Method for preparing dicyclopentadiene through gas-liquid phase depolymerization of C9 raw material

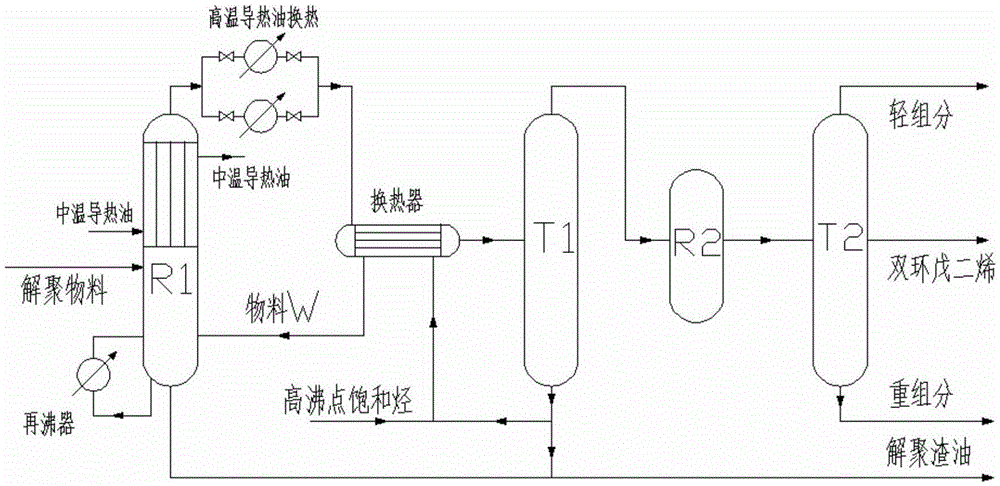

A technology for dicyclopentadiene and raw materials is applied in the field of preparing dicyclopentadiene by gas-liquid phase depolymerization of carbon nine raw materials, and can solve the problems of easy polymerization of crude dicyclopentadiene raw materials, large material loss, low conversion rate and the like , to reduce the depolymerization residence time, reduce production energy consumption, and achieve the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The C9 raw material is cut by vacuum rectification to obtain a thermal depolymerization raw material with a distillation range of 150-190 ° C. The composition is: cyclopentadiene 1.5%, styrene 1.0%, vinyltoluene 25.0%, β-DCPD 4.0% , α-DCPD45.0%, indene 3.0%, and the rest are various saturated aromatic hydrocarbons. The thermal depolymerization raw material is preheated to 155°C and transported into the middle of the depolymerization kettle R1; the thermal depolymerization raw material is depolymerized in the liquid phase at 210°C and the operating pressure is 0.11Mpa in the depolymerization kettle, and the gasified material is in the upper part of the depolymerization kettle The heater is heated to 270°C by medium-temperature heat-conducting oil to obtain gas-phase cyclopentadiene-enriched material. The composition is: cyclopentadiene 63.0%, styrene 1.5%, vinyl toluene 12.5%, β-DCPD 4.0%, α -DCPD 15.0%, indene 1.0%, and the rest are various saturated aromatic hydrocarbo...

Embodiment 2

[0047] The C9 raw material is cut by vacuum rectification to obtain a thermal depolymerization raw material with a distillation range of 150-190 ° C. The composition is: cyclopentadiene 1.6%, styrene 0.7%, vinyltoluene 24.6%, β-DCPD 3.5% , α-DCPD53.5%, indene 3.5%, and the rest are various saturated aromatic hydrocarbons. The thermal depolymerization raw material is preheated to 140°C and transported into the middle of the depolymerization kettle R1; the thermal depolymerization raw material is depolymerized in the liquid phase at 220°C and the operating pressure is 0.12Mpa in the depolymerization kettle, and the gasified material is heated in the upper part of the depolymerization kettle The gas-phase cyclopentadiene-enriched material was obtained by heating to 270°C with medium-temperature heat-conducting oil, and the composition was: cyclopentadiene 72.0%, styrene 1.0%, vinyl toluene 11.0%, β-DCPD 3.0%, α- 12.5% DCPD, 0.5% indene, and the rest are various saturated aromat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com