High-speed water entry buffer head cap of underwater vehicle

An underwater vehicle and buffer head technology, applied in the directions of underwater ships, underwater operation equipment, ships, etc., can solve the problems of inability to provide electromagnetic protection, limited buffer performance, unreliable installation, etc., and achieve excellent electromagnetic shielding performance and Thermal performance, vibration damping stress amplitude, effect of protecting electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

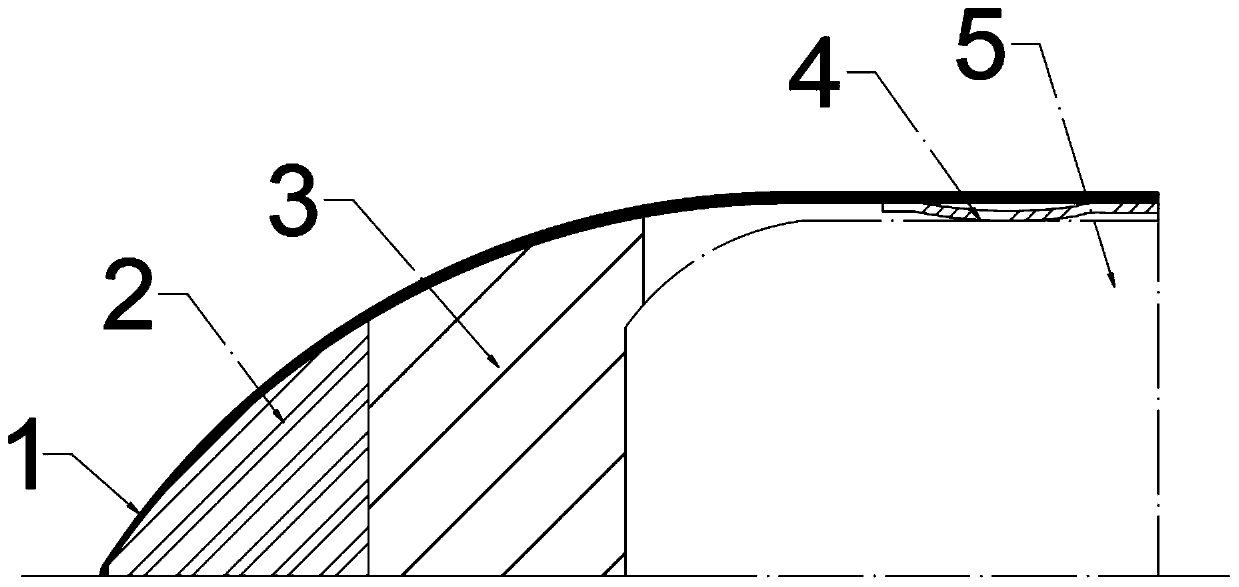

[0023] The buffer head cap designed by the present invention is mainly composed of a casing 1, a metal foam buffer 2, a foam plastic buffer 3, and a joint 4.

[0024] The casing 1 adopts the shape of a small ball head pointed arch, which is a commonly used aerodynamic shape. According to the speed and angle of the aircraft flying in the air, the maximum aerodynamic load and the minimum water impact load of the aircraft are simulated to determine the strength design range of the outer shell of the cushioning headgear.

[0025] The length of each part of the composite structure buffer is determined according to the hull strength of the aircraft 5 and the dynamic compression mechanical properties of the buffer material.

[0026] The buffer is a revolving body, followed by a metal foam buffer 2 and a foam plastic buffer 3, and the two are close to each other without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com