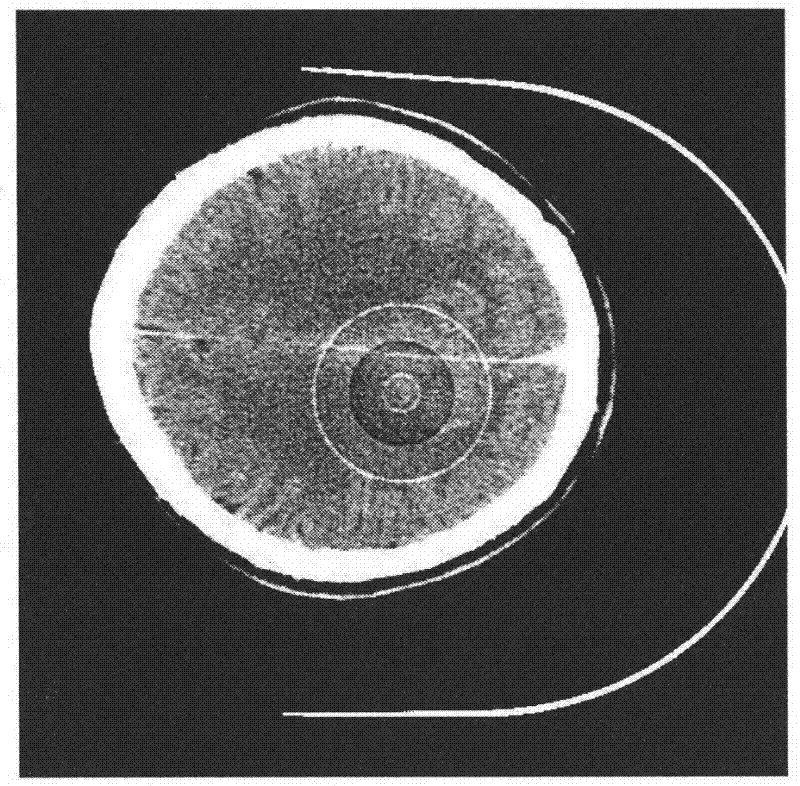

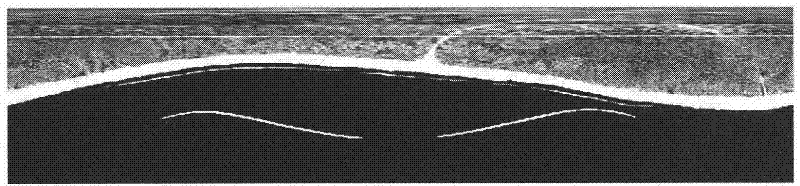

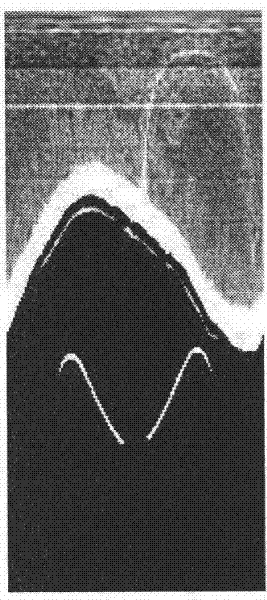

A Post-processing Method for Removing Ring Artifacts in CT Images

ActiveCN102274040ANo change in qualityNo resolution reductionComputerised tomographsTomographyImage resolutionRectangular coordinates

The invention relates to a post-processing method for removing ring artifacts in a CT (computed tomography) image, and the post-processing method comprises the following steps: converting the CT image with ring artifacts from a rectangular coordinate image to a polar coordinate image; extracting the ring image in polar coordinates with a comb filter in a polar coordinate image domain; converting the ring image extracted out of the polar coordinates to a ring image in rectangular coordinates; and subtracting the ring image in the rectangular coordinates from the original CT image with the ringartifacts to obtain a ring-free image. Through frequency domain comb filtering technology, the post-processing method provided by the invention subtracts the corresponding ring artifact image from the original image, without reduction of image resolution and change of quality of the original image. The post-processing method achieves the processing effect, and meanwhile the speed meets product requirements and has space for further optimization, so that the post-processing method is fully suitable for a CT machine with higher requirements for the reconstruction speed.

Owner:NEUSOFT MEDICAL SYST CO LTD

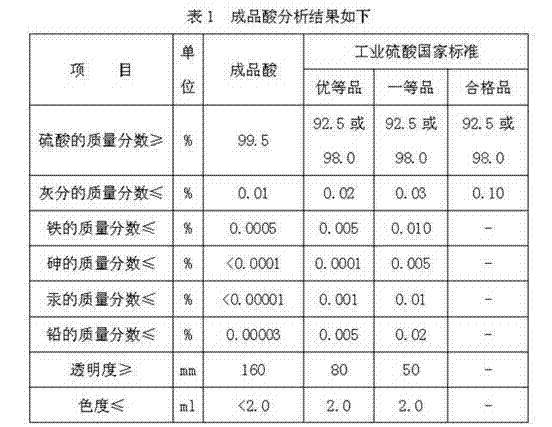

Method for decolorizing sulfuric acid by using hydrogen peroxide

InactiveCN102757021ANo change in qualityEliminate ChromaSulfur-trioxide/sulfuric-acidFlue gasEconomic benefits

The invention relates to a method for decolorizing sulfuric acid by using hydrogen peroxide. The method includes the following steps of injecting a hydrogen peroxide solution to the sulfuric acid in a closed sulfuric acid decolorizing tank at a speed of 6-18L / min*t with a volume ratio of the sulfuric acid to the hydrogen peroxide solution being 100: (6-22); and simultaneously continuously stirring a mixture at a speed of 8-15 revolutions per minute to obtain the finished sulfuric acid. By means of the hydrogen peroxide solution, the method is strong in oxidizability, good in selectivity, simple in process, convenient, flexible and capable of decolorizing tawny or black brown sulfuric acid; under acidic conditions, reduzate of the hydrogen peroxide is water, other metal ions can not added to the sulfuric acid finished product, and the quality of the sulfuric acid finished product can not be changed; therefore, the problem that the chromaticity and the transparency of the sulfuric acid finished product prepared by gypsum flue gases can't reach the standard can be eliminated, the quality of gypsum flue gas acid can reach the standard of high-class products of industrial concentrated sulfuric acid, the market competitiveness of the gypsum acid is improved, and economic benefits of enterprises are increased.

Owner:刘立文

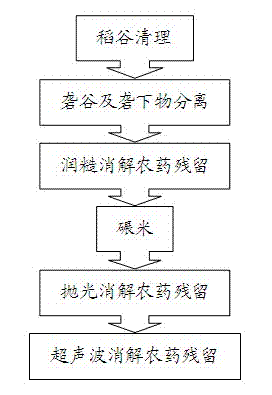

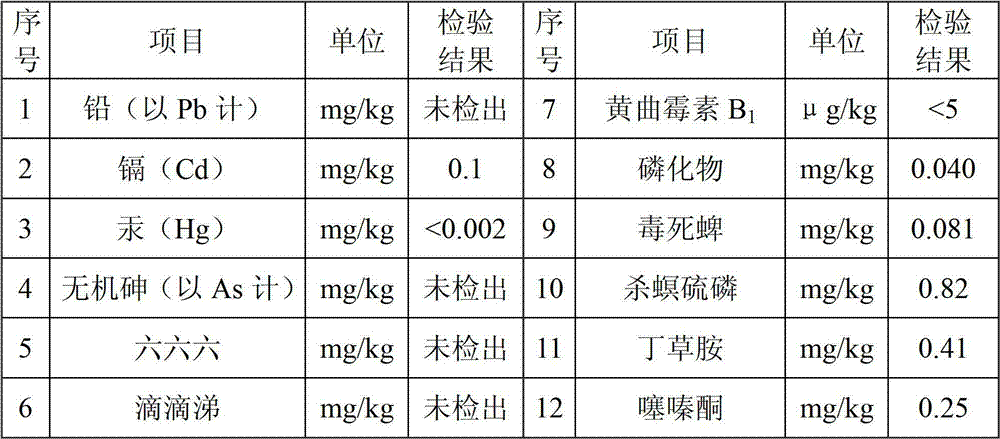

Paddy rice producing production technology for removing pesticide residue

ActiveCN102824934ASolve the problem of pesticide residuesChange qualityGrain huskingGrain polishingFlavorPesticide residue

The invention provides a paddy rice producing production technology for removing pesticide residue, and relates to the technical field of the processing and the producing of food, wherein the production technology comprises the following steps of: cleaning paddy, separating hull grains from hulled materials, removing the pesticide residue by means of coarseness humidifying, milling rice, removing the pesticide residue in a polishing way, and removing the pesticide residue by ultrasonic wave. The paddy rice producing production technology for removing the pesticide residue provided by the invention combines with the production of paddy rice producing, mainly aims at solving the problem that the paddy contains the pesticide residue, is scientific in technological process design, reasonable in technical method, and low in production cost, effectively and reliably removes the pesticide residue, can subsidiarily kill the toadstool in the paddy, can produce the paddy clearly, guarantees the quality safety of paddy-processed products, is free from secondary pollution of rice products in the process of processing and producing, can not change the original quality, nutrition and special flavor of the paddy, is particularly suitable for preparing the products which are higher in nutrition value and economic value such as germ-remaining rice, the clean rice and the like besides the common rice, and is further good for reducing the pesticide residue of byproducts prepared by comprehensive utilization.

Owner:DANYANG JIAHE RICE

Green nutritive rice with bamboo fragrance and its preparing method

InactiveCN1656921ASimple processAvoid infringementFood preservationUnknown materialsAdditive ingredientNutrient solution

Owner:潘士平

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

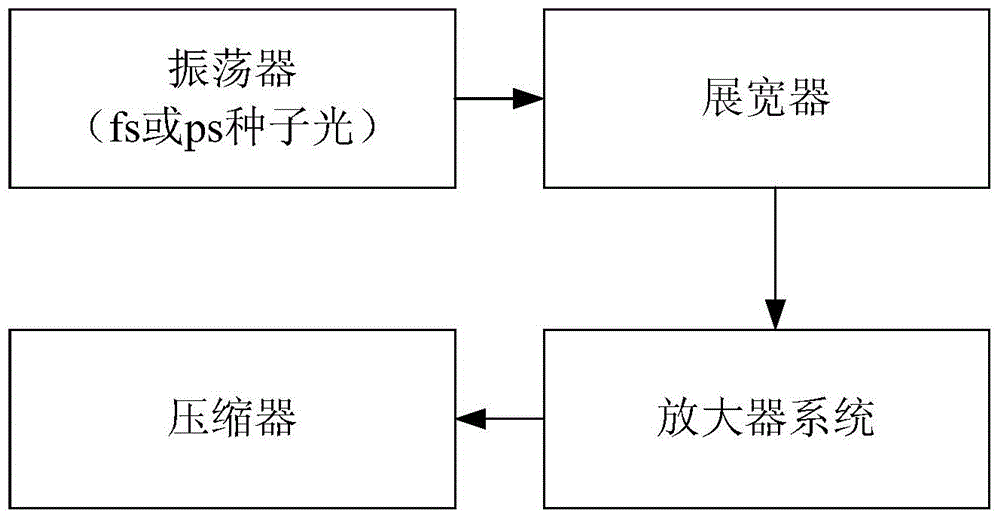

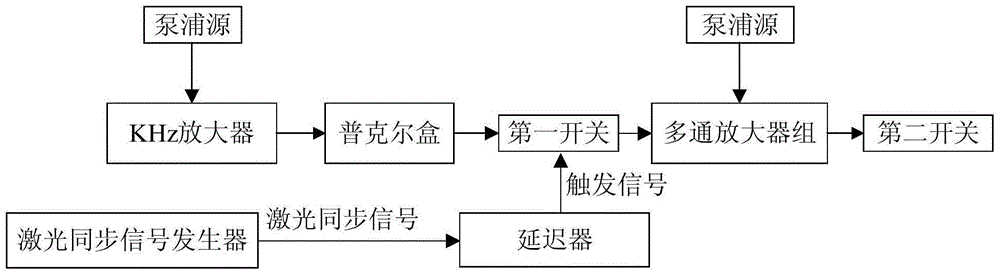

Laser pulse switch apparatus and control method therefor

ActiveCN105186279AAchieving single-shot lasingDoes not change the thermal effectLaser detailsAudio power amplifierLight beam

The invention discloses a laser pulse switch apparatus and a control method therefor. According to the laser pulse switch apparatus and the control method therefor, a first switch and a second switch are arranged behind a pockels cell and a multipass amplifier set respectively to form a two-switch single-shot system, a single pulse trigger signal is generated by inputting a laser synchronous signal into a delayer, and the first switch is controlled to be on once only, so that single-shot emission of laser pulses is realized; the first switch realizes that one laser pulse is quickly selected for passing, and the second switch takes effect of blocking light; the aperture and speed of the switch are realized by two switches respectively, so that the requirements on the aperture of the first quick switch and the speed of the second large-aperture switch are reduced; any change is not performed on a pump light path, so that the heat effect, the beam quality and the like of pump laser pulses are not changed and it is ensured that the quality of the whole laser device is not changed; and when a shooting range does not need the laser pulses subsequently, it can be ensured that the energy of the high-energy laser pulses in the multipass amplifier set is not accumulated for causing the problems of the heat effect and the like.

Owner:PEKING UNIV

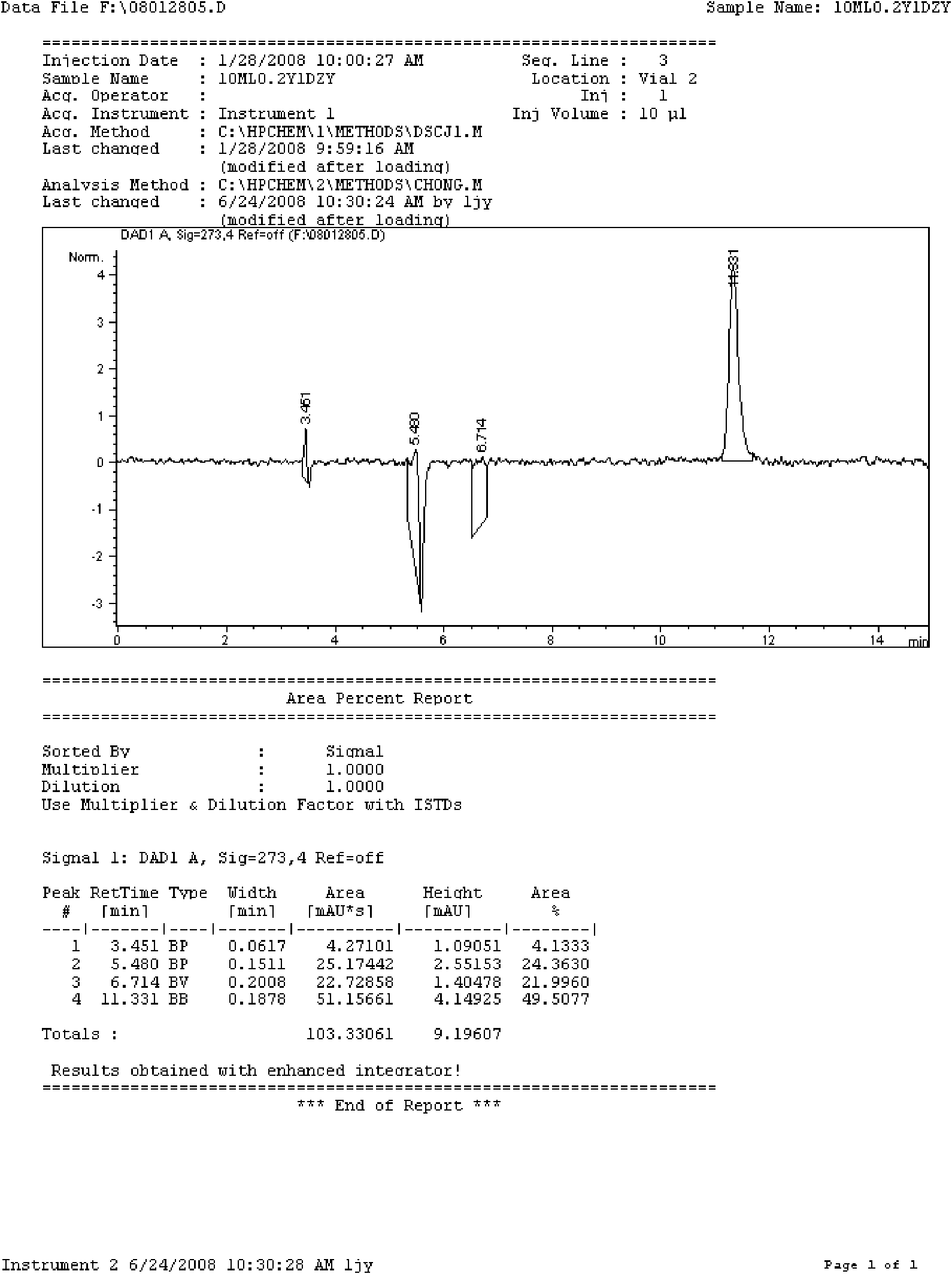

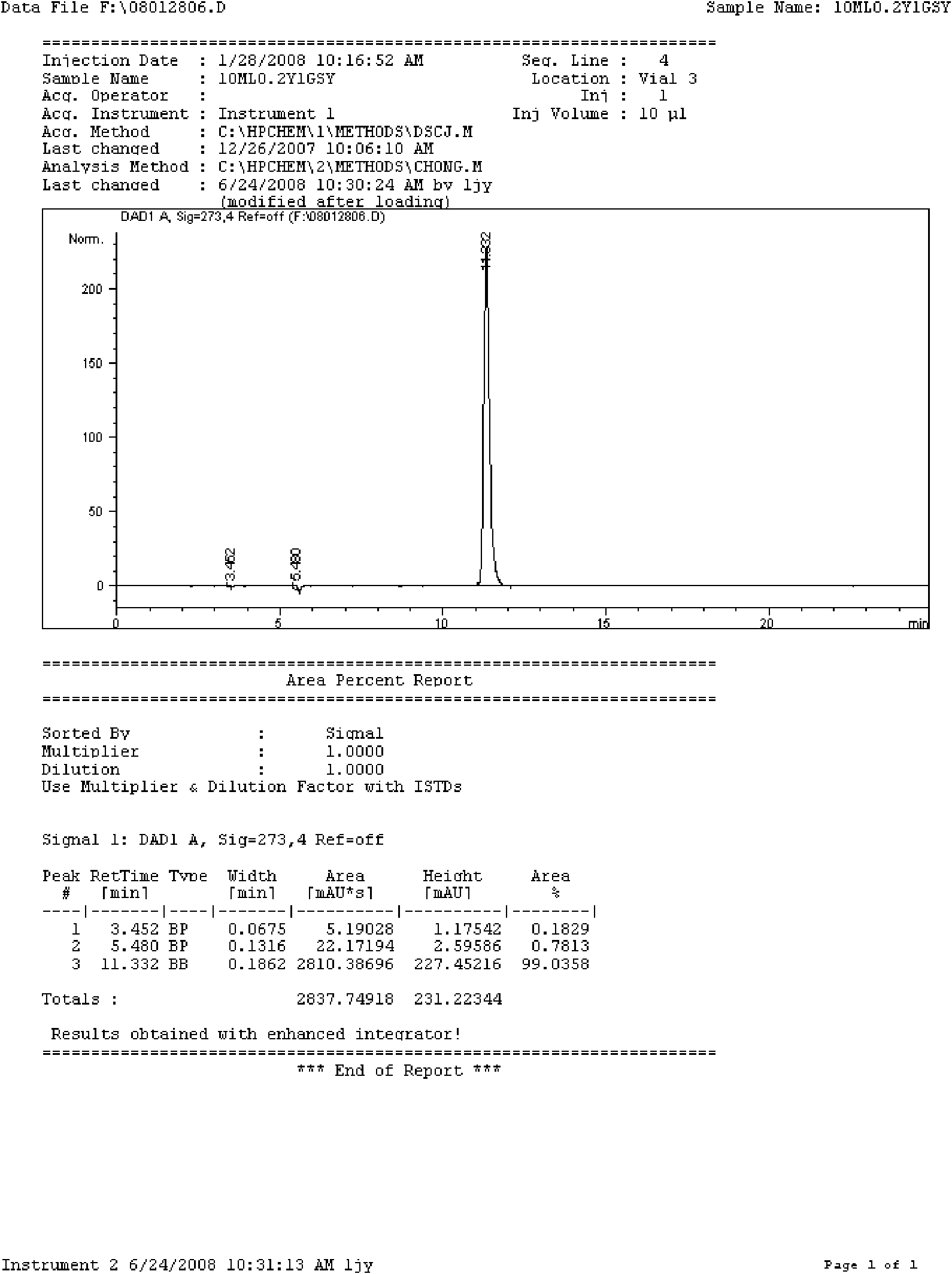

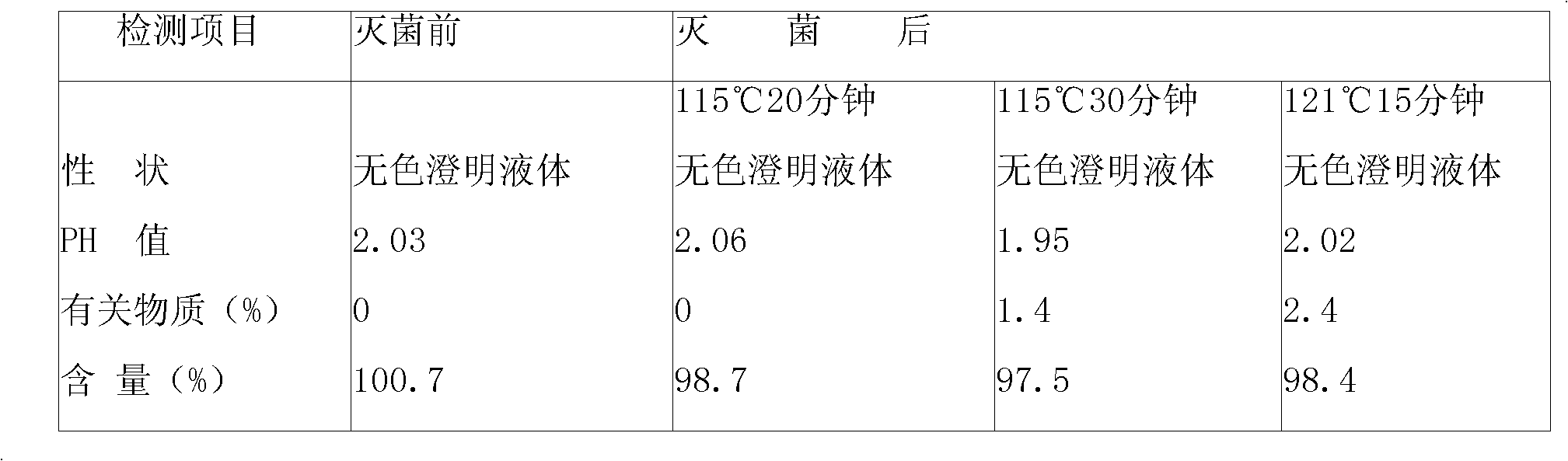

Doxofylline-contained liquid injection, preparation method and quality control method thereof

ActiveCN101569603AIncrease concentrationNot easy to precipitateComponent separationPharmaceutical delivery mechanismHigh concentrationDoxofylline

The invention relates to a doxofylline-containing liquid injection used for treating bronchiectasis, and provides the doxofylline with higher concentration. The injection comprises doxofylline, a water solvent, and a pH value regulating agent. The injection comprises the following components by weight percentage: 1 to 4 percent of the doxofylline, and 0.01 to 5 percent of the pH value regulating agent. The injection enriches specifications of the prior doxofylline injection, and brings convenience to the clinical application. The invention also provides a preparation method and a quality control method for the doxofylline liquid injection. Relevant materials in the doxofylline injection can be determined by an HPLC method to improve the product controllability.

Owner:HEILONGJIANG FUHE HUAXING PHARMA GROUP

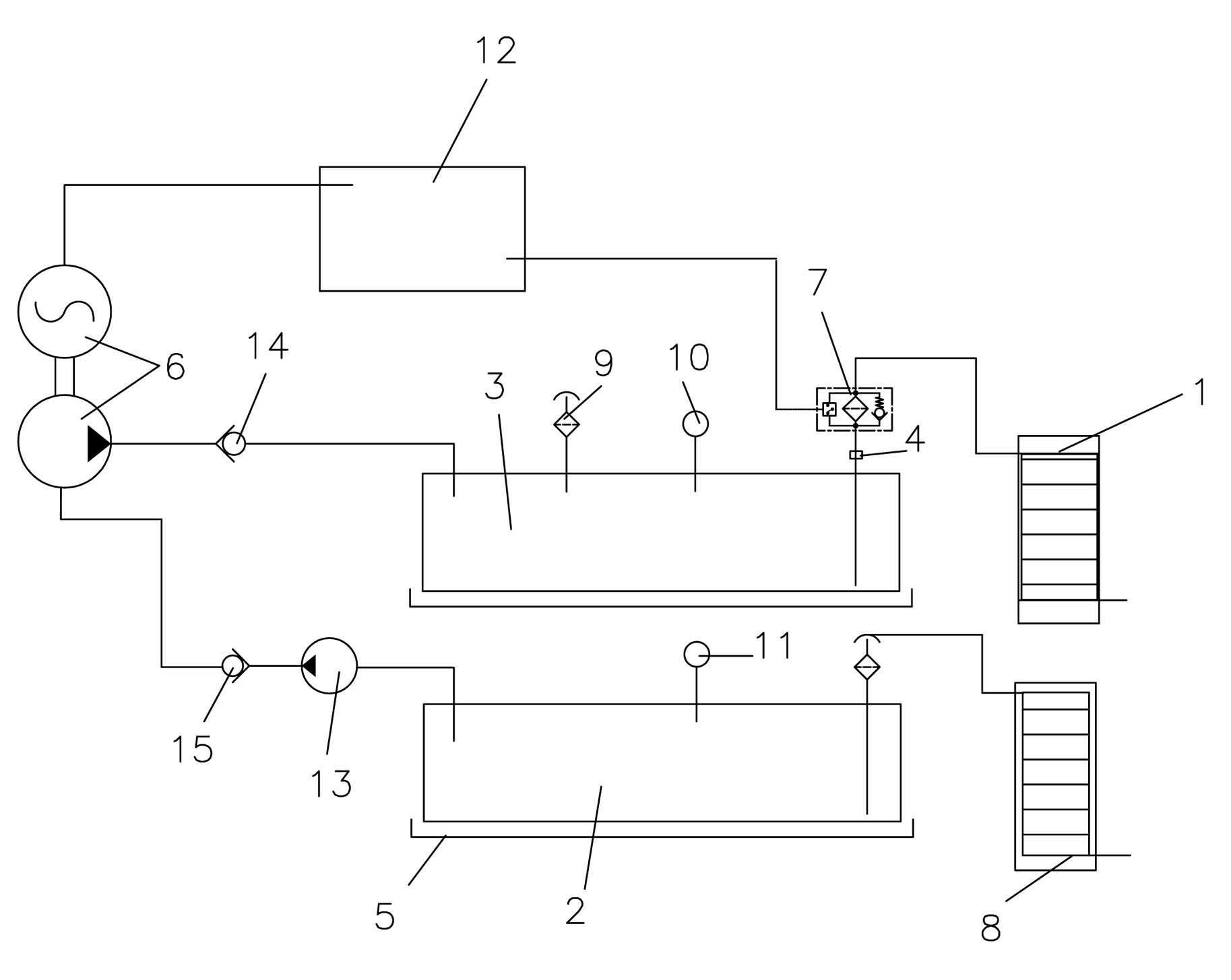

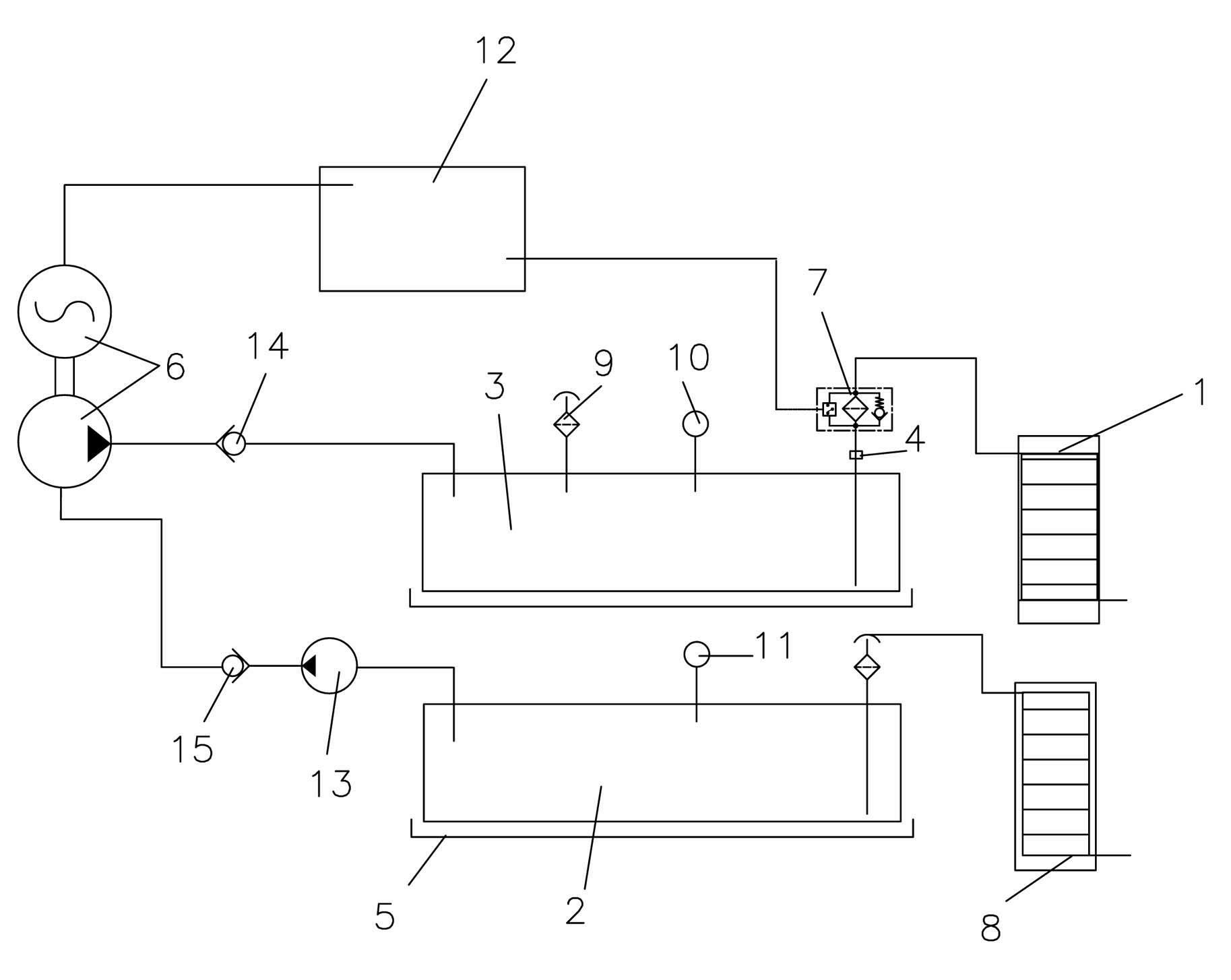

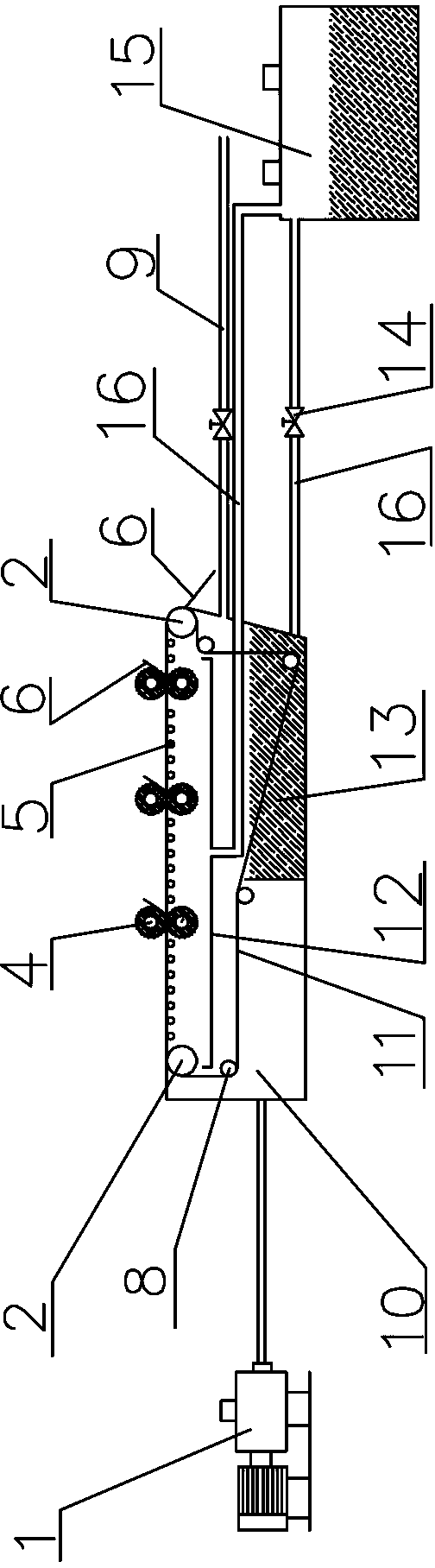

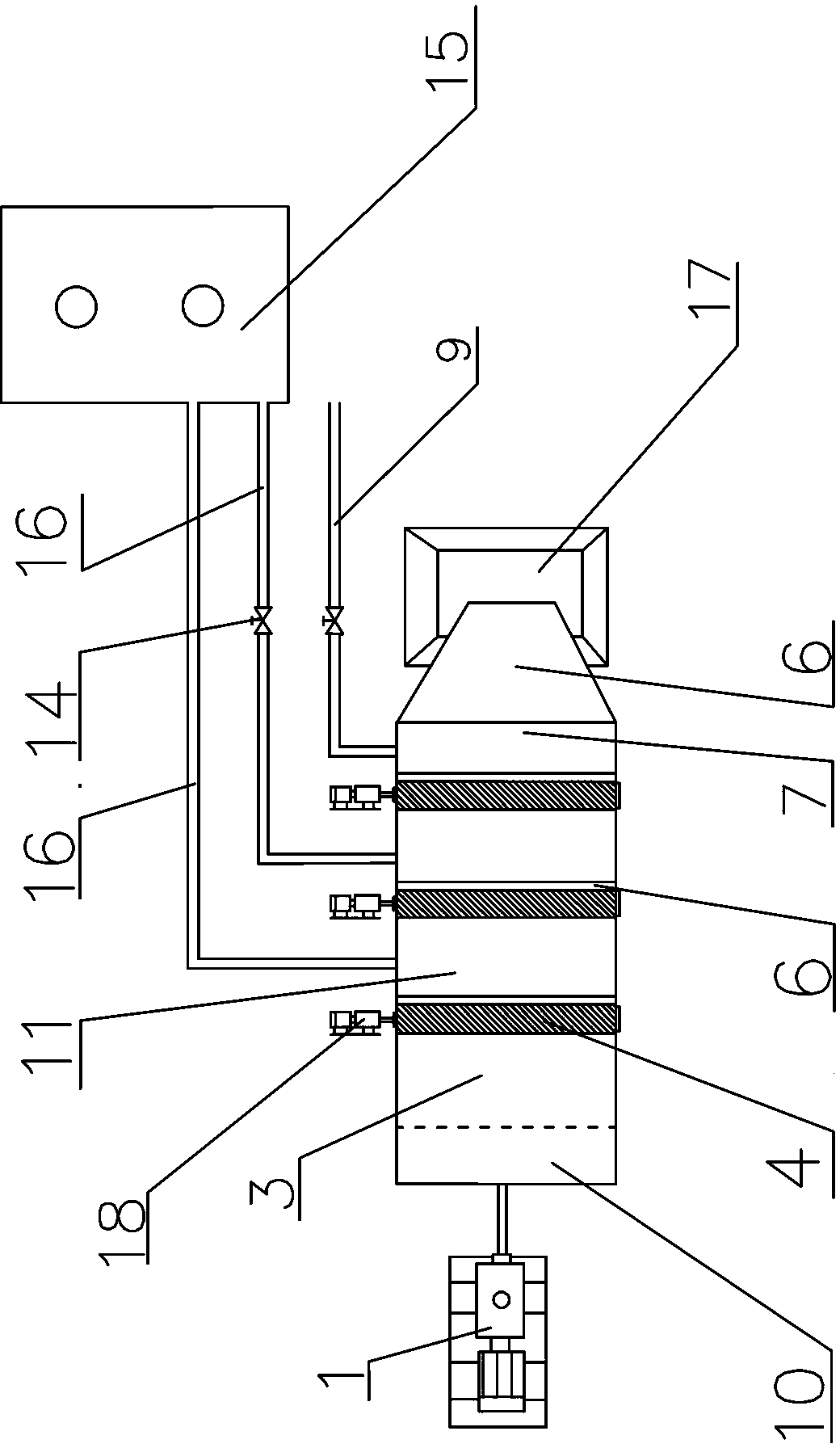

Vacuum-pressure oil changing device

InactiveCN102359711AGuarantee the quality of lubricating oilExtended service lifeGear lubrication/coolingConduits/junctionsGas pipelineVacuum pressure

The invention relates to an oil changing device, in particular to a vacuum-pressure oil changing device, which consists of a new oil tank and a wasted lubricating oil tank. The new oil tank and the wasted lubricating oil tank are respectively connected with an air compressor via gas pipelines, the air compressor is electrically connected with a control plate, a vacuum generator is disposed on the pipeline for connecting the wasted lubricating oil tank with the air compressor, an oil outlet of the new oil tank is connected with an oil injection pipe, and an oil inlet of the wasted lubricating oil tank is connected with an oil drainage pipe. The vacuum-pressure oil changing device has the advantages that a vacuum or pressure environment is created by the aid of an air source, pipelines are connected with the oil changing device and a gearbox to form an integral pressure pipe, liquid flows so as to achieve purposes of oil adding and oil changing, namely, vacuum is realized by the aid of air compression, and a pressure increasing or pressure relieving principle is set. Accordingly, lubricating oil can be changed by personnel on a tower base.

Owner:沈阳瑞祥风能设备有限公司

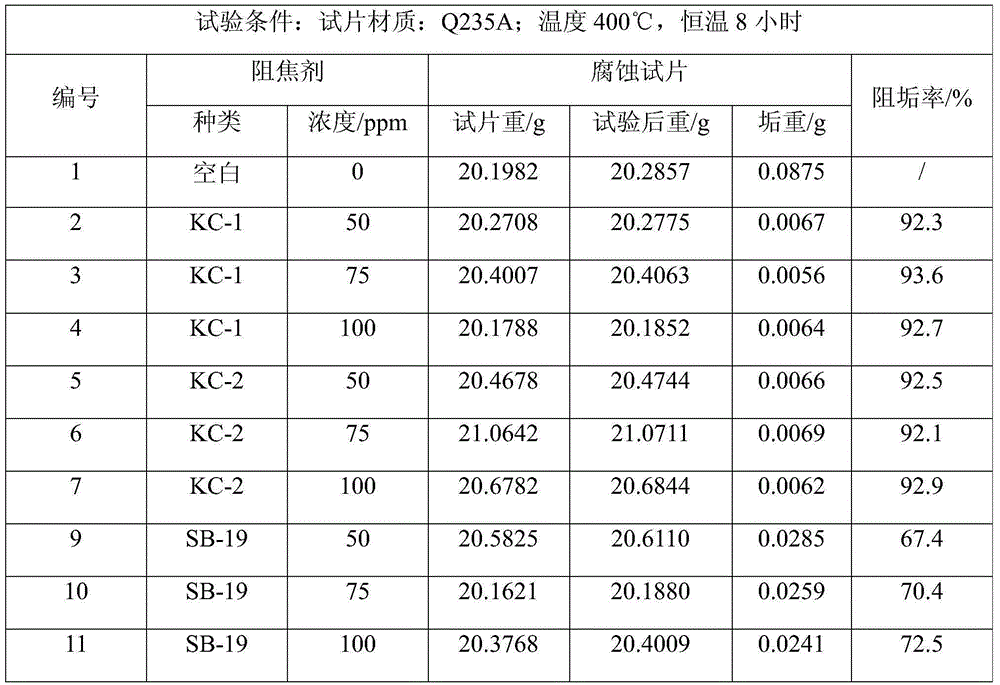

Anti-coking agent for delaying coking and preparation method of anti-coking agent

InactiveCN106479555AFacilitates homolysisReduce generationThermal non-catalytic crackingPentaerythritolAntioxidant

The invention discloses an anti-coking agent for delaying coking and belongs to the field of petrochemical engineering. The anti-coking agent for delaying coking is prepared from components in percentage by mass as follows: 10%-30% of a thermal cracking accelerative activator, 20%-40% of a free radical chain reaction inhibitor, 1%-15% of an anti-scorching agent, 1%-15% of an antioxidant and the balance of a solvent, wherein the thermal cracking accelerative activator is block polyether, the free radical chain reaction inhibitor is pentaerythritol ether, and the anti-scorching agent is a sulfonamide agent. The anti-coking agent for delaying coking can effectively prevent and inhibit cokes from settling in a furnace tube of a heating furnace and can inhibit a free radical chain reaction, reduce production of dry gas, prevent aromatic hydrocarbon from condensation, reduce coke production, improve the thermal cracking reaction activity and improve the selectivity of a coking reaction; coking and scale depositing caused by high-temperature oxidation of raw materials in the furnace tube can be prevented, the scale inhibiting ratio reaches 92% or above, and the device running cycle is prolonged by one time or more.

Owner:JIANGSU KECHUANG PETROCHEM

Environment protection decomposition technique for recycling plastic-aluminum, plastic-aluminum paper packing material

The invention relates to an environment-friend dissociation technique for recovering plastic-aluminum and plastic-aluminum paper package materials. The invention comprises a, mixing the materials of following mass ratio into a mixture organic solvent which contains 60-70% organic alcohol, 10-15% organic ester, 5-8% organic hydrocarbon, 10-15% organic ether and 1-3% organic phenol, b, immerging recovered plastic-aluminum and plastic-aluminum paper package materials into the mixture organic solvent which can submerge the recovered plastic-aluminum and plastic-aluminum paper package materials, c, immerging the recovered plastic-aluminum and plastic-aluminum paper package materials for 6-12h, while aluminum and plastic, or aluminum, plastic and paper can automatically separate, taking out aluminum, plastic and paper, classifying and packing. The invention has the advantages of safe operation, non environment pollution, low cost and high recovery rate.

Owner:林峰

Method and device for removing bromate in water

InactiveCN101585574ASimple processingDoes not change the decompositionWater/sewage treatment by irradiationWater contaminantsChemistryRaw water

The invention relates to a method and a device for removing the bromate in water, which is characterized by radiating the water by ultraviolet with the wavelength between 150-250 nm, and is particularly suitable for the natural water production that the water is radiated by the ultraviolet with the wavelength between 150-240 nm and then the bromate in water is measured not more than 0.01 mg / L. Compared with the prior art, the method is more simple, adds an ultraviolet radiation technology before filling the natural mineral water, restrains the bromate content in water, maintains the ozone residual effect in filling, does not change the raw water quality such as pH value and needs any processing medicament.

Owner:余建军

Plastic moisture removing foam eliminating mother particle

The present invention relates to a kind of plastic exsiccation defoaming mother granules for plastic application industry. Said mother granule composition includes (by wt%) 60-80% of calcium oxide, 10-20% of ethylene-vinyl acetate copolymer and 10-20% of amorphous olefin-copolymer dispersing agent. It can be used for exsiccation and defoaming in plastic product production.

Owner:黄定敏

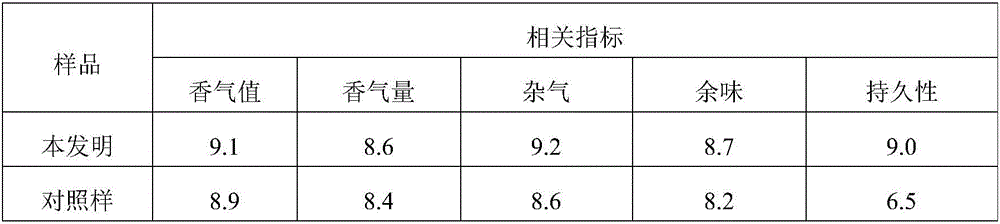

Composite tobacco essence, preparing method and application thereof

InactiveCN106072750AVolatile fastImprove stabilityTobacco preparationTobacco treatmentChemistrySucrose

The invention belongs to the technical field of application of composite tobacco essence in cigarette field. The invention discloses composite tobacco essence prepared from a wall material, a core material and an emulsifying agent, the wall material is a mixture of modified starch and Arabic gum, the core material is a mixture of trilobatin, geraniol and geranyl glycoside, and the emulsifying agent is sucrose fatty acid ester or distilled monostearin. The invention further discloses a preparing method of the composite tobacco essence and application to cigarette aroma enhancement. The composite tobacco essence can keep stability and durability of cigarette aroma and uniformity of aroma release along with time.

Owner:CHINA TOBACCO YUNNAN IND

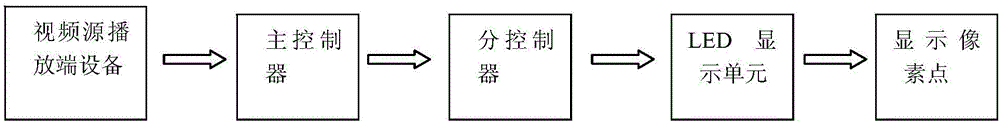

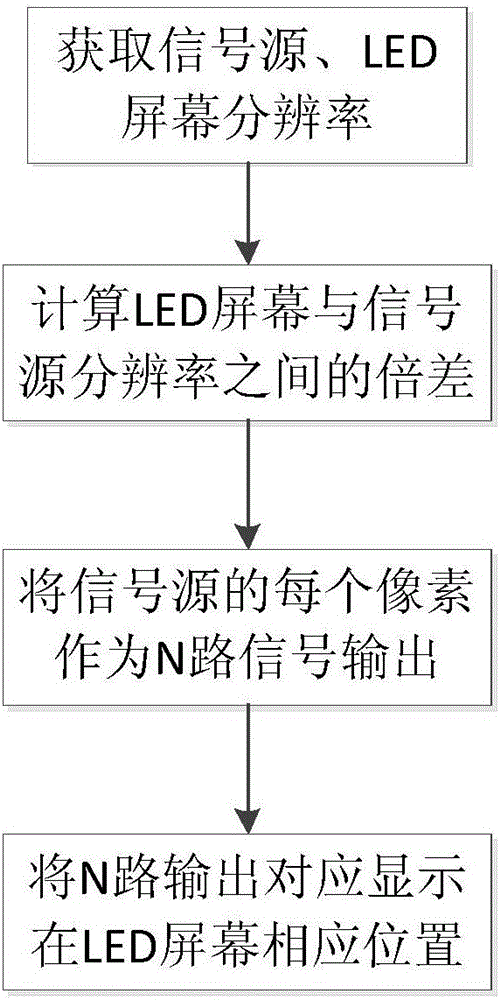

LED screen one-screen-multiple-mode display method and system

The invention provides an LED screen one-screen-multiple-mode display method. The method includes: acquiring resolution a signal source and an LED screen; according to the resolution of the signal source and the LED screen, acquiring multiple N between the two, wherein N is an integer; taking pixel points of the signal source as N-way signals to be output, and displaying at N display positions corresponding to the LED screen. By the method, one pixel point can correspond to multiple screen LED display lamp points, light emitting area of each LED display lamp point is increased, pictures are softer, and mosaic and moire phenomena of a high-density display screen under a camera lens can be avoided effectively. Investment on front-end equipment like a video processor and a screen system sending card is effectively reduced, and video material making difficulty is lowered.

Owner:长江龙新媒体有限公司

Cigarette

A cigarette features that an empty segemtn is arranged between tip filter and tobacco shreds segment for decreasing the consumption of tobacco, tar and nicotin, that is, decreasing the damage of cigarette to human body.

Owner:CHINA TOBACCO GUANGDONG IND

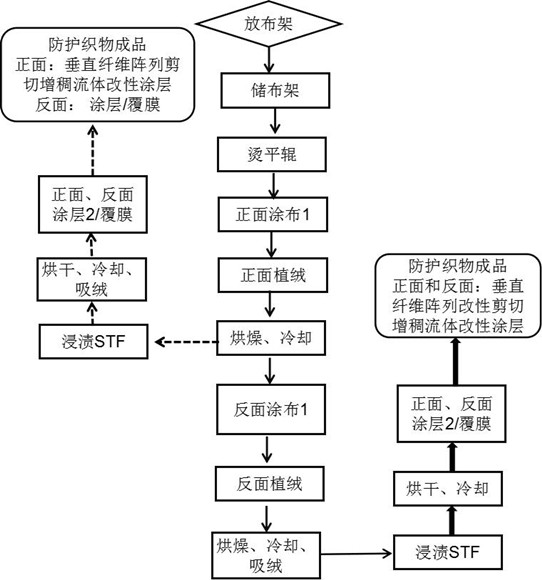

Stab-resistant bulletproof fabric based on shear thickening fluid and preparation method of stab-resistant bulletproof fabric

The invention discloses a stab-resistant bulletproof fabric based on shear thickening fluid and a preparation method of the stab-resistant bulletproof fabric. The stab-resistant bulletproof fabric is formed by compounding four parts, namely base cloth, a functional fiber powder modified coating agent, the shear thickening fluid and short fiber fluff. According to the invention, the flocked fabric is immersed in the shear thickening fluid, the interior and periphery of the vertically arranged functional short fibers are wrapped by the shear thickening fluid, and after drying, cooling and down absorption, secondary coating or film covering is carried out to obtain the finished fabric. According to the invention, the vertical fiber array short fluff layer is used as an accommodating and supporting area, and the functional fiber powder modified coatings on the upper and lower sides and the seals on the two sides are combined, so that a shear thickening fluid area is more stable; the short fibers can play a role of a pin in the coating to enhance the acting force between the surface of the fabric and the coating, so that the wear resistance and other mechanical properties of the coated fabric are improved.

Owner:湖北金龙新材料有限公司 +1

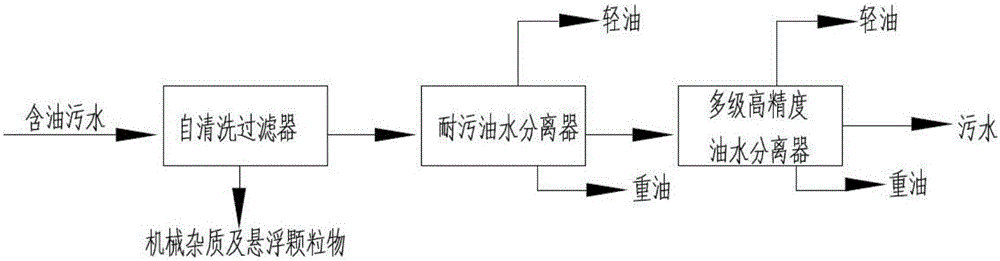

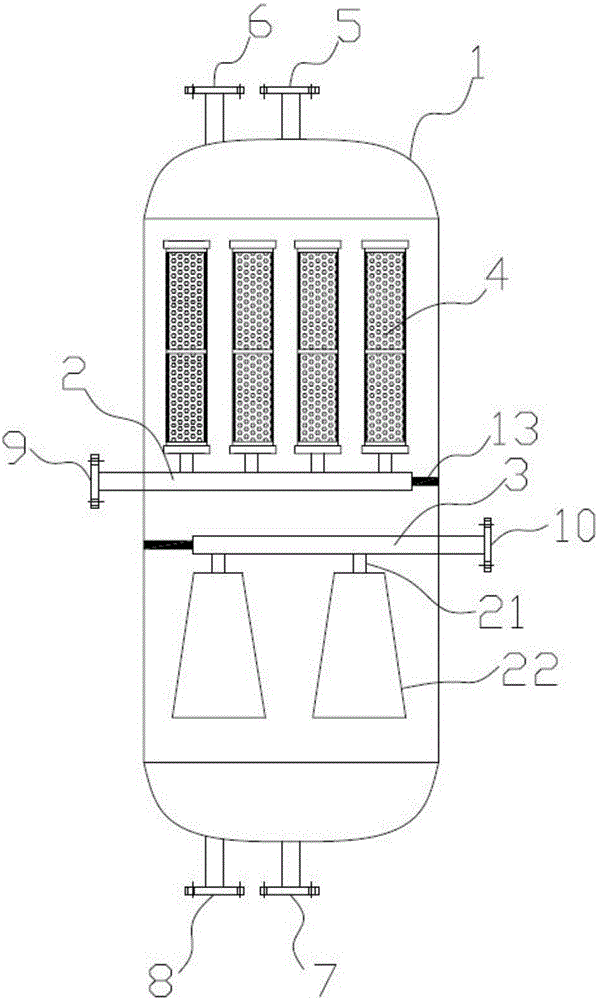

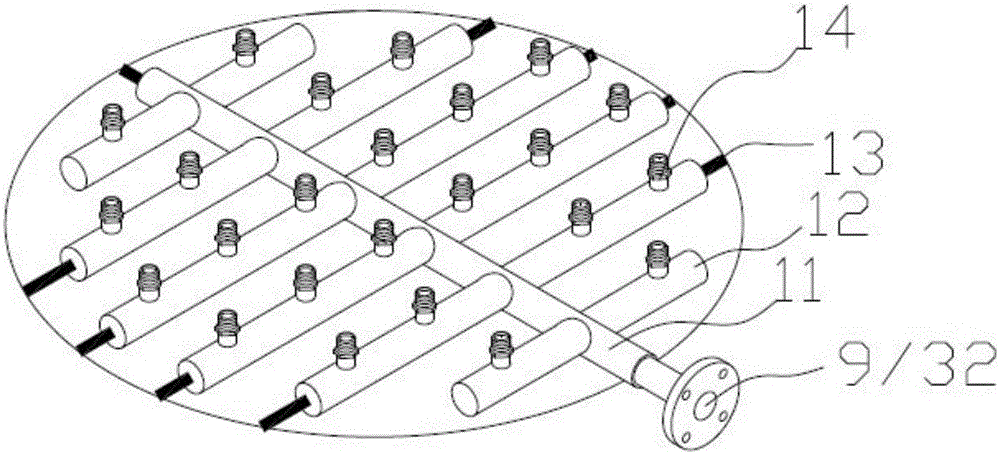

United multistage oil-water separation process

ActiveCN106045088AEasy to separateNo secondary pollutantsFatty/oily/floating substances removal devicesTreatment involving filtrationEconomic benefitsSewage

The invention discloses a united multistage oil-water separation process. The united multistage oil-water separation process comprises the specific steps of 1 pretreatment, 2 primary separation and 3 secondary separation, wherein united multistage treatment is conducted on oily sewage by serially connecting a self-cleaning filter, a stain-resisting oil-water separator and a multistage high-precision oil-water separator, oil in oily sewage, especially dispersed oil, emulsified oil and the like, are rapidly separated in a pure physical mode, and oil recycling is achieved. The united multistage oil-water separation process comprises simple steps, is low in operating cost, good in operability and good in separation accuracy, can greatly improve the oil-water separation efficiency and effect and achieve recycling of various types of oil, can also produce remarkable economic benefits while achieving the environmental protection purpose and is suitable for industrialized application.

Owner:湖州深净环境科技有限公司

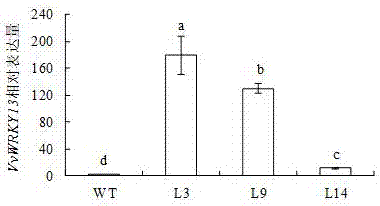

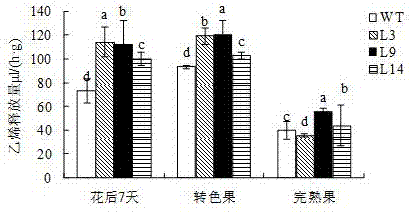

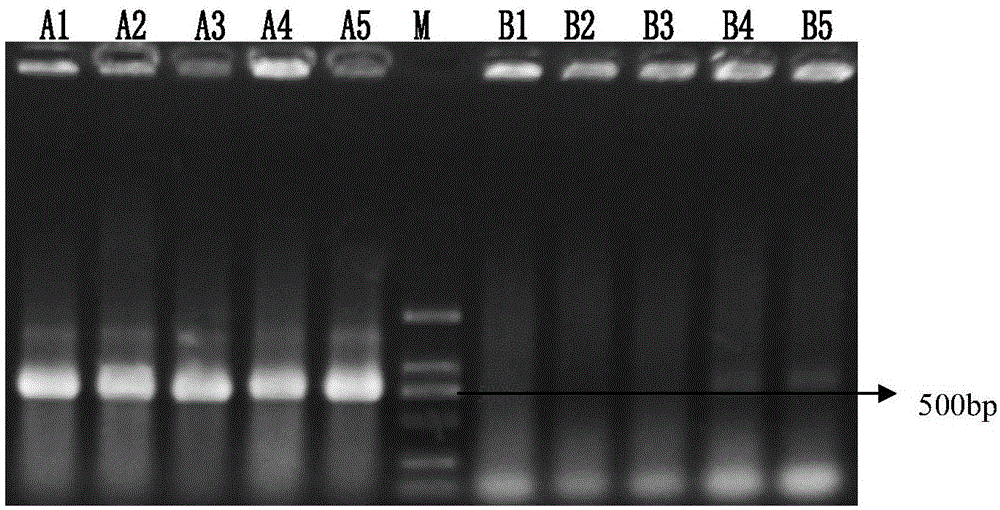

Application of grape earliness gene VvWRKY13 in regulation and control of biosynthesis of ethylene in plants

ActiveCN107142275ASolve production problems that are difficult to maintain fruit qualityGenerate noVector-based foreign material introductionAngiosperms/flowering plantsEnzyme GeneEthylene biosynthesis

The invention provides application of a grape earliness gene VvWRKY13 in regulation and control of biosynthesis of ethylene in plants. The application comprises the steps of carrying out leaf dish infestation on an EHA105 agrobacterium tumefaciens strain carrying recombinant plasmids so as to obtain an over-expressed tomato material of VvWRKY13, and carrying out repeated selfing so as to obtain at least three independent pure transgenic lines; and detecting the ethylene generation amounts of transgenic tomato lines in different growth and development periods, the expression amount of key enzyme genes for synthesis of ethylene, relevant phenotypic characters of ethylene, lengths of transgenic fruits in different growth cycles and relevant quality indexes of mature fruits. An experiment result proves that by applying VvWRKY13 to the regulation and control of the key enzyme genes of ethylene and the biosynthesis of ethylene, the expansion period of young fruits of transgenic tomatoes is shortened, the early maturing of the fruits is promoted, the quality functions of the mature fruits are not changed, and the theoretical basis and the experimental foundation are provided for the early-maturing breeding of berry fruits such as the tomatoes.

Owner:QINGDAO AGRI UNIV

Grain dry segmented steam explosion pretreatment method for fermenting liquor by using pure grain in solid state

InactiveCN102115702AGuaranteed puffed floweringSolve the problems of low production efficiency, high energy consumption and loss of fermentable sugarAlcoholic beverage preparationPressure risePretreatment method

The invention discloses a grain dry segmented steam explosion pretreatment method for fermenting liquor by using pure grain in solid state, which belongs to the field of liquor fermentation. The method comprises the following basic steps of: pre-balancing the moisture content of the grain; putting the grain into a two-way air inlet quick-opening steam explosion reaction tank separately or together; introducing superheated steam and high-temperature air until a certain pressure is achieved; and maintaining for a certain period of time, and quickly opening a ball valve at the bottom of the steam explosion tank after the pressure rises to a peak valve to explode a material into a normal-pressure collecting tank. In the grain treated by the method, the cell tissue is completely damaged, the curing degree of starch is high, and the utilization ratio is high in a fermenting process; meanwhile the grain is sterilized, so that bacteria are removed. By adopting the method, the grain treatment energy consumption in a liquor plant can be lowered, the liquor yield and the superior product rate are increased, and the comprehensive benefit is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

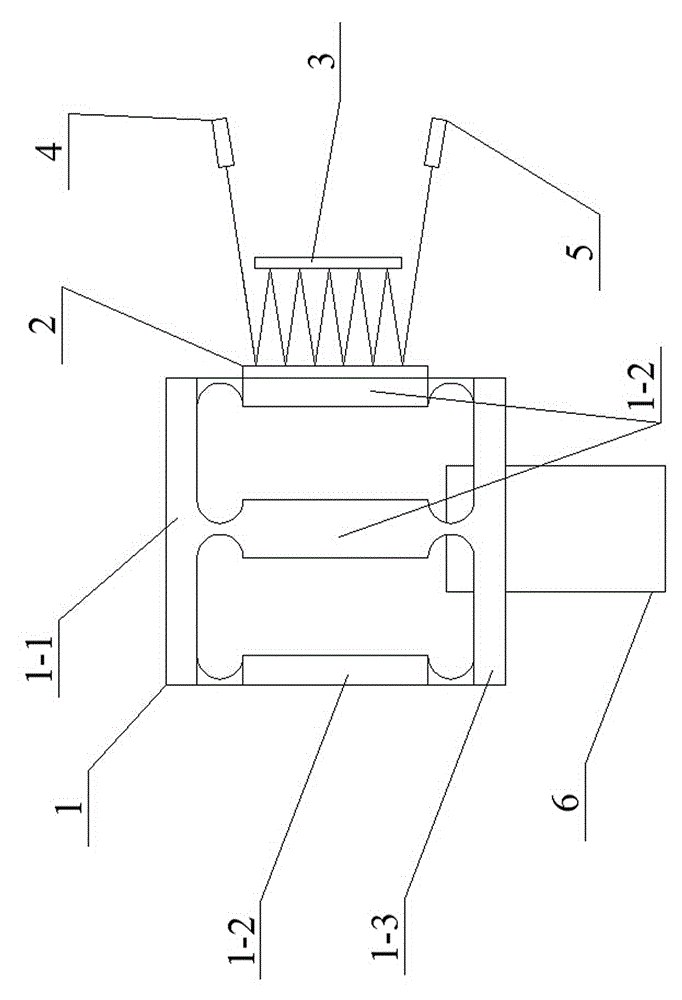

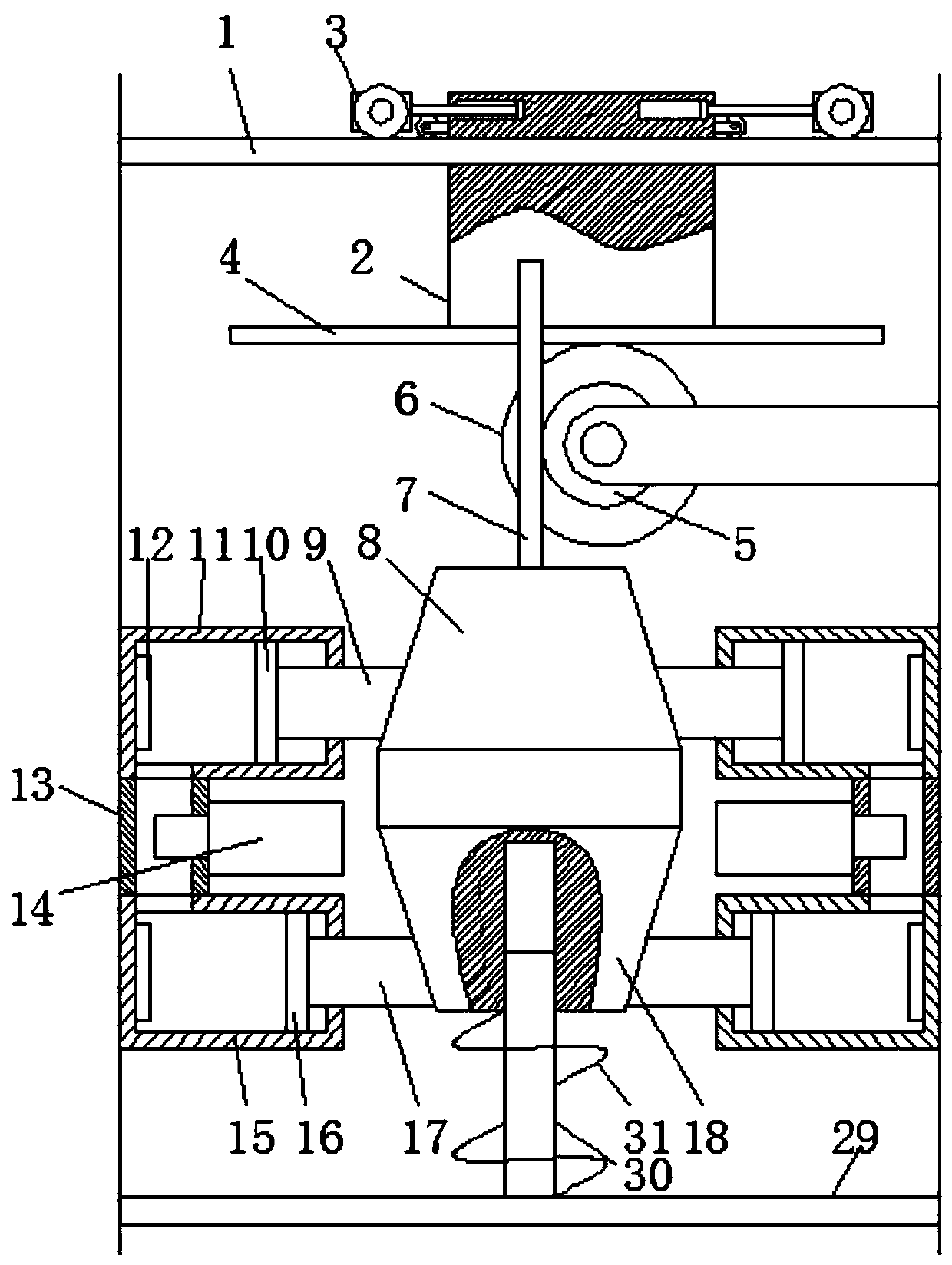

Two-dimensional force measuring main shaft fixture based on phase-sensitive detector (PSD) principle

ActiveCN104907889ASmall sizeGood monochromaticityMeasurement/indication equipmentsPlane mirrorEngineering

The invention discloses a two-dimensional force measuring main shaft fixture based on a phase-sensitive detector (PSD) principle, which belongs to the technical field of precision measurement, wherein a flexible main shaft seat comprises an upper fixed plate which is connected with a lower fixed shaft plate through a plurality of flexible stand columns, when a detected shaft is forced by external force, the detected shaft can drive a fixed shaft plate to swing because the flexible stand columns are low in rigid value, and also can drive a follow-up reflective plane mirror which is arranged on the right end surface of a flexible stand column which is arranged on the right of the flexible main shaft seat to swing simultaneously, reflective surfaces of the follow-up reflective plane mirror and a fixed reflective plane mirror are parallel and opposite to each other, laser which is launched from a semiconductor laser is sent into a photosensitive window of a one-dimensional PSD position sensor after being reflected through the reflective planes of the follow-up reflective plane mirror and the fixed reflective plane mirror for many times. The two-dimensional force measuring main shaft fixture based on the PSD principle converts force to micro displacement by utilizing a flexible hinge main shaft seat, detects force of a main shaft by further utilizing a magnifying principle of light lever and adopting PSD to measure positions, and achieves force feedback.

Owner:HARBIN INST OF TECH

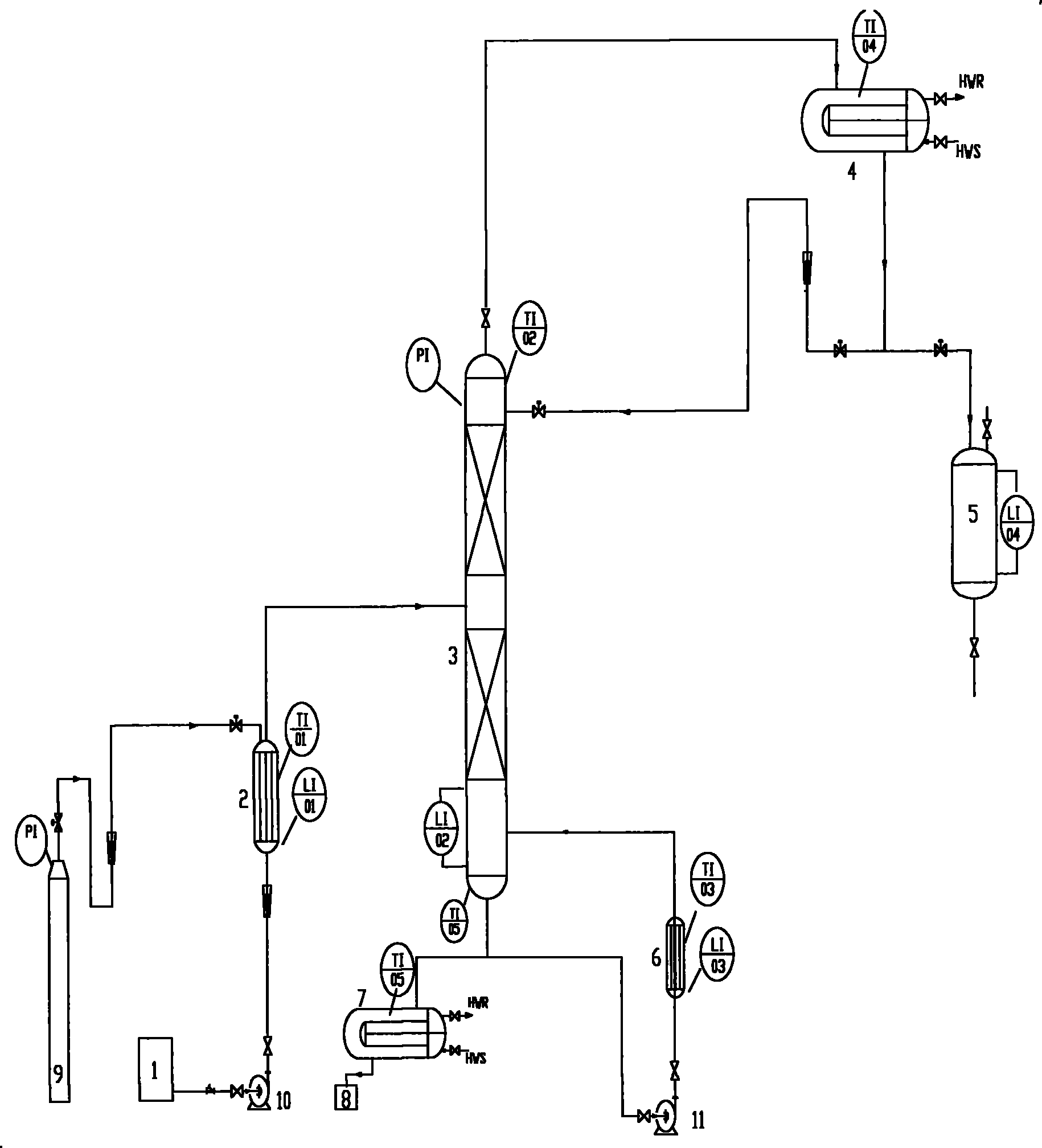

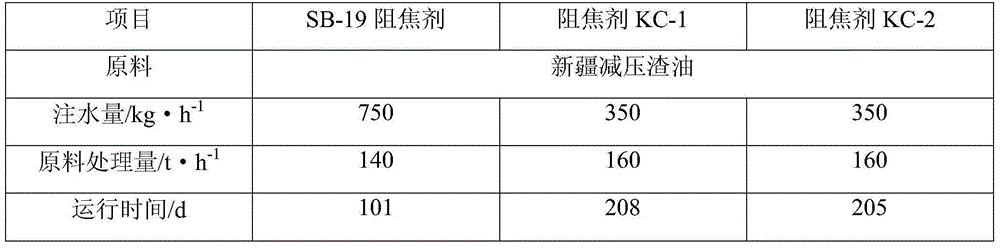

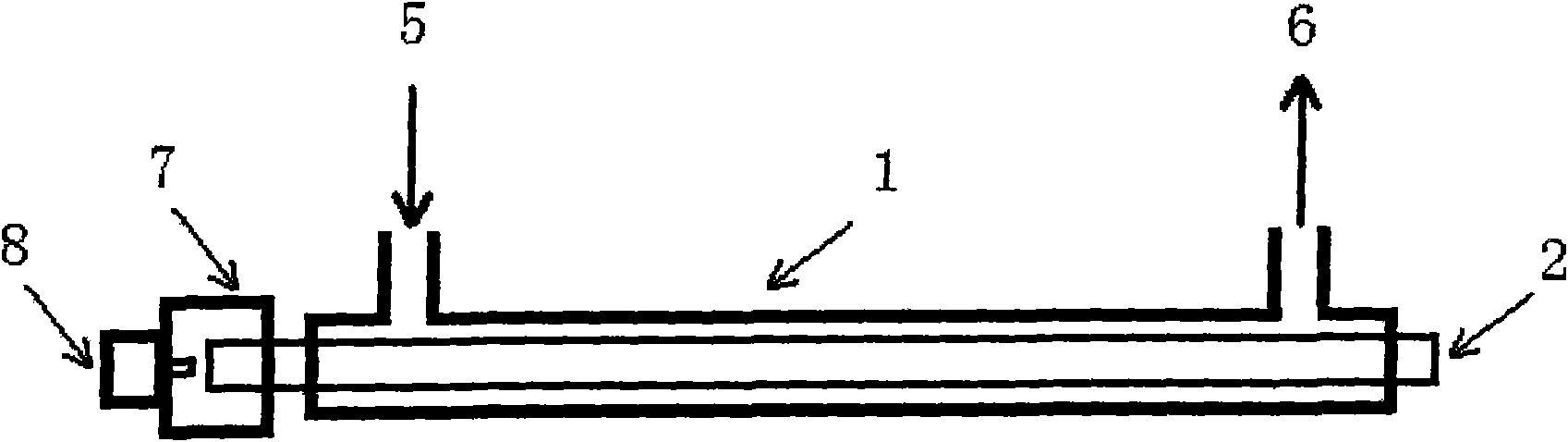

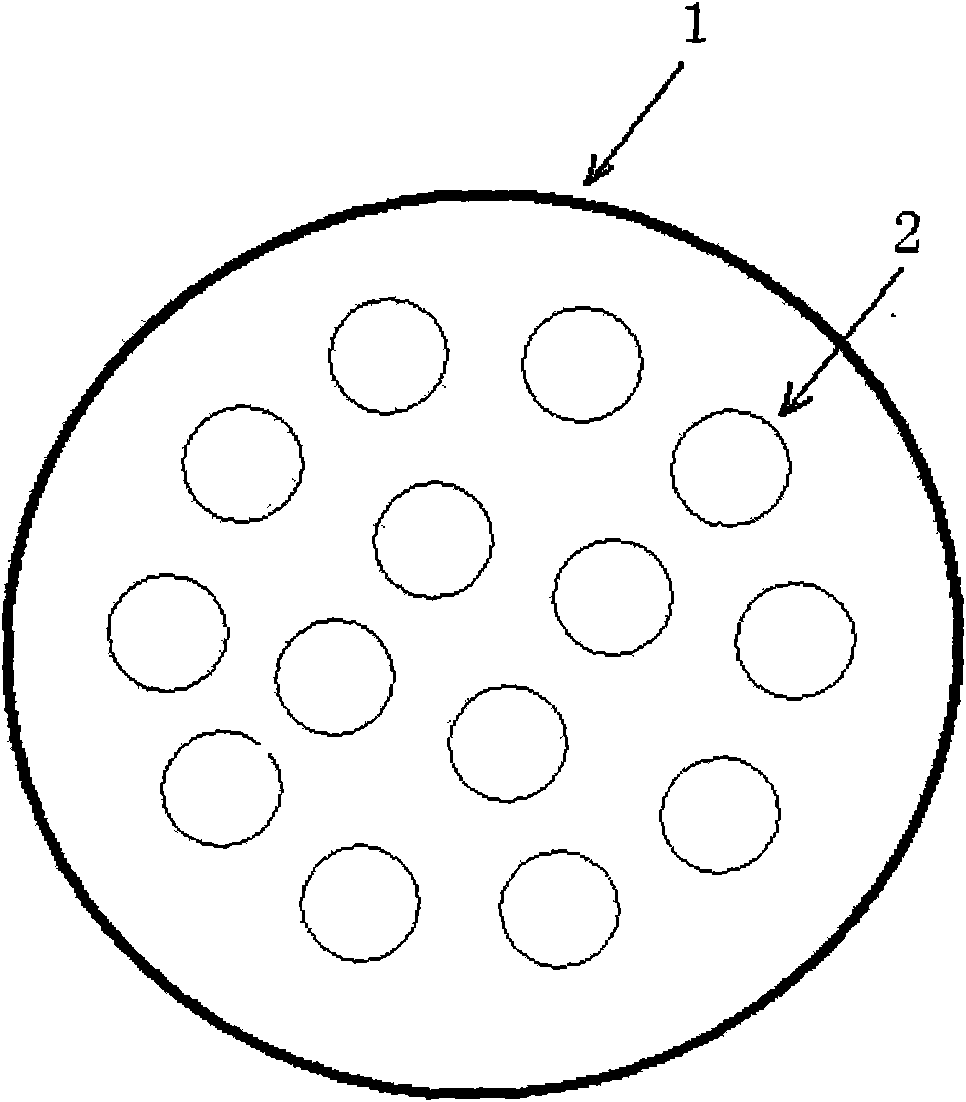

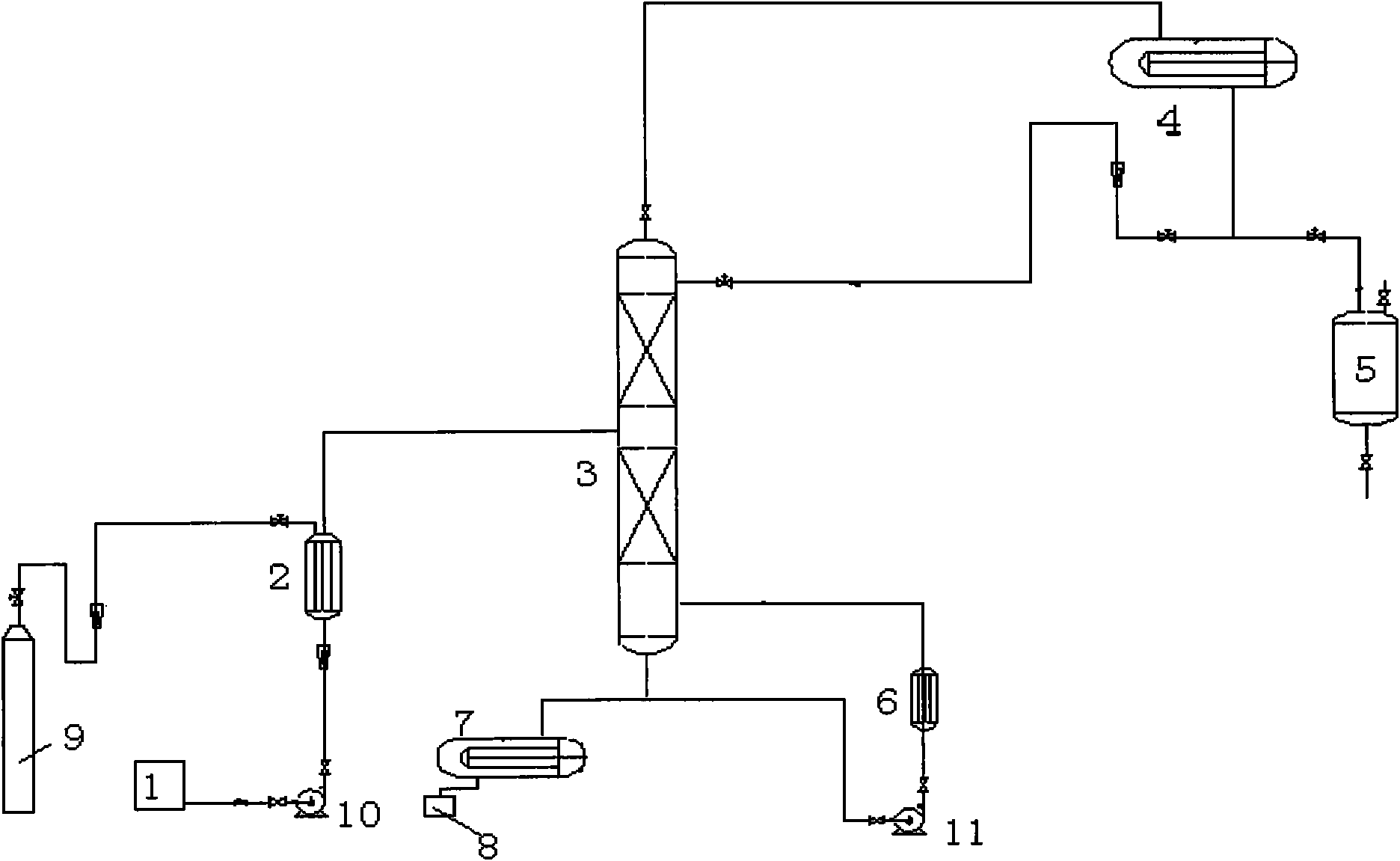

Method for preparing cyclopentadiene through continuous depolymerization and rectification

InactiveCN102336628AMild reaction conditionsControllableHydrocarbon by depolymerisationHeat conductingHeat sensitive

The invention relates to a method for preparing cyclopentadiene through continuous depolymerization and rectification. The method comprises steps that: under the protection of nitrogen, a composite polymerization inhibitor and pure heat conducting oil are added into a thermal decomposition apparatus according to a weight ratio of 0.005-0.01:1, and are heated to a depolymerization temperature of 270 to 300 DEG C; a crude product dicyclopentadiene is continuously and stably added into the thermal decomposition apparatus, a thermal depolymerization reaction time is 1.5 to 2s, and depolymerized cyclopentadiene is delivered into a rectification tower; cyclopentadiene separated from the tower top is delivered into a collecting device through a condenser; small amounts of dicyclopentadiene which is not decomposed, and by products are heated in a tower-bottom re-boiling apparatus, and are rectified again. According to the method, the composite polymerization inhibitor is a complex of an active immobile polymerization inhibitor, a heat sensitive polymerization inhibitor, and cupric salt, wherein a weight ratio of the three is 1:1:0.5-1. The method provided by the invention has advantages of simple equipment, high production capacity, and low coking. According to the invention, the raw material heat conducting oil and the equipment can be used for a long term.

Owner:PETROCHINA CO LTD

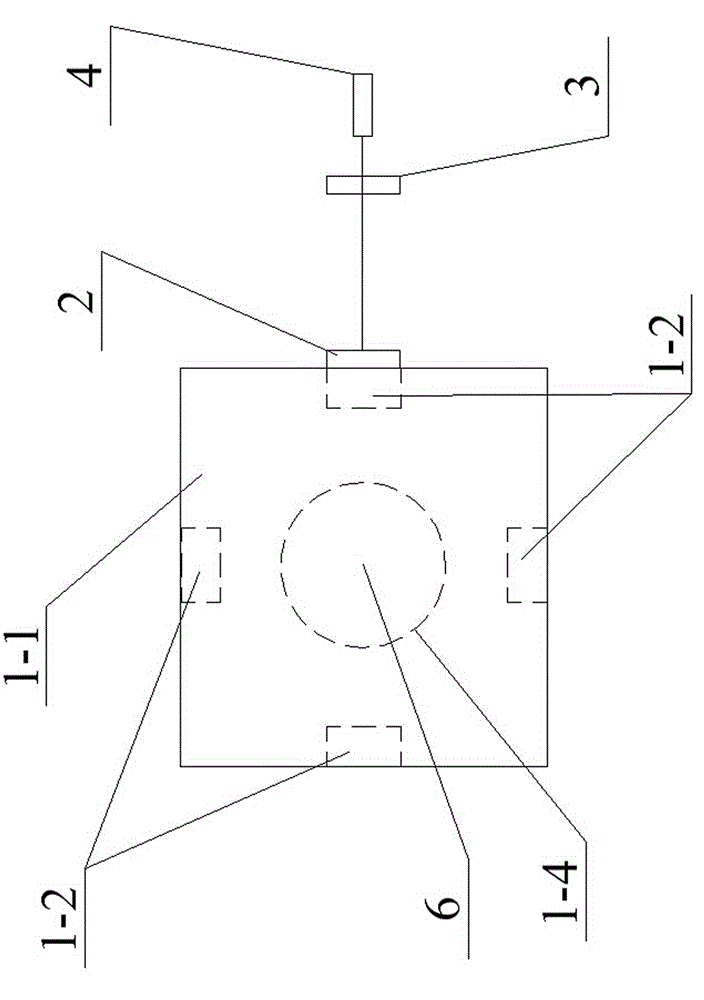

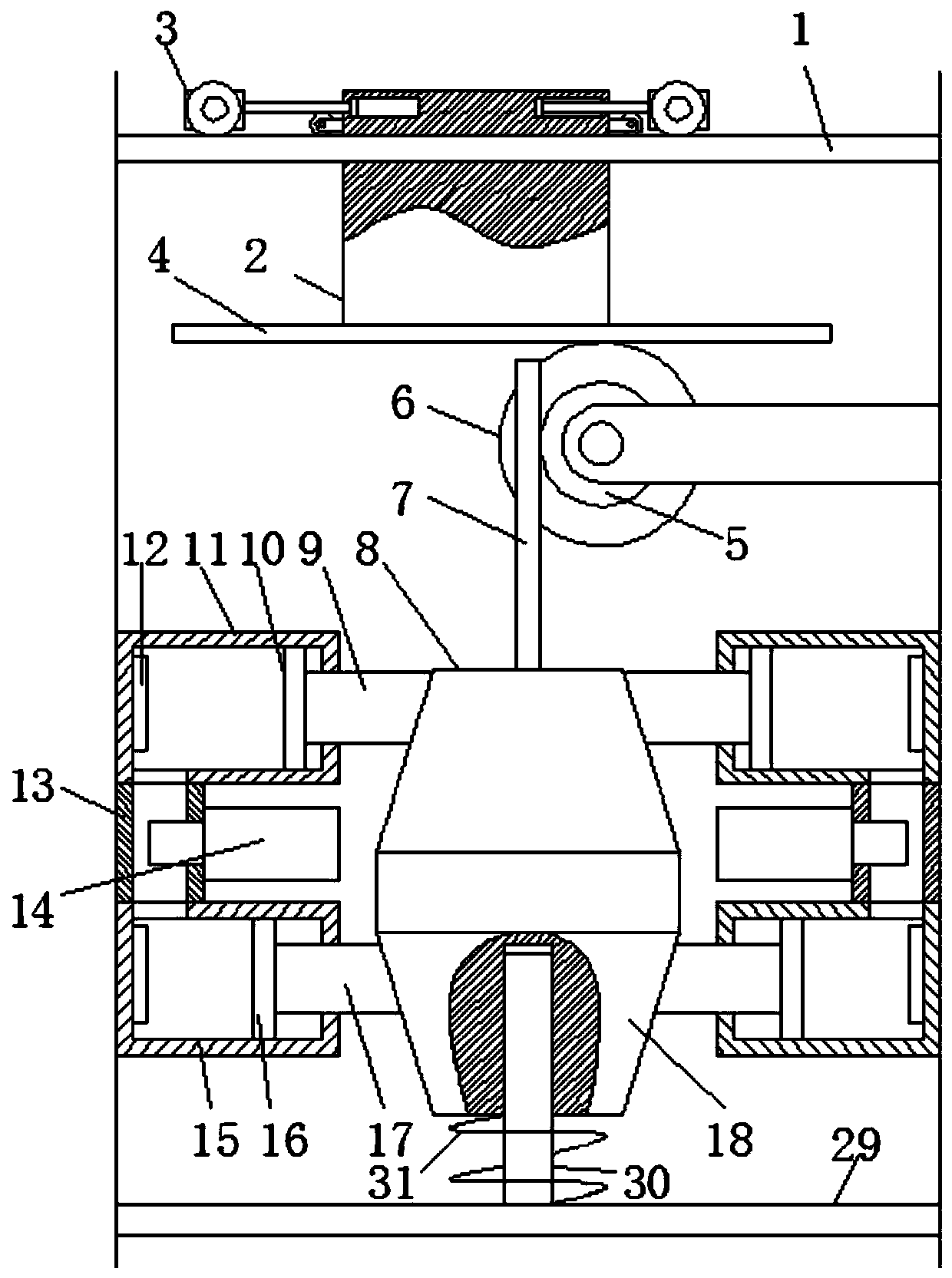

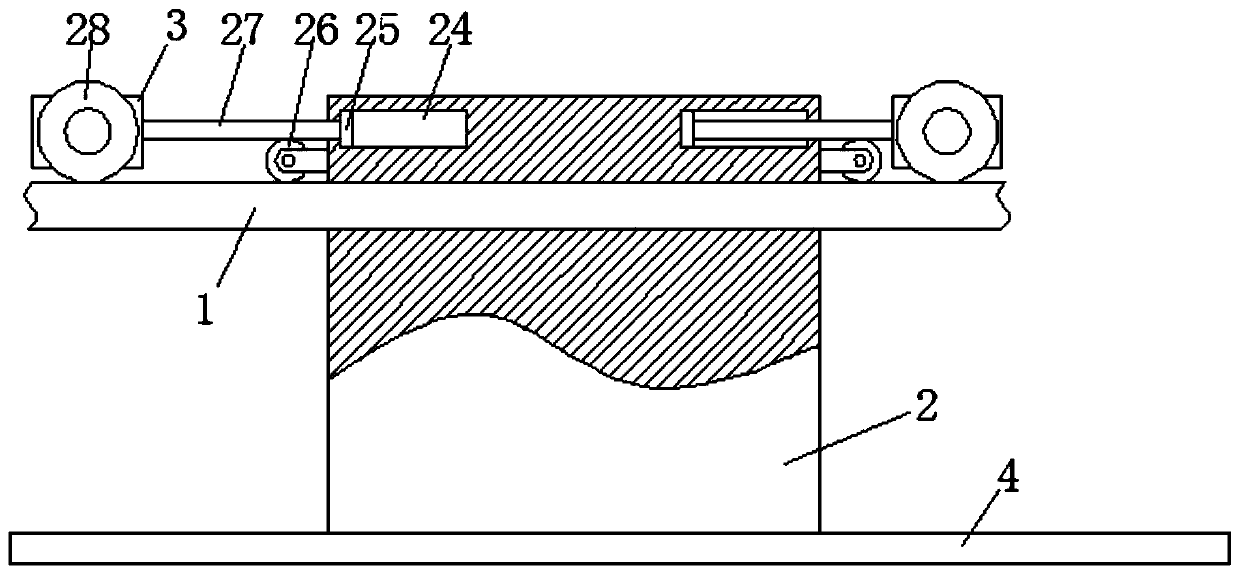

Self-adaptive adjusting tuned mass damper and using method thereof

InactiveCN111236463AExcellent vibration protectionExpand the range of vibration resistanceProtective buildings/sheltersShock proofingControl theoryTuned mass damper

The invention relates to the field of building anti-vibration equipment, in particular to a self-adaptive adjusting tuned mass damper and a using method thereof. The self-adaptive adjusting tuned massdamper comprises a first rack fixed to a building body, the first rack is horizontally arranged, a mass body is connected to the first rack in a sliding mode, the self-adaptive adjusting tuned mass damper further comprises an energy consumption mechanism fixed to the building body, an energy conversion mechanism is arranged on the mass body, the mass block is in transmission connection with the energy consumption mechanism, a flow adjusting mechanism is arranged on the energy consumption mechanism, and the energy conversion mechanism is electrically connected with the flow adjusting mechanismthrough a wire. According to the self-adaptive adjusting tuned mass damper and the use method thereof, the mass body drives the energy conversion mechanism to convert impact energy into electric energy, so that the energy consumption mechanism is adaptively adjusted, corresponding adjustment is made according to the size change of external excitation, the anti-vibration range is expanded, and better damping and protection effects on the building body are achieved. Moreover, the mass of the whole device does not need to be changed, and the self-adaptive adjusting tuned mass damper is simple instructure and easy to implement.

Owner:徐玮祎

Complete- degradable plastic film

InactiveCN101338048AThe overall thickness is thinHigh strengthFlat articlesPolymer scienceVolumetric Mass Density

The invention discloses a totally degradable plastic film. The raw materials of the plastic film comprise high-density polyethylene or low-density polyethylene, middle-density polyethylene particles and fillers, adding with TDPATM additives which are produced by EPT company, Canada, and recovery connatural waste recycled plastic particles. The raw material and the weight ratio of the plastic film are 40 to 70 percent of the polyethylene particles, 2 to 30 percent of the TDPATM additives, 2 to 30 percent of the additives and 2 to 30 percent of the waste recycled plastic particles. 1 to 8 percent colored polyethylene particles are added in the raw materials to be made into colored film. The raw materials are mixed in proportion according to the production requirements, are added in an inflation film manufacturing machine to be heated up to the prescribed temperature and then the totally degradable plastic film is produced. The totally degradable plastic film has simple prescription, easy fabrication, few process steps, short flow and few used equipment with only the inflation film manufacturing machine. The thickness of the totally degradable plastic film can reach as thin as 0.02, with the middle; wherein, 0.025 thickness film has 33 MPa of longitudinal tension degree and 25 MPa of transverse tension degree of the mechanical properties, 260 percent of longitudinal tensile stretch and 620 percent of transverse tensile stretch and 3 months to 2 years of adjustable degradation time.

Owner:河南省南街村(集团)有限公司

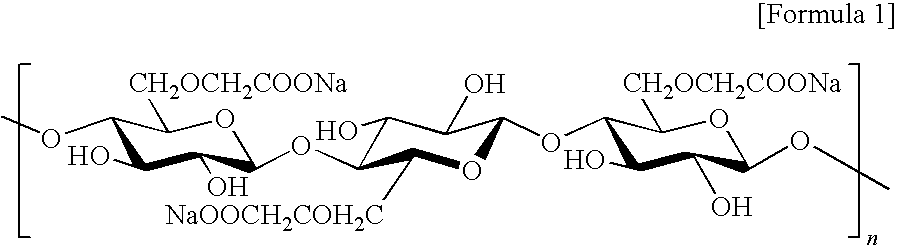

Water-based cutting fluid having ceramic powder

InactiveUS20100043301A1Low viscosityHigh trafficOther chemical processesLubricant compositionCelluloseWater based

A water-based cutting fluid includes a water-soluble polymer dissolved in water and ceramic powder dispersed in the water. The cutting fluid further includes water glass. Further, the water-soluble polymer is one selected from a group consisting of polyvinyl alcohol (PVA), cellulose, methyl cellulose, carboxymethyl cellulose (CMC), starch, or a combination thereof.

Owner:GANGNEUNG WONJU NAT UNIV IND ACAD COOPERATION GROUP

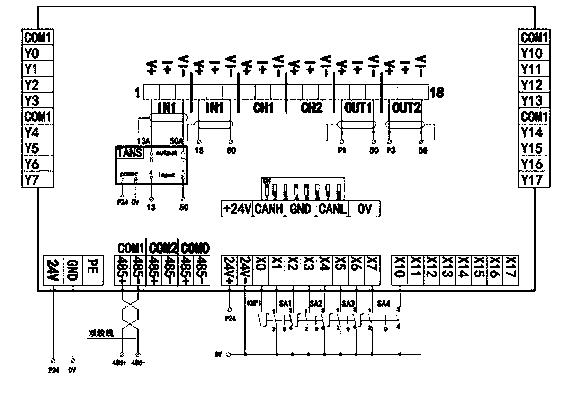

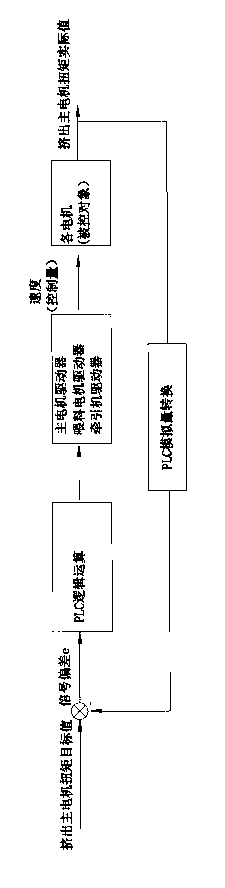

Method and device for controlling conical twin-screw extruder

InactiveCN103273638ASolve the interference problem of current changeQuality changeInterference problemControl theory

The invention discloses a method for controlling a conical twin-screw extruder. The method comprises the following steps of: S1, setting a conventional current signal and a current deviation value; S2, collecting current signals of a main motor of the conical twin-screw extruder; S3, comparing the collected current signals with a set normal current signal so as to obtain a deviation current; and S4, outputting the deviation current as a signal, and controlling the rotating speeds of the main motor, a feeding motor and a traction motor of the conical twin-screw extruder, wherein when the current of the main motor of the extruder is increased suddenly and deviated from the set deviation value, the speed of the main motor is reduced, and the speeds of the feeding motor and the traction motor are decreased in proportion; and conversely, when the current of the main motor of the extruder is decreased suddenly and deviated from the set deviation value, the speed of the main motor is increased, and the speeds of the feeding motor and the traction motor are increased in proportion. According to the method, through detecting the current mutation of the main motor of the conical twin-screw extruder, the current is operated, and after operation, the speeds of the main motor, the feeding motor and the traction motor are changed, and the main motor is kept running at a same torque. Therefore, various interference problems such as non-uniform blanking and the like causing the current changes of the main motor are solved. The invention also discloses a control device using the method.

Owner:GUANGDONG LIANSU MACHINERY MFG

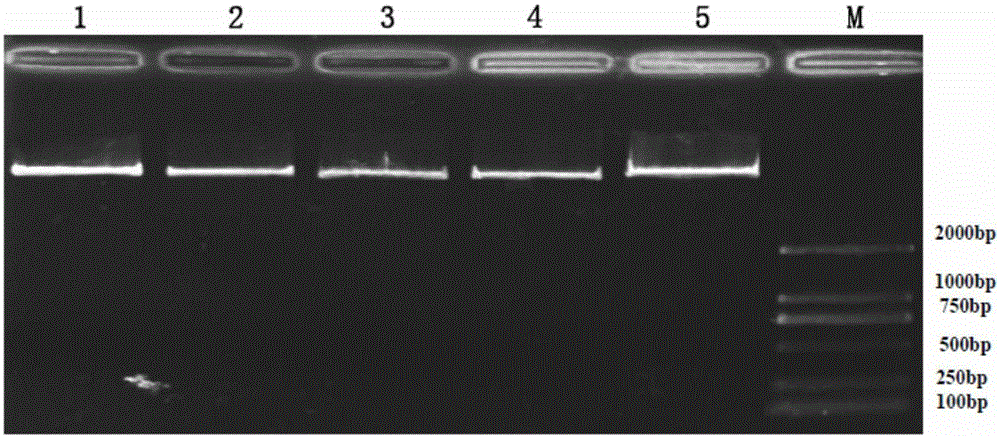

Rapid extraction method for plant mitochondrion DNA

The invention discloses a rapid extraction method for plant mitochondrion DNA. The method includes the steps of firstly, preparing Buffer A (containing betaine and cysteine), Buffer B (containing BSA), a solution W1, a solution W2, a solution W3, buffer WT and buffer TB; secondly, adding Buffer A for grinding after preprocessing fresh and tender tissue, collecting filtered fluid, keeping the pH value at 7.0 or above, and conducting 12000g centrifugation on the supermatant after conducting 1000g centrifugation on collected fluid; thirdly, taking sediment, and adding Buffer B to sediment for resuspension, and conducting 1000g centrifugation; fourthly, taking supermatant, adding DNase I and EDTA for reaction, and then conducting 12000g centrifugation; fifthly, adding the solution W1 to the sediment for suspending sediment; sixthly, adding the solution W2 and the solution W3 for gentle perversion, taking supermatant after centrifugation, and extracting the mitochondrion DNA through an adsorption column. By means of the method, the high-quality plant mitochondrion DNA can be efficiently and rapidly obtained.

Owner:SHANDONG CROP GERMPLASM CENT

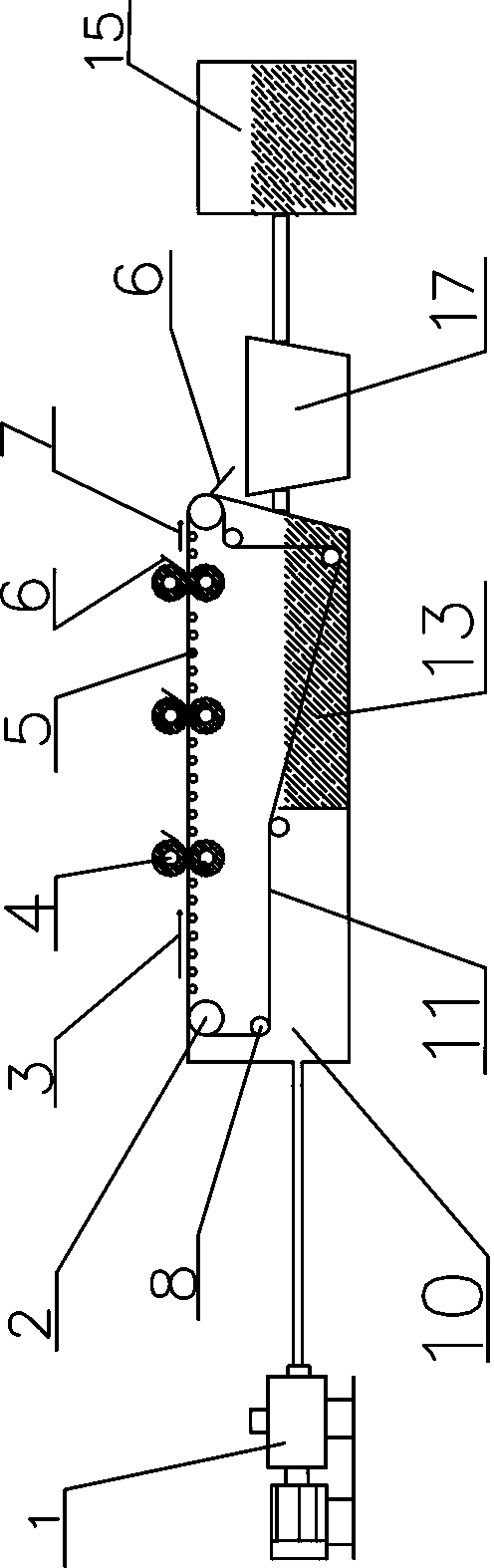

Sulfur-free konjak powder processing equipment

ActiveCN103815312AReduce browningChange qualityFood preparationProcess equipmentWater treatment system

Sulfur-free konjak powder processing equipment comprises a vacuum chamber connected to a vacuum pump, a circular penetration conveying belt is arranged on a transmission supporting and steering device in the vacuum chamber, a plurality of squeezing devices is arranged on the circular penetration conveying belt, the two sides of the plurality of squeezing devices are respectively provided with a material inlet and a material outlet, the lower part of the circular penetration conveying belt is inserted into a washing tank in the bottom of the vacuum chamber, a waste liquid collecting disc is arranged in a vacuum chamber arranged between the circular penetration conveying belt and the washing tank, the upper part of the washing tank is communicated with a purified water pipeline, the lower part of the washing tank and the waste liquid collecting disc are communicated with a water processing system, and one end of the upper part of the circular penetration conveying belt matches with a material collecting tank arranged on one side of the material outlet. The sulfur-free konjak powder processing equipment carries out a dehydration treatment on fresh konjak by simultaneously adopting a mechanical squeezing technology and a vacuum absorbing technology, can overcome the shortages of high residual sulfur oxide content and high cost existing in conventional process equipment, and improves the quality of finished konjak powder product.

Owner:HUBEI YIZHI KONJAC BIOTECH

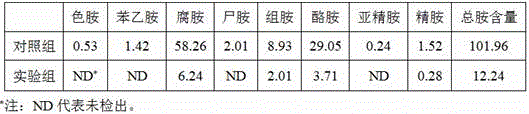

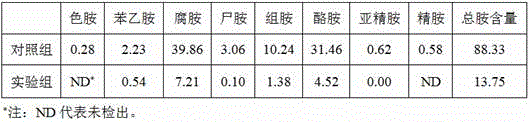

Integrated treatment method for reducing bioamine content in yellow wine

The invention discloses an integrated treatment method for reducing bioamine content in yellow wine and belongs to the technical field of yellow wine brewing. The method, on the basis of not changing a yellow wine brewing process, includes three steps of: adding propolis and [epsilon]-polylysine to rice before fermentation in a tank or sweet mash before alcohol fermentation, adding laccase and copper gluconate to fermented mash liquid before finishing fermentation, and performing adsorption through a zirconyl pyrophosphate packed column before fill packaging of the yellow wine, thereby reducing the bioamine content in yellow wine by more than 80% than a conventional process, wherein the traditional indices and flavors of the yellow wine are not influenced. The method has simple operations, is totally green and environment-friendly, is free of addition of much equipment and is suitable for large-scale promotion.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com