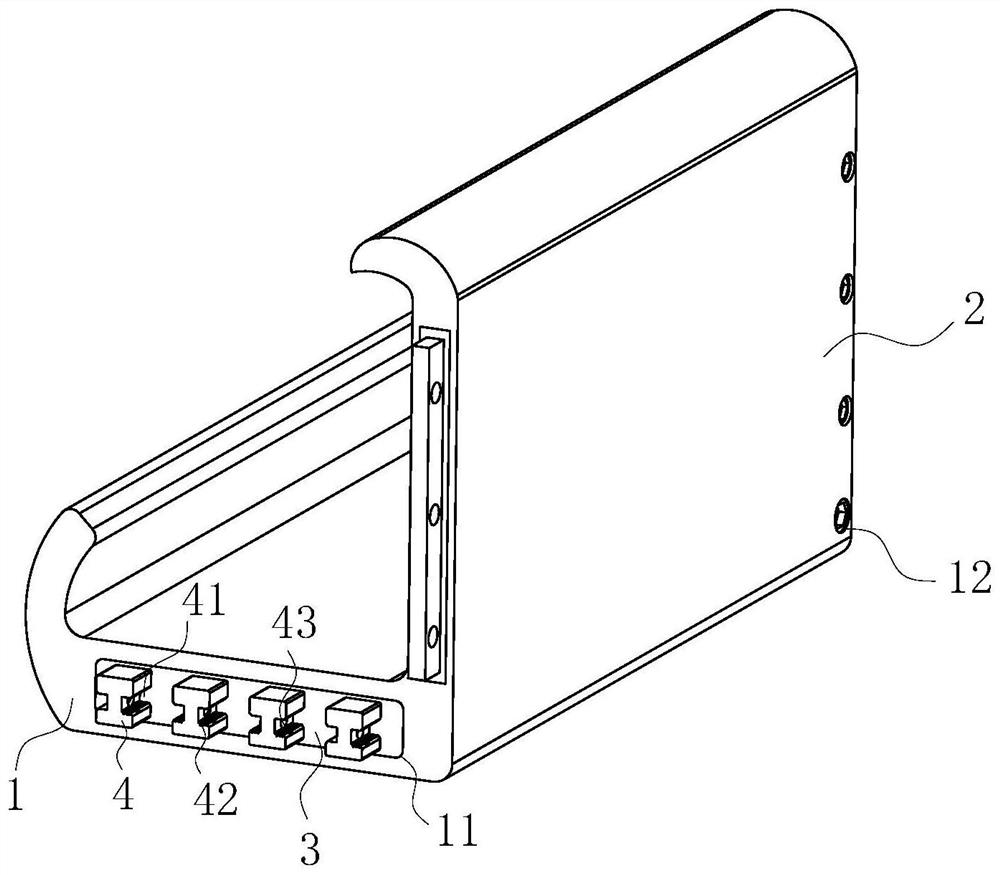

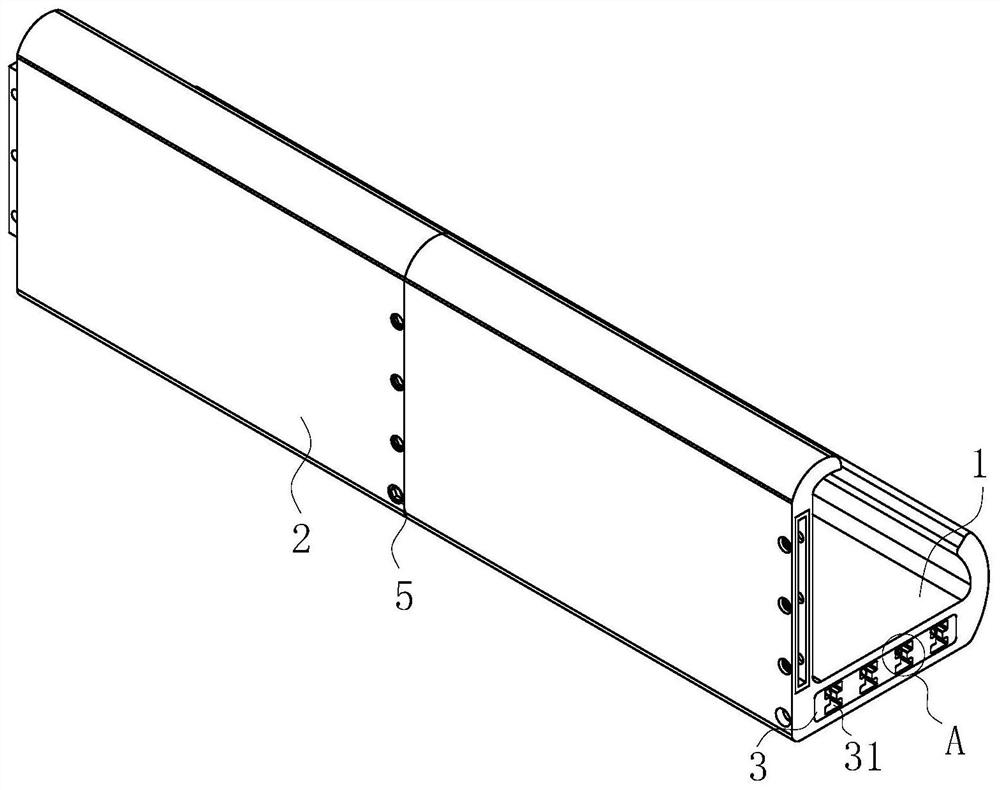

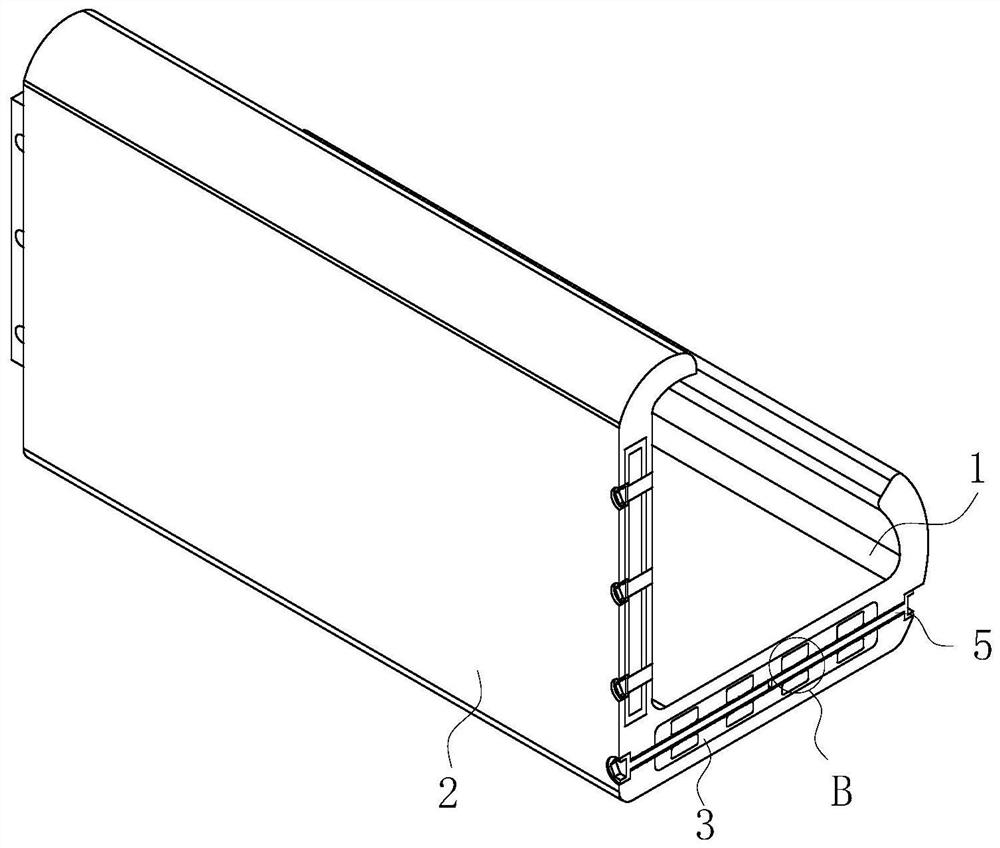

L-shaped edge sealing aluminum profile

An aluminum profile, L-shaped technology, applied in the direction of the wing frame, window/door, building components, etc., can solve the problem of affecting the safe use of aluminum profiles, the poor stability and rigidity of the joints of aluminum profiles, and the trouble of installing aluminum profiles And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] As an embodiment of the present invention, the threaded hole 36 is internally threaded with a coil spring 6, and the interior of the coil spring 6 is a cavity structure; the internal thread of the coil spring 6 is connected with a fixing bolt 5; the fixing bolt 5 The screw rod is made of foamed aluminum, and the outer end of the fixing bolt 5 is made of aluminum alloy; when working, when the fixing bolt 5 needs to be screwed into the threaded hole 36, the operator first turns the coil spring 6 into the threaded hole. In the hole 36, the helical spring 6 is screwed into the threaded hole 36, and then the fixing bolt 5 is screwed and inserted into the helical spring 6, so that the fixing bolt 5 and a plurality of plug-in blocks 4 form an elastic helical connection effect, At the same time, the fixing bolt 5 is made of foamed aluminum instead of the existing fixing bolt 5, which not only reduces the overall weight of the edge-sealing aluminum profiles spliced together, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com