Successive pyrolysis system of waste synthetic-highly polymerized compound

a pyrolysis system and high-polymer technology, applied in the direction of combustible gas coke oven heating, charging-discharging device combination, products, etc., can solve the problems of high heat transfer, many difficulties in the pyrolysis system type, and achieve the effect of maximizing the operating rate of the pyrolysis devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be explained in detail on below, which is to explain the present invention in detail to the extent that one skilled in the art may easily work the invention, and does not limit the technical idea and scope of the present invention.

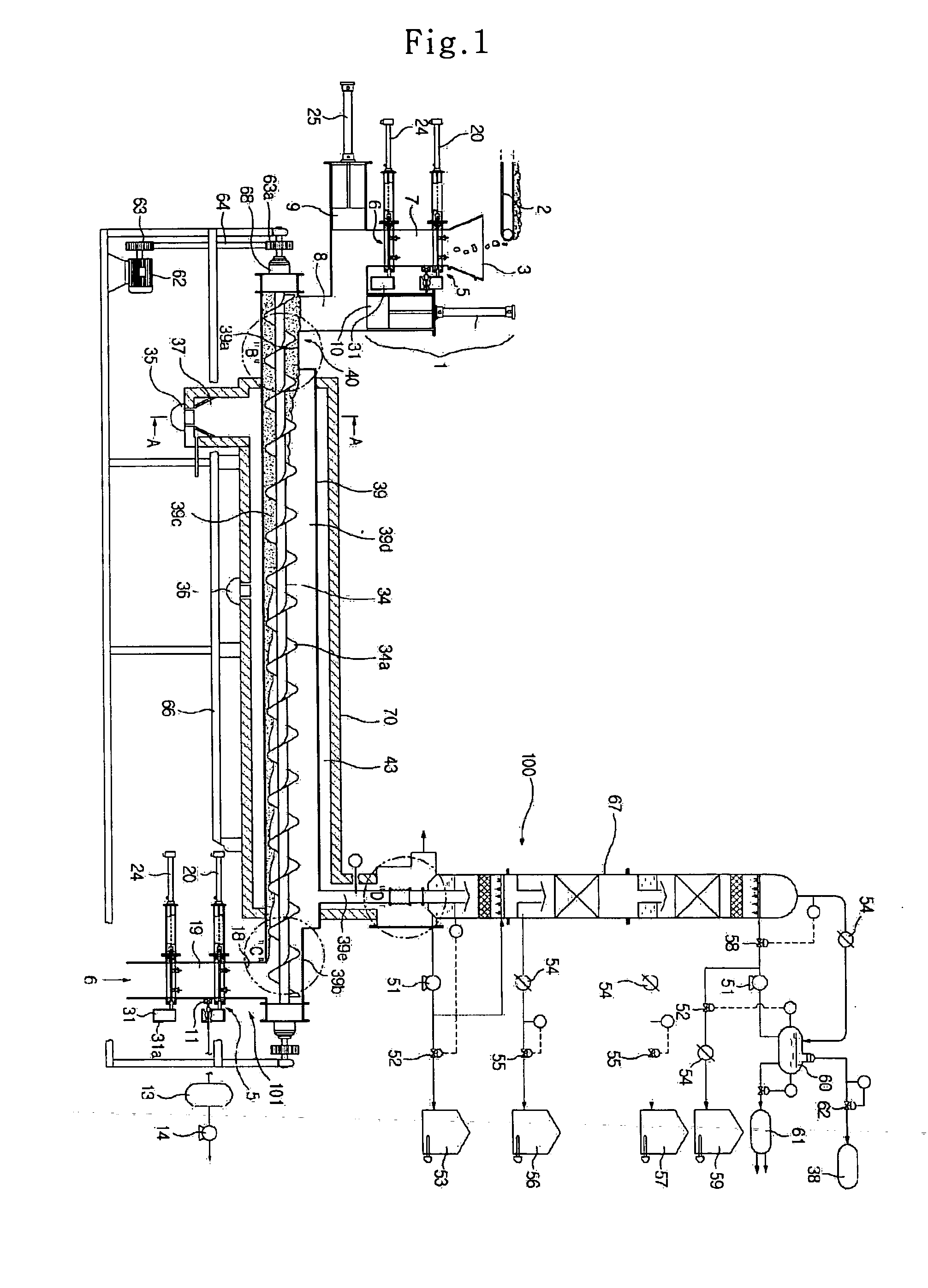

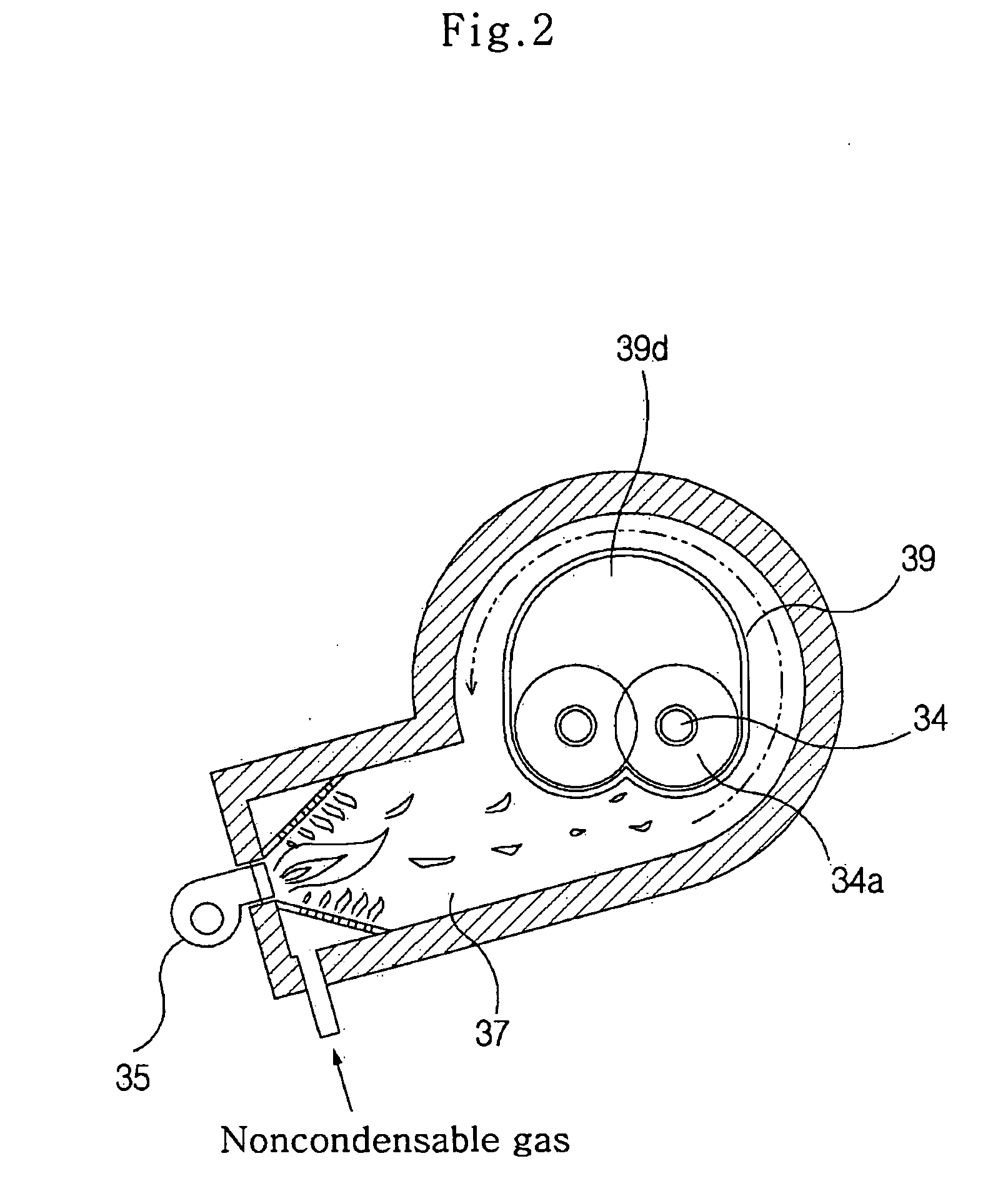

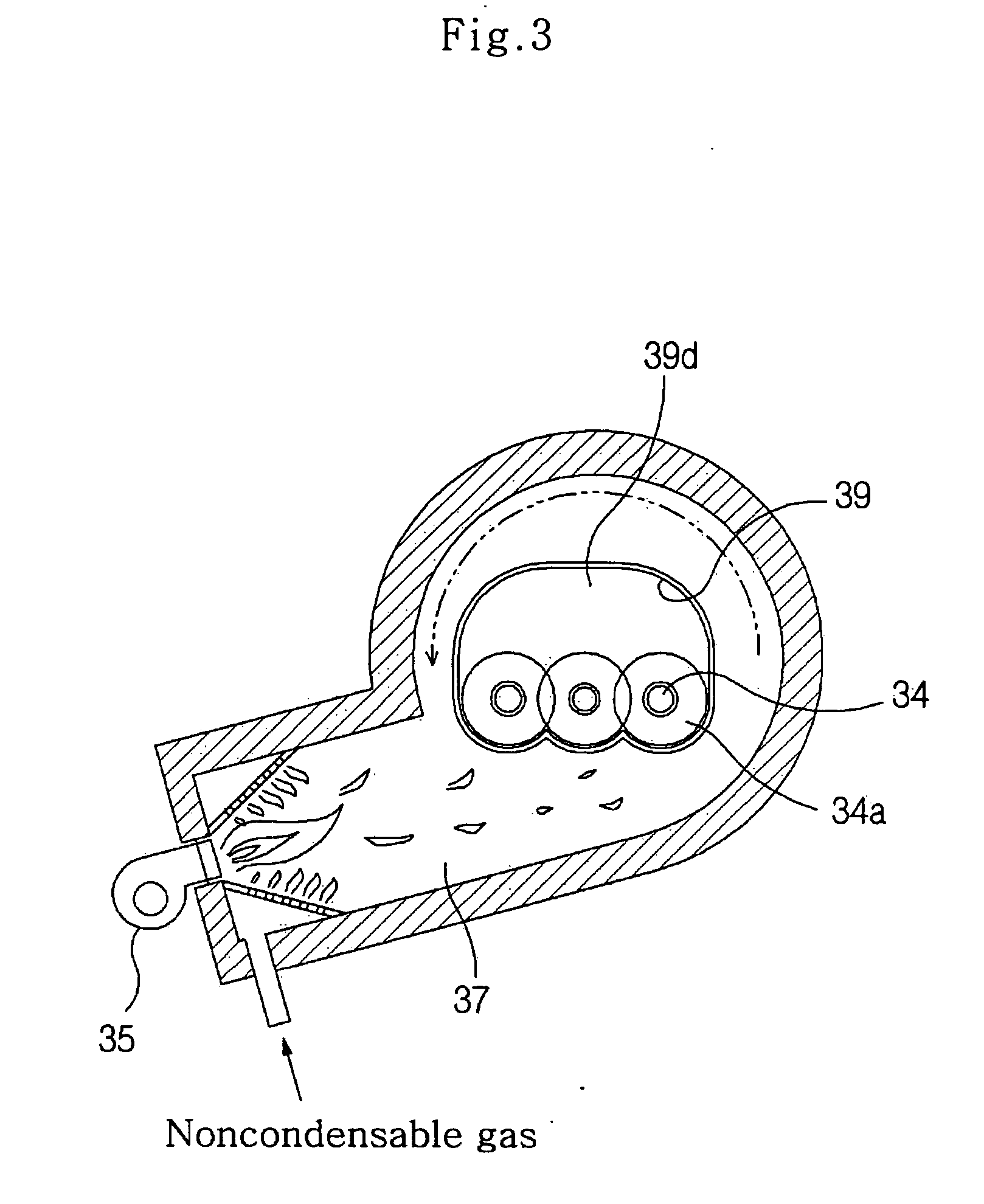

[0043] As illustrated in FIGS. 1-12, the successive pyrolysis system of waste synthetic-highly polymerized compound in accordance with the present invention comprises a hopper 3, which the waste is provided to and is stored in a predetermined amount; an automatic waste injection device 1, which automatically discharges a predetermined amount of waste from the hopper 3, and comprises an air removing means for maintaining a hypoxic environment inside by removing external air flowing in along with the waste; a pyrolysis chamber 39 for maintaining a high-temperature (250-450° C.) and hypoxic environment, and successively pyrolizing the waste by indirect heating, in which two or more transport screws 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com