Preparation of b-doped g-c by a non-metallic liquid phase doping 3 no 4 photocatalytic method

A photocatalyst, g-c3n4 technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited activity and high recombination rate, and achieve novel Tissue structure morphology, the effect of high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

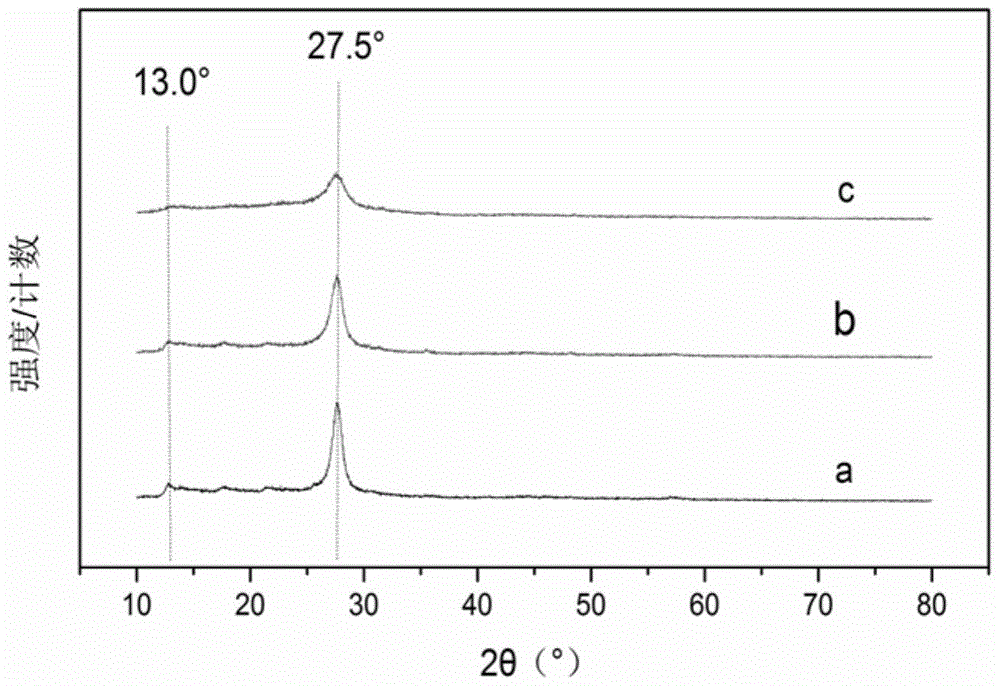

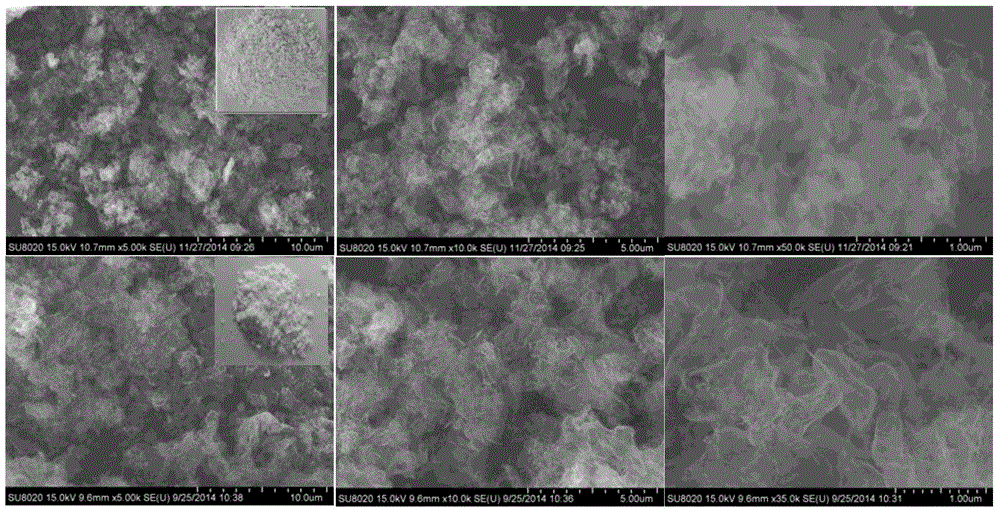

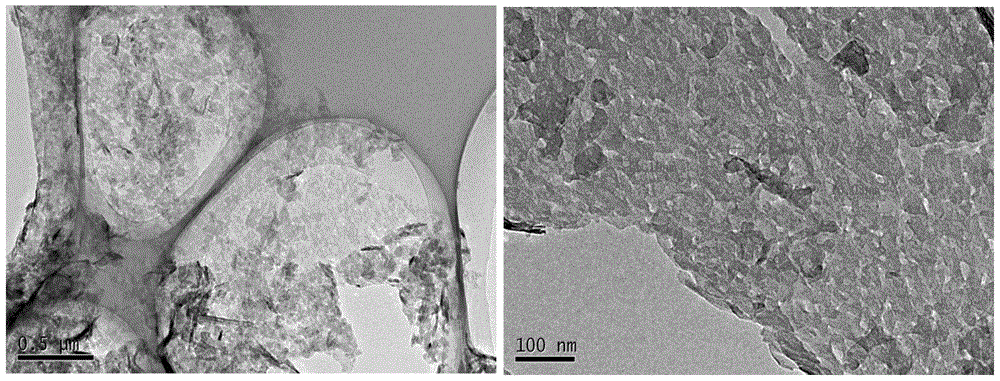

[0028] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water and ultrasonically for 0.5h, then continue stirring for 12h to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 1 hour, centrifuge and pour the supernatant, add a certain amount of water to 200ml, and stir well to obtain the CNP solution. Take 20ml of CNP solution, drop 20ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 1h, and dry the obtained solid at 60°C for 8 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 500°C, and the heating rate is 5°C / min. After 4 hours of heat preservation, it is naturally cooled, and the obtained powder is g-C modified by doping for non-metallic liquid phase...

Embodiment 2

[0030] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water for 1 hour, then continue to stir for 12 hours to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 2 hours, centrifuge and pour the supernatant, add a certain amount of water to 200ml, and stir well to obtain the CNP solution. Take 20ml of CNP solution, drop 50ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 2h, and dry the obtained solid at 60°C for 12 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 520°C, and the heating rate is 1°C / min. After 4 hours of heat preservation, it is naturally cooled to obtain a powder That is, non-metallic liquid phase B doped modified g-C 3 N 4 The phot...

Embodiment 3

[0032] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water for 2 hours, then continue to stir for 24 hours to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 3h, centrifuge and pour a certain amount of water to 200ml after pouring the supernatant, and fully stir to obtain the CNP solution. Take 20ml of CNP solution, drop 70ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 2h, and dry the obtained solid at 80°C for 8 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 500°C, and the heating rate is 1°C / min. After 4 hours of heat preservation, it is naturally cooled to obtain a powder That is, non-metallic liquid phase B doped modified g-C 3 N 4 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com