Patents

Literature

42 results about "Thermal depolymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal depolymerization (TDP) is a depolymerization process using hydrous pyrolysis for the reduction of complex organic materials (usually waste products of various sorts, often biomass and plastic) into light crude oil. It mimics the natural geological processes thought to be involved in the production of fossil fuels. Under pressure and heat, long chain polymers of hydrogen, oxygen, and carbon decompose into short-chain petroleum hydrocarbons with a maximum length of around 18 carbons.

Energy reclaiming process

Owner:HELLEUR DONALD

Successive pyrolysis system of waste synthetic-highly polymerized compound

InactiveUS20060076224A1Maximizes operating rateProductsCombustible gas coke oven heatingCombustion chamberBoiling point

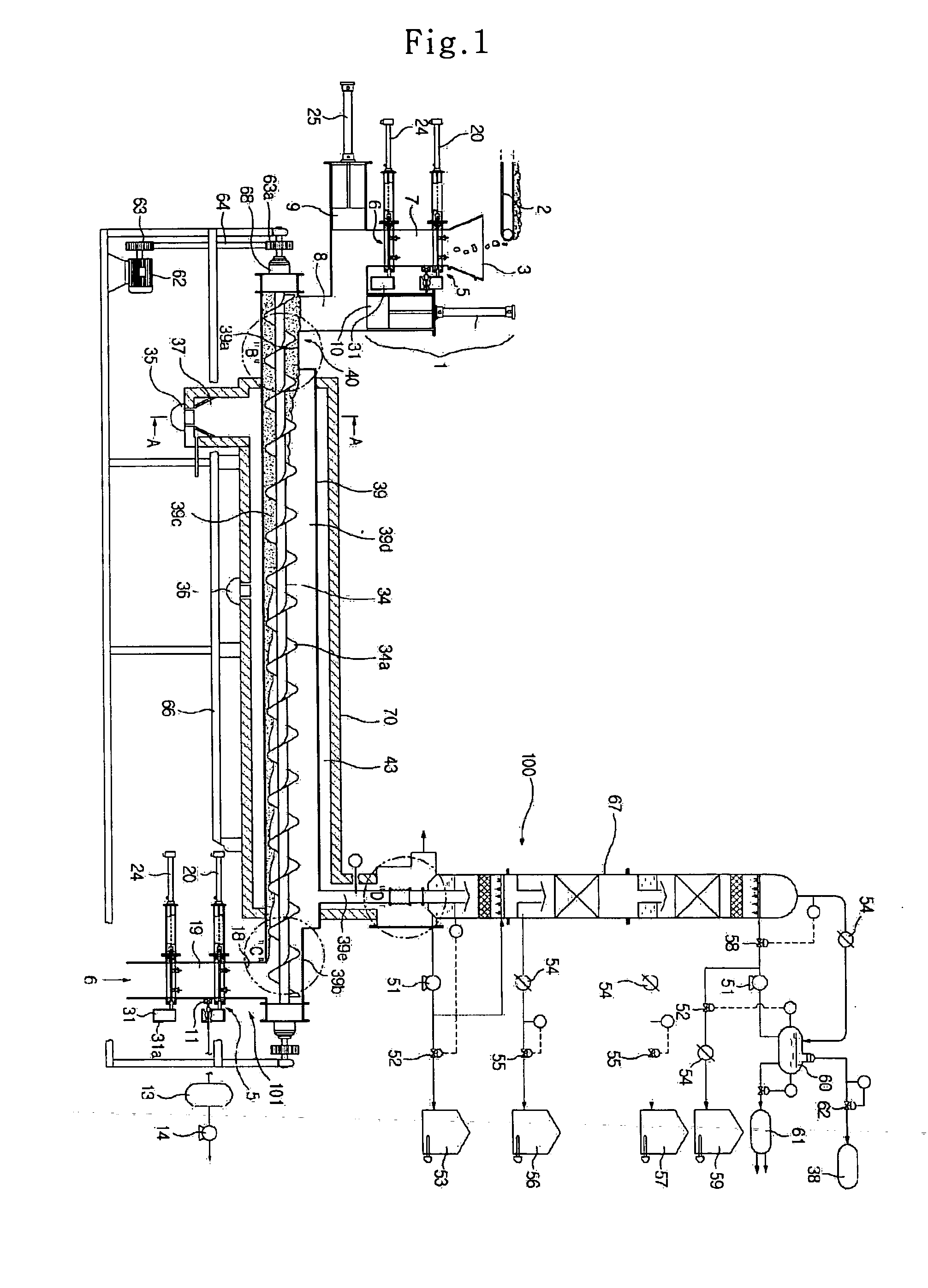

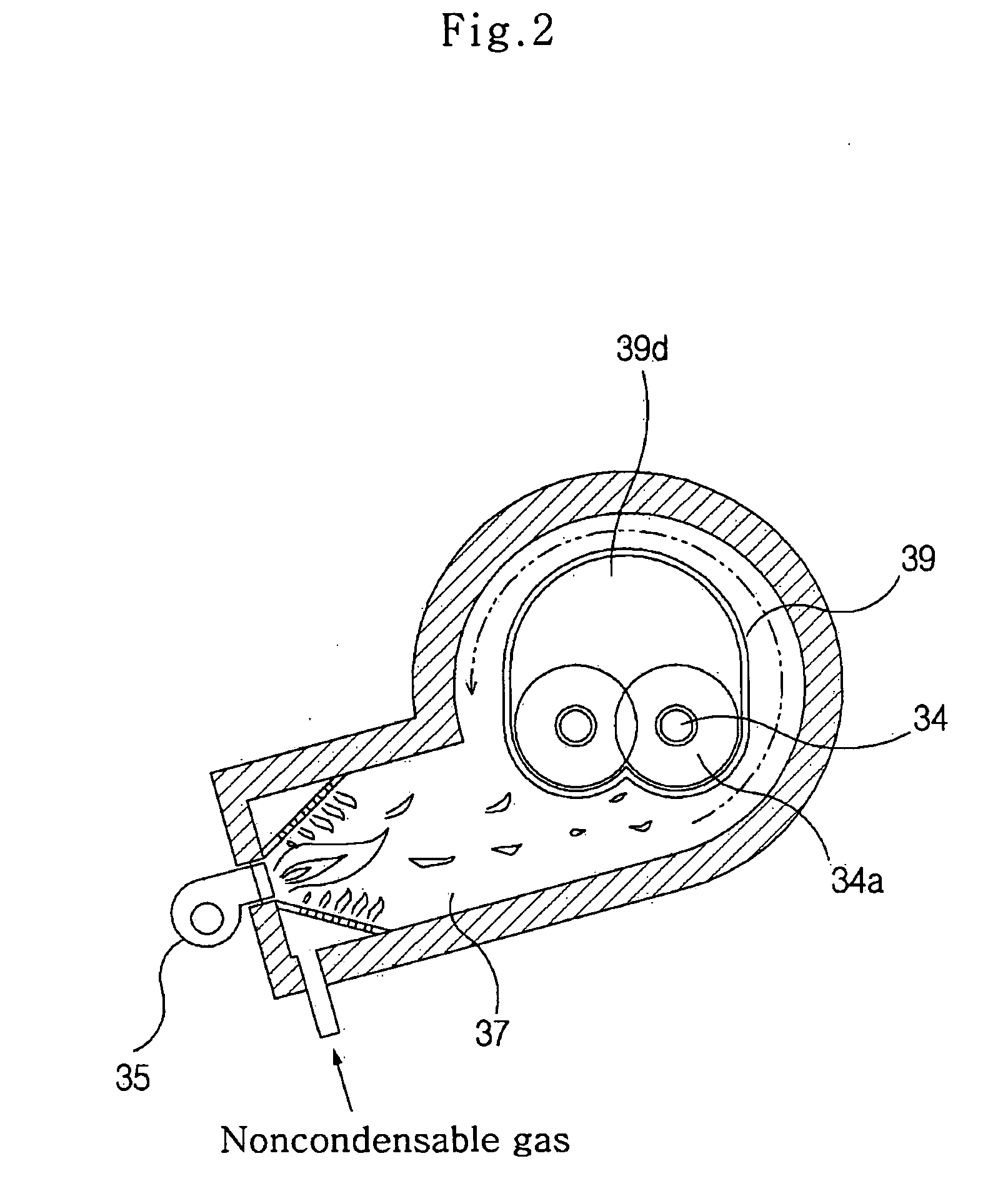

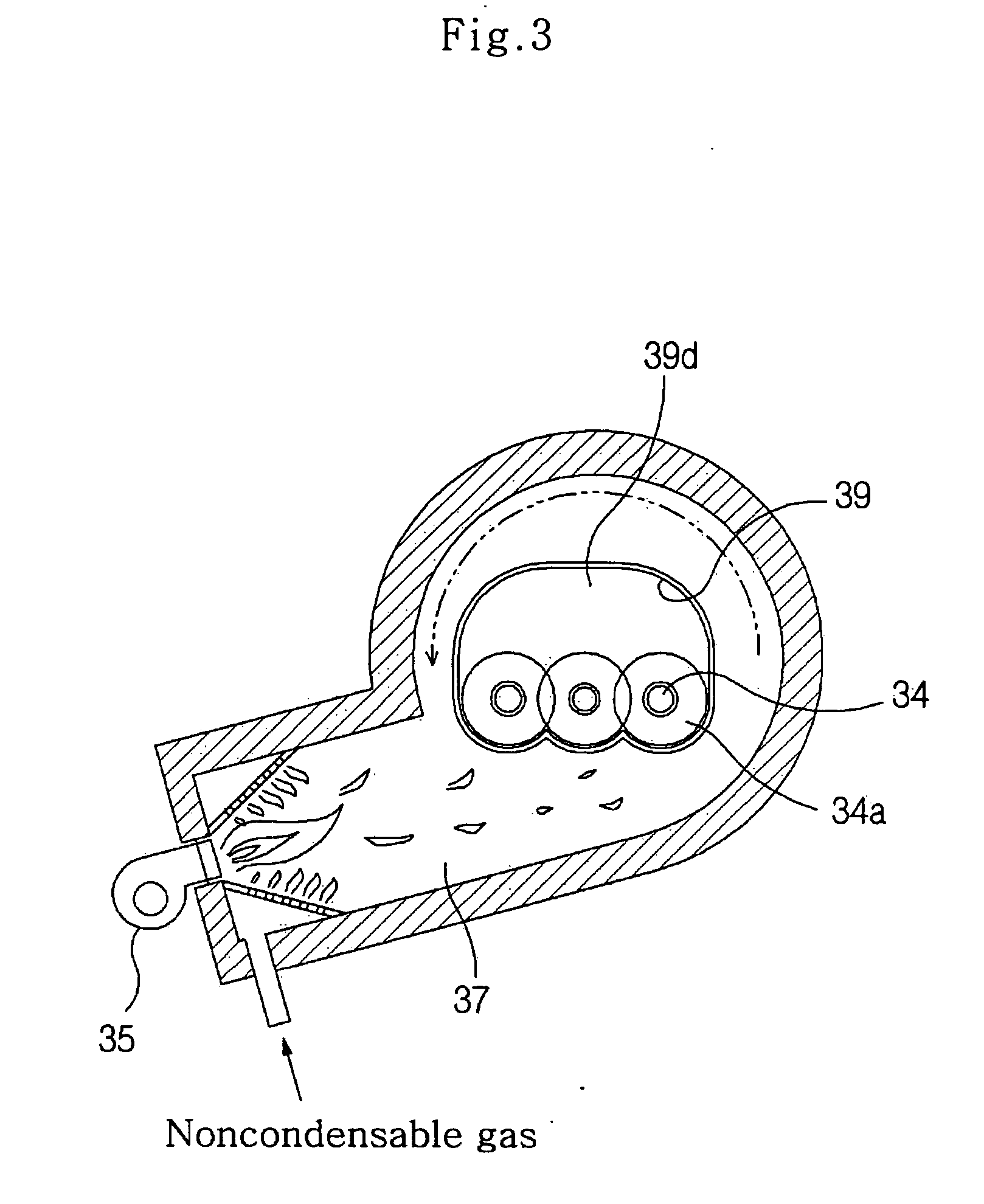

Disclosed is a successive pyrolysis system of waste synthetic-highly polymerized compound for successively pyrolizing combustible waste by indirect heating at a pyrolysis chamber maintaining an anaerobic or hypoxic environment, and producing refined oil like heavy oil and light oil according to boiling points at a distillation column to be used as heat source for the pyrolysis of the waste. The successive pyrolysis system comprises a hopper; an automatic waste injection device, which discharges a predetermined amount of waste from the hopper; a pyrolysis chamber for maintaining a high-temperature and hypoxic environment, and successively pyrolizing the waste by indirect heating; a gas burning chamber for burning noncondensable gas among pyrolysis gas produced at the time of the pyrolysis of the waste, and providing heat of a predetermined temperature to the outer surface of the pyrolysis chamber to be used as heat source for the pyrolysis of the waste; a refined oil producing means for producing refined oil from the pyrolysis gas reformed after going through catalyst reaction and providing residual noncondensable gas to the gas burning chamber; and an automatic discharging device for successively discharging ashes transported after being pyrolized from the pyrolysis chamber.

Owner:ALPO

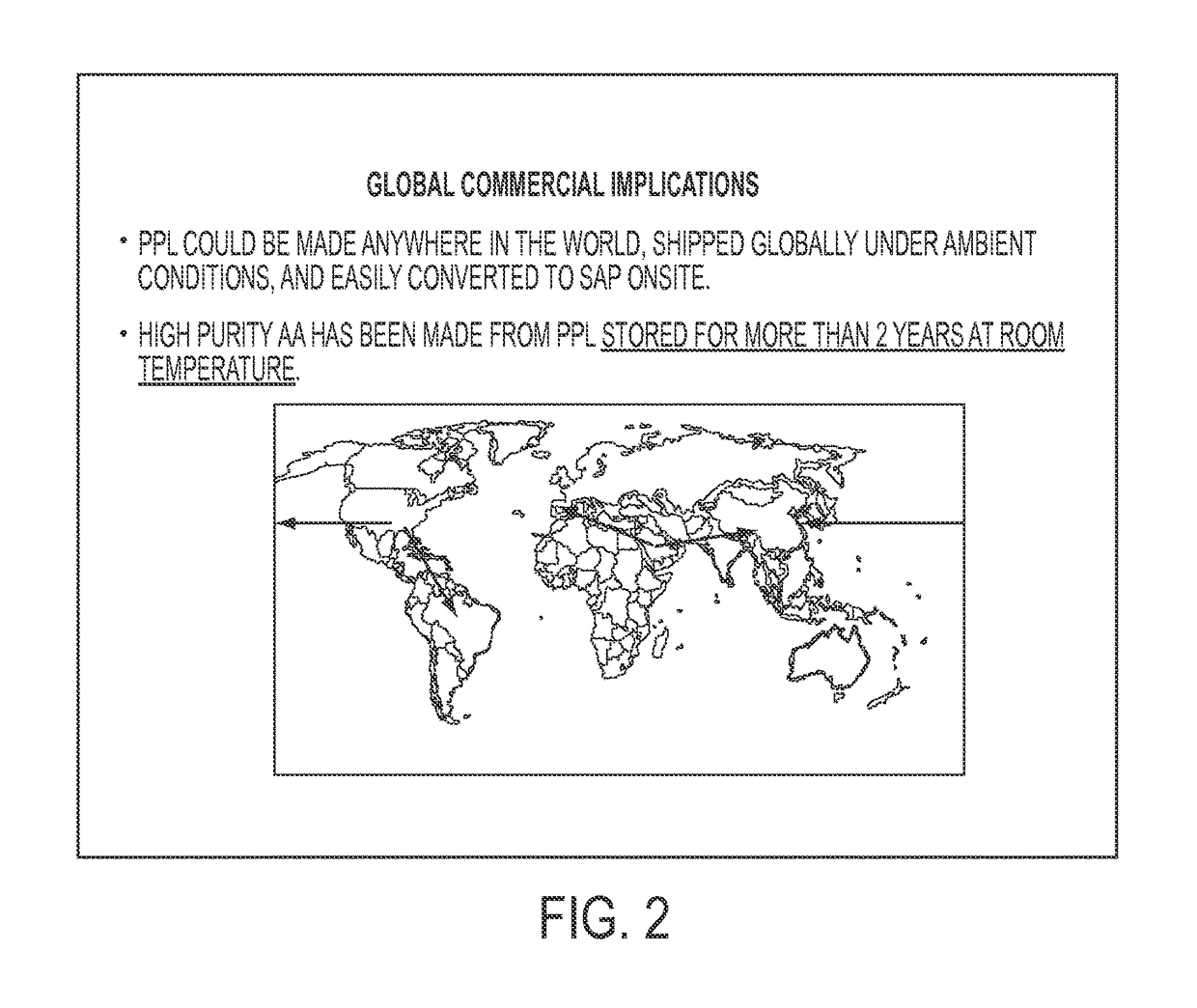

Acrylic acid production methods

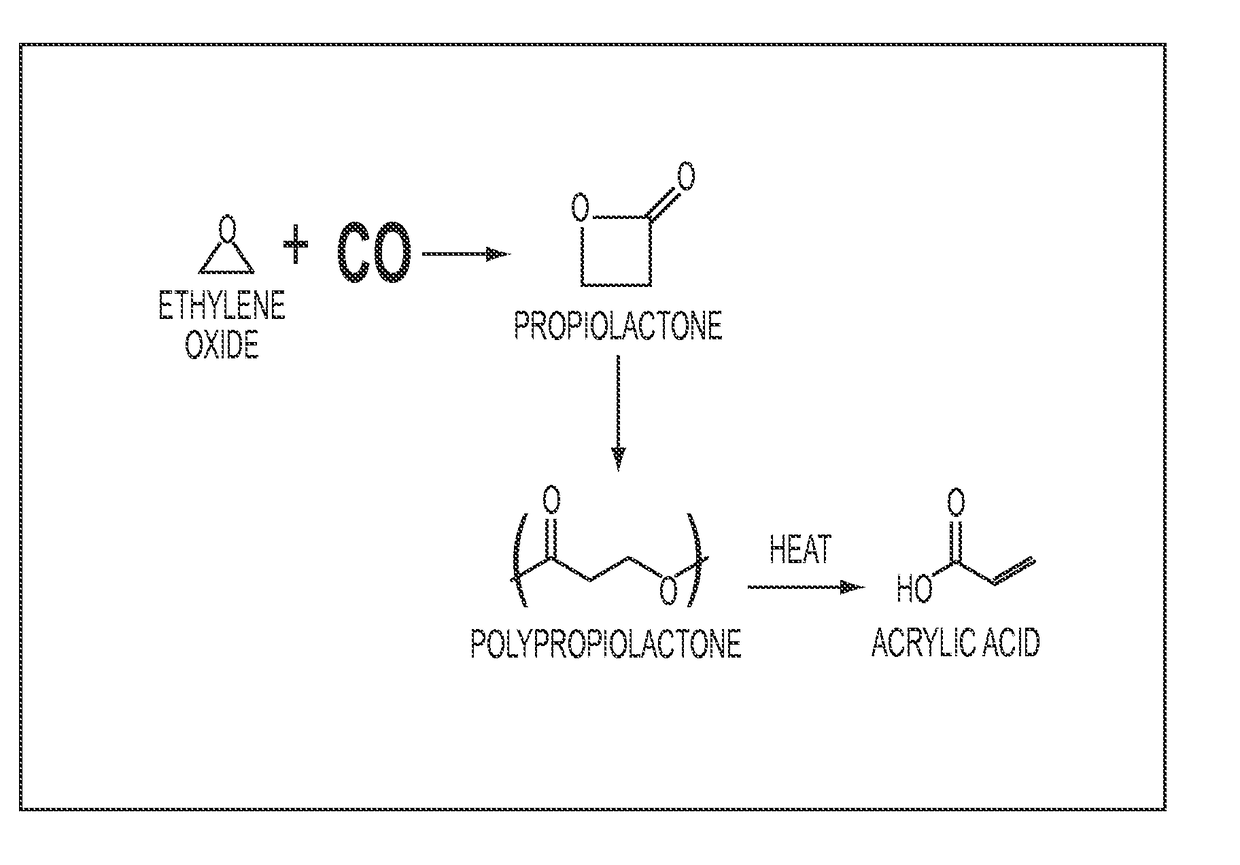

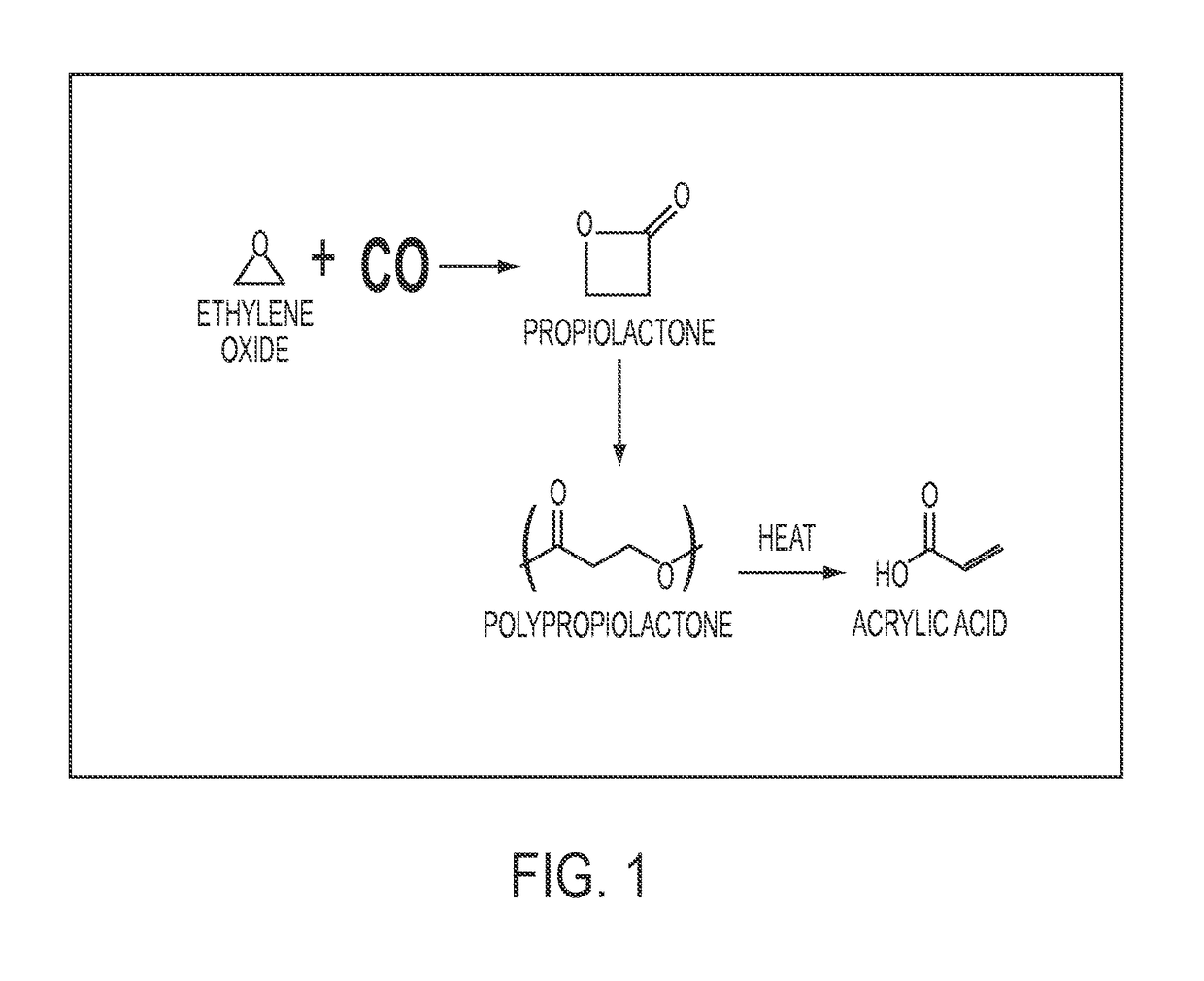

InactiveUS20170145126A1Transportation safetyLess expensiveMarket predictionsPreparation from carboxylic acid esters/lactonesEthylene oxideLactone

In one aspect, the present invention encompasses safe and efficient methods for providing highly pure acrylic acid. In certain embodiments, the inventive methods include the step of producing polypropiolactone from ethylene oxide at a first location, transporting the polymer to a second location and pyrolyzing the polypropiolactone to provide glacial acrylic acid. In certain embodiments, the step of pyrolyzing the polymer is performed continuously in conjunction with a polymerization process to make SAPs.

Owner:NOVOMER INC

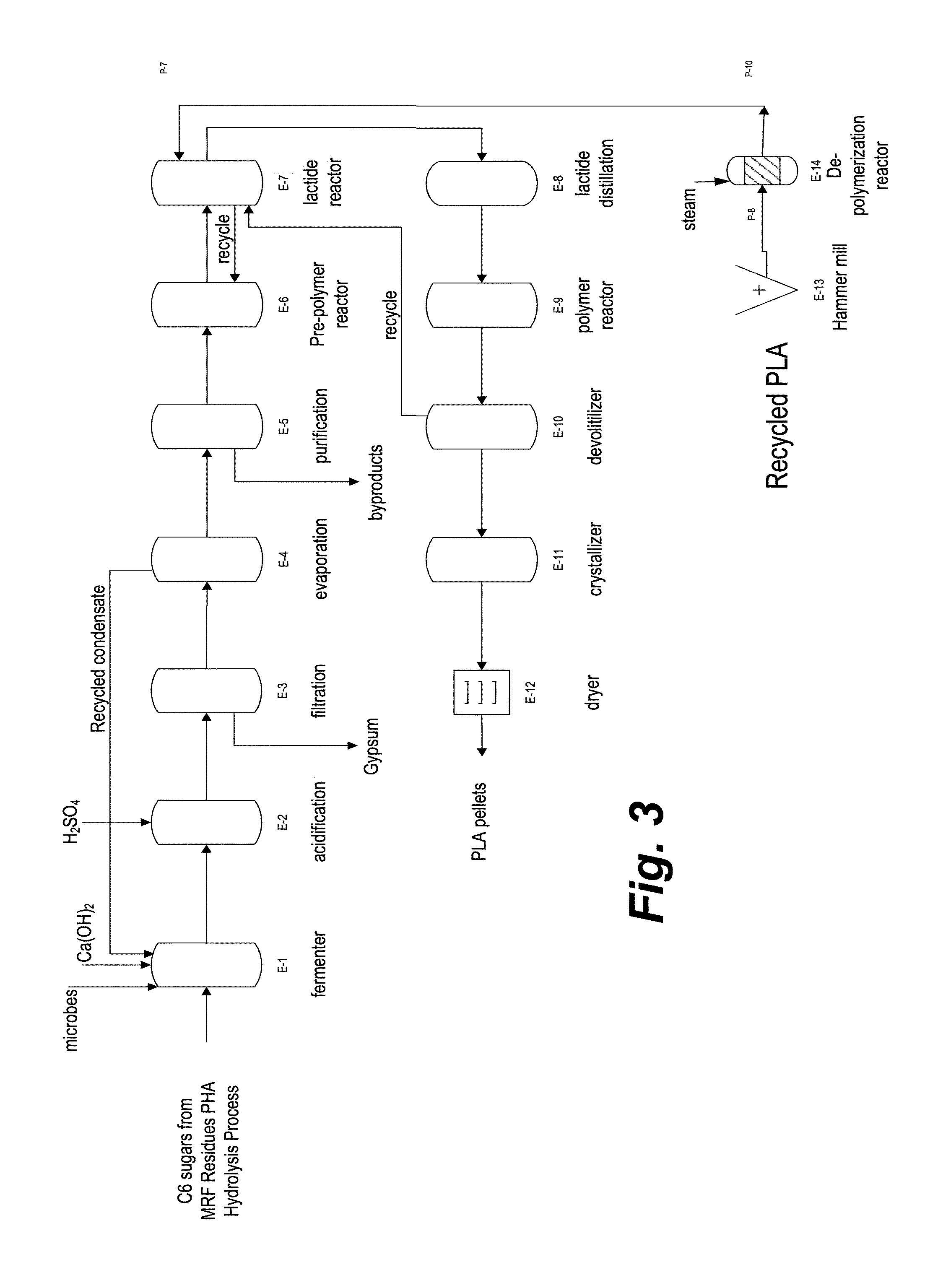

Lactide Production from Thermal Depolymerization of PLA with applications to Production of PLA or other bioproducts

InactiveUS20130023674A1Reduce shipping costsLow costOrganic chemistryPlastic recyclingBioproductsLactide

Methods and systems are disclosed for producing lactide, which can be used for PLA production or other valuable bioproducts. PLA is heated to undergo thermal depolymerization to recover lactide. The lactide can be used for PLA production or other valuable bioproducts.

Owner:NARAYAN RAMANI +2

Methods for converting plastic to wax

Methods for converting plastic to wax are provided. In one embodiment, a method for converting a waste plastic to wax includes introducing the waste plastic into a chamber and adding hydrogen to the chamber. The method includes heating the waste plastic and hydrogen sufficiently to thermally depolymerize the waste plastic to form a wax product comprising paraffin and olefin compounds.

Owner:HONEYWELL INT INC

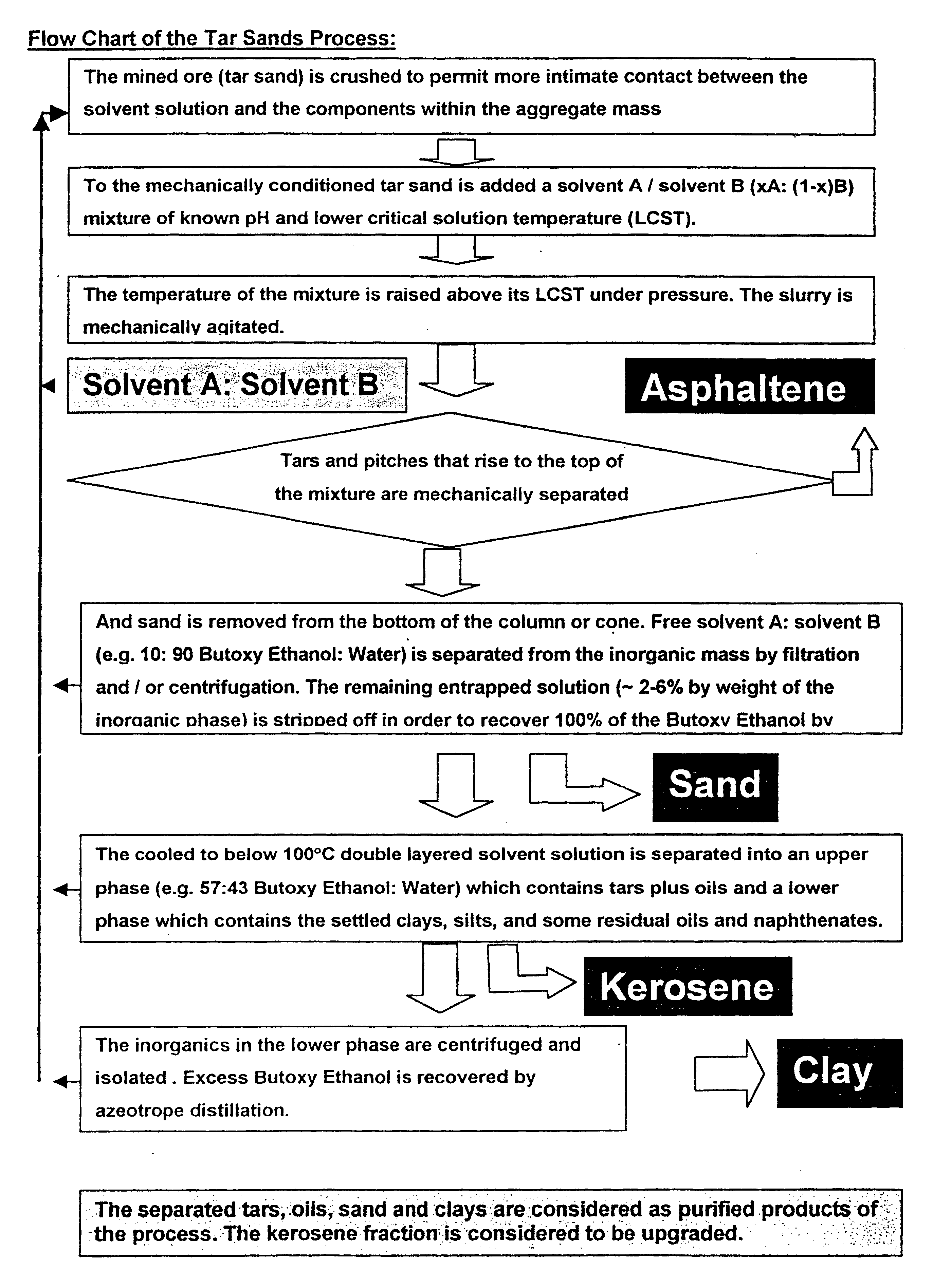

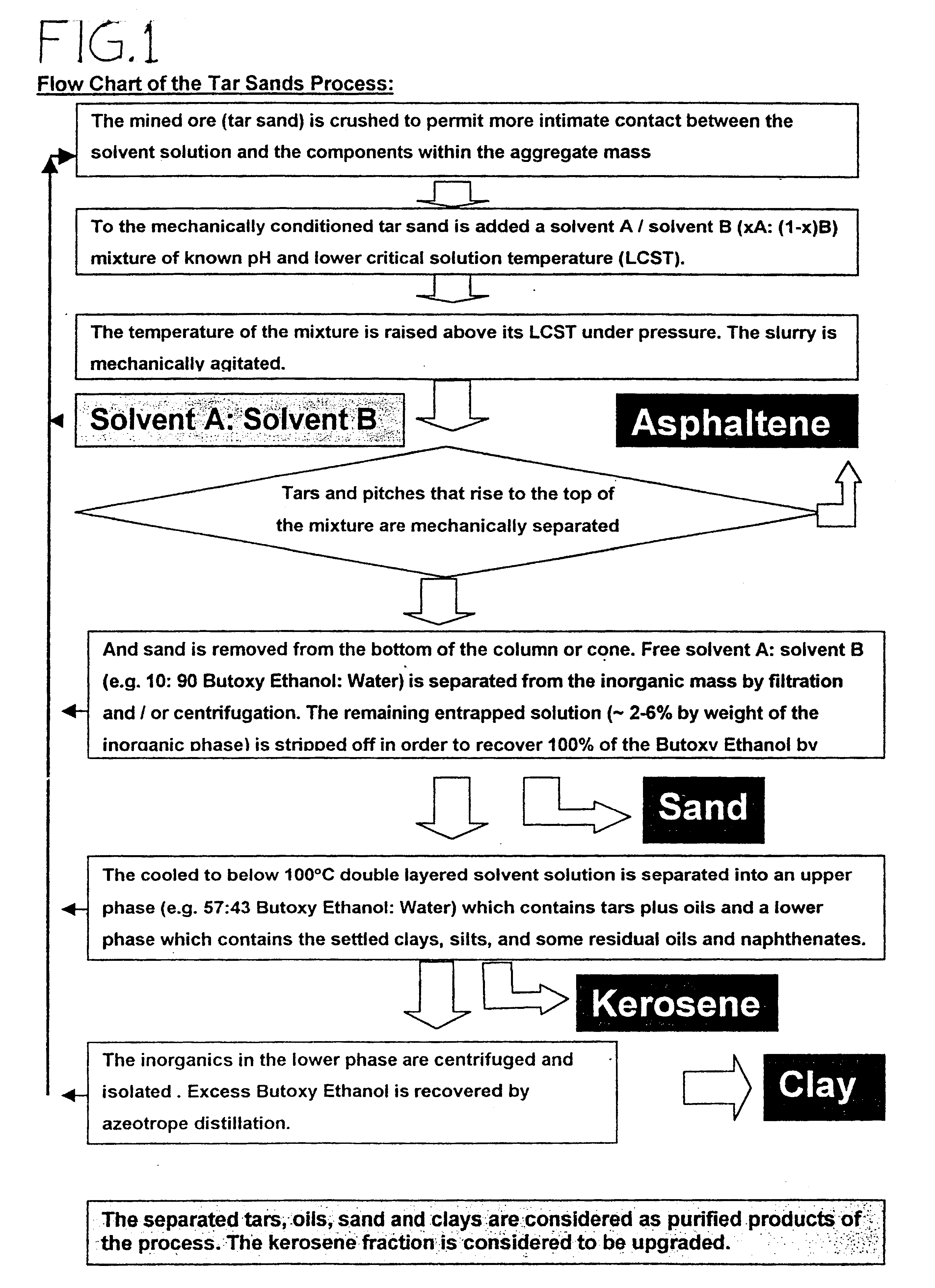

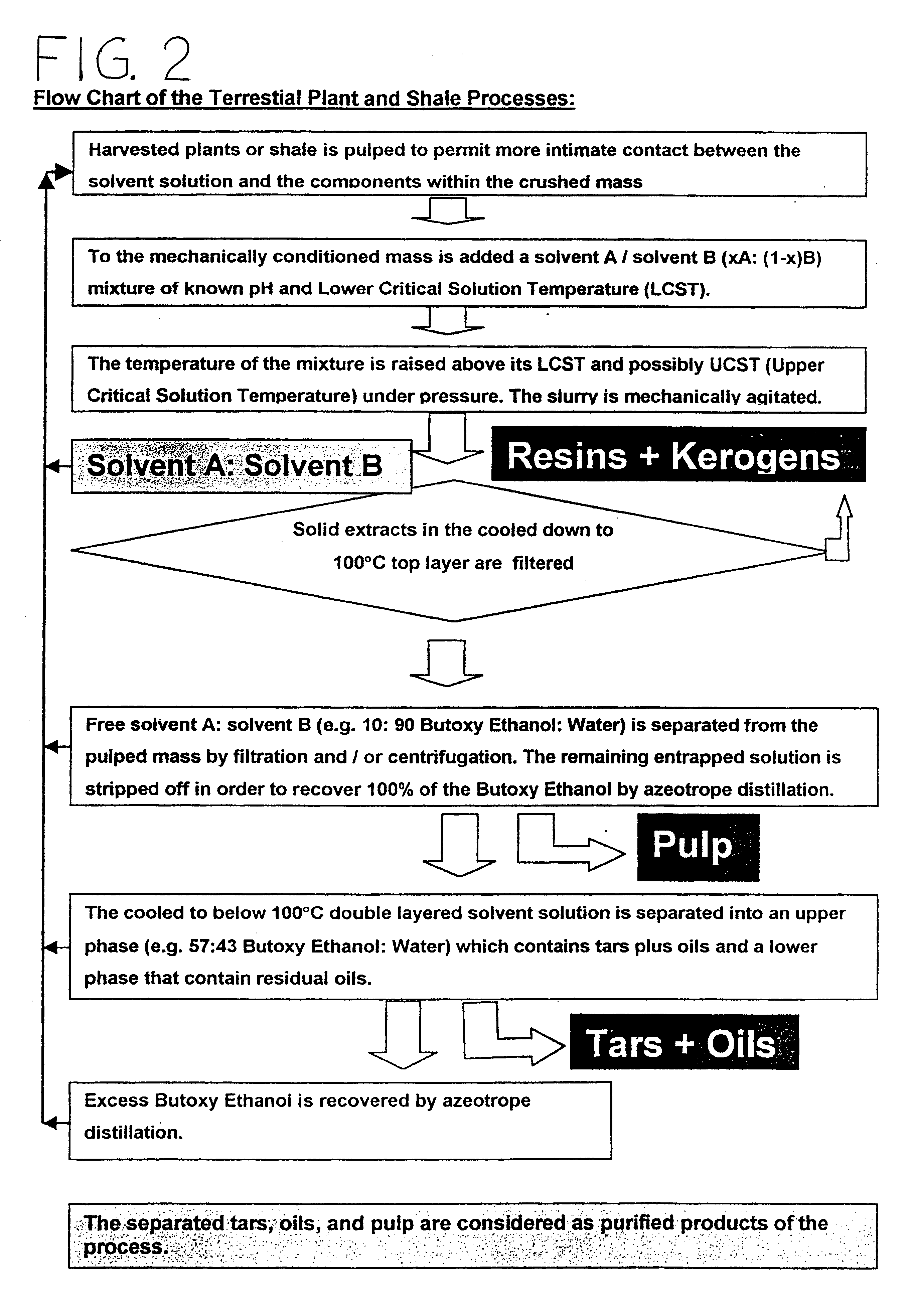

Separation of tars, oils and inorganic constituents from oil bearing sands or shales

InactiveUS6464856B1Improve featuresEasy to separateWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCelluloseKerogen

An improved process for the total separation and recovery of four constituents, namely, 1) insoluble pitches and tars also known as asphaltenes, 2) a kerosene based oil fraction, 3) clays and silts of less than 80 mum mesh and 4) sands of greater than 80 mum mesh. Recombination of the hydrocarbon fractions is the bitumen portion of tar sands. A further process for the extraction and separation of plant resins from cellulose and kerogen from oil shale that on thermal depolymerization become a source for aromatic and kerosene based oil fractions respectively.

Owner:DEINKING SOLVENT EXTRACTION TECH

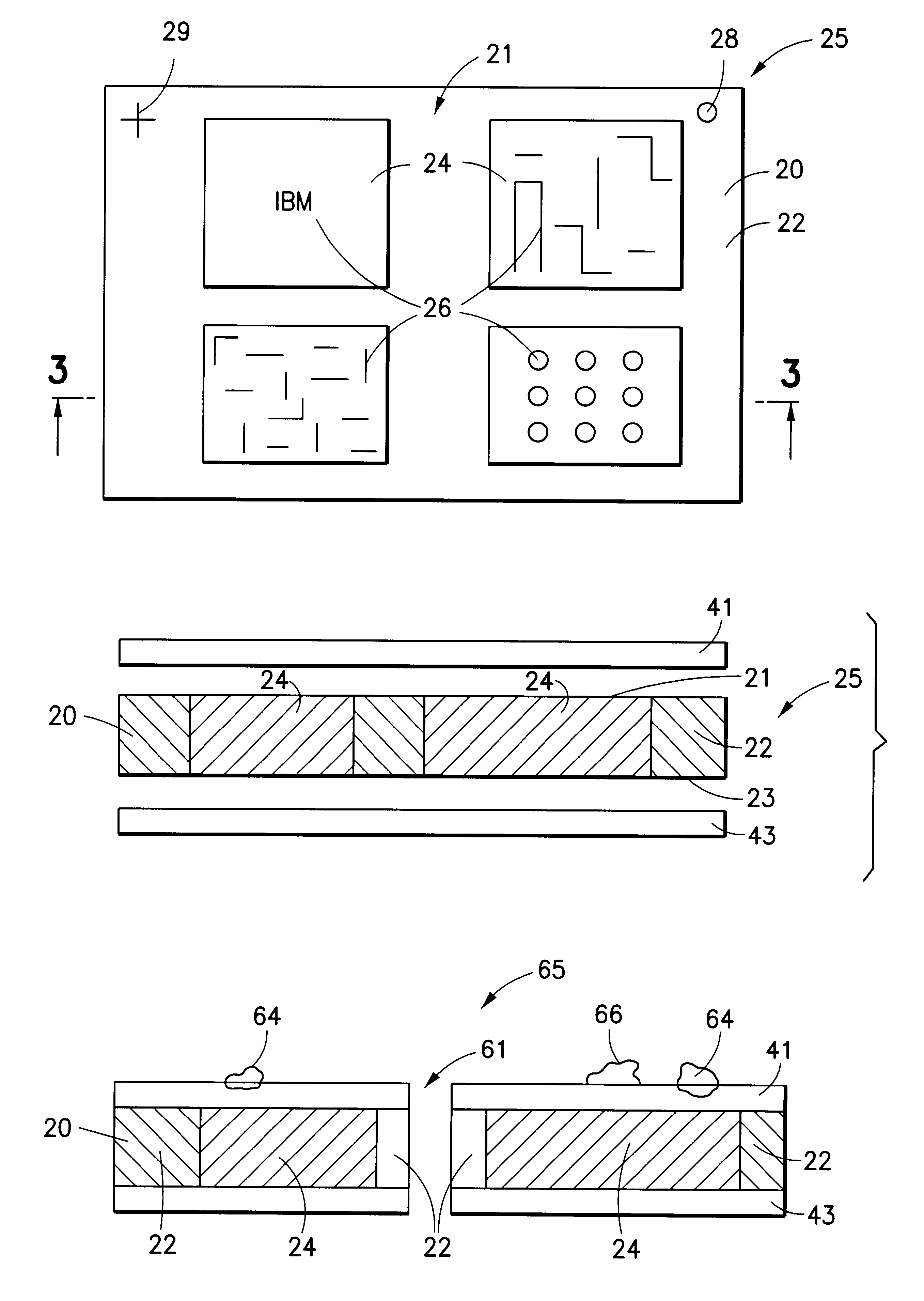

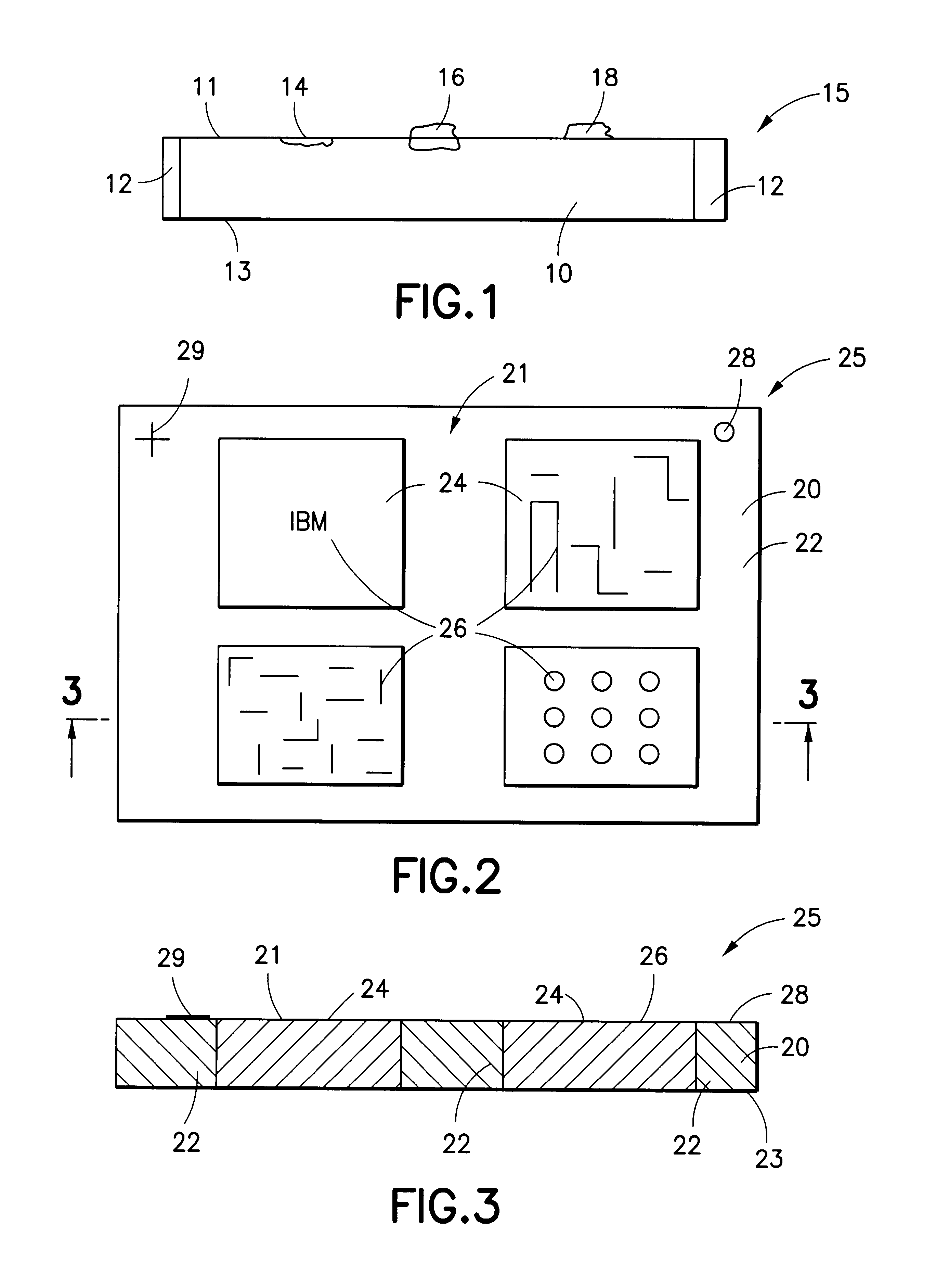

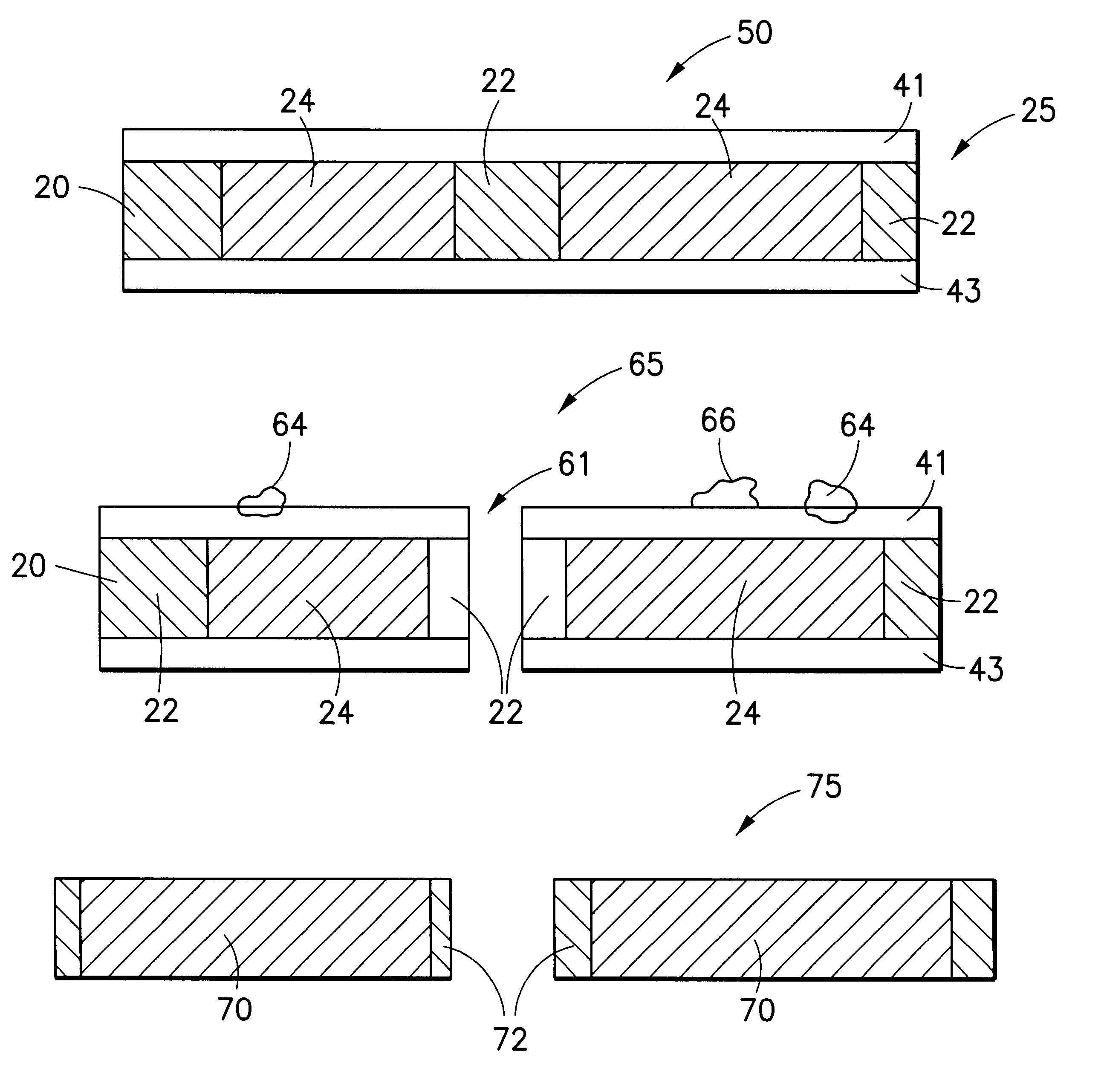

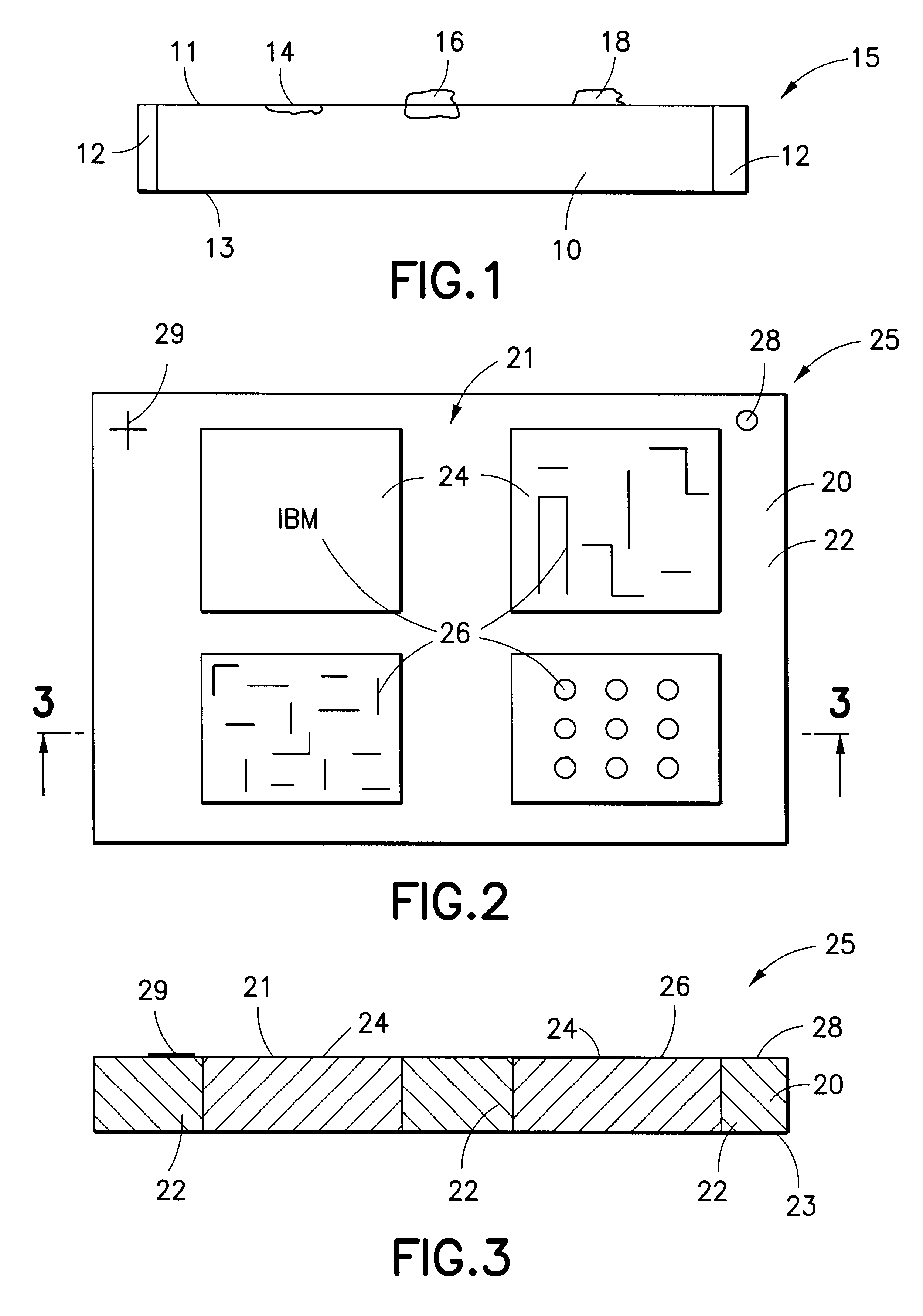

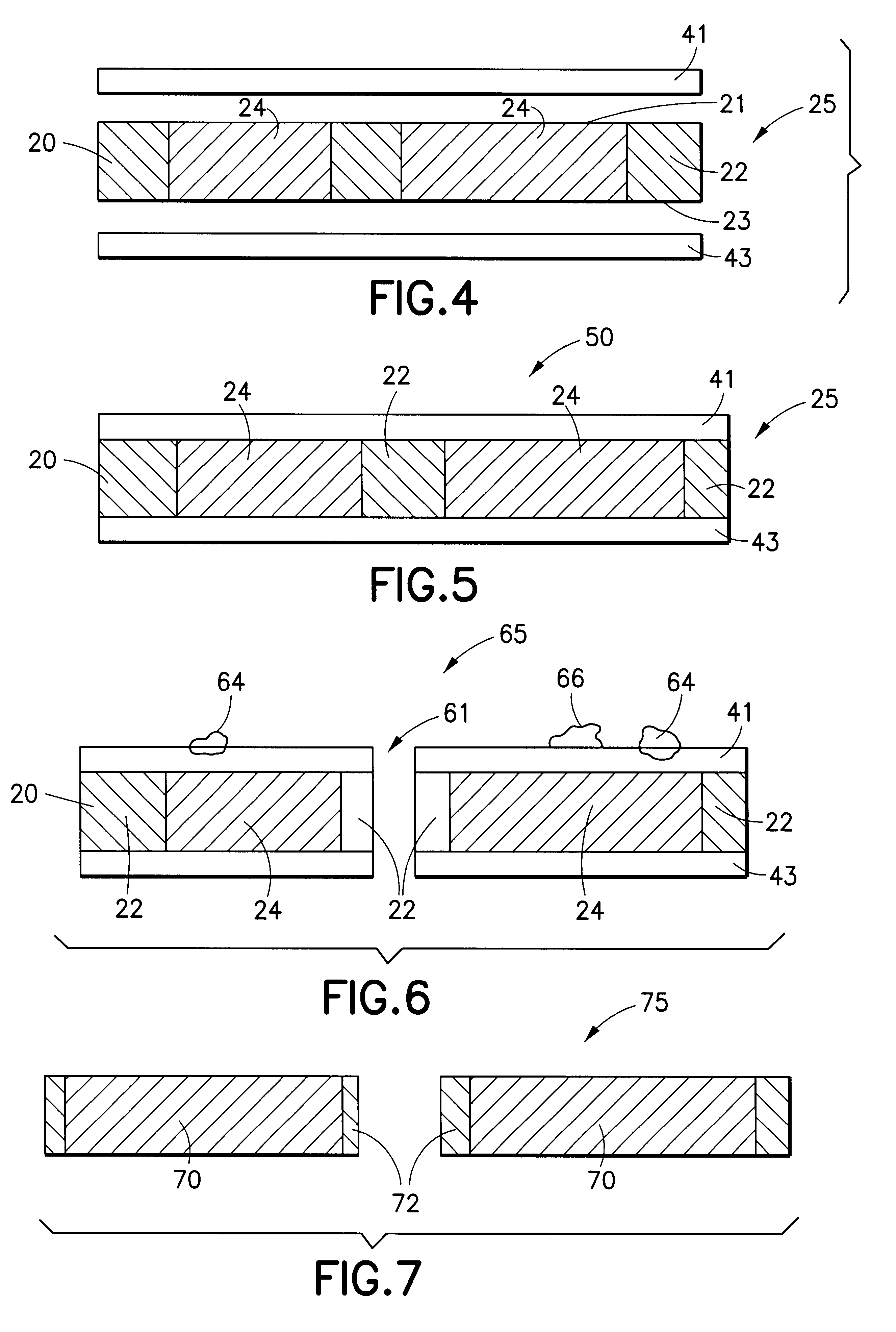

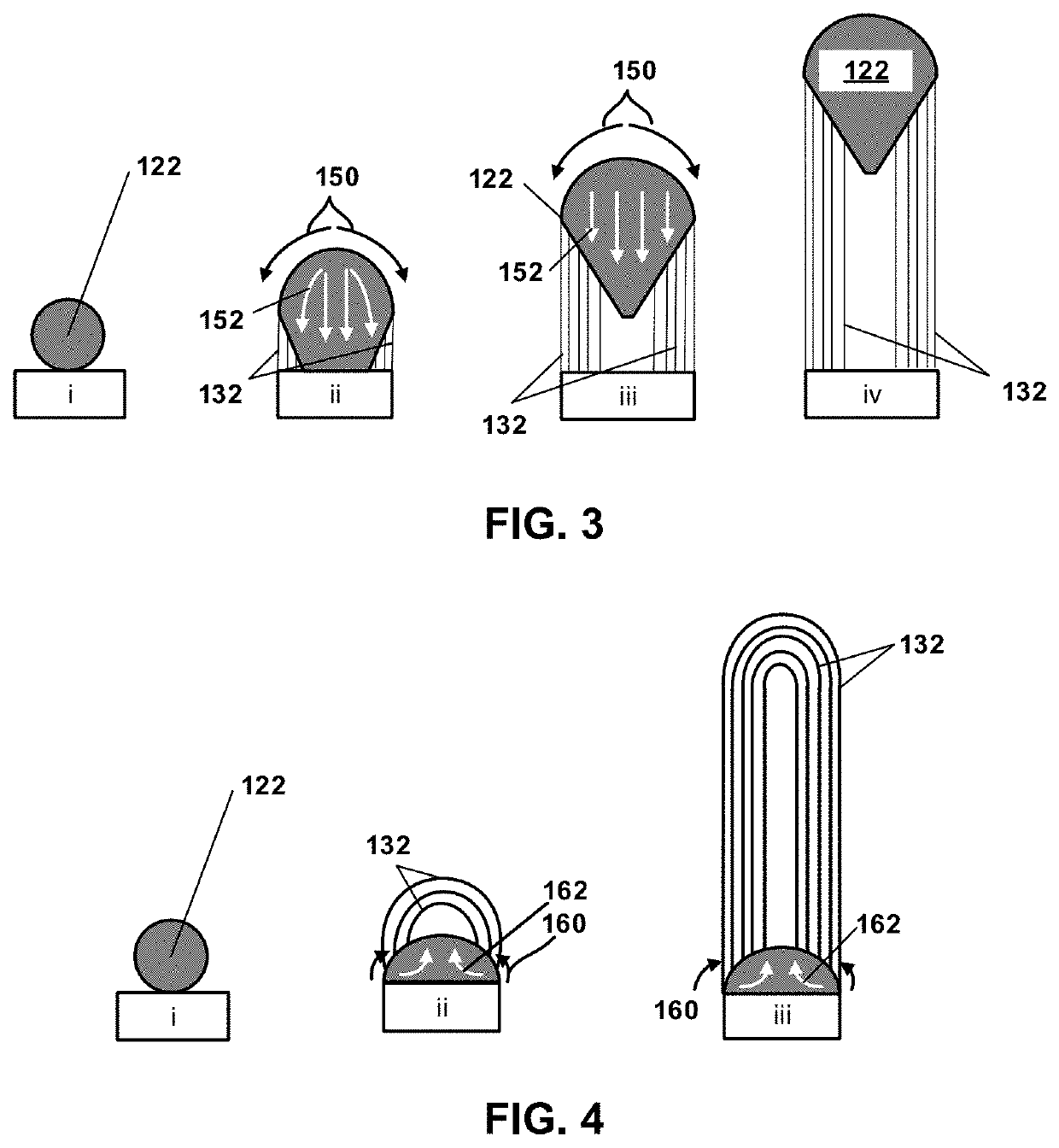

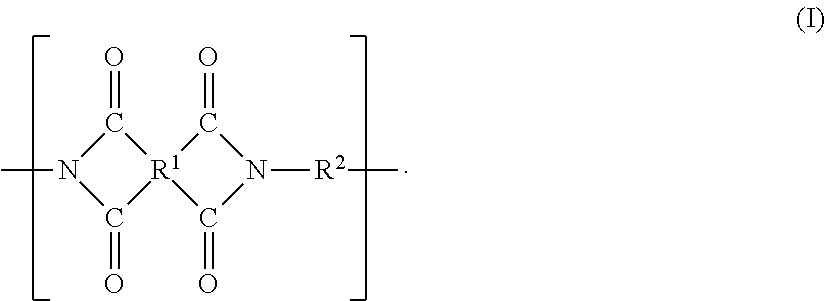

Method of forming defect-free ceramic structures using thermally depolymerizable surface layer

InactiveUS6261927B1Minimize and eliminate processing defectImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSurface layerTopography

This invention relates generally to a new method of forming semiconductor substrates with defect-free surface metallurgical features. In particular, the invention related to a method for providing surface protected ceramic green sheet laminates using at least one thermally depolymerizable surface layer. More particularly, the invention encompasses a method for fabricating semiconductor substrates wherein a thermally depolymerizable / decomposable surface film is placed over a ceramic green sheet stack or assembly prior to lamination and caused to conform to the surface topography of the green sheet during lamination. The invention also encompasses a method for fabricating surface protected green sheet laminates which can be sized or diced without causing process related defects on the ceramic surface. After lamination the thermally depolymerizable / decomposable film is conveniently and cleanly removed due to thermal depolymerization and burn-off of volatile species during the sintering process, thus providing surface defect-free ceramic substrates.

Owner:IBM CORP

Method of forming defect-free ceramic structures using thermally depolymerizable surface layer

InactiveUS6597058B1Minimize and eliminate processing defectImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSurface layerTopography

Owner:INT BUSINESS MASCH CORP

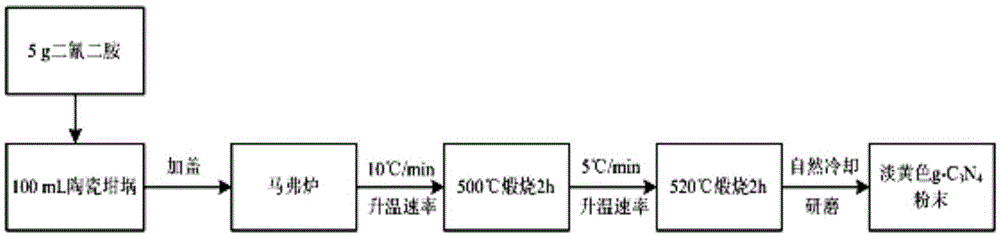

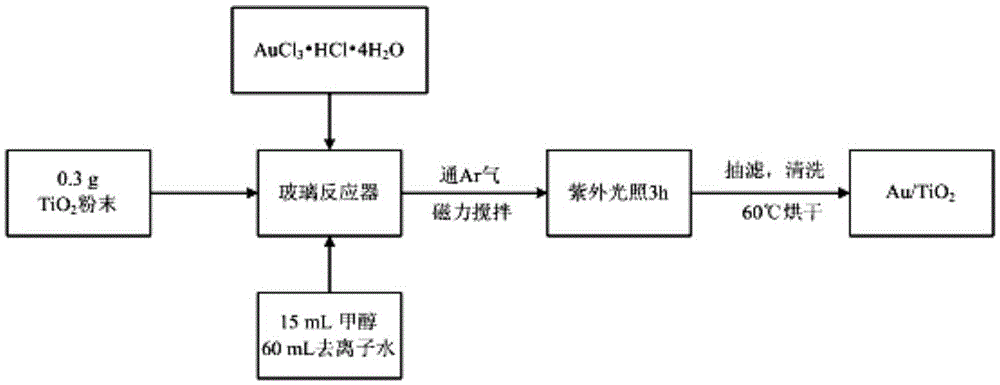

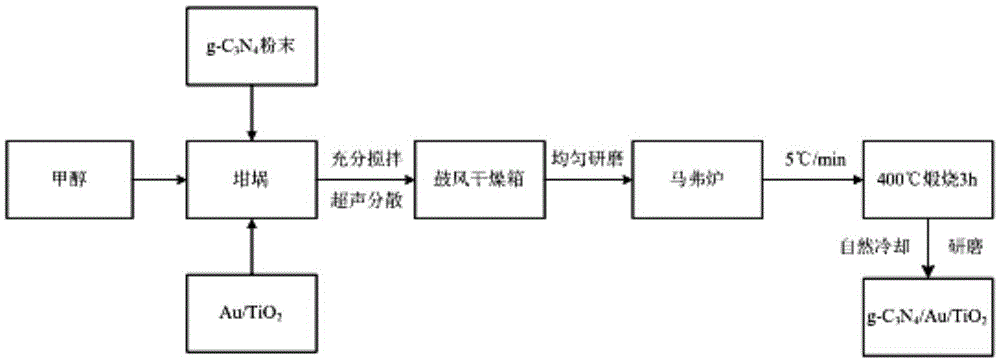

Preparation method of highly visible light electron transfer g-C3N4/ Au/TiO2 Z type photocatalyst

InactiveCN105536843AImprove responsivenessEasy to separateCatalyst activation/preparationMaterials preparationPhotocatalytic reaction

The invention relates to the fields of material preparation and photocatalysis, and aims at providing a preparation method of a highly visible light electron transfer g-C3N4 / Au / TiO2 Z type photocatalyst. The method comprises the steps: preparing g-C3N4 by a precursor pyrolysis polymerization method, preparing an AuCl3.HCl.4H2O stock solution, preparing Au / TiO2 and preparing the g-C3N4 / Au / TiO2 Z type photocatalyst. In the g-C3N4 / Au / TiO2 Z type photocatalyst, firstly, TiO2 is loaded with Au, then the loaded TiO2 and g-C3N4 are calcined to form a whole, and Au is located between TiO2 and g-C3N4. Au is used as an electron transfer body and can promote complete separation of photogenerated electrons and hole pairs; an SPR effect of Au can enhance the response ability of the catalyst on visible light; with synergistic effect of a Z type electron transfer path and the SPR effect of Au, the activity of a photocatalytic reaction can be ultimately improved.

Owner:ZHEJIANG UNIV

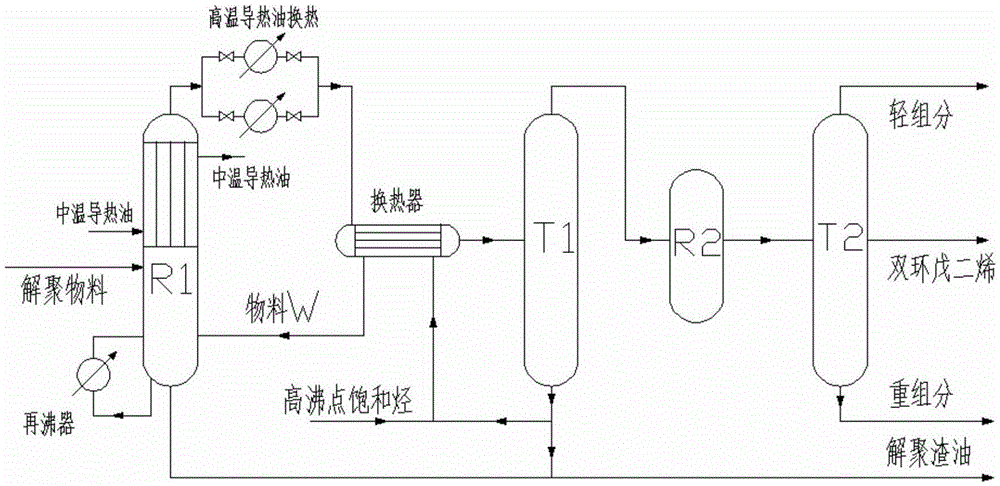

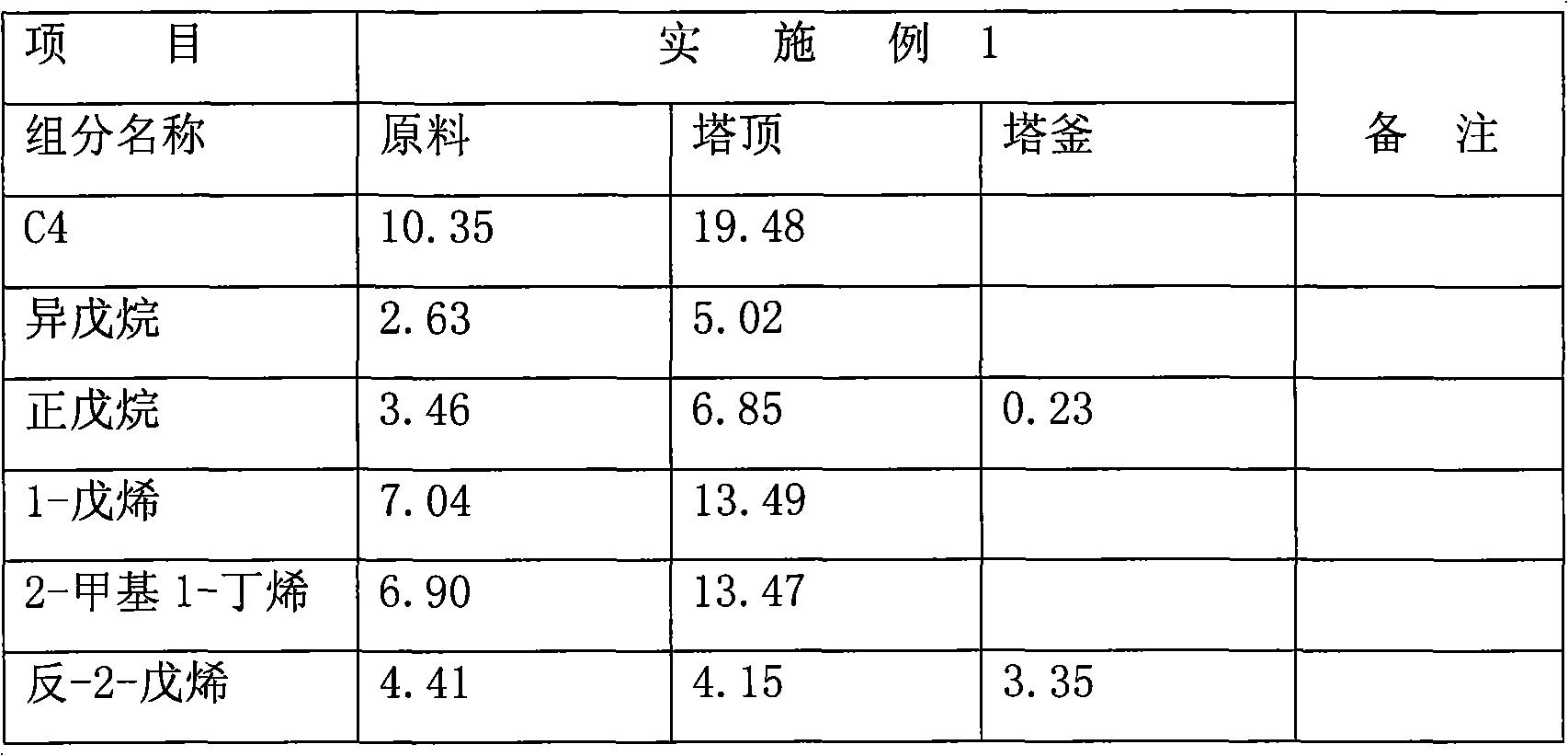

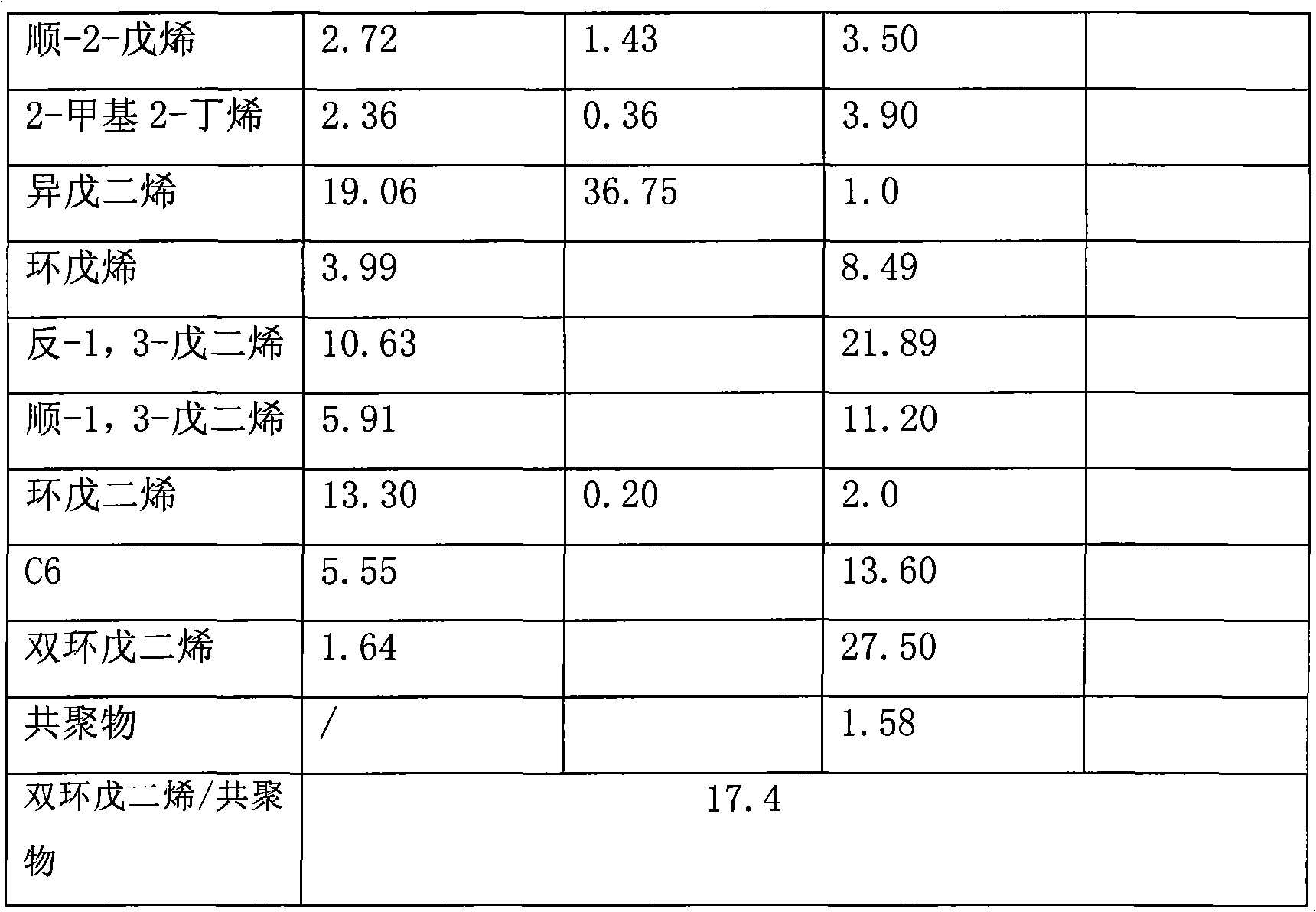

Method for preparing dicyclopentadiene through gas-liquid phase depolymerization of C9 raw material

ActiveCN105399590AImprove conversion rateAdvanced technologyHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationGas phaseTower

The invention relates to a method for preparing dicyclopentadiene through gas-liquid phase depolymerization of a C9 raw material. The method comprises the following steps: carrying out reduced pressure rectification division on the C9 raw material to obtain a thermal depolymerization raw material, preheating the thermal depolymerization raw material, and conveying the preheated thermal depolymerization raw material into a depolymerization kettle R1; carrying out liquid phase to obtain a gasification material, and carrying out a gas phase depolymerization reaction on the gasification material in the upper portion of the depolymerization kettle to obtain a gas phase depolymerization material; adding the gas phase depolymerization material to a tubular heater, heating, carrying out gas phase depolymerization, adding the obtained material to a cooling heat exchanger, carrying out heat exchange to cool in order to obtain a gas phase material and a liquid phase material, allowing the gas phase material and the liquid phase material to enter a rectifying tower T1, obtaining CPD at the top of the rectifying tower T1, allowing CPD to enter a dimerization reactor R2, and dimerizing to obtain DCPD; and allowing the DCPD to enter a rectifying tower T2, carrying out reduced pressure recitification, removing light fraction from the top of the rectifying tower T2, and removing heavy fraction from the bottom of the rectifying tower T2 to obtain dicyclopentadiene. The method has the advantages of advanced process, high conversion rate of the C9 raw material for preparing the DCPD, full recycling of system waste heat, and suitableness for industrial application, and the purity of the obtained DCPD product is not lower than 99%.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

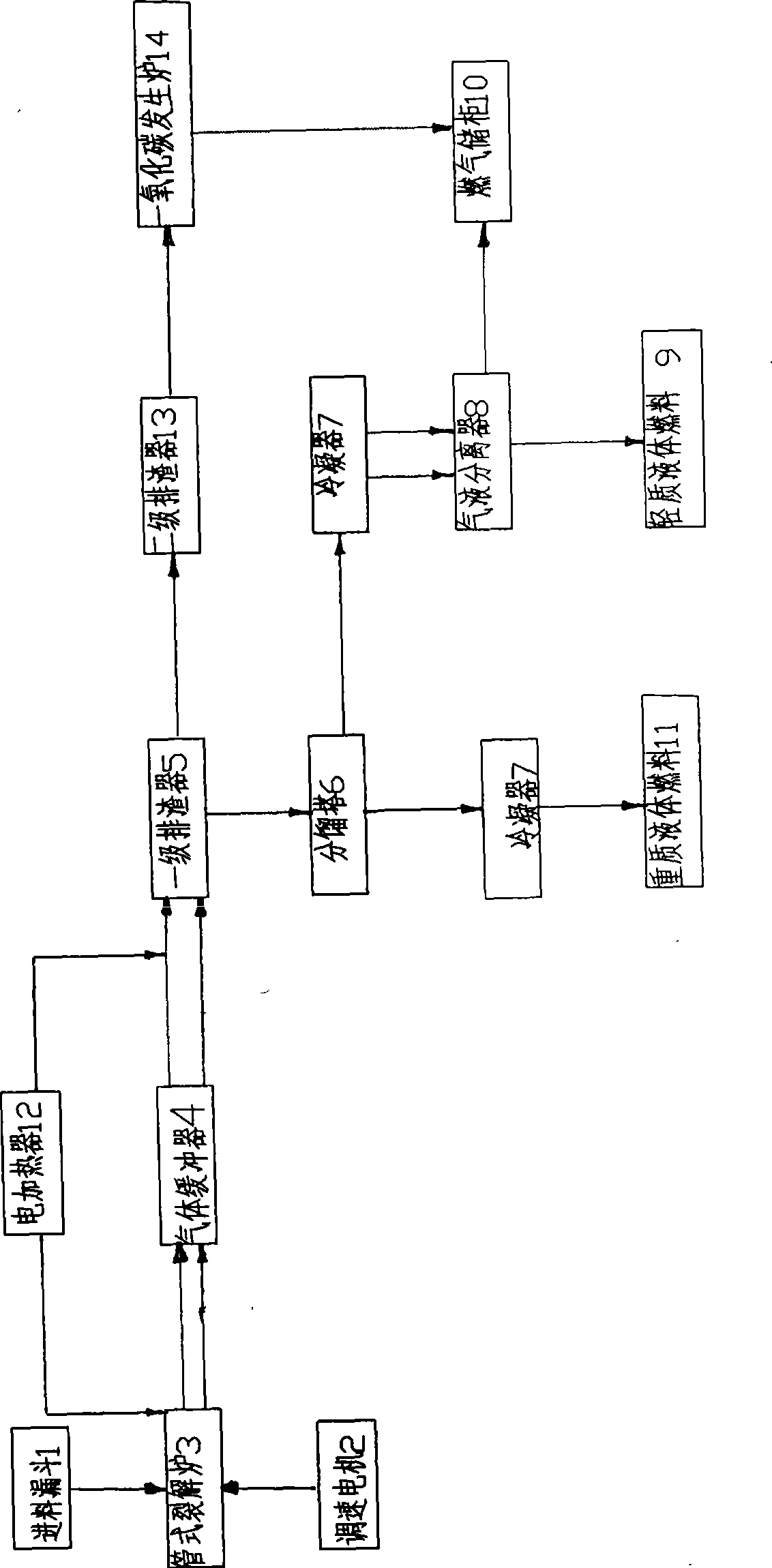

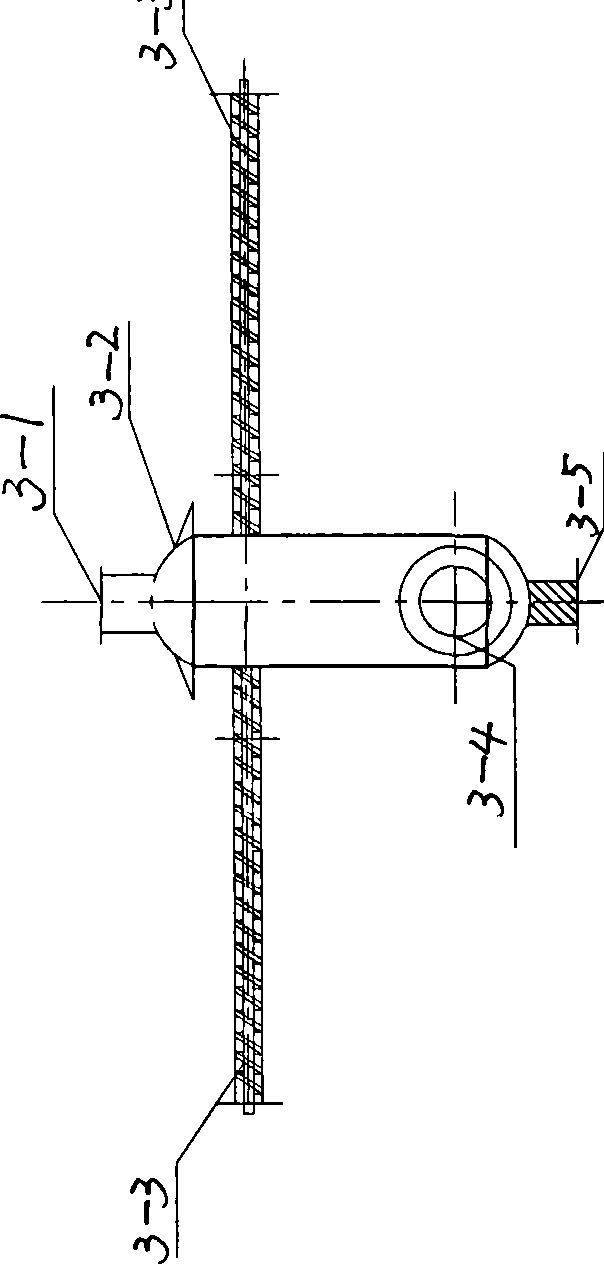

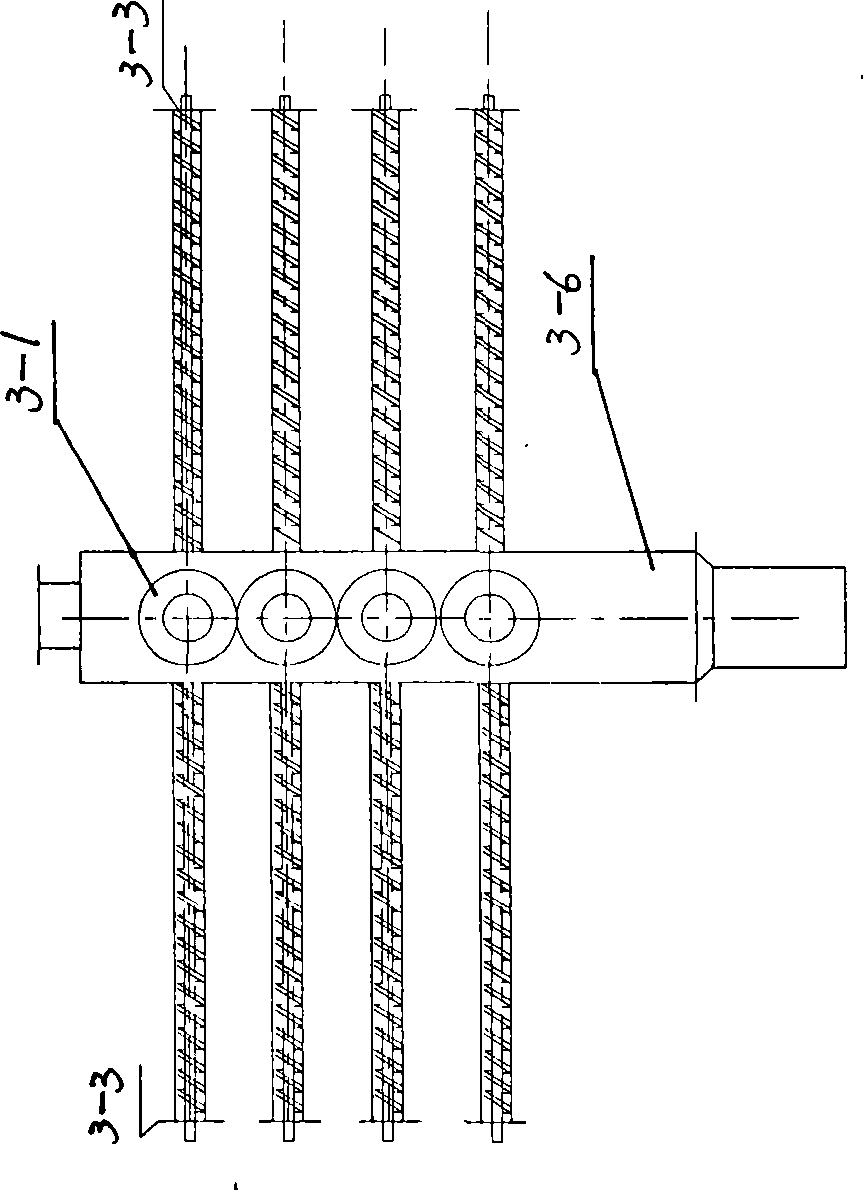

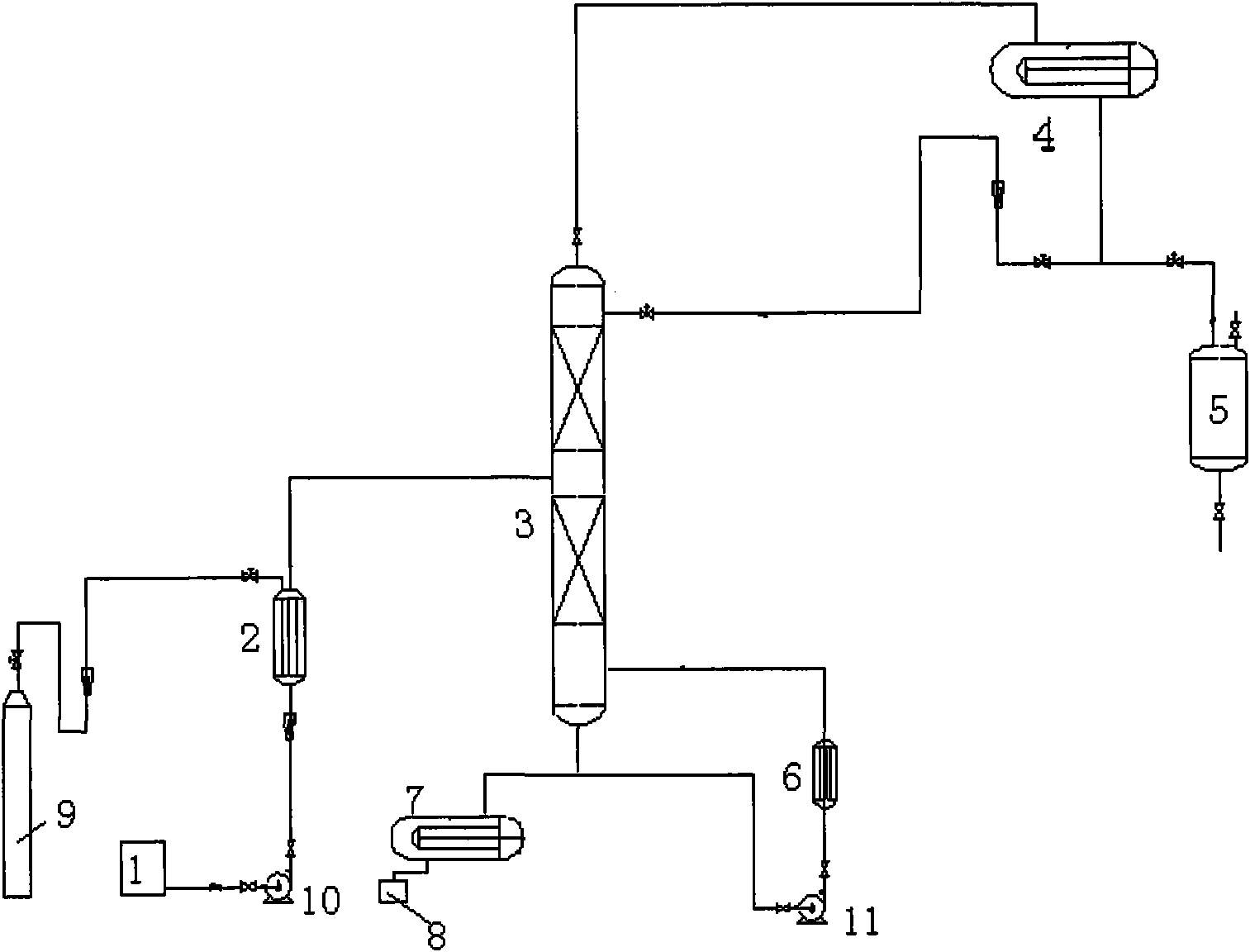

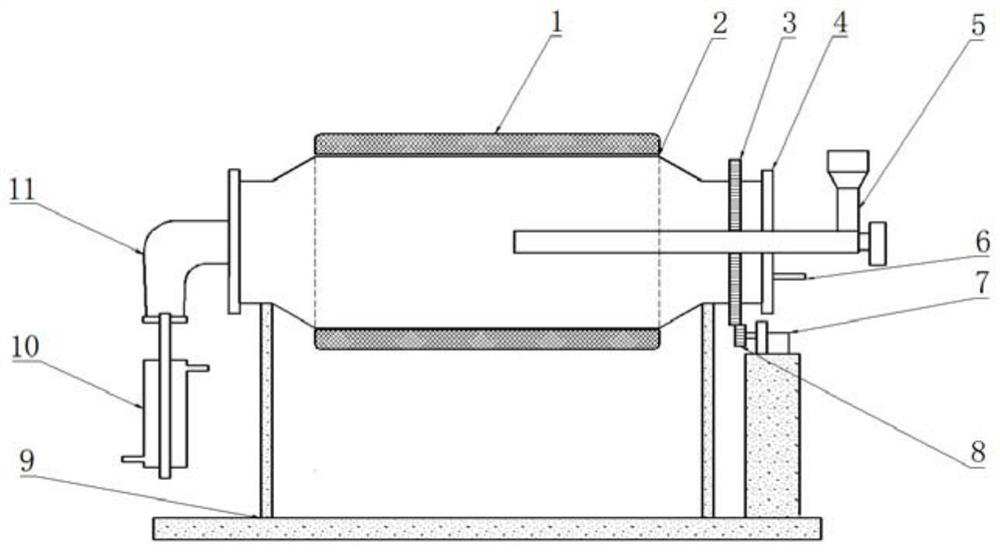

Method and special equipment for recycling to produce fuel

The invention relates to a method and a special equipment for recycling organic wastes to generate fuels. The method is as follows: the organic wastes are delivered from two ends of a feed delivery tube [3-3] to a tube cracking furnace [3] and finally to a collector with a heating device, followed by thermal depolymerization at the temperature ranging from 200 to 240 DEG C; the depolymerized gasified material enters a primary discharging unit [5] for cracking at the temperature ranging from 200 to 240 DEG C via the collector, and enters a fractionating tower [6], the un-gasified material is subjected to the thermal cracking at the temperature ranging from 240 to 350 DEG C until the process of the catalytic cracking is completed at the temperature ranging from 420 to 450 DEG C, the gas-liquid fuel is obtained via post-treatments. The tube cracking furnace solves the difficult technical problems in the heating and feeding production of current kettle-type thick tubes, is heated uniformly without congestion, realizes consecutive production operation and can treat 60-90T of the organic wastes per day with the recycling rate reaching over 50%. The primary discharging unit is high in the strength of the apparatus and free from dead corners and residual slag when delivering the materials, which avoids the apparatus from local overheating and deformation due to scale formation and coking, furthermore, the unit has small volume, high safety factor in the production process and low replacement frequency of the unit and the components thereof.

Owner:CHAOYANG SHENYUAN ACTIVE CARBON

Method for in situ growth of axial geometry carbon structures in electrodes

Owner:GM GLOBAL TECH OPERATIONS LLC

Manufacturing carbon molecular sieve membranes using a pyrolysis atmosphere comprising sulfur-containing compounds

ActiveUS20160184775A1Satisfactory performanceSemi-permeable membranesMembranesCompound aMolecular sieve

A carbon molecular sieve (CMS) membrane is made by pyrolyzing a polymeric precursor membrane in a pyrolysis atmosphere containing a sulfur-containing compound.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

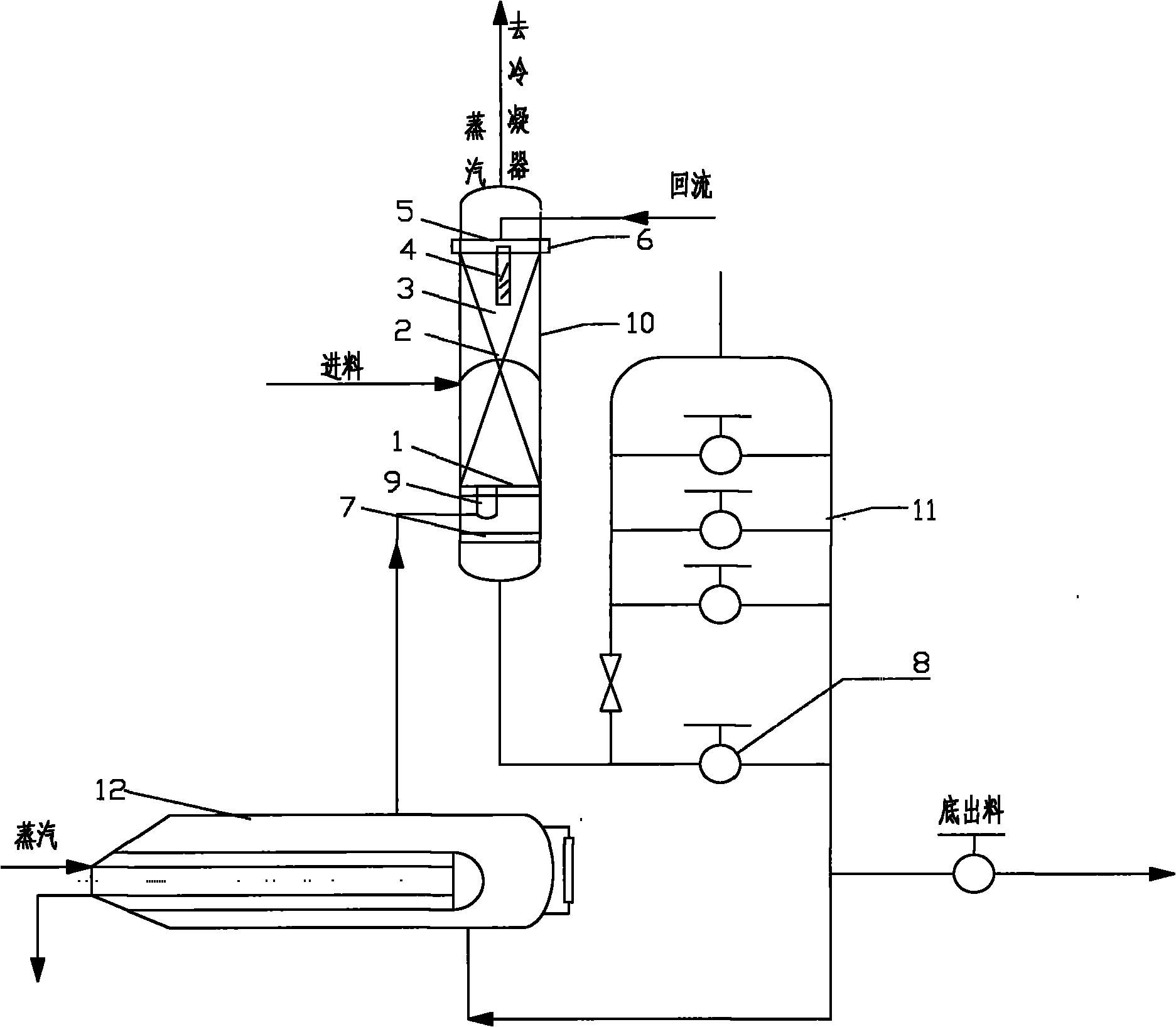

Method for preparing dicyclopentadiene and emulsifying packed tower used thereby

InactiveCN102040456AIncrease throughputImprove efficiencyHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionDistillationTower

The invention discloses a method for preparing dicyclopentadiene and an emulsifying packed tower used thereby. The method of the invention comprises: feeding a raw material to be cracked to form C5 fraction into the emulsifying packed tower, performing distillation and thermal depolymerization in the emulsifying packed tower, obtaining light dydrocarbon which mainly consists of isoprene from the top of the emulsifying packed tower, delivering the light dydrocarbon to extraction tower directly, and obtaining an isoprene product; and delivering materials separated from the emulsifying packed tower to a pentadiene removing tower to obtain a dicyclopentadiene product. When the method of the invention is adopted, the loss of the isoprene in the raw material to be cracked to form the C5 fraction is reduced, the quality of the dicyclopentadiene is improved, the mass transfer effect of the equipment is reinforced, and the method and the emulsifying packed tower can be used for production in an industrial process conveniently.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cyclopentadiene through continuous depolymerization and rectification

InactiveCN102336628AMild reaction conditionsControllableHydrocarbon by depolymerisationHeat conductingHeat sensitive

The invention relates to a method for preparing cyclopentadiene through continuous depolymerization and rectification. The method comprises steps that: under the protection of nitrogen, a composite polymerization inhibitor and pure heat conducting oil are added into a thermal decomposition apparatus according to a weight ratio of 0.005-0.01:1, and are heated to a depolymerization temperature of 270 to 300 DEG C; a crude product dicyclopentadiene is continuously and stably added into the thermal decomposition apparatus, a thermal depolymerization reaction time is 1.5 to 2s, and depolymerized cyclopentadiene is delivered into a rectification tower; cyclopentadiene separated from the tower top is delivered into a collecting device through a condenser; small amounts of dicyclopentadiene which is not decomposed, and by products are heated in a tower-bottom re-boiling apparatus, and are rectified again. According to the method, the composite polymerization inhibitor is a complex of an active immobile polymerization inhibitor, a heat sensitive polymerization inhibitor, and cupric salt, wherein a weight ratio of the three is 1:1:0.5-1. The method provided by the invention has advantages of simple equipment, high production capacity, and low coking. According to the invention, the raw material heat conducting oil and the equipment can be used for a long term.

Owner:PETROCHINA CO LTD

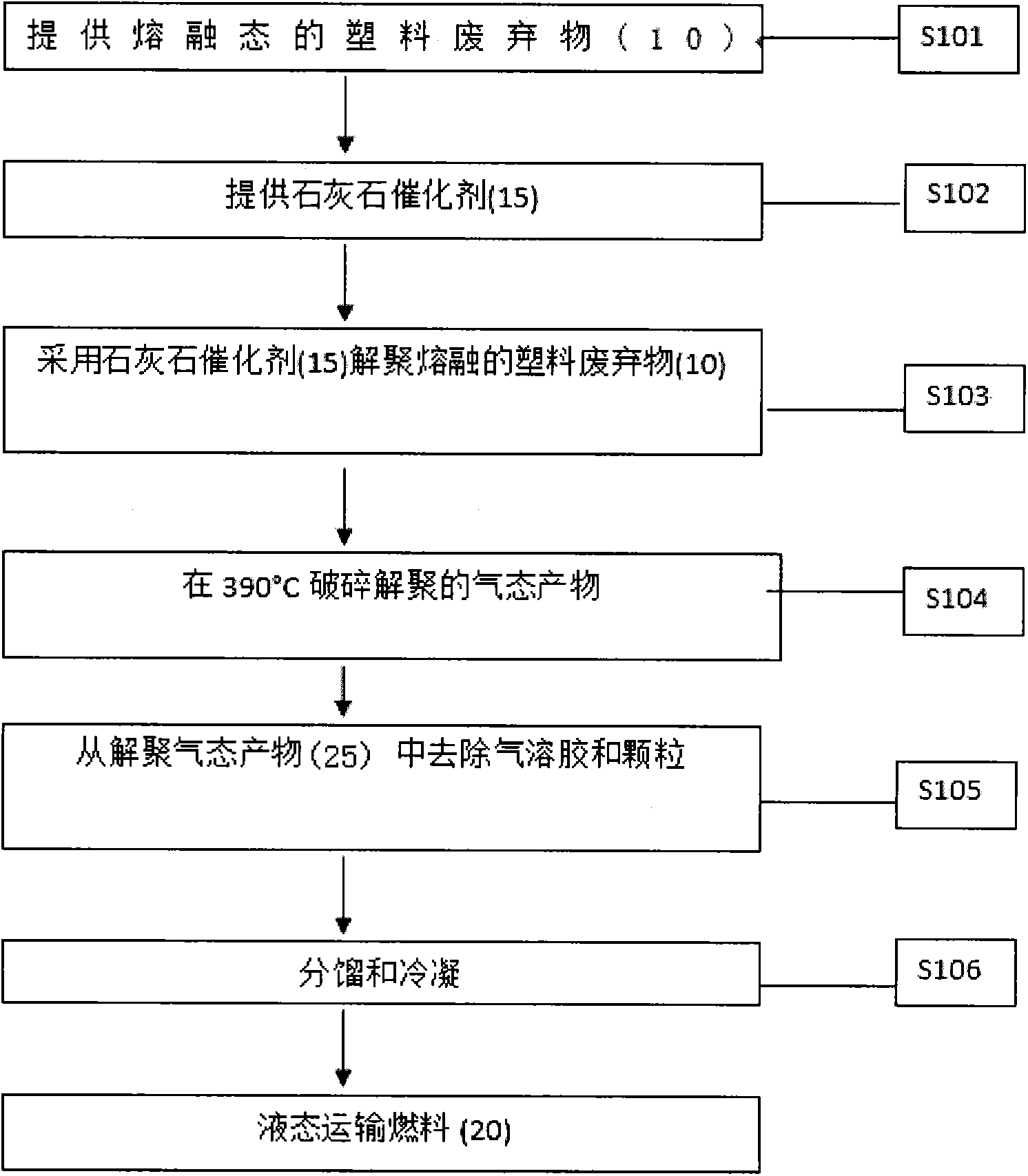

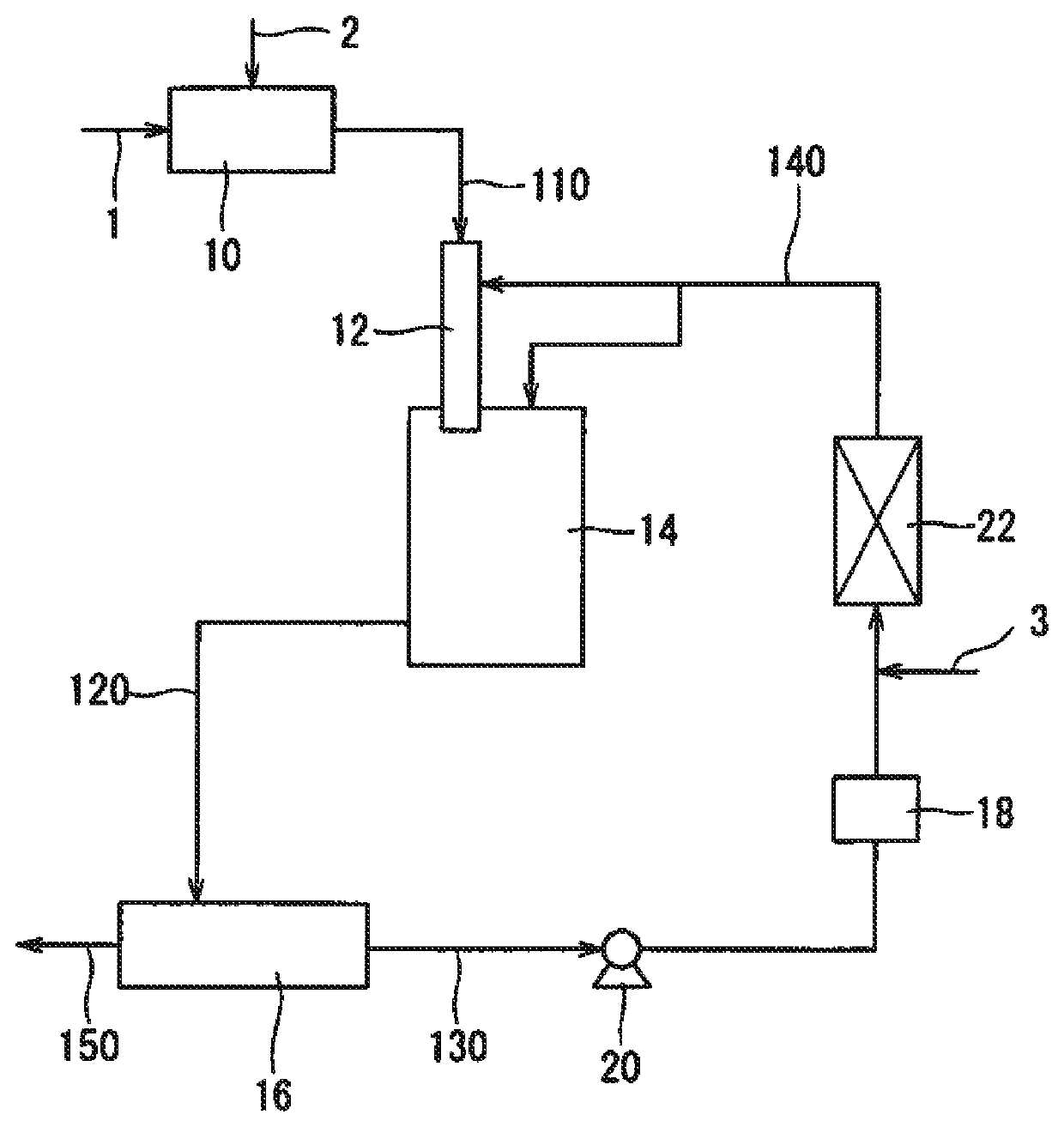

Thermal de-polymerization process of plastic waste materials

The present invention relates to a process for producing liquid transportation fuel (15) based on plastic waste materials (10), comprising the step of: providing (S101) plastic waste materials (10) in molten form; de-polymerizing (S103) molten plastic waste materials (10) into a reaction chamber using a limestone catalyst (20) at a temperature ranging 420 DEG C to 450 DEG C under normal atmospheric pressure condition of 1 Bar; and introducing (S106) gaseous de- polymerized products (25) to a distillation unit thereby allows the gaseous de-polymerized products (25) to be fractionally distilled and condensed into liquid transportation fuels (15).

Owner:SYNGAS

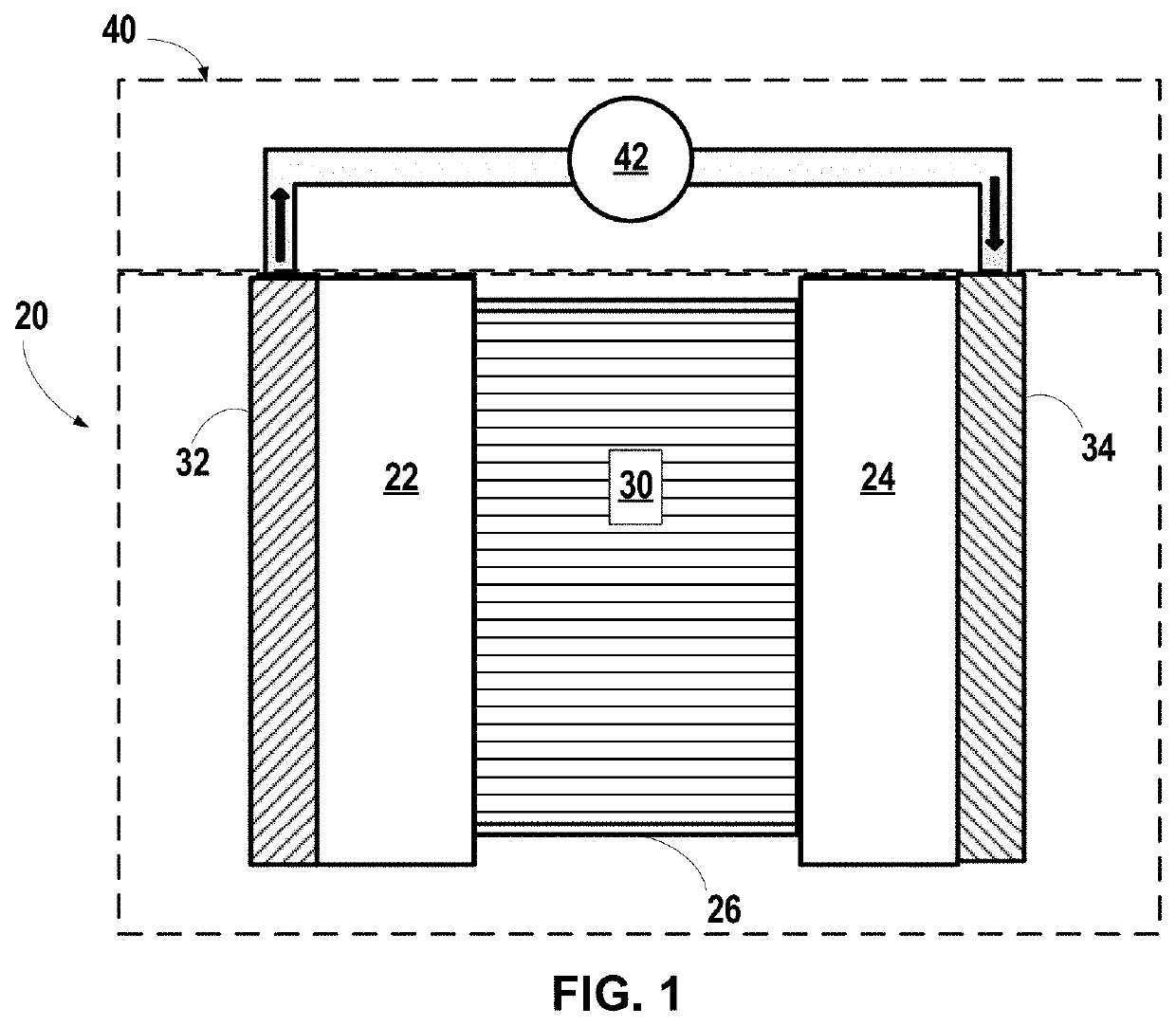

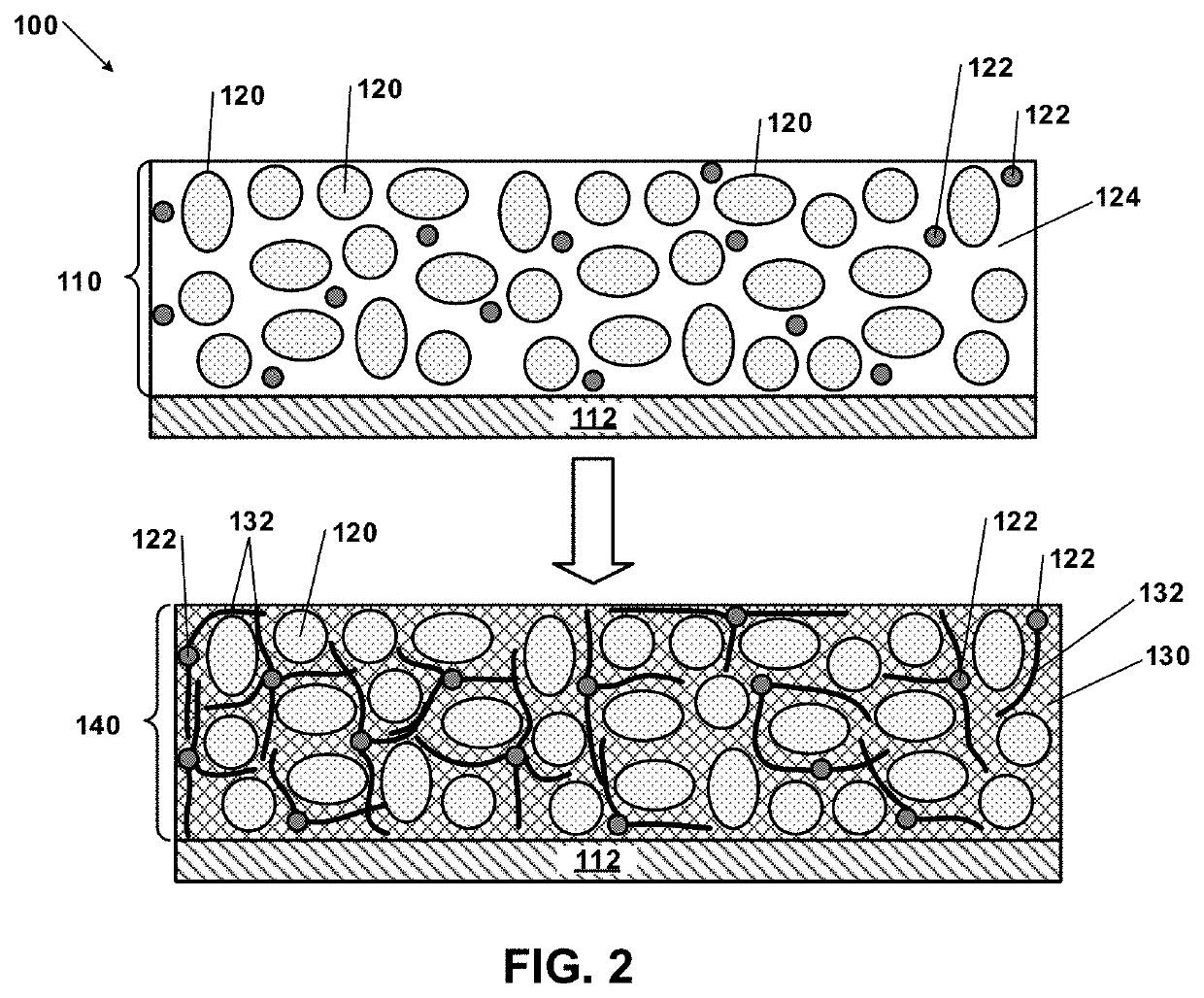

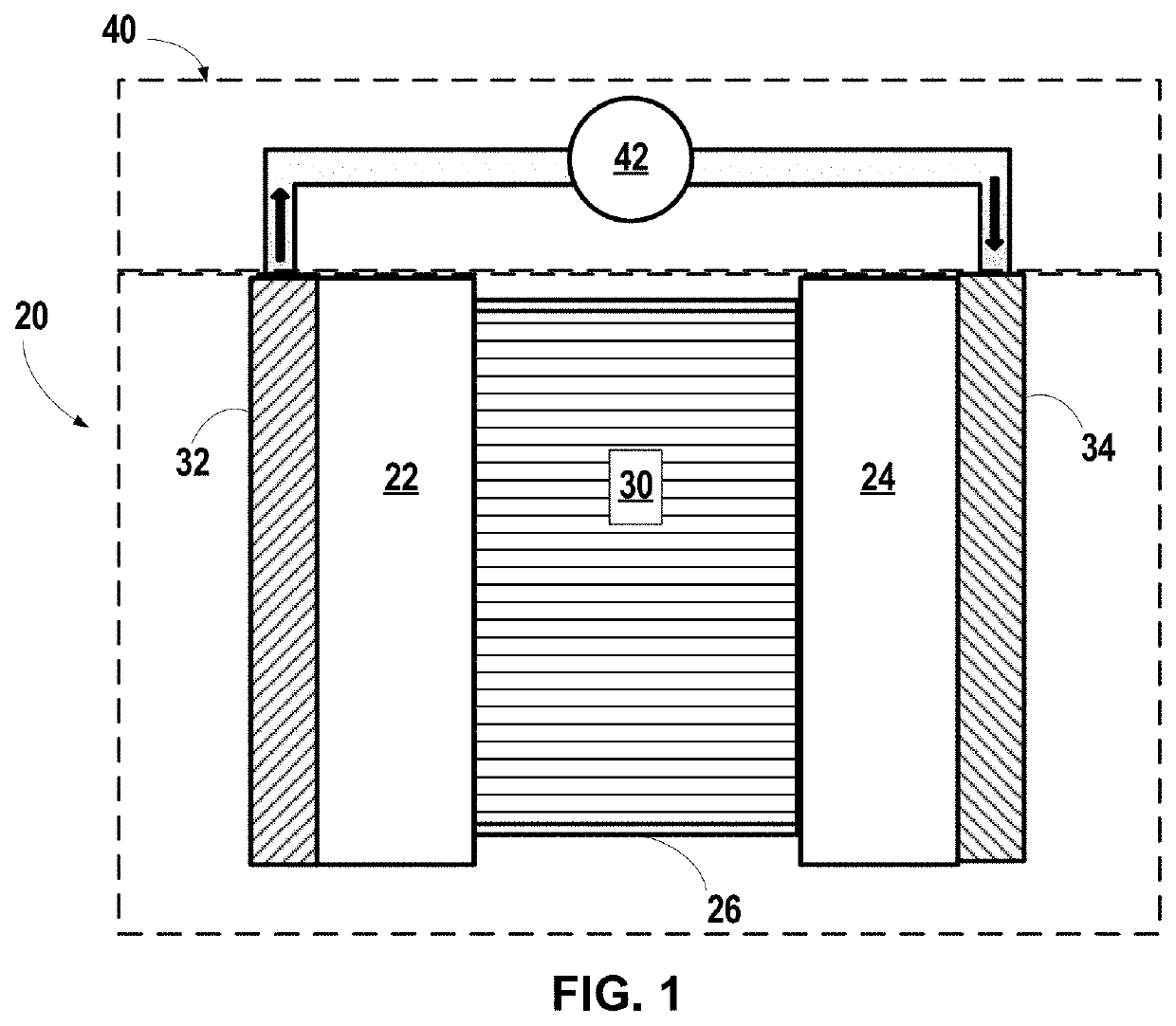

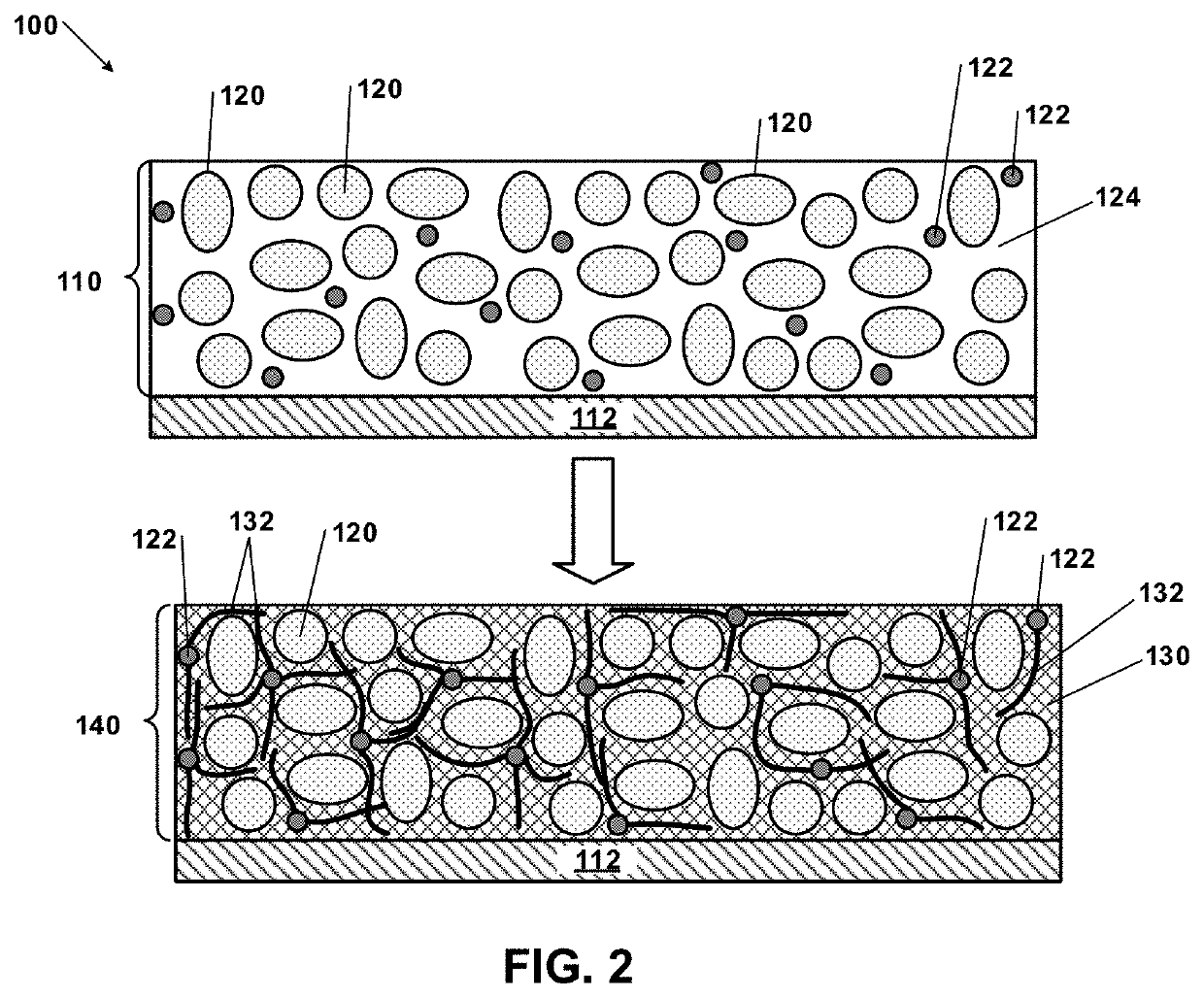

Method for in situ growth of axial geometry carbon structures in electrodes

ActiveUS20200220153A1Increase flexibilityGood mechanical integrityElectrode thermal treatmentSecondary cellsFiberCarbon fibers

Methods of forming a plurality of axial geometry carbon structures (e.g., carbon nanotubes or carbon fibers) in situ in an electrode of an electrochemical cell that cycles lithium ions are provided. Electroactive particles that undergo volumetric expansion are mixed with a polymer precursor and a plurality of catalytic nanoparticles comprising a metal selected from the group consisting of: iron, nickel, cobalt, alloys, and combinations thereof to form a substantially homogeneous slurry. The slurry is applied to a substrate and then heated in an environment having a temperature of ≤about 1000° C. and in certain aspects, ≤about 895° C. to pyrolyze the polymer precursor. The plurality of catalytic nanoparticles facilitates in situ precipitation of carbon to grow a plurality of axial geometry carbon structures. After the heating, the electrode includes an electrically conductive carbonaceous porous network comprising the plurality of electroactive particles and the plurality of axial geometry carbon structures.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pyrolysis method of polyolefin waste plastic

The invention belongs to the field of resource utilization of waste plastics, and particularly relates to a pyrolysis method of polyolefin waste plastics. The method comprises the following steps: byusing modified activated carbon as a catalyst, putting a reaction amount of modified activated carbon and polyolefin waste plastics into a reactor, quickly conducting heating under the protection of inert atmosphere for catalytic pyrolysis, condensing a product to obtain aromatic hydrocarbon-rich liquid, and collecting non-condensable gas to obtain hydrogen-rich gas. Nitric acid modified activatedcarbon is selected as the catalyst for catalytic pyrolysis of polyolefin waste plastic for the first time, the catalyst is simple in preparation method, low in cost, recyclable and long in catalyticlife, the surface property of the catalyst is improved after nitric acid oxidation treatment, the catalytic activity and target product selectivity of the catalyst are improved, the technological process is simple, reaction conditions are mild, the reaction process can be completed under normal pressure, the reaction period is short, the catalyst cost is low, existing equipment can be used for production, operation is easy, and the method is suitable for large-scale commercial production.

Owner:SHANDONG UNIV OF TECH

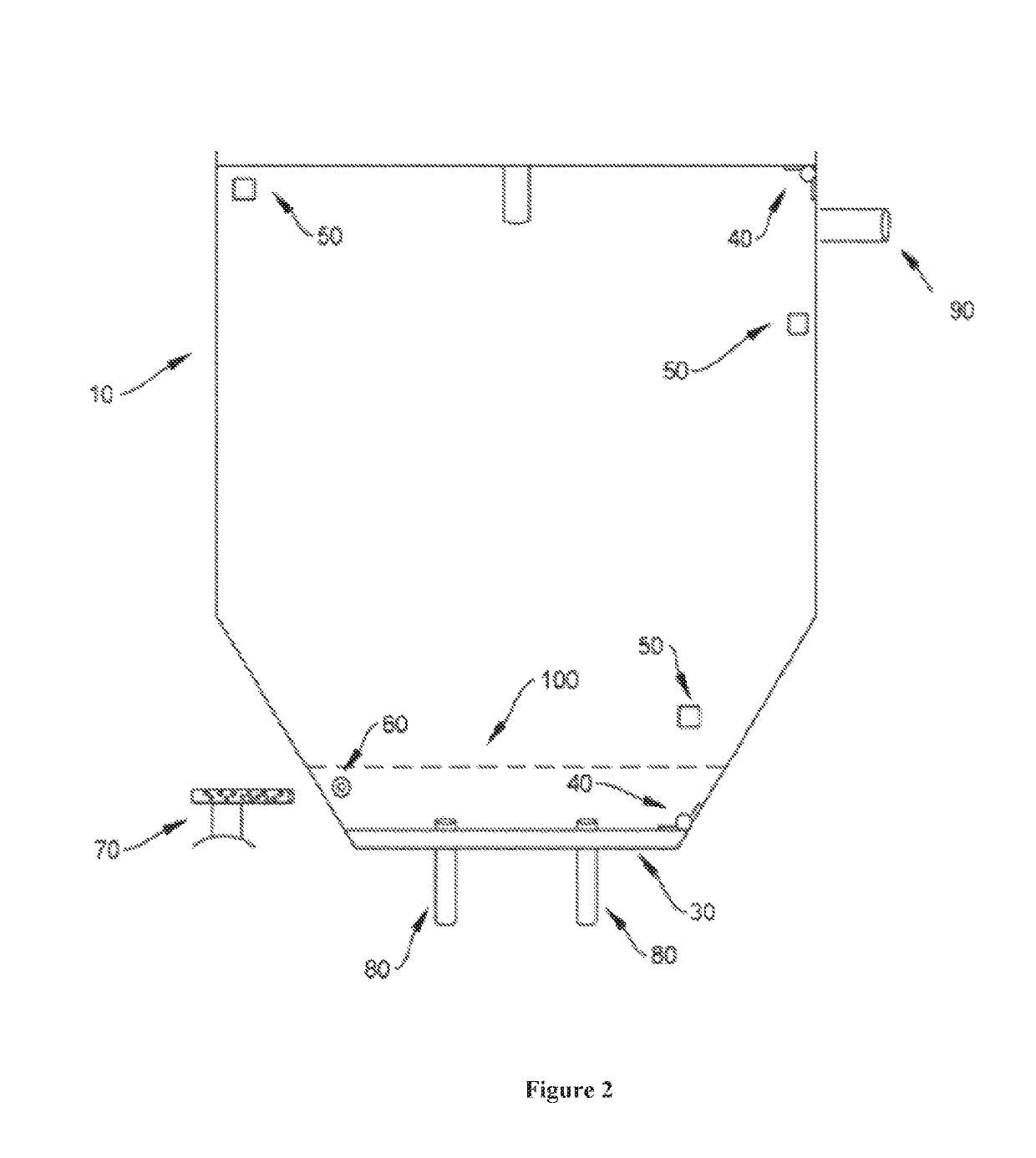

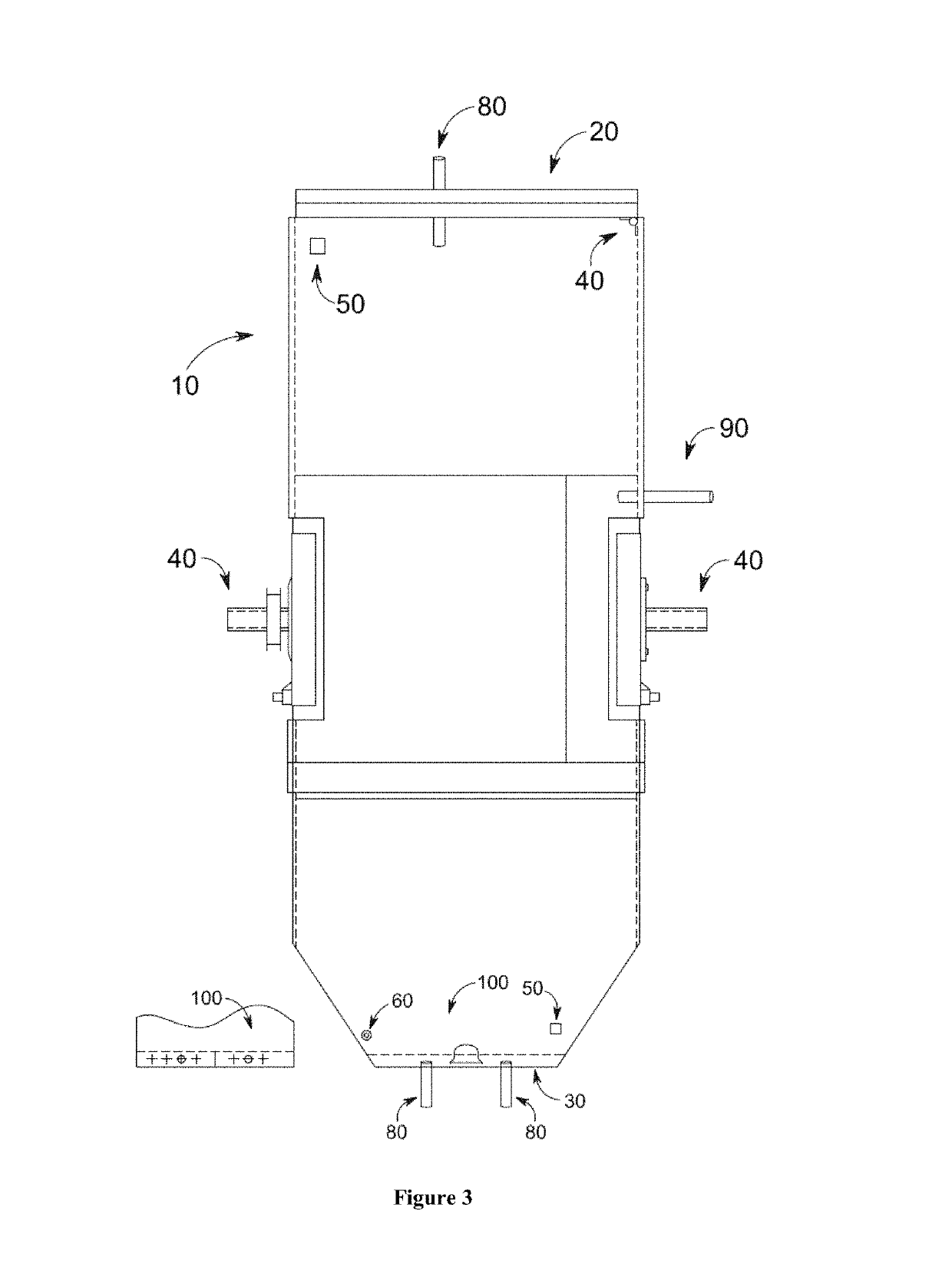

Apparatus and method for thermally demanufacturing tires and other waste products

ActiveUS20180244889A1Maintain working temperatureImprove isolationDirect heating destructive distillationLiquid hydrocarbon mixture productionHydrogenSulfur

An apparatus and process for thermally de-manufacturing tires and other materials. The apparatus is a retort chamber with various zones in which tires are combusted to provide energy for the thermal depolymerization reaction, depolymerization takes place, and products leave the retort chamber. In one embodiment, the process reacts water with iron present in steel-belted tires to produce hydrogen, which helps to break sulfur-sulfur bonds in vulcanized materials. The water also helps control the temperature of the reaction, which allows for control over the types and relative amounts of the various depolymerization products.

Owner:PRTI GLOBAL MANAGEMENT LLC

Apparatus and method for thermally demanufacturing tires and other waste products

ActiveUS10329400B2Improve isolationDirect heating destructive distillationLiquid hydrocarbon mixture productionHydrogenSulfur

Owner:PRTI GLOBAL MANAGEMENT LLC

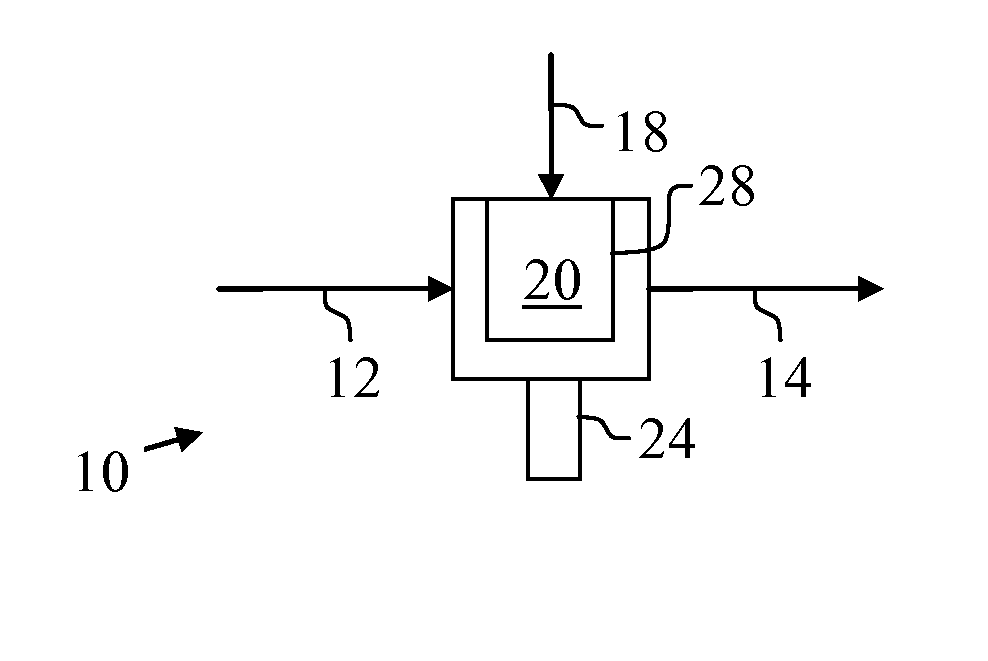

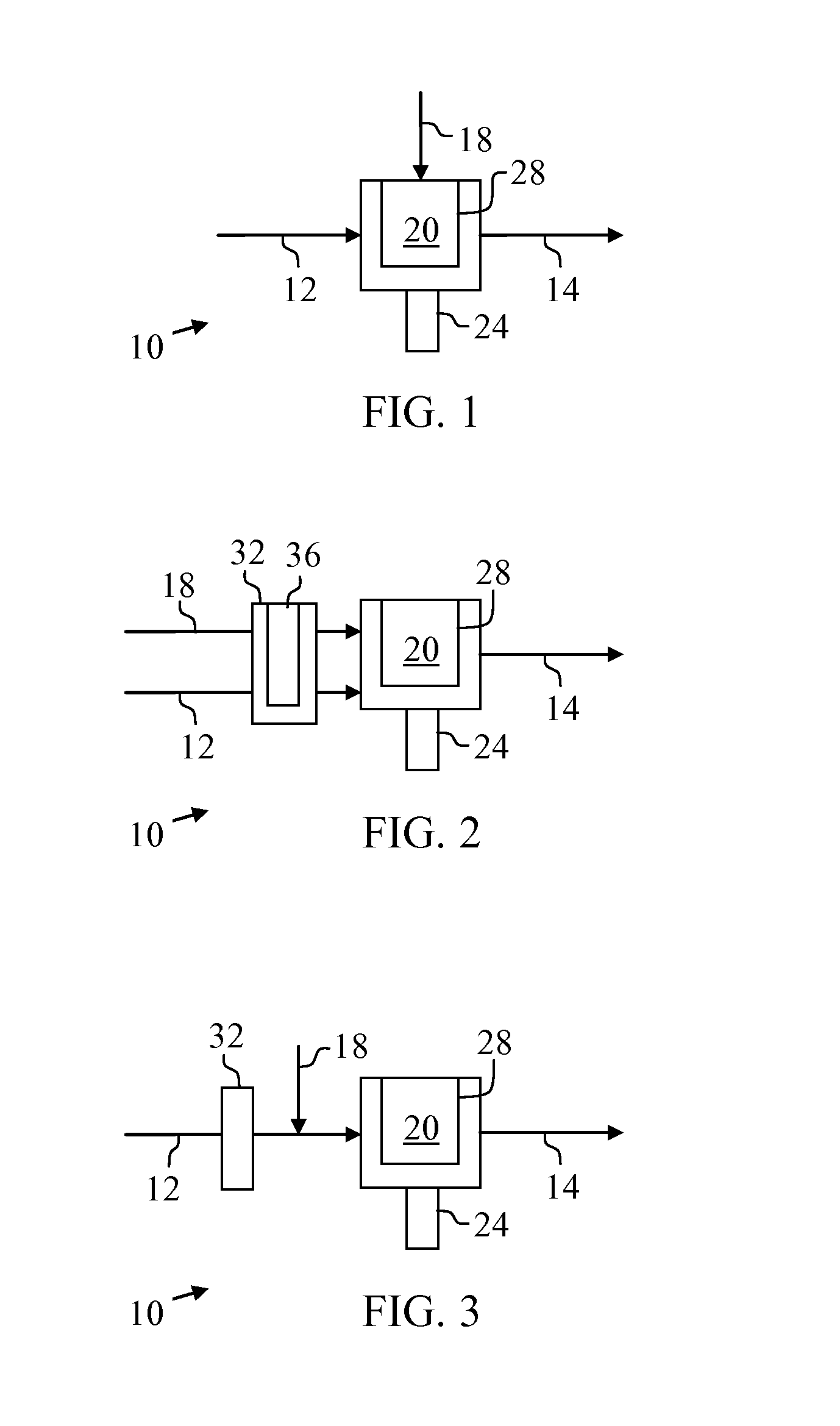

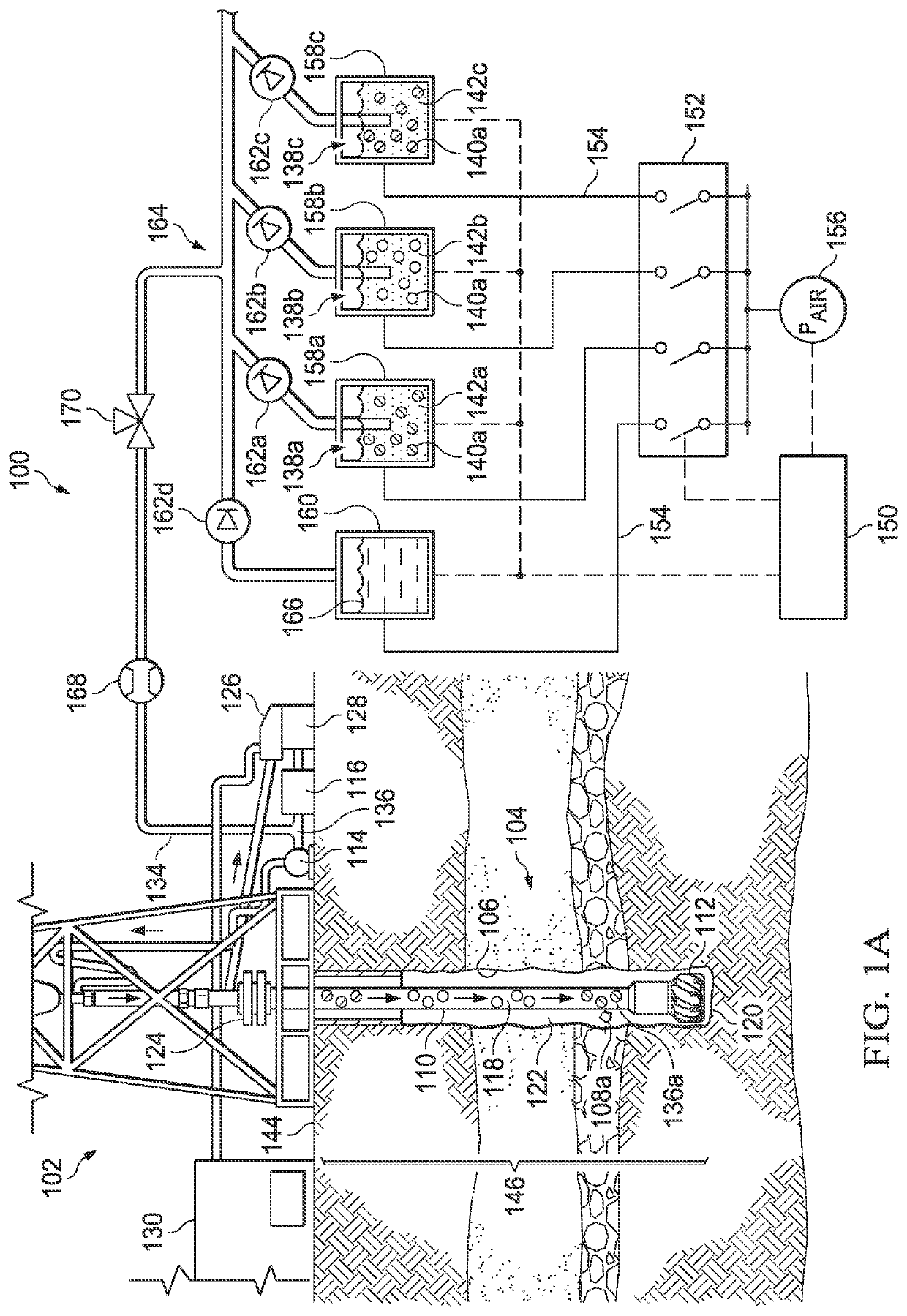

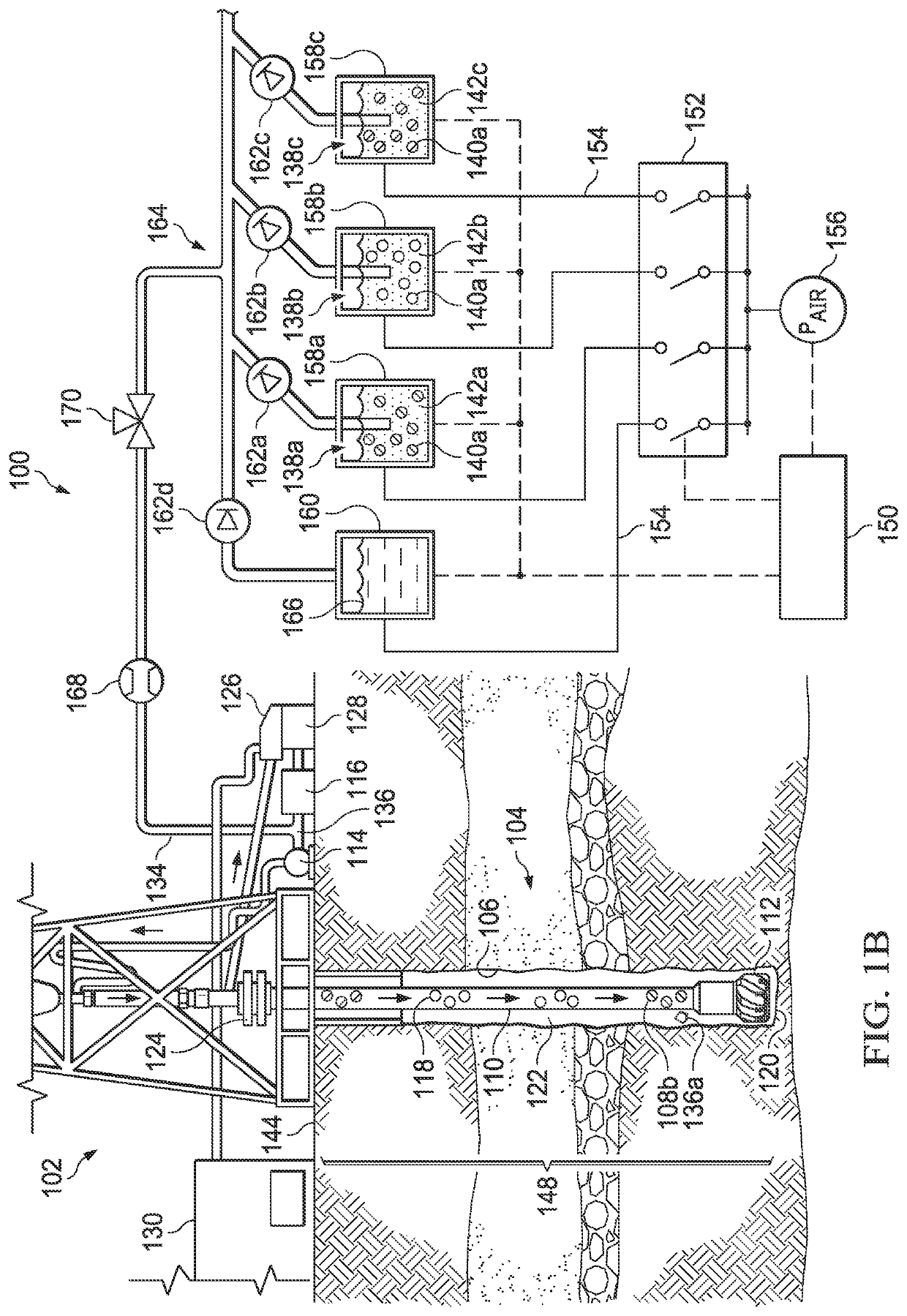

Injecting multiple tracer tag fluids into a wellbore

A method and a system for injecting multiple tracer tag fluids into the wellbore are described. The method includes determining multiple injection concentrations of multiple respective tracer tag fluids, determining an injection sequence of the tracer tag fluids into a wellbore, and injecting the tracer tag fluids into the wellbore according to the injection concentrations and the injection sequence. The tracer tag fluids include synthesized polymeric nanoparticles suspended in a solution. The synthesized polymeric nanoparticles are configured bind to a wellbore cutting. The synthesized polymeric nanoparticles are configured to undergo a thermal de-polymerization at a respective temperature and generate a unique mass spectra. The injection sequence includes an injection duration determined by a depth interval of the wellbore to be tagged by the synthesized polymeric nanoparticles and an injection pause to prevent mixing the multiple tracer tag fluids in the wellbore.

Owner:SAUDI ARABIAN OIL CO

Recovery and treatment process of acrylate waste oil

InactiveCN110437034AImprove cracking conversion rateHigh recovery rateOrganic compound preparationChemical industryAlcoholWaste oil

The invention discloses a recovery and treatment process of acrylate waste oil. The recovery and treatment process comprises the steps of primary depolymerization, extracting, secondary depolymerization, secondary extracting and acrylic acid extracting. According to the recovery and treatment process of the acrylate waste oil, through the joint effect of thermal depolymerization and ultrasonic depolymerization, the pyrolysis conversion rate of beta-butoxy ester and dimers in the acrylate waste oil can be increased, alcohols can be recovered in time so as to reduce side reactions of esterification, by adopting the treatment process, the acrylate waste oil can be recycled, raw materials are high in recycling rate and high in purity, and energy conservation and environment protection are facilitated.

Owner:JIANGSU XINDONGFENG CHEM TECH

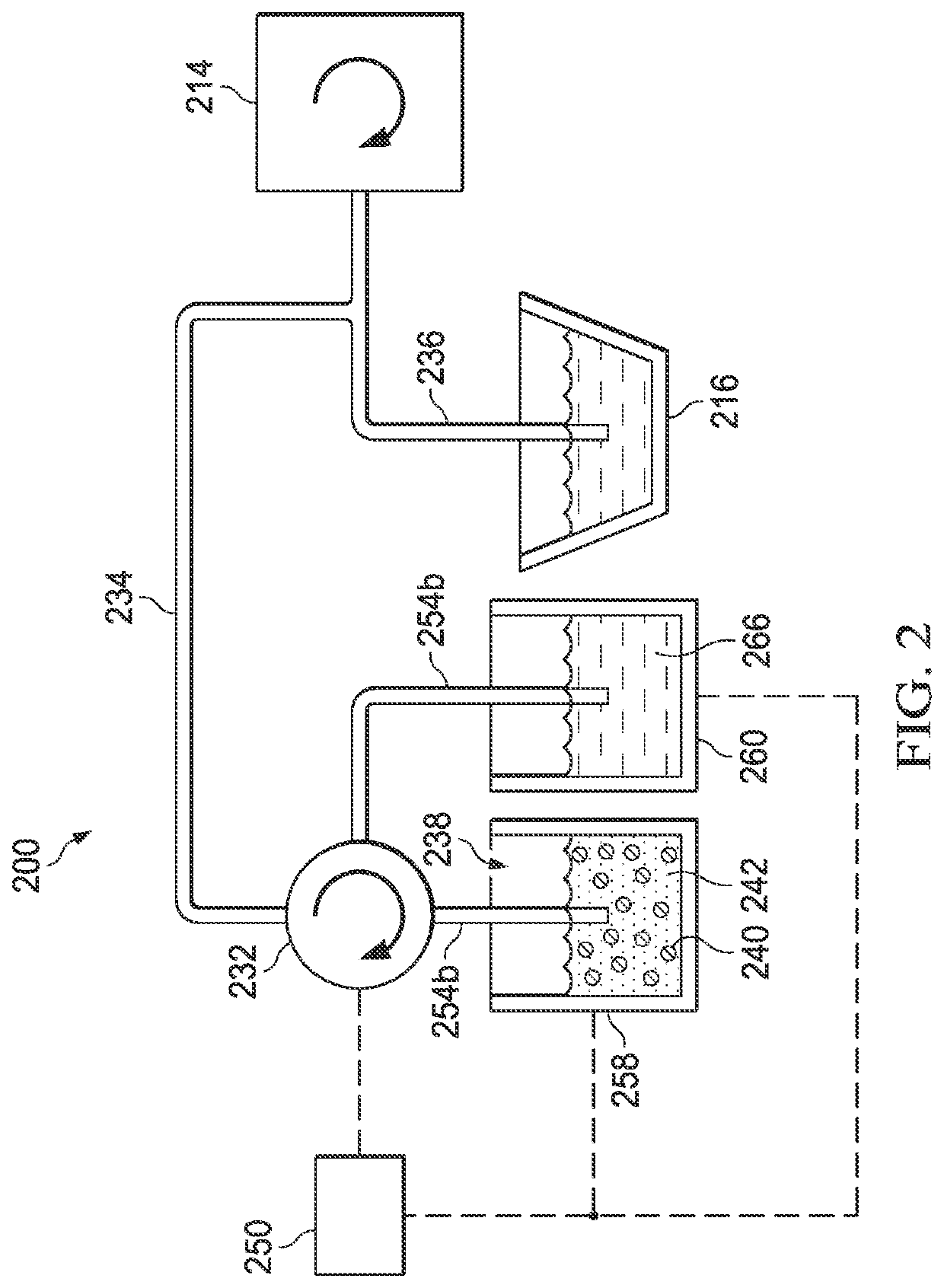

Method for producing water-absorbent resin

ActiveUS10640591B2Quality improvementEfficient preparationChemical/physical/physico-chemical stationary reactorsMonomer compositionPolymer science

[Object] To provide a method for stably producing a water-absorbent resin in powder form or particle form, which has excellent physical properties such as water absorption performance and the like, without any production trouble.[Solution] A method for producing a water-absorbent resin includes mixing a monomer composition, which contains at least a monomer and a pyrolytic polymerization initiator, with an organic solvent, a temperature of the organic solvent is not lower than 70° C. at time of mixing, and when a mass per unit time of the monomer in the monomer composition to be mixed with the organic solvent is expressed as an amount per unit volume of the organic solvent, a lower limit is 0.01 g / ml / min, and an upper limit is 0.2 g / ml / min.

Owner:NIPPON SHOKUBAI CO LTD

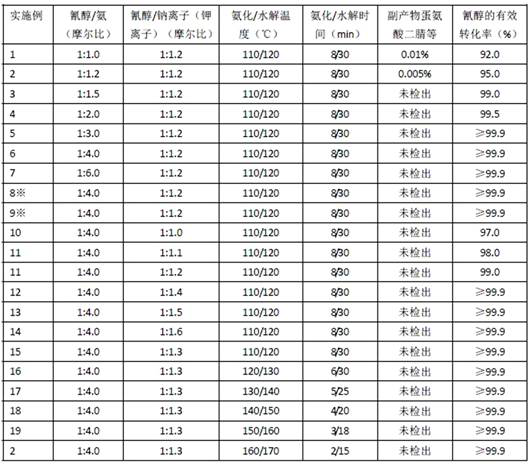

A kind of technology of continuous rapid synthesis of methionine by cyanohydrin method

The invention provides a process for continuously and rapidly synthesizing methionine by the cyanohydrin method, which includes: (1) ammoniation reaction: passing ammonia and 2-hydroxy-4-methylthiobutyronitrile into a microchannel reactor for ammoniation reaction, and controlling The reaction temperature is 60-200°C, the residence time of the reactants is 0.5-8.0min, and an aqueous solution of 2-amino-4-methylthiobutyronitrile is obtained; (2) Alkaline hydrolysis reaction: the step (1) 2-amino-4-methanol The thiobutyronitrile aqueous solution and the alkali are simultaneously added into the microchannel reactor for reaction, the reaction temperature is 80-200°C, the pressure is 1.0-2.5MPa, the reaction residence time is 10-60min, and DL-methionine is obtained after post-treatment. The invention adopts ammoniation and non-catalyzed alkaline hydrolysis process to prepare methionine, which simplifies the preparation process of methionine; selects microchannel reactor to carry out ammoniation and alkaline hydrolysis reaction under catalyst-free conditions, has fast reaction time and high yield, which affects product yield The quality and quality of raw material pyrolysis polymers and side reaction products are greatly reduced, which is beneficial to the cost reduction and quality improvement of methionine in industrialization.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

Sampling device and method for effectively collecting nano plastic in air

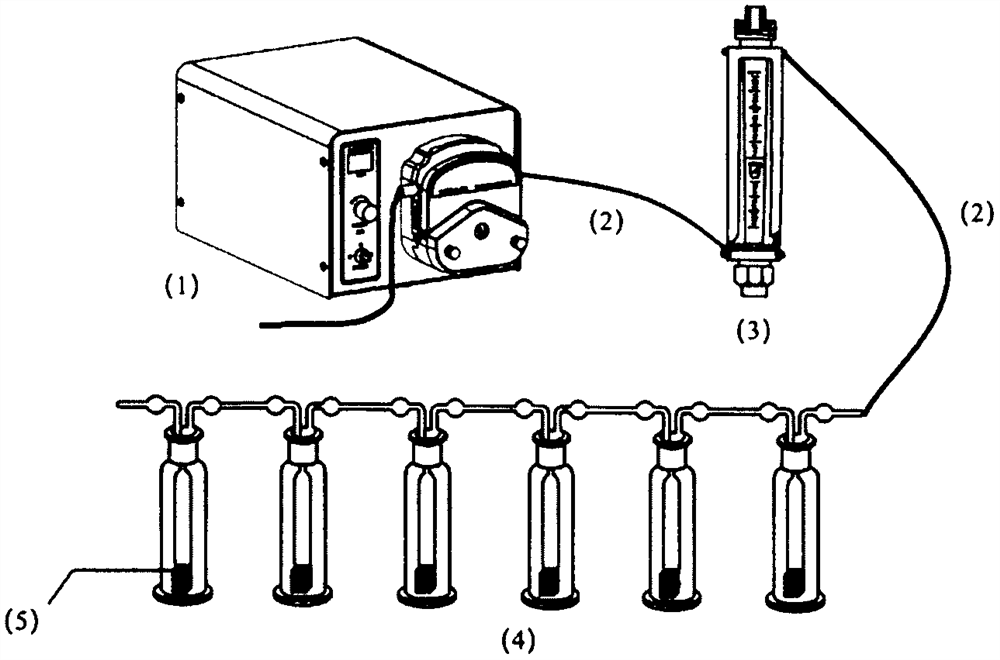

InactiveCN113340679AIncrease contactSmall diameterComponent separationWithdrawing sample devicesPeristaltic pumpFluid phase

The invention provides a sampling device and method for effectively collecting nano plastic in air. The sampling device consists of five parts, namely a peristaltic pump, a glass rotor flow meter, a Montella gas washing bottle group, mixed gas washing liquid and a microporous pure titanium aeration head; during sampling, gas in the environment is collected by one end of a hose of a peristaltic pump, the other end of the hose of the peristaltic pump is connected into a glass rotameter, the sampling flow rate is corrected to be 0-1000mL / min through the flow meter, and the collected air enters a Montella gas washing bottle group along the hose and is continuously absorbed by mixed gas washing liquid, so that the last group of gas washing liquid is not detected by nano plastic. After the sample is collected, the quantitative analysis of the nano plastic in the air is realized by virtue of an alkali-assisted thermal depolymerization-liquid chromatography-mass spectrometry technology.

Owner:NANKAI UNIV

Gradual Classification of Garbage and Thermal Decomposition and Energy Efficiency Enhancement Method

ActiveCN105805755BAvoid resynthesisAvoid it happening againIncinerator apparatusGas phaseMedical waste

The invention discloses an effect improving method for progressive and classified pyrolysis and energy gathering of waste. The method aims to overcome the defects that in an existing waste pyrolysis process, dioxin is likely to be generated, the environment is polluted, the pyrolysis effect is poor, auxiliary energy consumption is needed, and the construction and operation cost of a project is high. The method comprises the steps that firstly, hot air at the temperature below 300 DEG C is introduced into waste for pyrolysis, and gas phase combustible organic matter is guided out; then the gas phase combustible organic matter is mixed with hot air at the temperature of 500 DEG C, obtained combustible smoke and the guided gas phase combustible organic matter are mixed with hot air at the temperature of 600 DEG C for incineration and pyrolysis, and heat exchange is conducted between obtained high-temperature flame gas and air; and the obtained hot air is input into the step a, the step b and the step c for utilization. The method is mainly used for harmless environment-friendly treatment of household waste and medical waste, the situation that the dioxin is generated during waste pyrolysis, and accordingly the environment is polluted can be avoided, and heat energy generated during waste pyrolysis is used for classified waste incineration and pyrolysis in the hot air mode; the energy is greatly saved, the effect is good, the efficiency is high, the investment is reduced, and the practicability is high.

Owner:周小华

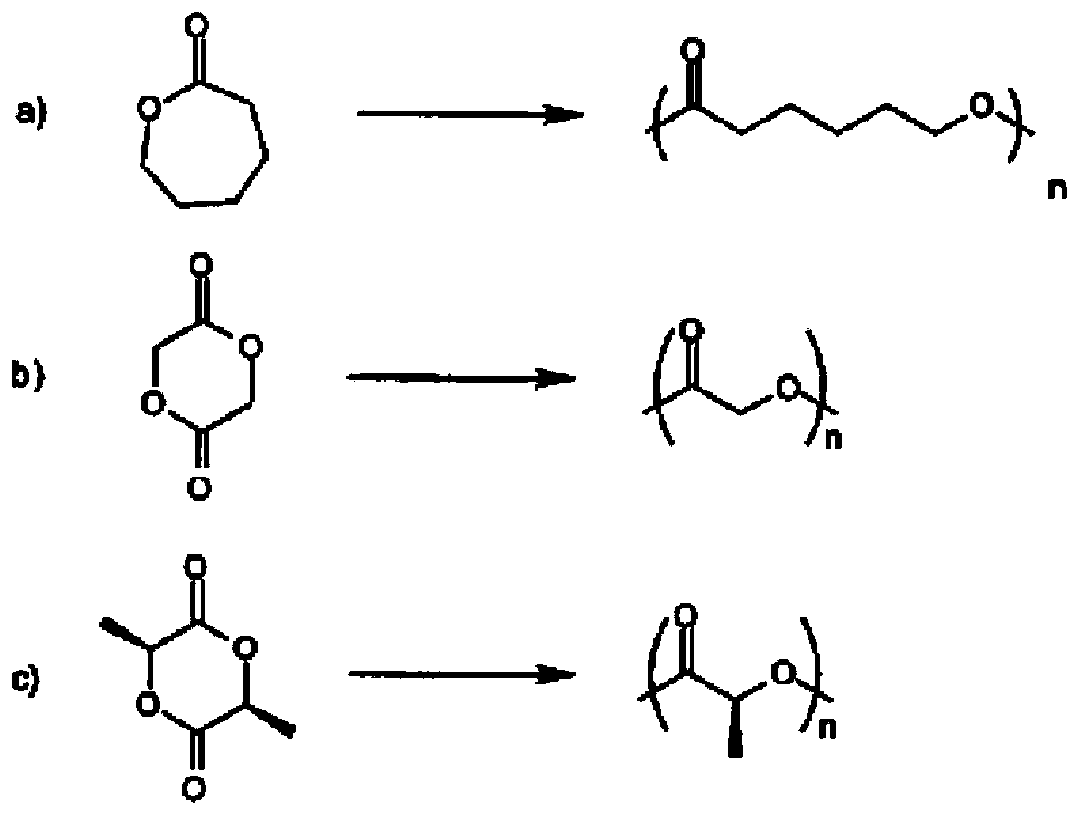

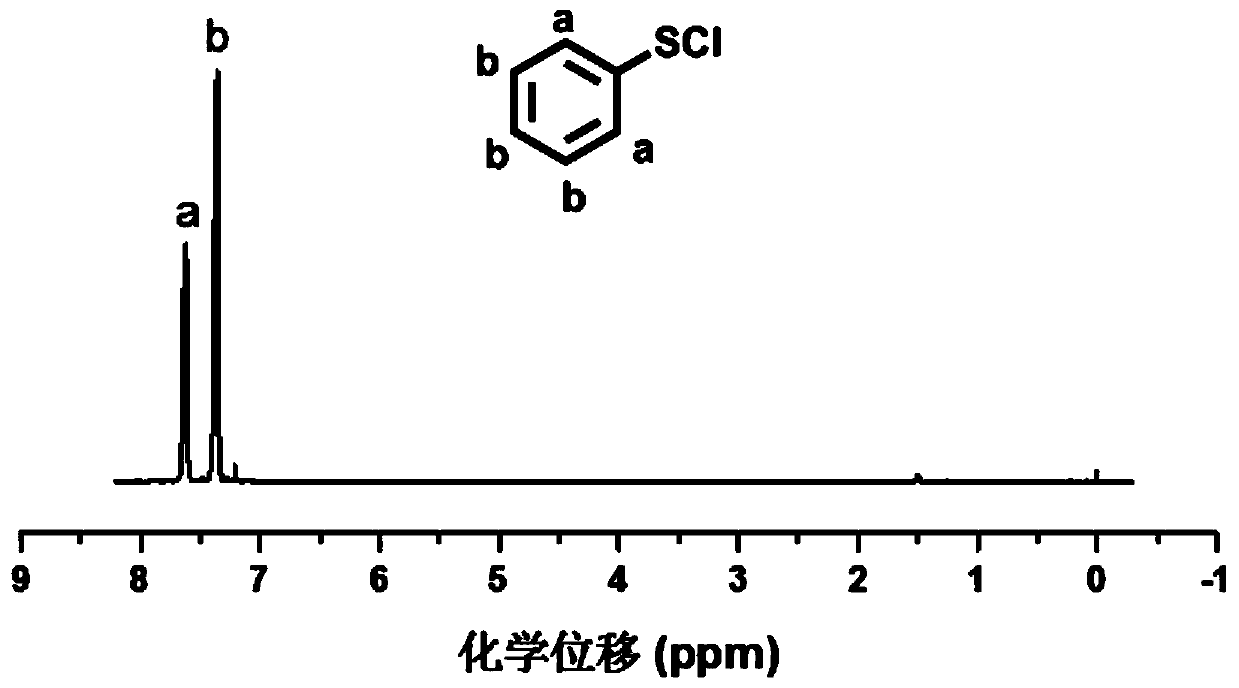

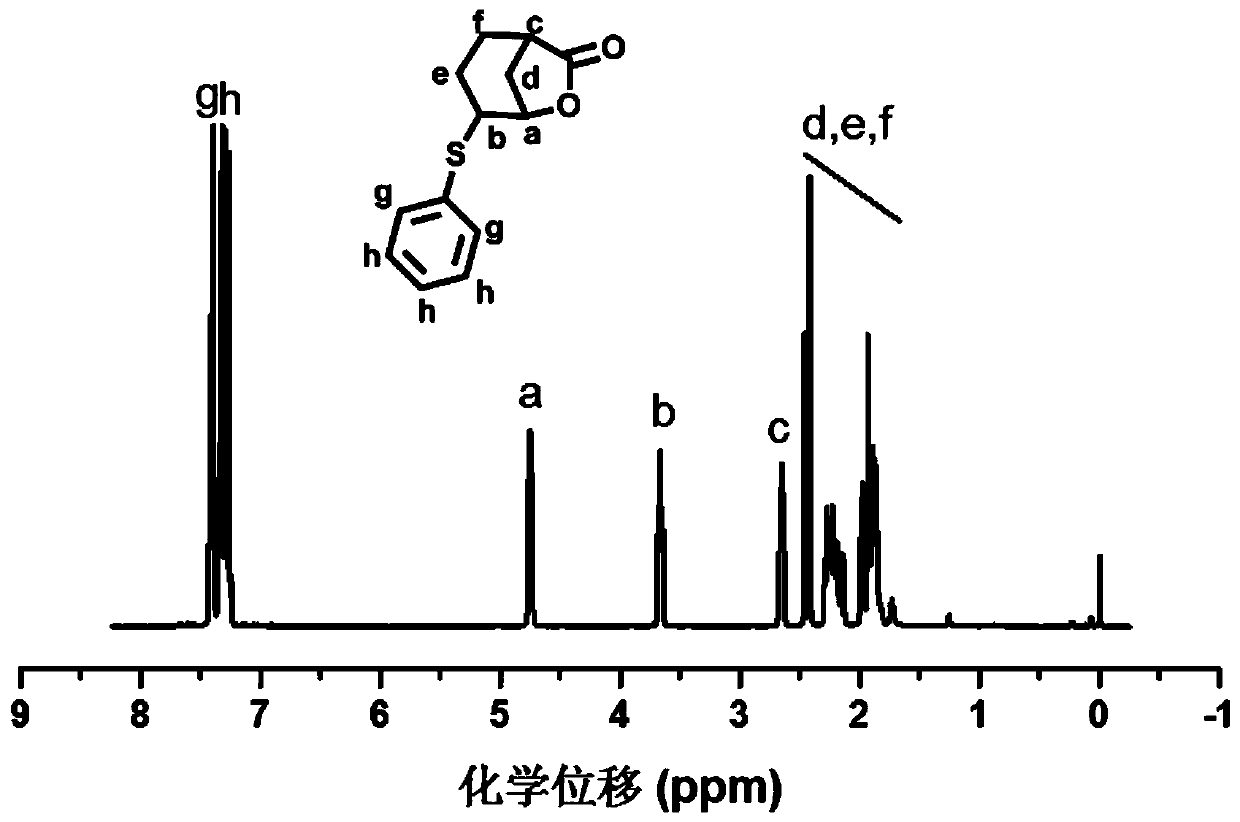

PhSGBL polymer, and preparation method and application thereof

The invention relates to a polymerization method of PhSGBL and an application of the prepared polyester. The PPHSGL prepared by the method is controllable in molecular weight and narrow in molecular weight distribution index. A sulfoxide or sulfone polymer can be further prepared by utilizing oxidation performance of the polymer. The PHSGBL has acid degradation performance and thermal depolymerization recovery performance simultaneously. The invention also provides a method for copolymerizing the PHSGBL and epsilon-caprolactone (CL) to obtain a random copolymer.

Owner:SUZHOU UNIV

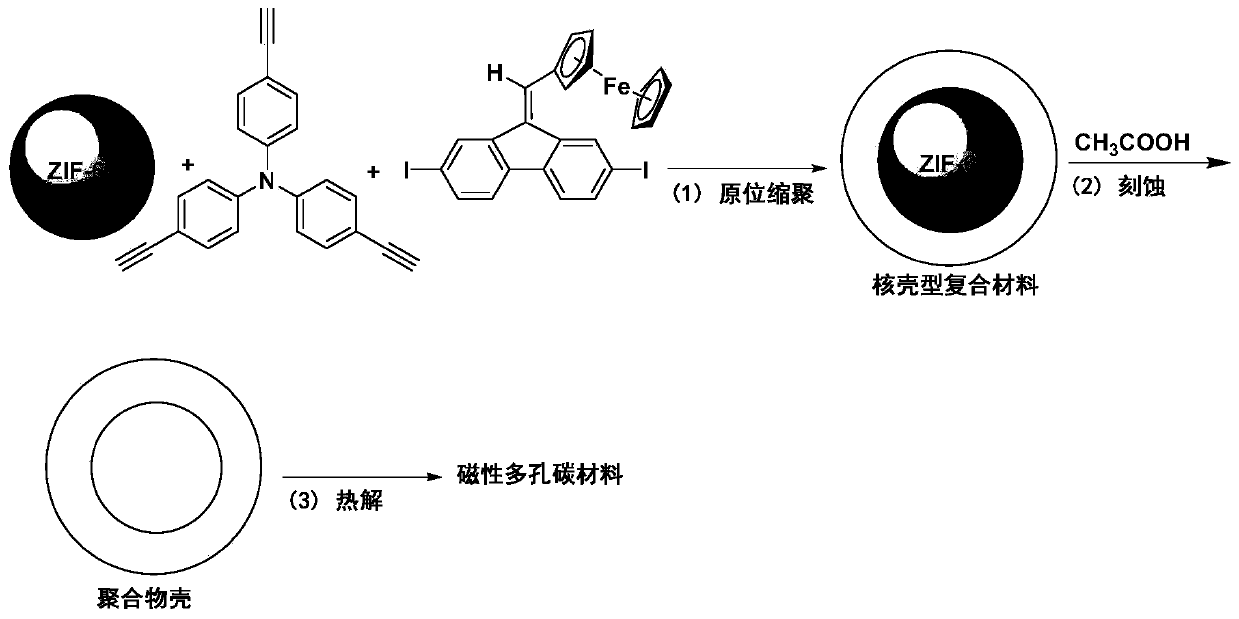

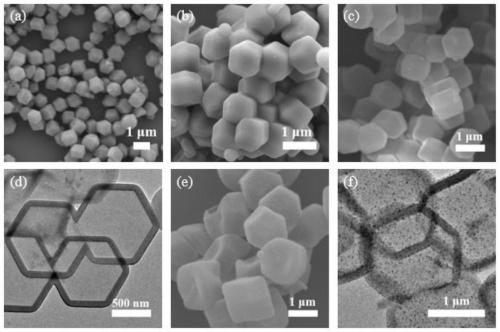

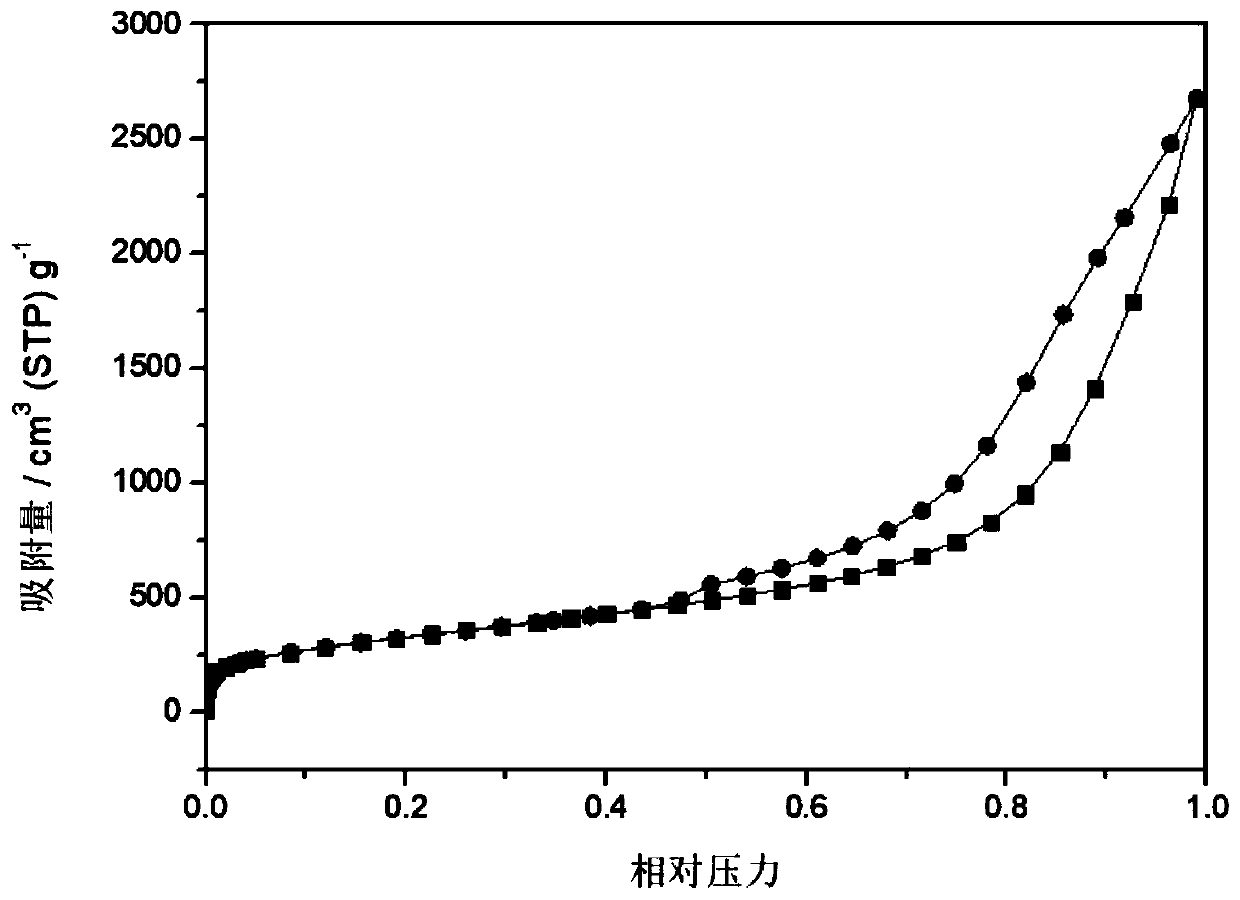

A kind of magnetic porous carbon material and preparation method thereof

ActiveCN109166682BHigh reuse rateLarge specific surface areaWater contaminantsInductances/transformers/magnets manufactureOrganic acidPtru catalyst

A magnetic porou carbon material and preparation method thereof are disclosed. That method comprise the following steps of: under an inert atmosphere, a structure guide template, a catalyst is dispersed to an acid binding agent and an organic solvent, and the mixture is stirred by 1: 3h, adding ferrocenyl dihalogenated monome and alkynyl monomer, stirring for 24-72h at the temperature of 60-100 DEG C,, purify to obtain that core-shell composite material; The core-shell composites were dispersed in organic acids and stirred for 10-30 min, purify to obtain polymer shell; In an inert atmosphere,pyrolyzing the polymer shell to obtain magnetic porous carbon material at 500-700 DEG C; The ferrocenyldihalogenated monomer is shown in the description, wherein X is Br or I; The alkynyl monomer is shown in the description. The preparation method can control the specific surface area of the material by changing the structure of the monomer to control the pore size of the polymer. The magnetic porous material has large specific surface area and excellent adsorption performance for organic pollutants. Magnetism is good and phase separation does not occur, so the material recycling rate can be improved by magnetic recovery.

Owner:SHENZHEN UNIV

Method and reaction device for catalytically depolymerizing polymethyl methacrylate into monomer

ActiveCN114634413ARealize continuous productionWill not cause collapseOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention provides a method and a device for depolymerizing polymethyl methacrylate into a monomer, and particularly relates to a method and a reaction device for catalytically depolymerizing polymethyl methacrylate into a monomer. The method comprises the following steps: preparing a first catalyst; adding a first catalyst into the reaction device, and heating to a depolymerization temperature; adding polymethyl methacrylate into the reaction device, carrying out thermal depolymerization reaction under normal pressure, discharging monomer gas from an outlet of the reaction device, condensing, and collecting a monomer product. The device is a rotary furnace reaction device. By designing the rotary furnace reaction system and adjusting the catalyst and the adding process thereof, the mass and heat transfer effect is obviously improved, the depolymerization selectivity is improved, and the product yield is improved; the depolymerization temperature is reduced, and the energy consumption is reduced; and the inactivated catalyst can be continuously discharged for in-situ regeneration, so that continuous production is realized.

Owner:BEIJING UNIV OF CHEM TECH

Preparation of b-doped g-c by a non-metallic liquid phase doping 3 no 4 photocatalytic method

InactiveCN104549500BGood thermal stabilityGood chemical stabilityOrganic-compounds/hydrides/coordination-complexes catalystsEnergy inputSemiconductor materialsNew energy

The invention discloses a method for preparing a B-doped g-C3N4 photocatalyst through nonmetal liquid-phase doping, and belongs to the technical field of hydrogen production through photocatalytic materials. According to the prepared organic polymer semiconductor material g-C3N4 photocatalyst, cheap chemical material urea is taken as a reactant source, sodium tetraphenylborate is taken as a doping source, PEI (polyethyleneimine) is taken as a surface charge modifier, and the B-doped g-C3N4 photocatalyst is successively prepared with a pyrolysis and polymerization method easy to operate. The nonmetal liquid-phase doping modified g-C3N4 photocatalyst has novel organization structure appearance, good response of visible light with wavelength larger than 420 nm and good photocatalytic hydrogen generation property, and promotes solar energy conversion into new energy under the photocatalysis action at a low cost; the provided preparation method has the advantages of cheap raw materials, simple and convenient technology and the like and has an important research value and a wide industrialized application prospect.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com