Stab-resistant bulletproof fabric based on shear thickening fluid and preparation method of stab-resistant bulletproof fabric

A bulletproof fabric and fluid technology, applied in textiles, papermaking, textile decoration, etc., can solve the problems of difficult to maintain a fixed shape, prone to side leakage, poor stability, etc., to enhance the force, reduce the number of composite layers, the ratio of The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

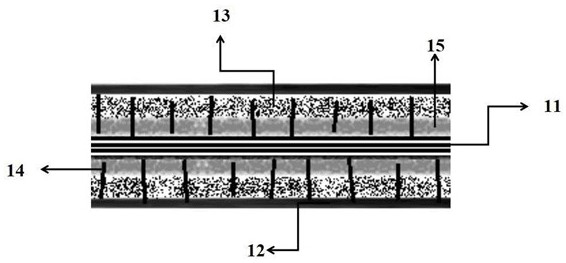

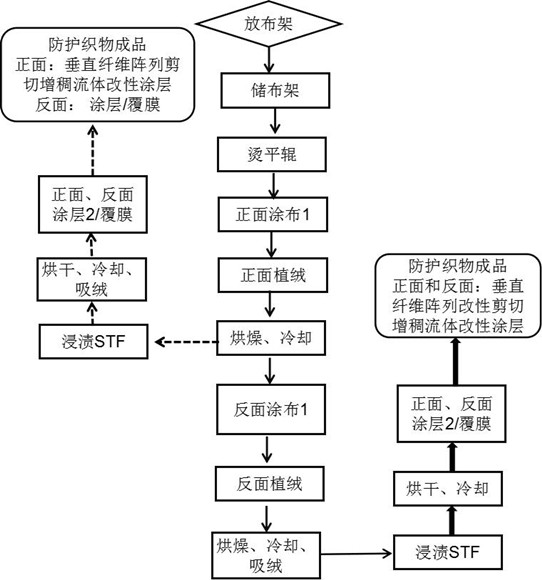

[0042] A stab-proof and bullet-proof fabric based on shear thickening fluid, which is composed of four parts: UHMWPE fiber fabric, kapok fiber powder modified PTFE coating slurry, shear thickening fluid, and 0.8mm antibacterial PA short fiber fluff. The specific preparation is as follows:

[0043] (1) Evenly scrape and coat a layer of PTFE modified coating slurry containing kapok fiber powder on the front of the base fabric, and immediately flock the coating surface through a high-voltage electrostatic zone. The short fiber fluff needs to be dried at 120°C for 2 hours, the electric field voltage in the high-voltage electrostatic area is 35 kV, and the pole distance is 10 cm, and then the fabric is sent to the dryer for drying, cooling, and velvet absorption;

[0044] (2) Evenly scrape a layer of modified coating slurry containing kapok fiber powder on the reverse side of the base fabric, and immediately flock the coating surface through the high-voltage electrostatic area. The...

Embodiment 2

[0056] A stab-proof and bullet-proof fabric based on shear thickening fluid, which is composed of plain aramid woven fabric, PA fiber powder modified PU coating slurry, shear thickening fluid, and 1.2mm flame-retardant PP short fiber fluff. made. The shear thickening fluid is specifically prepared as follows:

[0057] 1) Treat nano-SiO with silane coupling agent KH560 2 Particles, to prevent the agglomeration of nanoparticles;

[0058] 2) The prepared SiO 2 The powder was dried in a blast drying oven at 90°C for 12 hours, and then dried at 120°C to constant weight;

[0059] 3) SiO 2 The powder and agate balls are put into a ball mill tank according to a certain ball-to-material ratio for dry powder ball milling for 0.5h, and a certain quality of modified SiO 2 Particles are placed in a ball mill tank, added PEG200 for ball milling, and a certain mass of powder is added every 0.5h until good shear thickening performance occurs, and SiO with a mass fraction of 20% is obta...

Embodiment 3

[0073] In the embodiment of the present invention, a stab-proof and bullet-proof fabric based on shear thickening fluid is composed of plain nylon fiber fabric, graphene oxide modified PU coating slurry, shear thickening fluid, 1.0mm antistatic PA short fiber It is made of fluff and graphene oxide modified PU film. The specific preparation is as follows:

[0074] (1) Evenly scrape a layer of PU coating slurry containing graphene oxide on the front of the base fabric and immediately flock the coating surface through a high-voltage electrostatic zone. Graphene oxide accounts for 2wt% of the PU coating adhesive, and short fibers The fluff needs to be dried at 120°C for 2 hours, the electric field voltage in the high-voltage electrostatic area is 40 kV, and the pole distance is 15 cm, and then the fabric is sent to the dryer for drying, cooling, and fluff absorption;

[0075] (2) Evenly scrape the PU coating slurry containing graphene oxide on the reverse side of the fabric, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com