Patents

Literature

57results about How to "Avoid resynthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

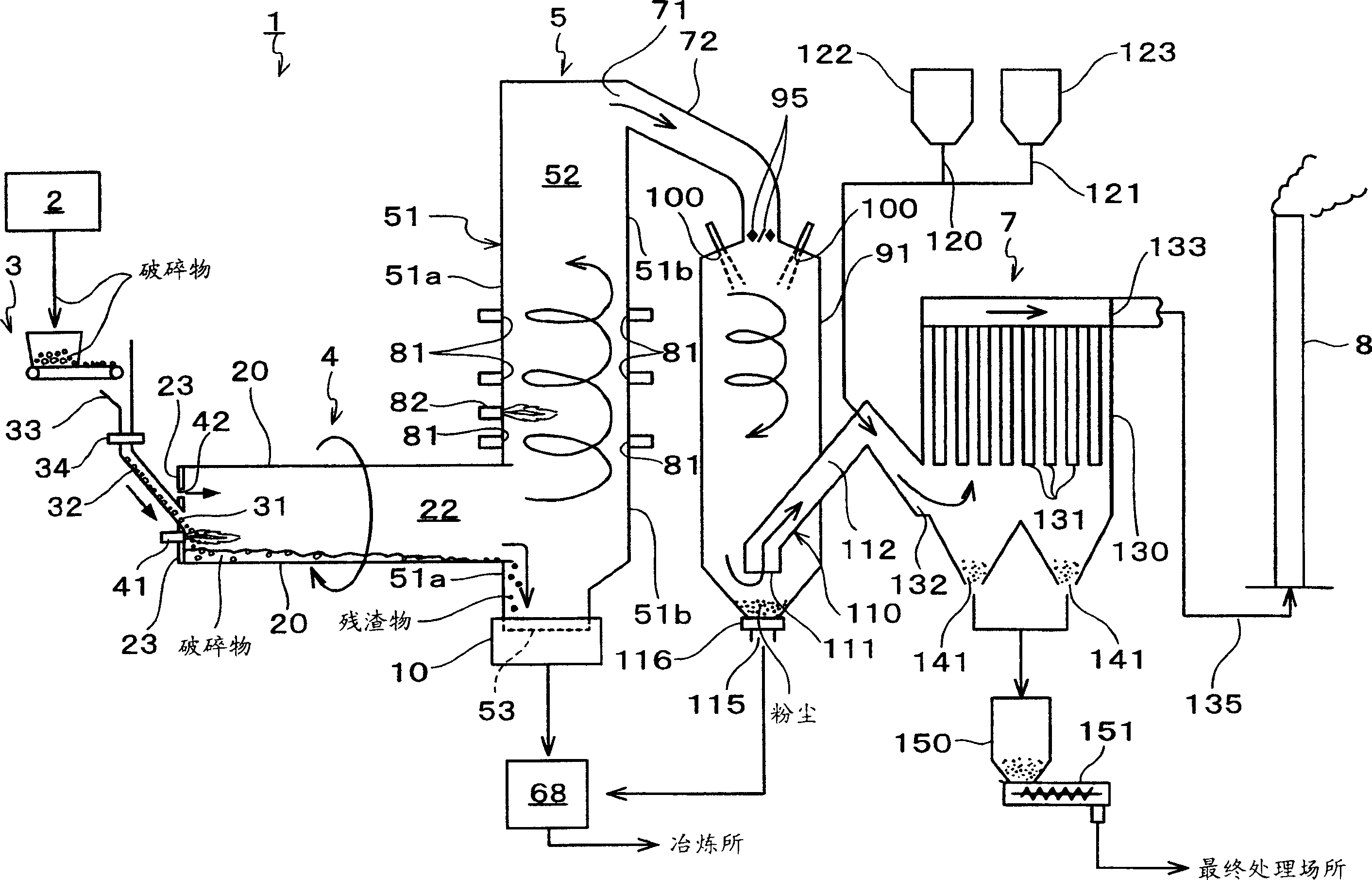

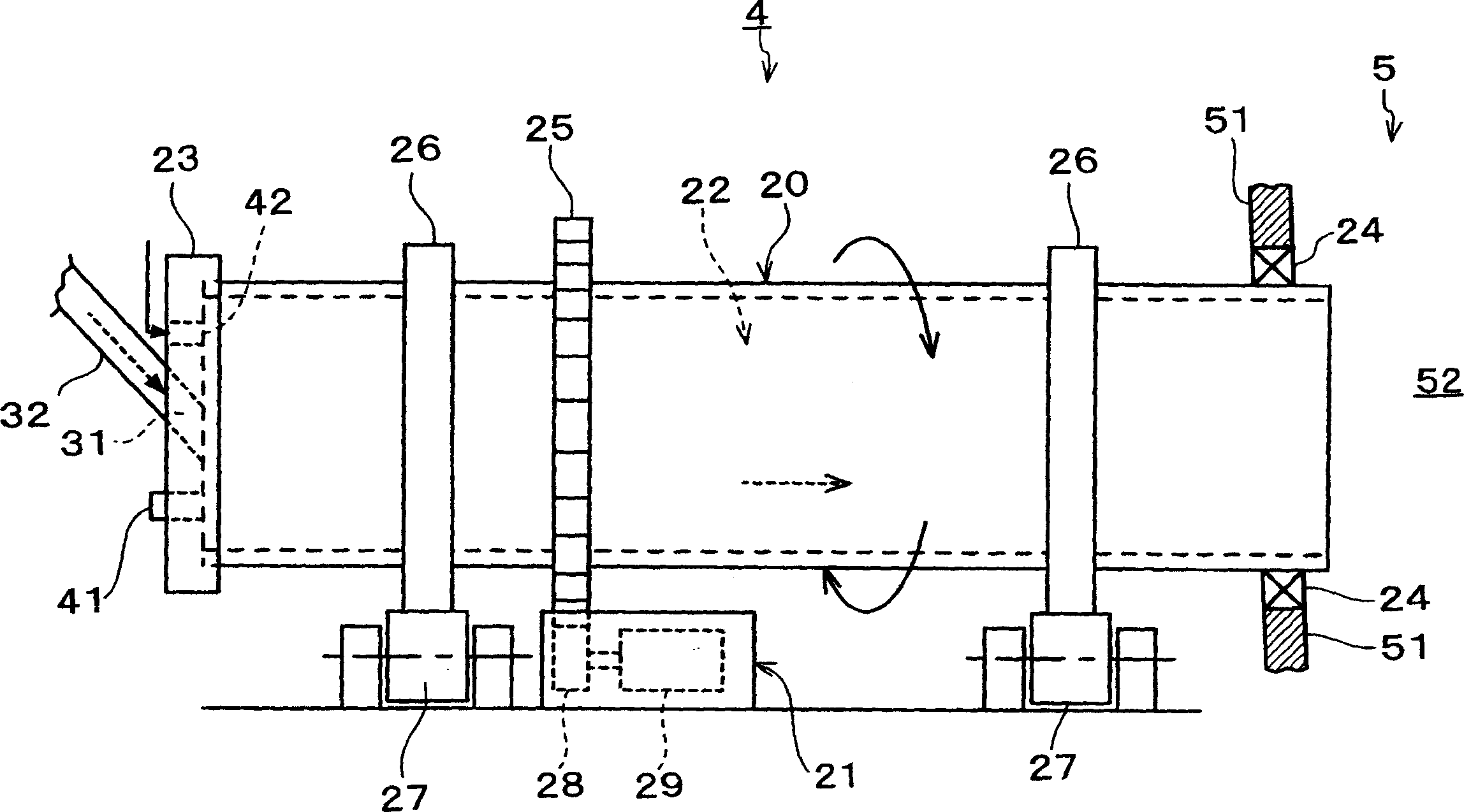

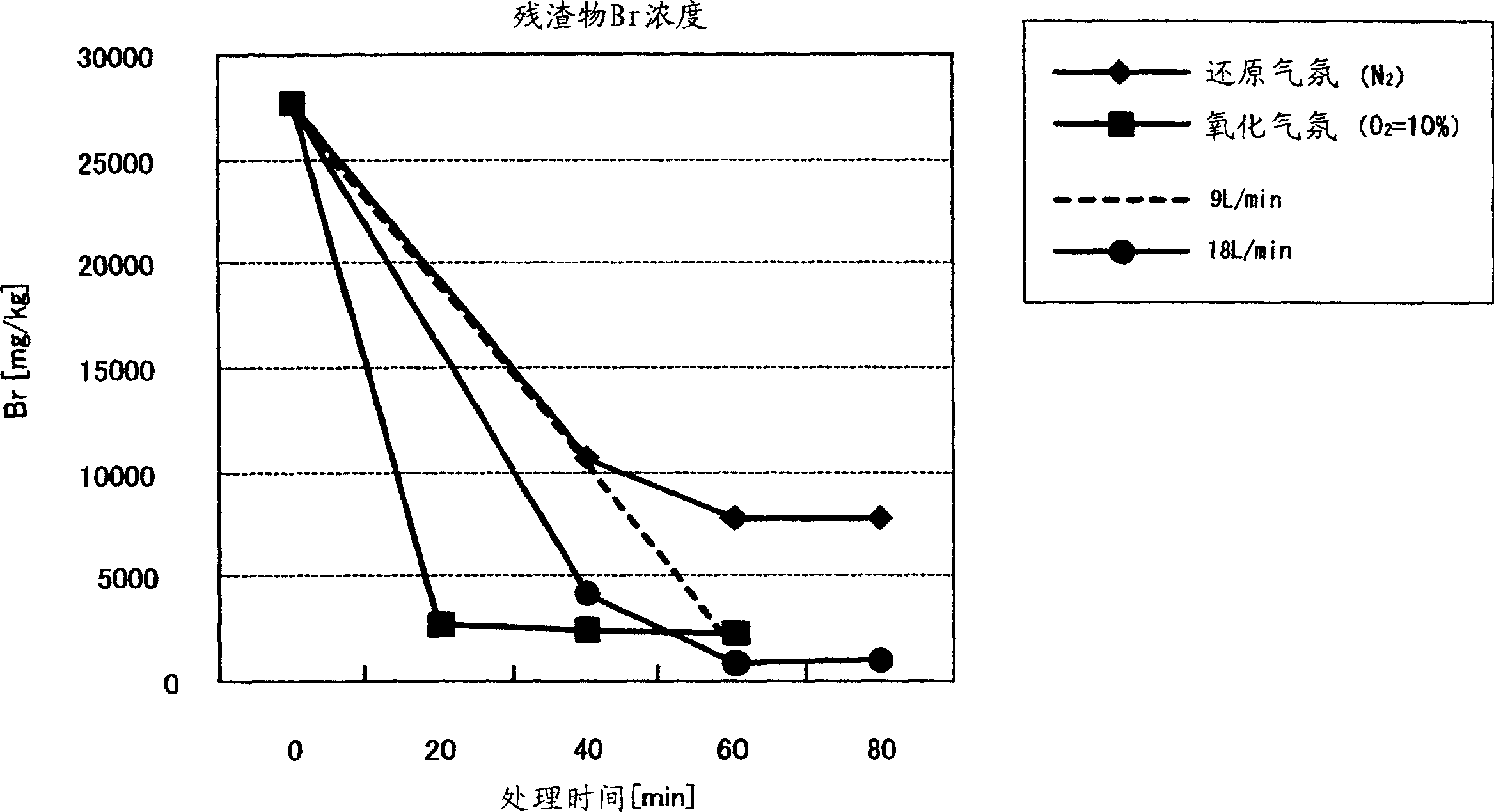

Castoff processing method and system

ActiveCN1834537AEfficient combustionEfficient gasificationProcess efficiency improvementIncinerator apparatusWaste processingHazardous substance

The invention relates to a waste processing method and a waste processing system which can avoid discharging harmful material as dioxins and effectively attain the slag of value metal. Wherein, the method for recycling value metal comprises: burning the waste, recycling the slag that containing value metal, and fully burning generated gas , and cooling said burning gas with the cooling speed that avoiding generating dioxins. With said method, the invention can gasify the resin component in the waste via burning waste, to obtain the slag of value metal in short time.

Owner:DOWA METALS & MINING CO LTD

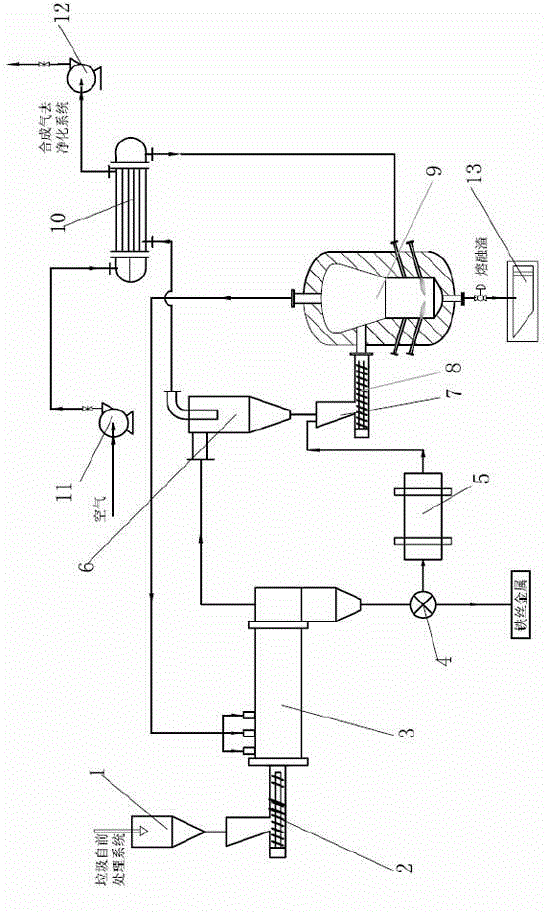

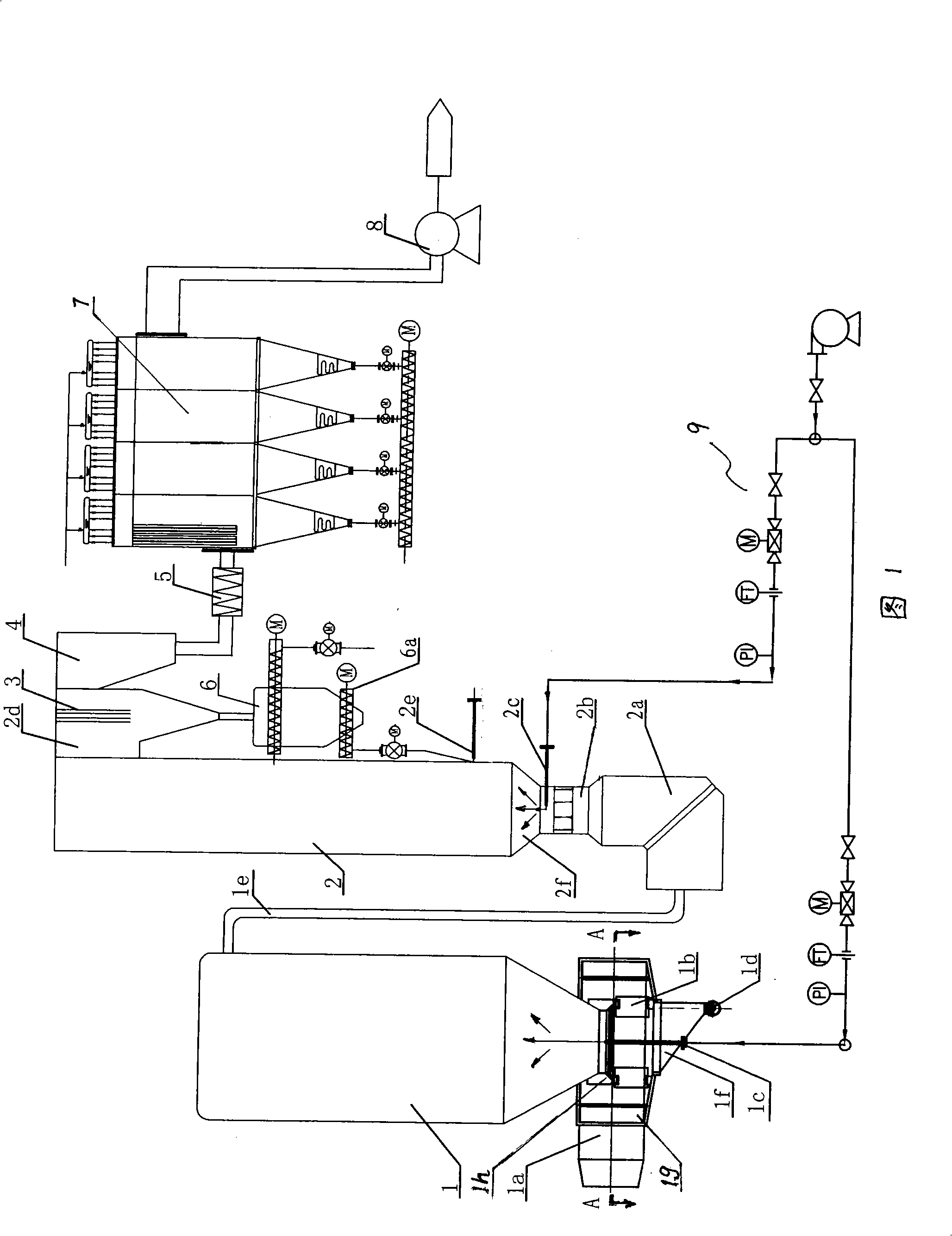

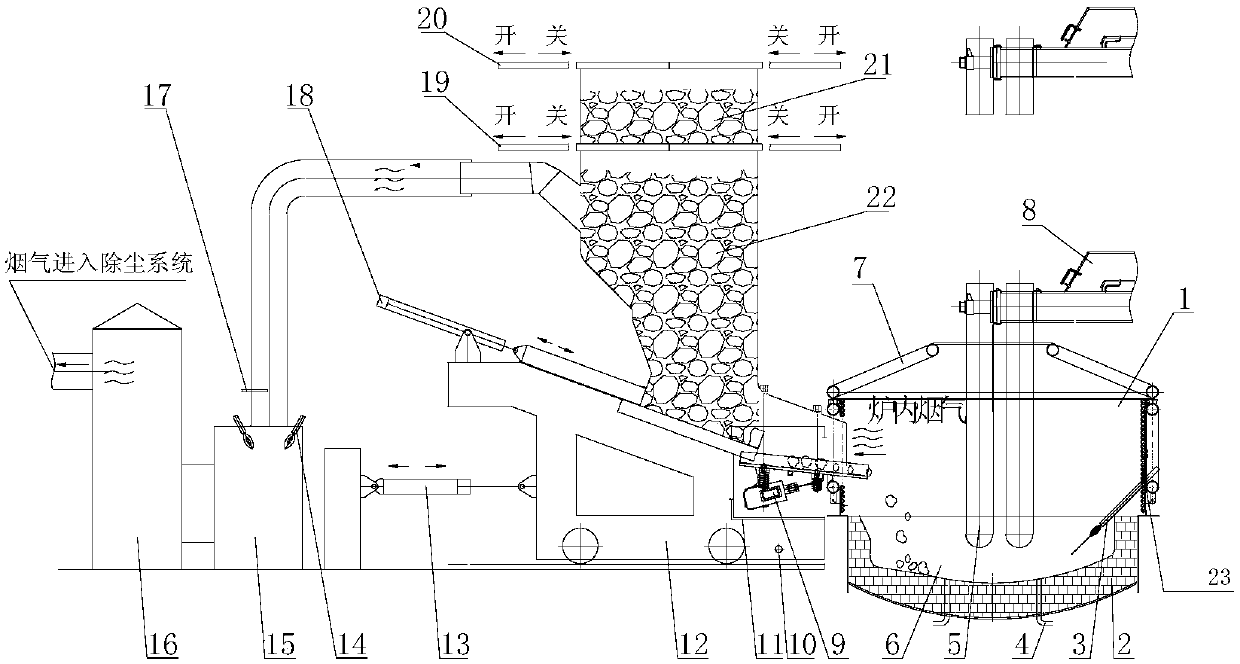

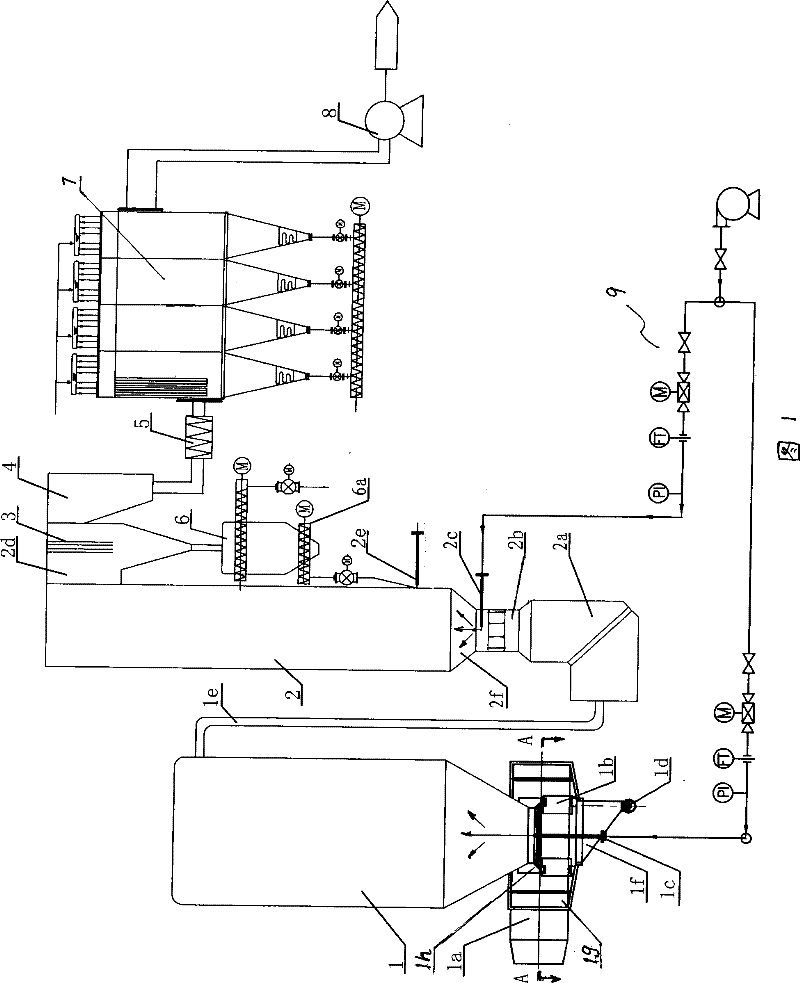

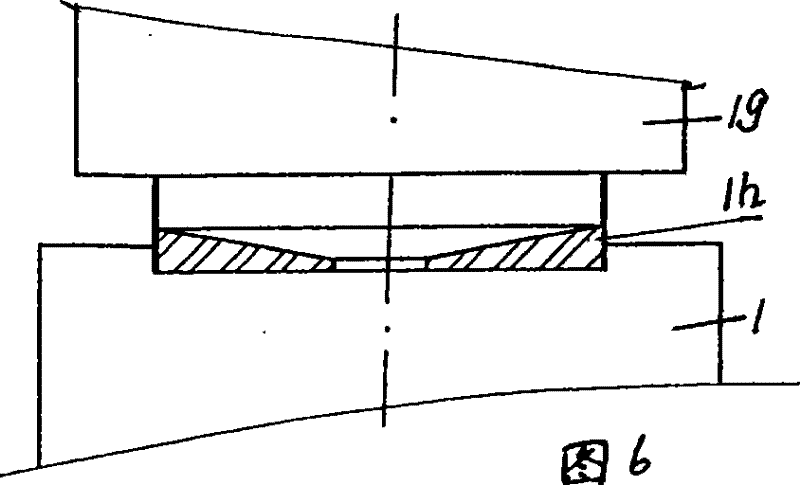

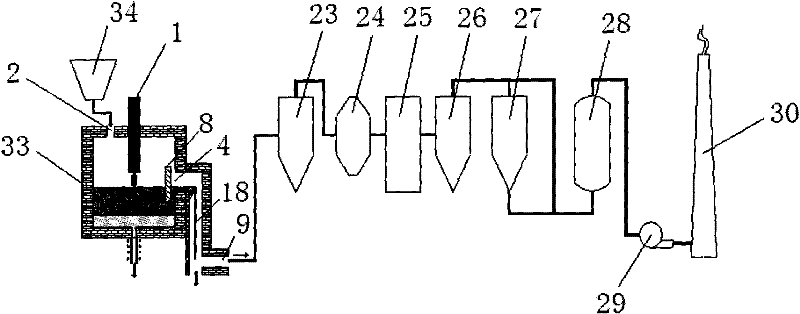

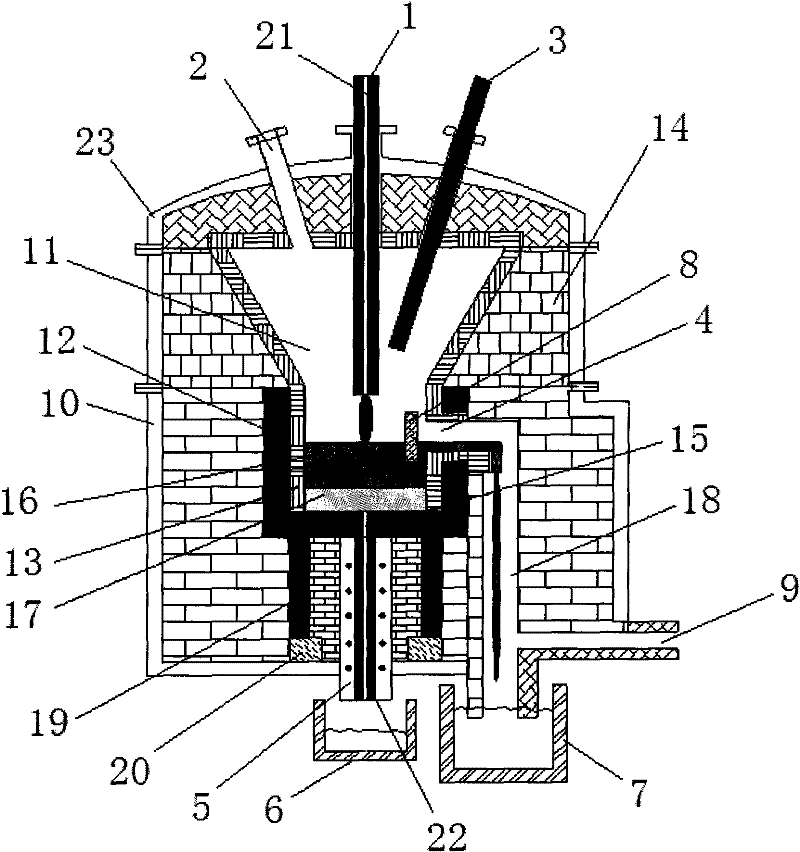

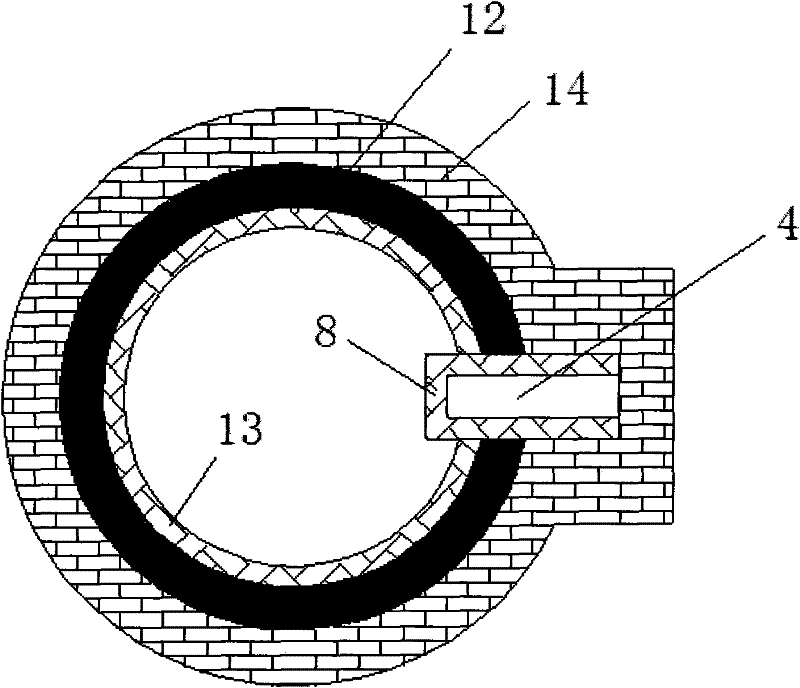

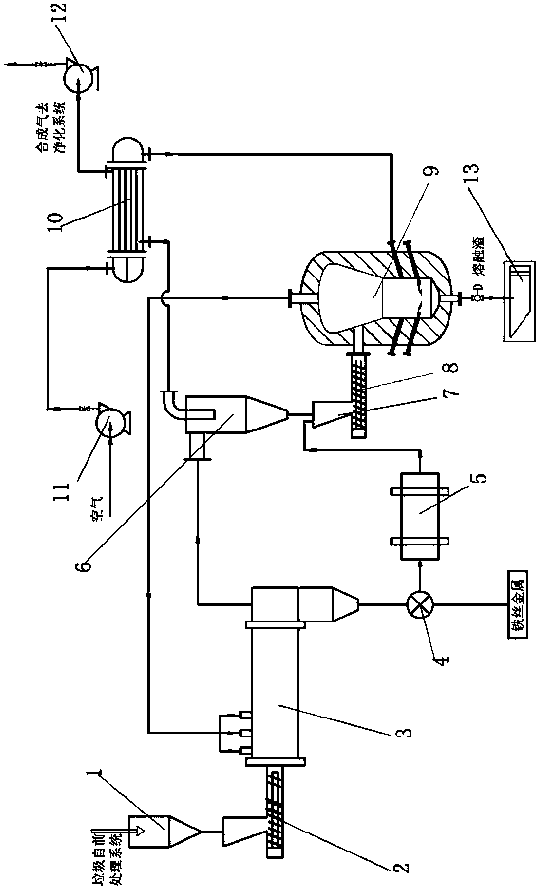

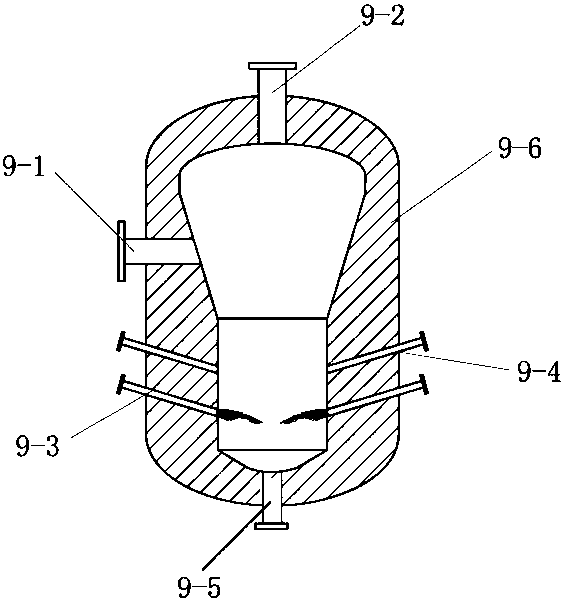

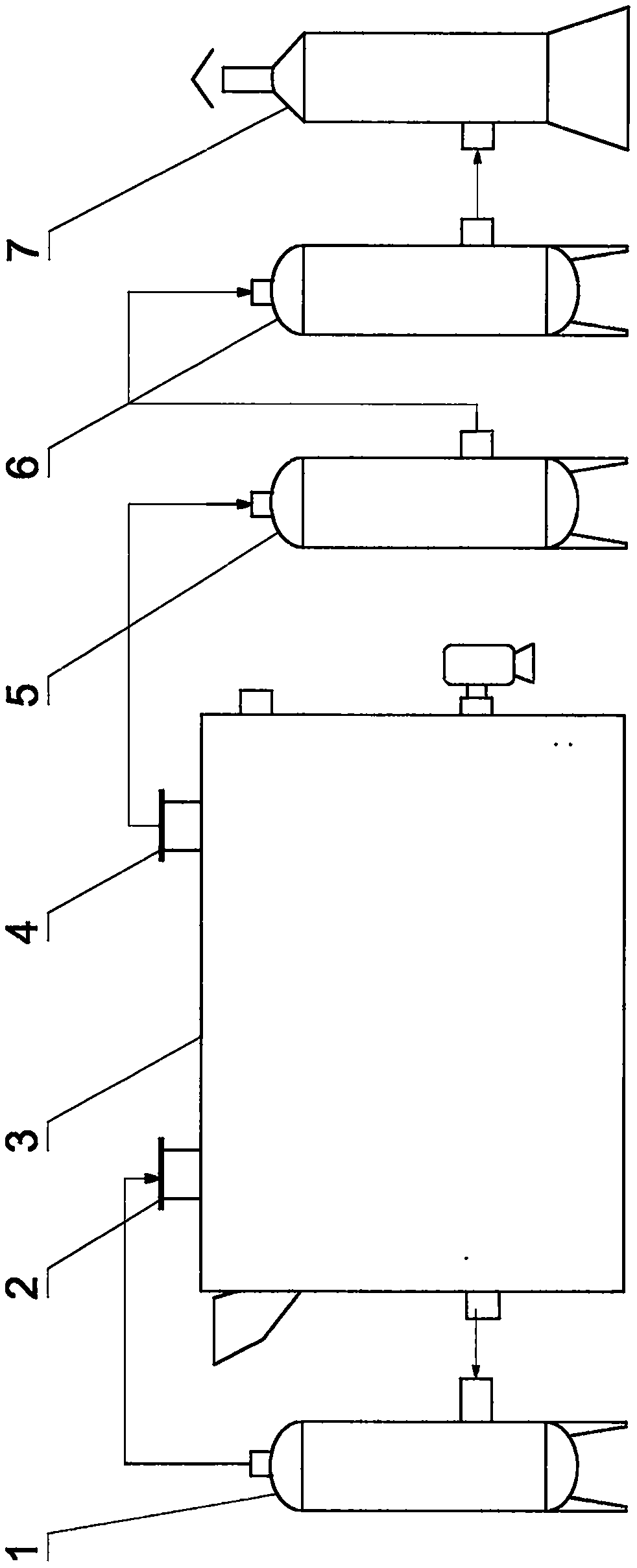

Household garbage classified gasification system with rotary kiln gasification and plasma fusion capability

ActiveCN104976622AReduce energy consumptionReduce processing costsIncinerator apparatusAir preheaterCyclone

The invention discloses a household garbage classified gasification system with rotary kiln gasification and plasma fusion capability. The household garbage classified gasification system comprises a rubbish feeder, a rotary kiln type pyrolysis vaporizer, a metal sorting machine, a crusher, a high-temperature cyclone separator, an ash hopper, an ash feeder, a plasma fusion furnace and an air preheater; household garbage is sequentially subjected to the pyrolysis gasification, metal sorting and crushing of the rotary kiln type pyrolysis vaporizer and the further gasification treatment of the plasma fusion furnace; the low-temperature rotary kiln vaporizer and the high-temperature plasma fusion furnace can be effectively combined, and the ash generated by pyrolysis and gasification of the rotary kiln vaporizer is fused by virtue of taking plasma torch as a high-quality heat source; the household garbage classified gasification system can effectively take the heat of synthesis gas and the gas fume generated by the fusion furnace as an outer heat source of the rotary kiln vaporizer so as to heat the air entering in the plasma fusion furnace, the comprehensive energy use efficiency is improved, and the secondary pollution problem of dioxin and heavy metal is avoided.

Owner:中国东方电气集团有限公司

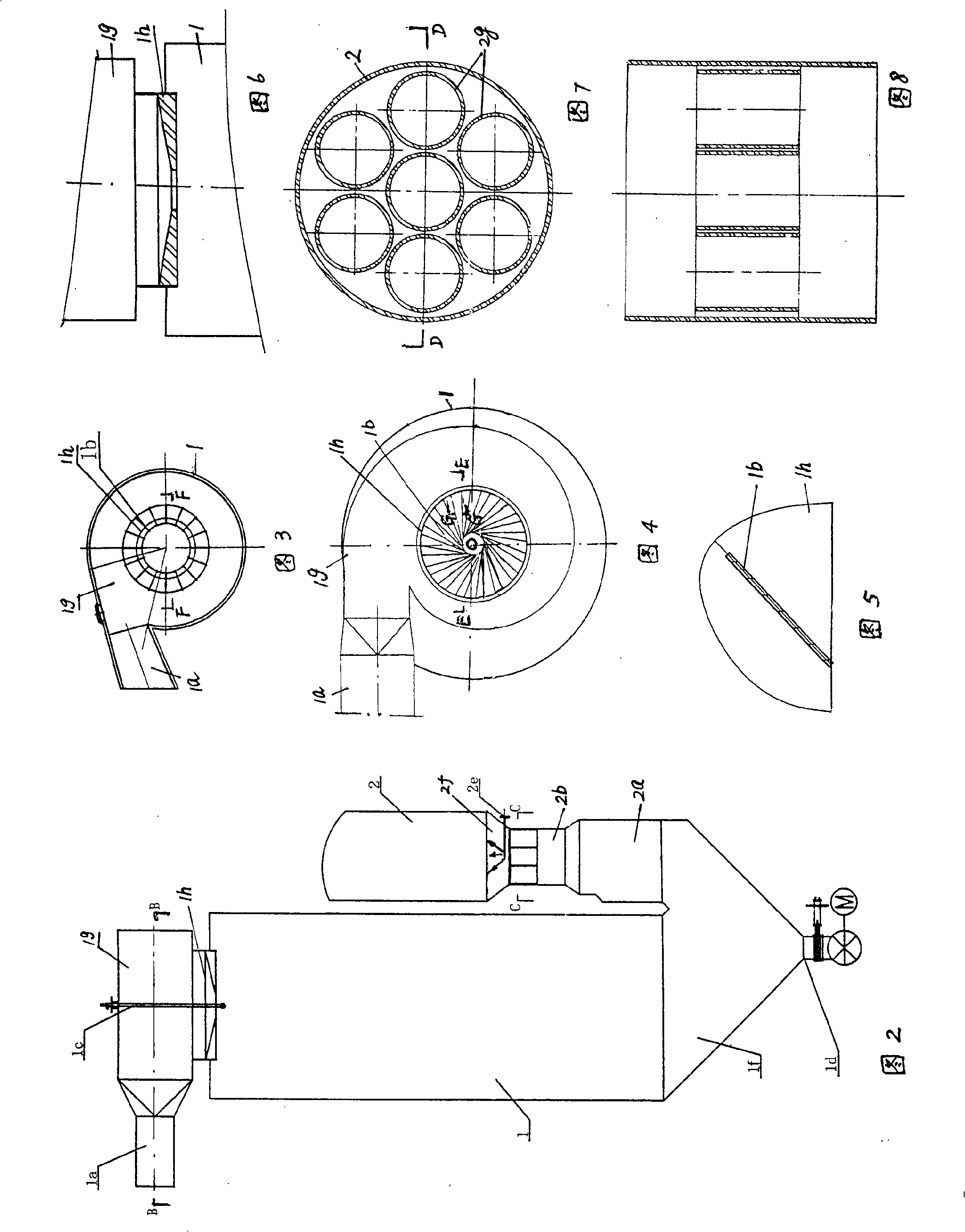

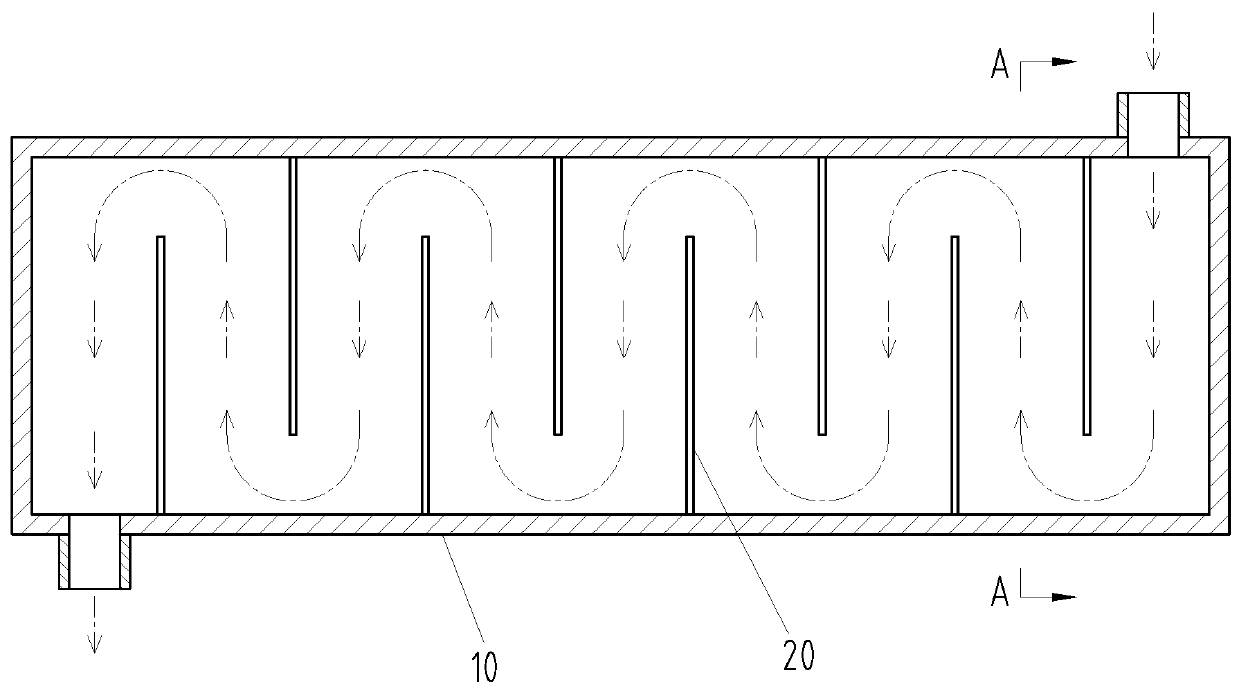

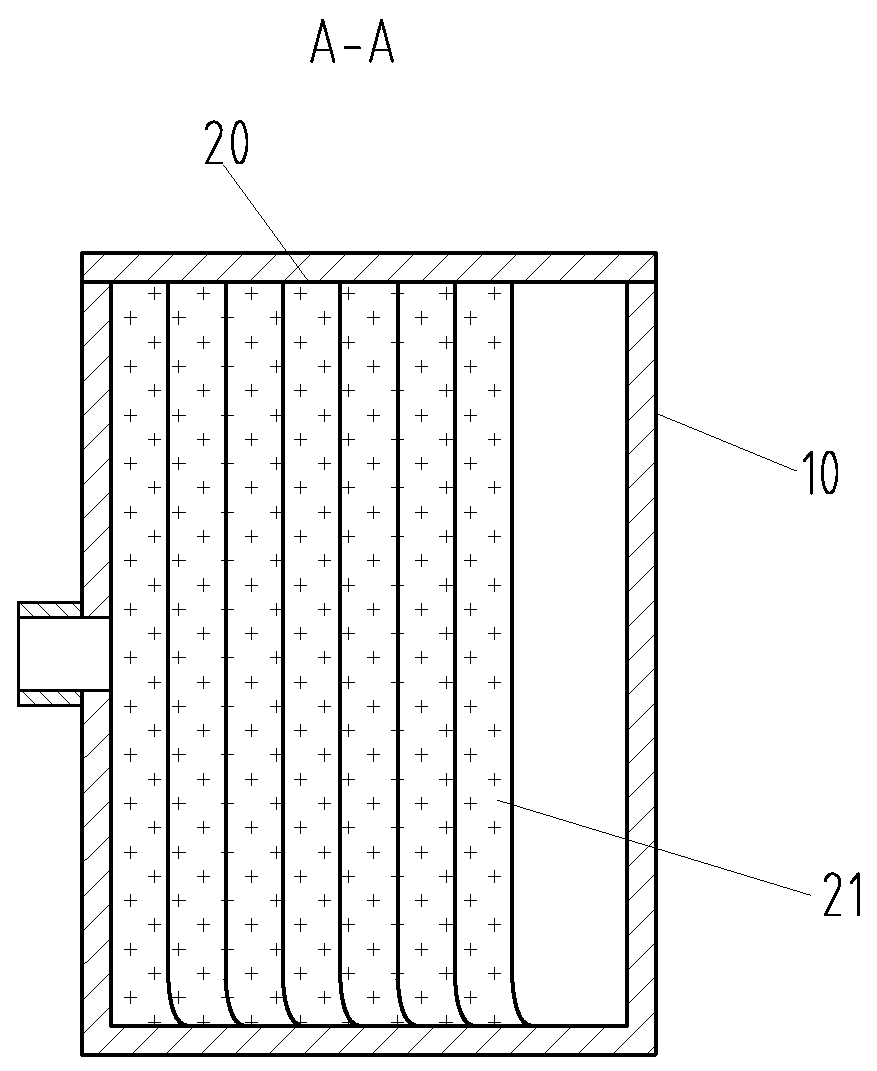

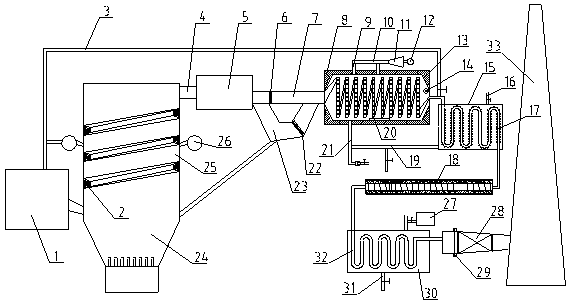

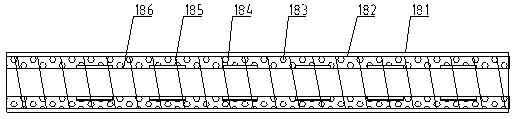

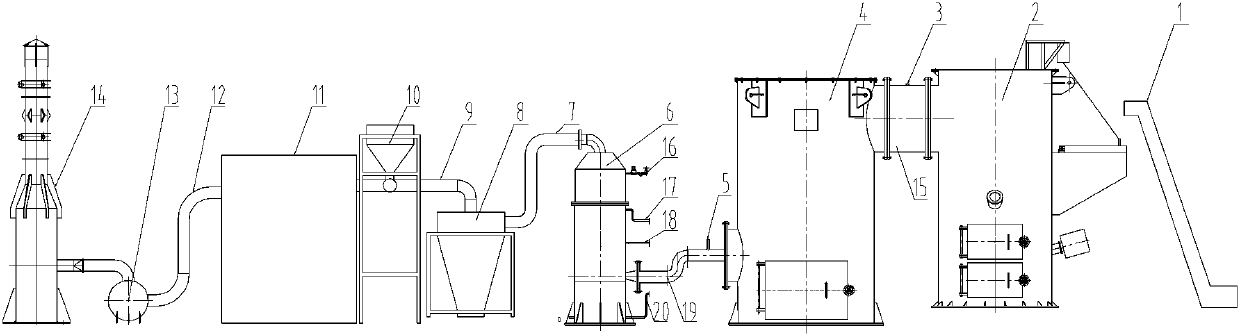

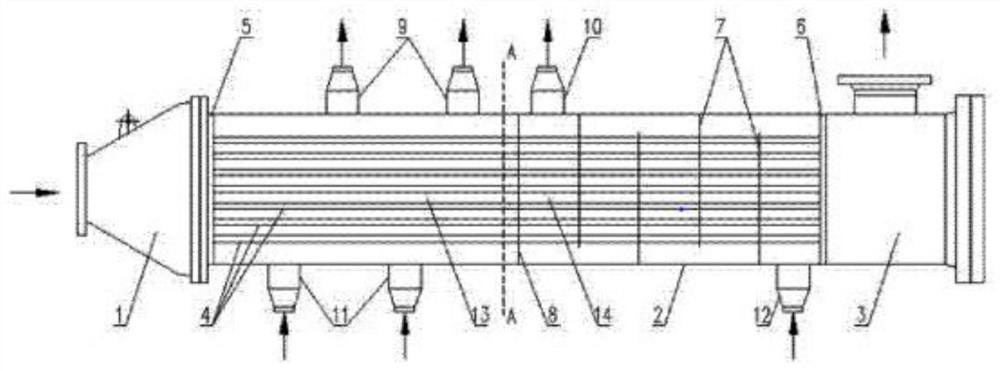

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458AEnhanced rectificationImprove current sharing effectDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smoke purification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

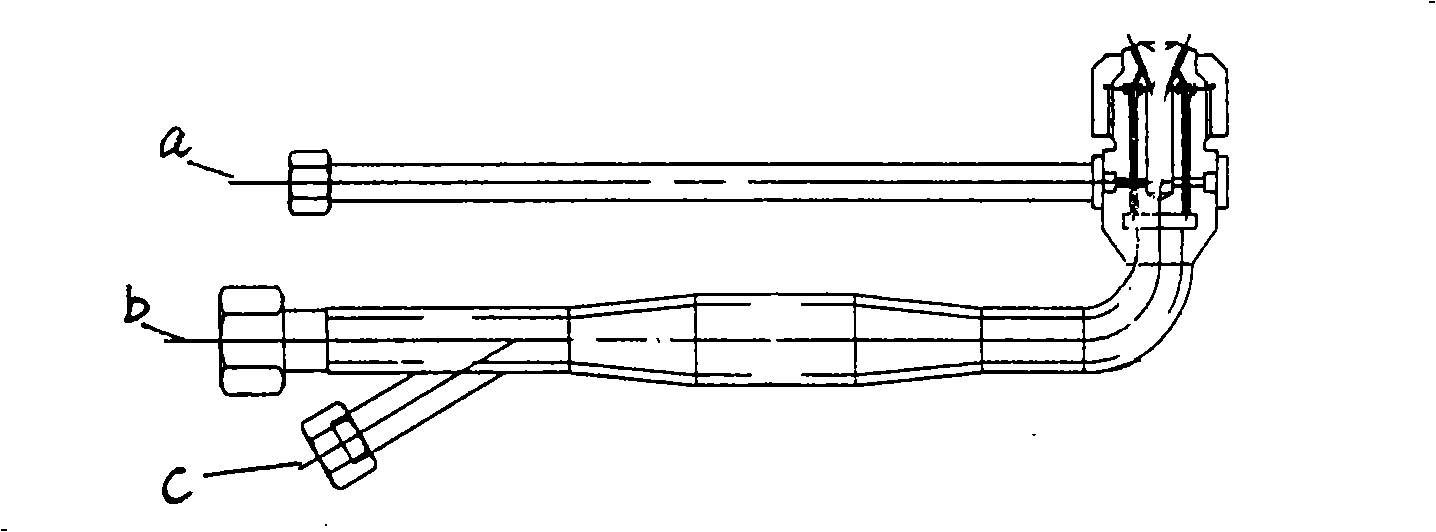

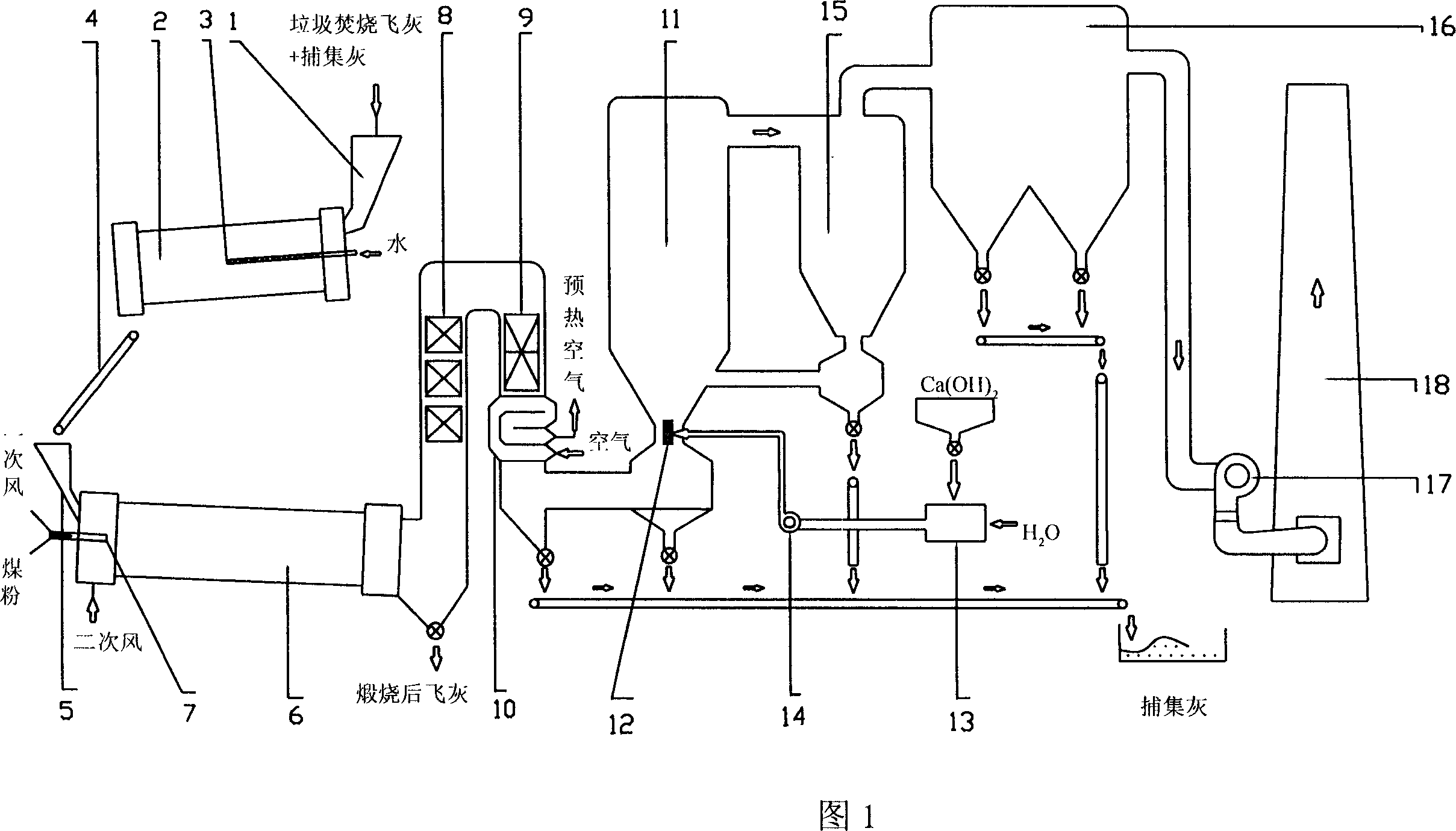

Method and its device for garbage burning and flyash incinerating treatment

InactiveCN1987202APrevent resynthesisEnergy savingEnergy industryIncinerator apparatusPelletizingEnvironmental Engineering technology

A process for treating the fly ash generated by incinerating garbage includes such steps as spray water onto fly ash, granulating, pre-heating, high-temp burning, recovering the afterheat from generated fume, cleaning the fume, and exhausting. Its apparatus is composed of drum-type granulating machine, conveying belt, rotary calcining furnace, afterheat recovering system, and fume cleaning system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

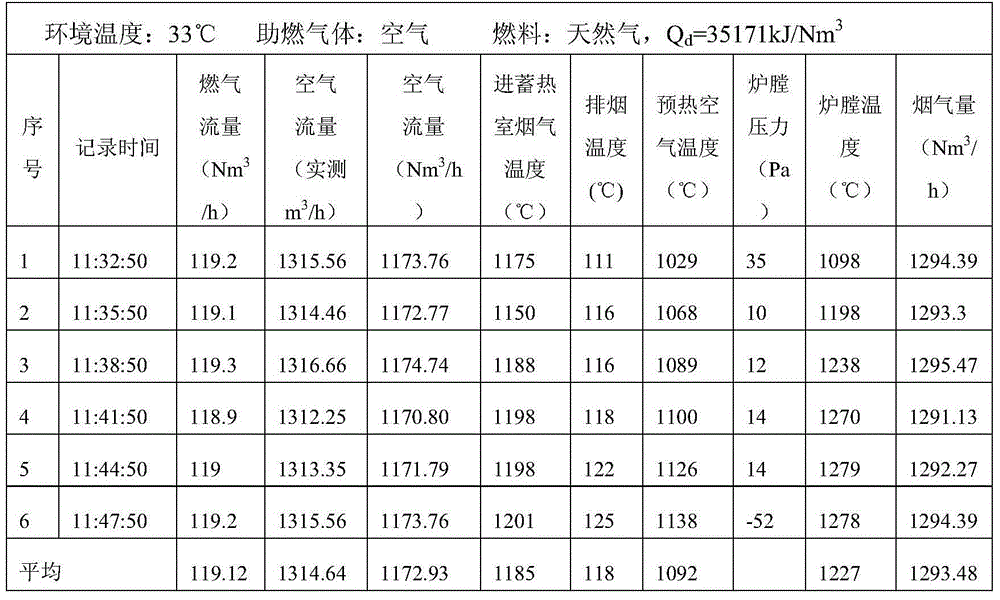

Regenerative combustion device

InactiveCN104457302ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCombustorLow nitrogen

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

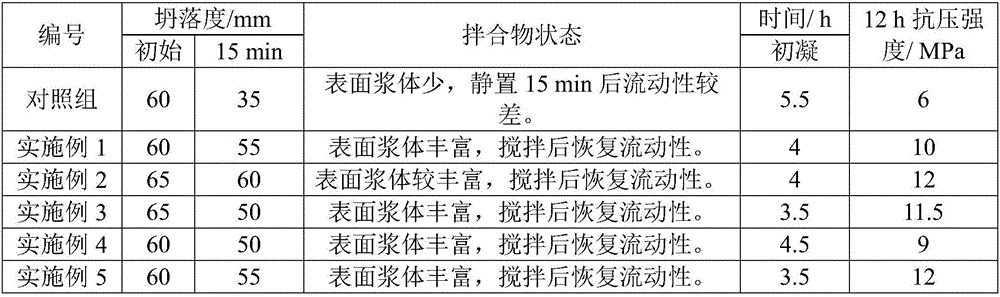

Thixotropic agent for polycarboxylate superplasticizer, thixotropic type polycarboxylate superplasticizer and application of thixotropic agent

The invention provides a thixotropic agent for a polycarboxylate superplasticizer. The thixotropic agent is mainly prepared from components of raw materials in parts by mass as follows: 0.2-1 part of white carbon black, 3-12 parts of alkali carbonate and 1.5-6 parts of sulfate, wherein the thixotropic agent for the polycarboxylate superplasticizer and a polycarboxylate superplasticizer mother solution are sufficiently and uniformly mixed in water, and the thixotropic type polycarboxylate superplasticizer with excellent thixotropic performance in the precast concrete application process can be obtained. The thixotropic type polycarboxylate superplasticizer containing the thixotropic agent is doped in precast concrete, the thixotropy of the newly blended concrete can be remarkably improved, early strength development is promoted, and the problem that existing polycarboxylate superplasticizers don't have sufficient thixotropic performance in the precast concrete application process is effectively solved.

Owner:中建西部建设新材料科技有限公司 +2

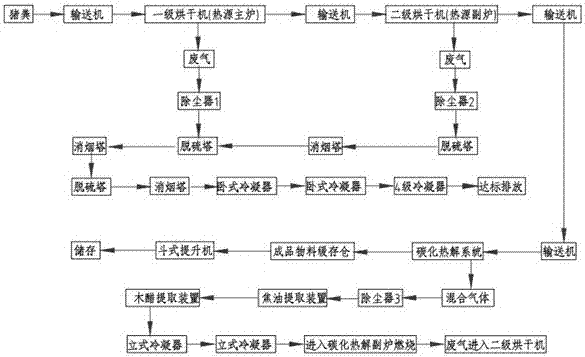

Comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology

InactiveCN107162373ARealize "three modernizations" processingImprove thermal efficiencySludge treatment by pyrolysisByproduct vaporizationHazardous substanceRetention time

The invention provides a comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology. Through steps including multi-stage drying to the pig manure, carbonization pyrolysis to the pig manure, flue gas treatment and the like, the pig manure is subjected to dry pyrolysis in a furnace, high-temperature pyrolysis gasification, and re-pyrolysis gasification to flue gas (outlet flue gas temperature is higher than 850 DEG C), wherein retention time of flue gas in the furnace is prolonged to more than 2 sec. In the whole pyrolysis process, generation of PCDDs / PCDFs harmful substances is effectively inhibited. Through quenching cooling to high-temperature flue gas, re-synthesis of dioxin is effectively avoided. Main measurements, such as a desulfurization column, adsorption in a smoke removal column, liquefaction in a condenser and the like, are all employed in the technology, so that national smoke and dust discharge standard at present can be satisfied.

Owner:FUJIAN YUYI ENVIRONMENT TECH CO LTD

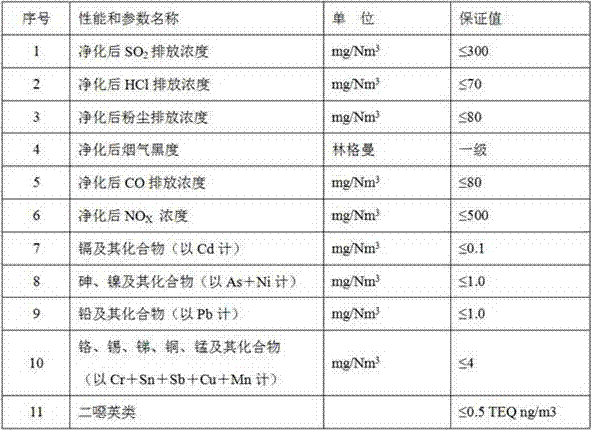

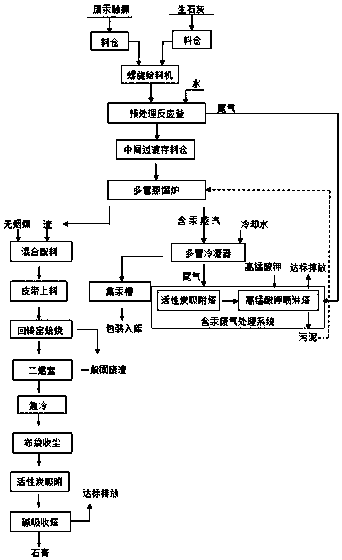

Mercury recovering and residue harmless treatment process for waste mercury catalyst

InactiveCN108559857AHigh recovery rateReduce pollution impactGas treatmentDispersed particle separationActivated carbonCombustion chamber

The invention relates to a mercury recovering and residue harmless treatment process for a waste mercury catalyst. On the basis of the technological process of an existing distillation method, a technology processing method involving a high temperature rotary kiln, a second combustion chamber, quenching and activated carbon adsorption is added to waste activated carbon residues discharged out of adistilling furnace, so that the residues produced by the distilling furnace are completely converted into common solid waste residues and duly handled, and the problem that the residues cause secondary environment pollution in the previous technological process and need to be transferred to a unit with the further handling qualification is solved.

Owner:喜德县良在硅业有限公司

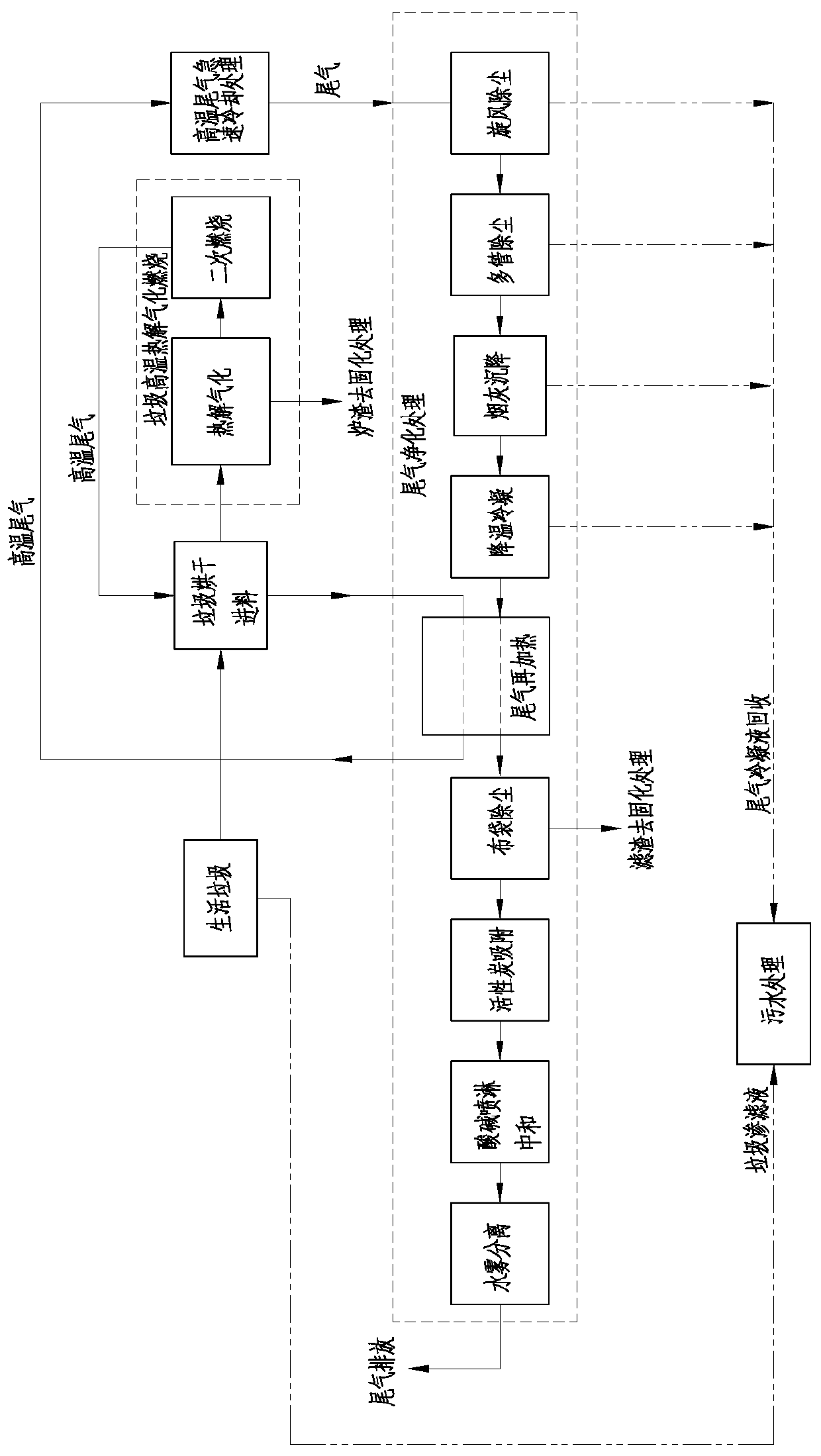

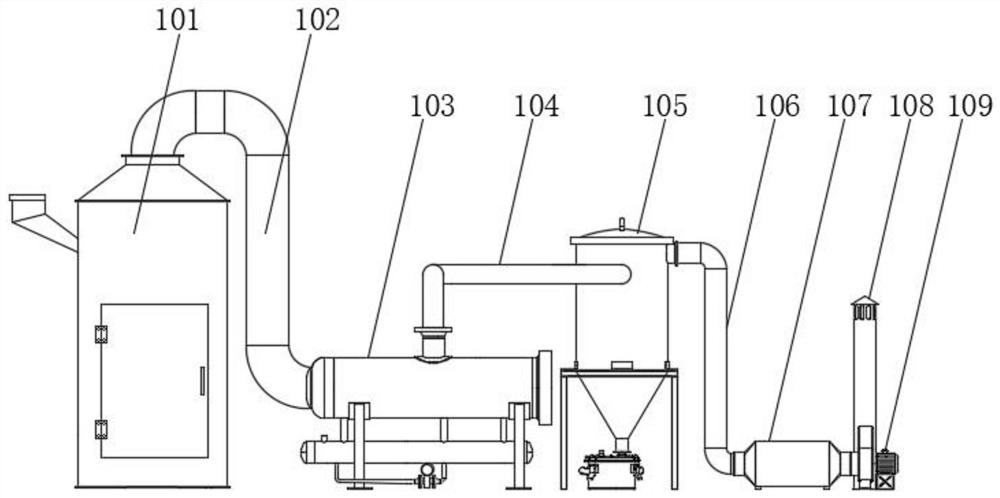

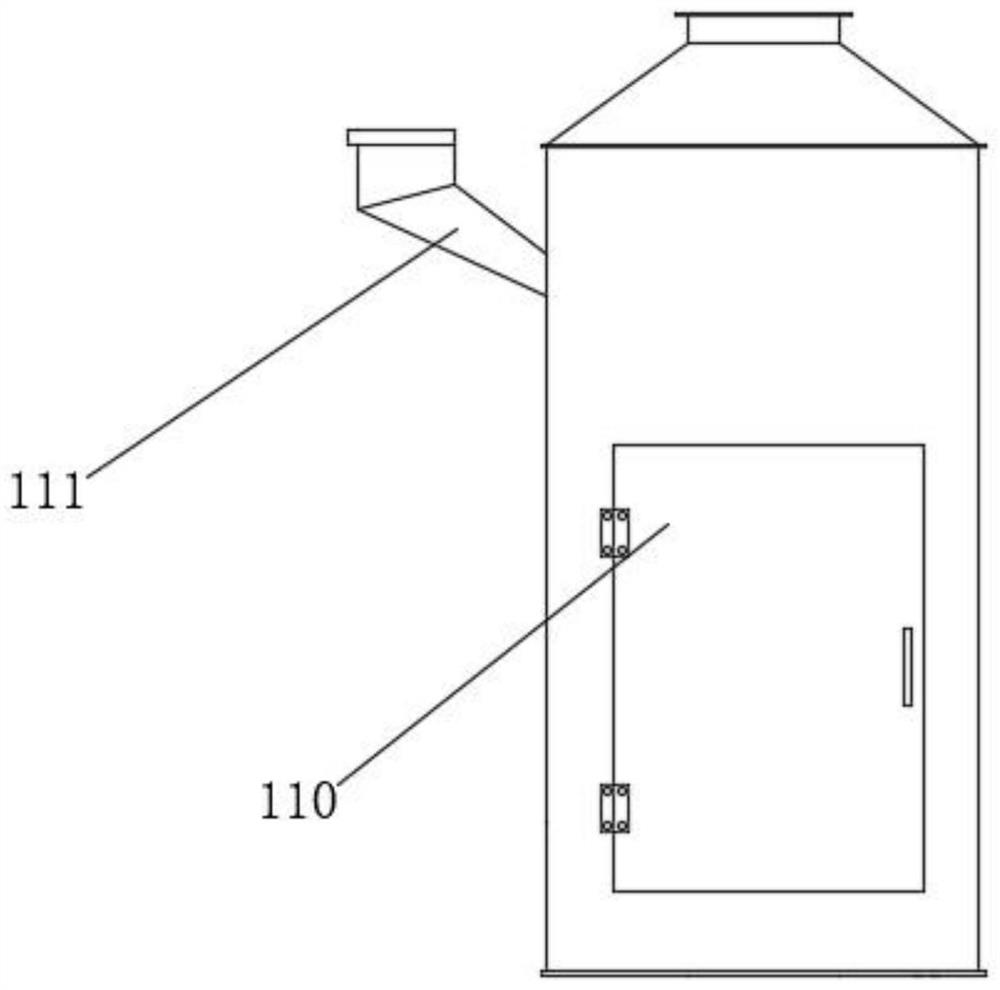

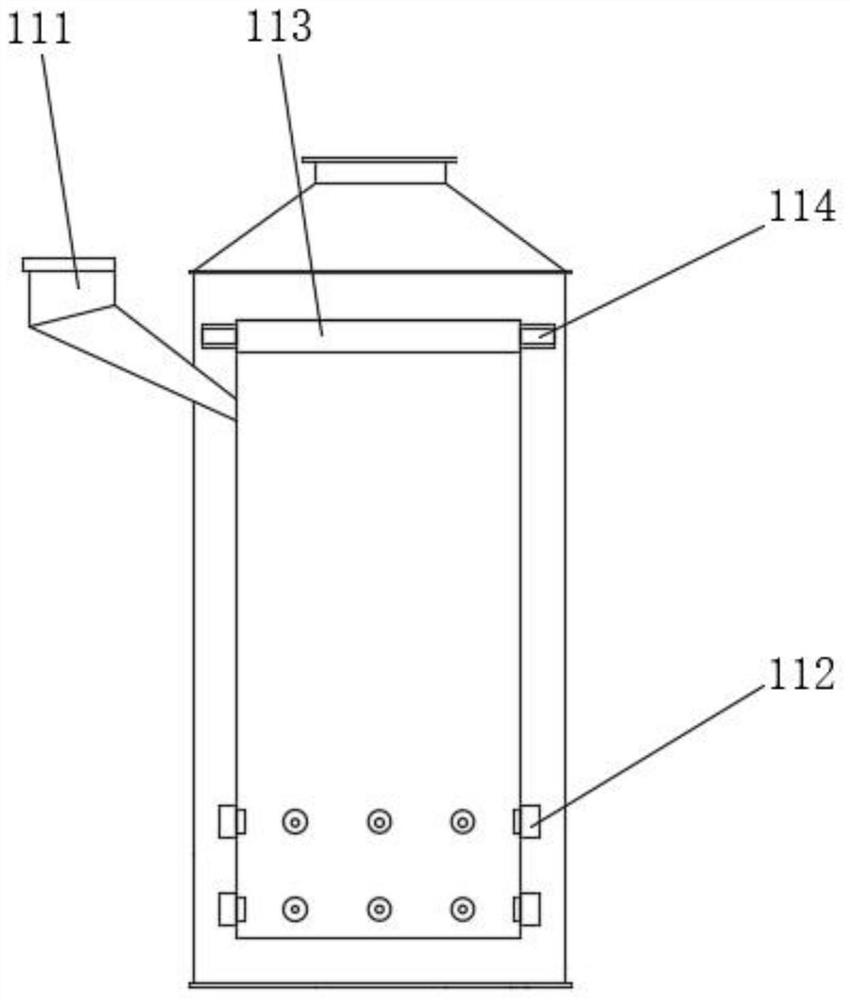

High-temperature pyrolysis gasification treatment system and process for household garbage

PendingCN109974006AEfficient use ofWon't leakCombination devicesCombustion technology mitigationLiquid wasteHazardous substance

The invention provides a high-temperature pyrolysis gasification treatment system and process for household garbage. The high-temperature pyrolysis gasification treatment system for household garbageinvolves a shaftless spiral drying conveyor, a high-temperature pyrolysis gasifier, a water-gas heat exchanger, a cyclone dust collector and a series of equipment; the high-temperature pyrolysis gasification treatment process for household garbage comprises following five steps of garbage drying and feeding, garbage high-temperature pyrolysis and gasification combustion, high-temperature tail gasrapid cooling treatment, tail gas purification treatment, solid waste and liquid waste treatment and the like. According to the system and the process, equipment selection and technological process design is reasonable, garbage feeding control is accurate, drying effect is good, the high-temperature pyrolysis gasification combustion temperature of the garbage is high, the high-temperature pyrolysis gasification combustion time is long, various toxic and harmful gases such as dioxin can be effectively decomposed, the high-temperature tail gas is subjected to rapid cooling treatment, so that thedioxin is prevented from being synthesized again; and when the tail gas is purified, various dust, water vapor and toxic and harmful substances in the tail gas can be absorbed and subjected to harmless treatment in a targeted manner, so that zero pollution discharge of tail gas can be realized.

Owner:南宁科创金属结构件有限责任公司

Steelmaking device and process for continuously preheating scrap steel

PendingCN111321272ASpeed up meltingIncrease the composition of homogeneous molten steelProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

Owner:MCC CAPITAL ENGINEERING & RESEARCH

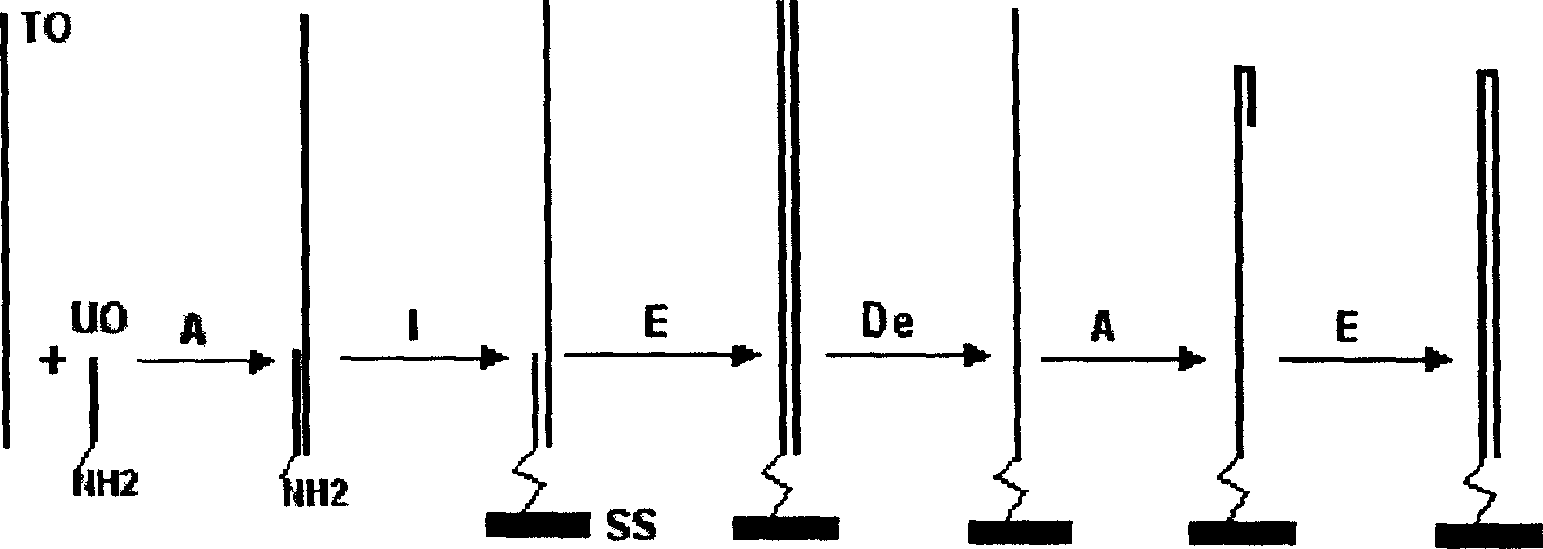

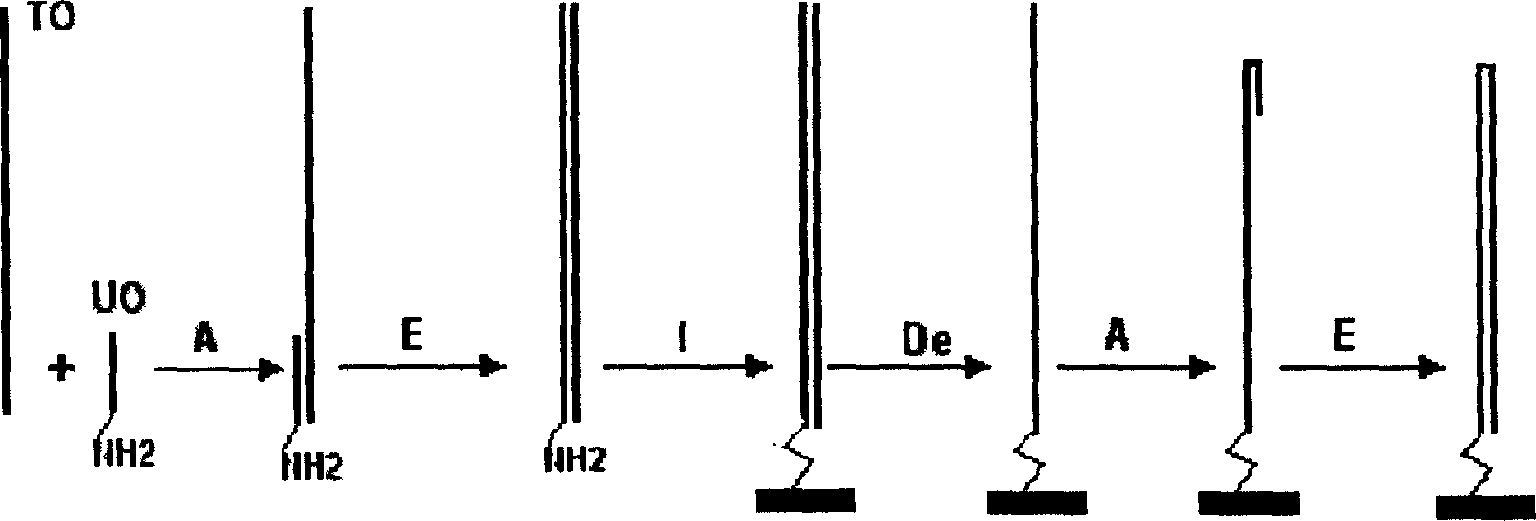

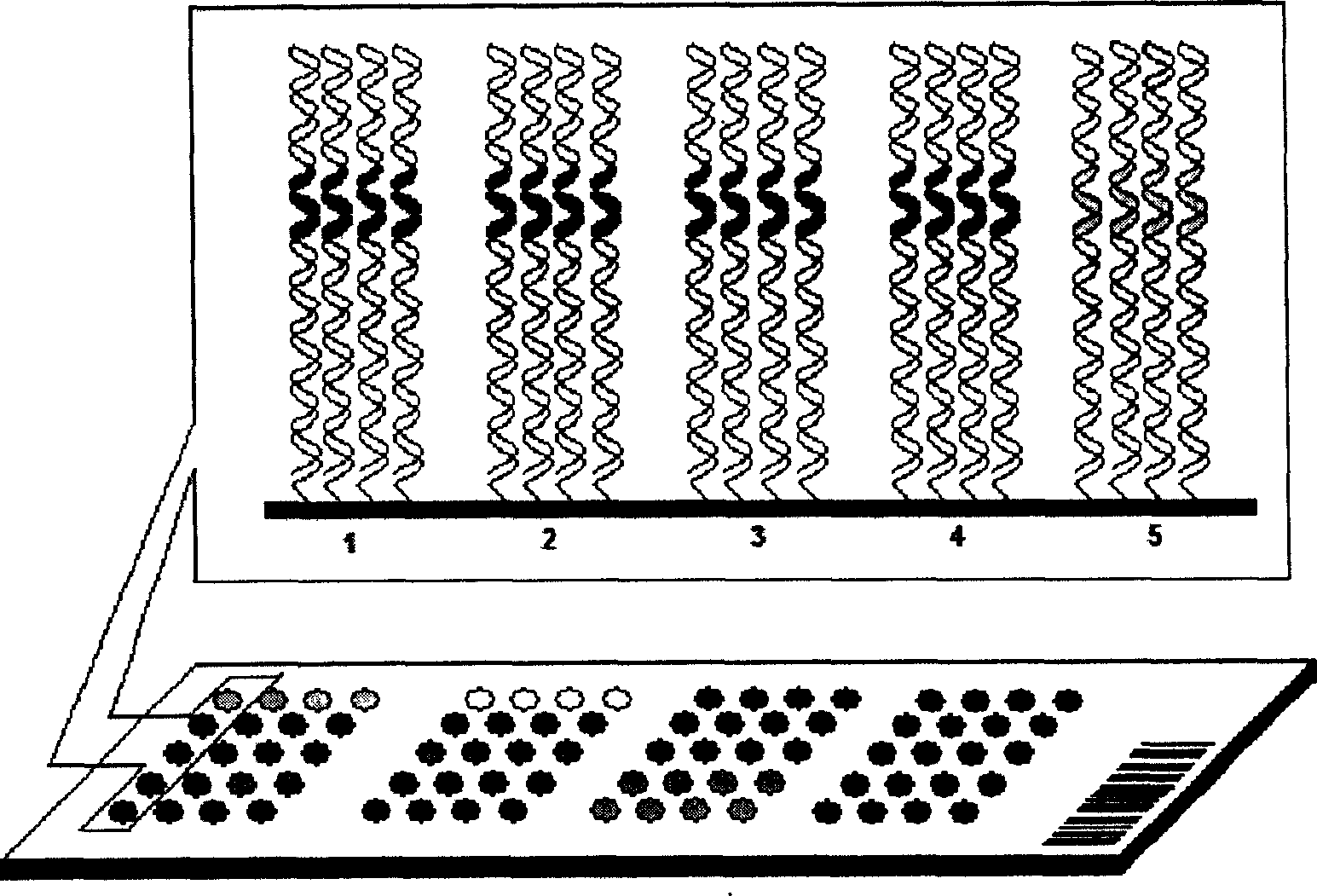

Single molecule dsDNA microarray chip preparation method

InactiveCN1590559APromote commercial applicationReduce manufacturing costMicrobiological testing/measurementBiological studiesPolymerase L

A process for preparing the unimolecular ds DNA microarray on the surface of solid carrier includes chemically synthesizing target oligonucleotide and universal oligonucleotide, renaturation of them, linking them to the surface of solid carrier to become oligonucleotide microarray, on-chip polymerase elongation reaction to become bimolecular dsDNA microarray, modifying to become ssDNA microarray, renaturation to form hairpin structure, and on-chip polymerase elongation reaction.

Owner:王进科 +2

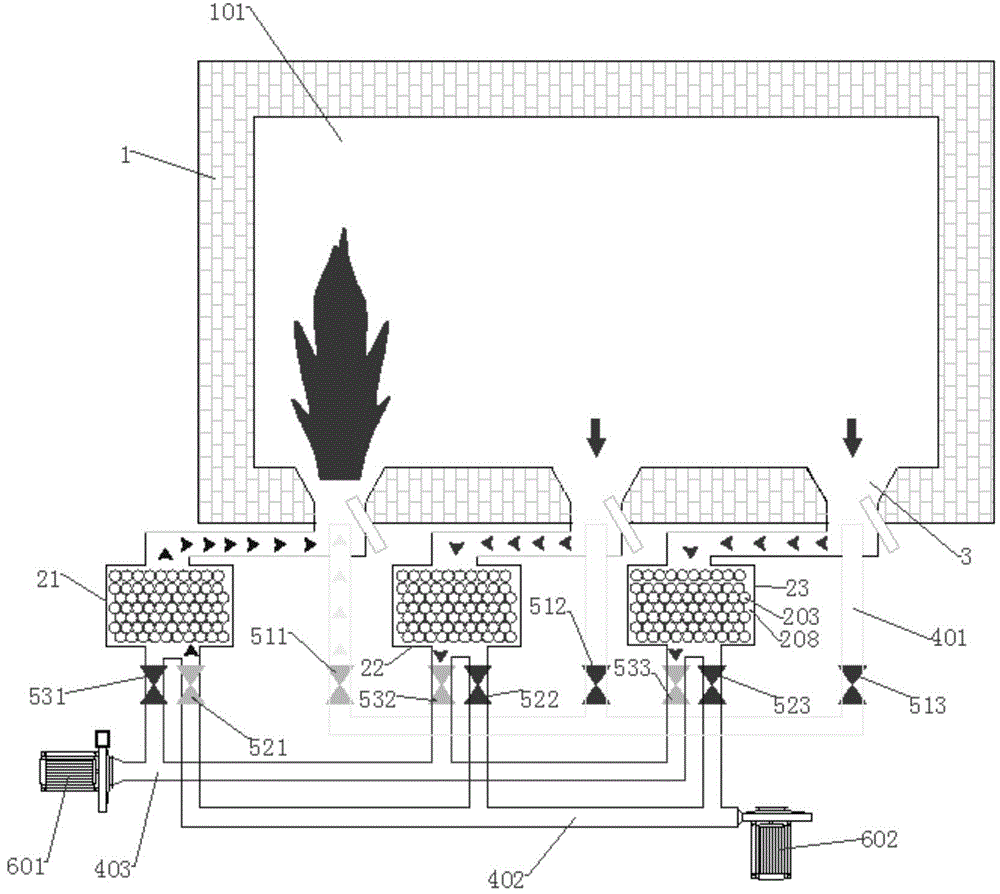

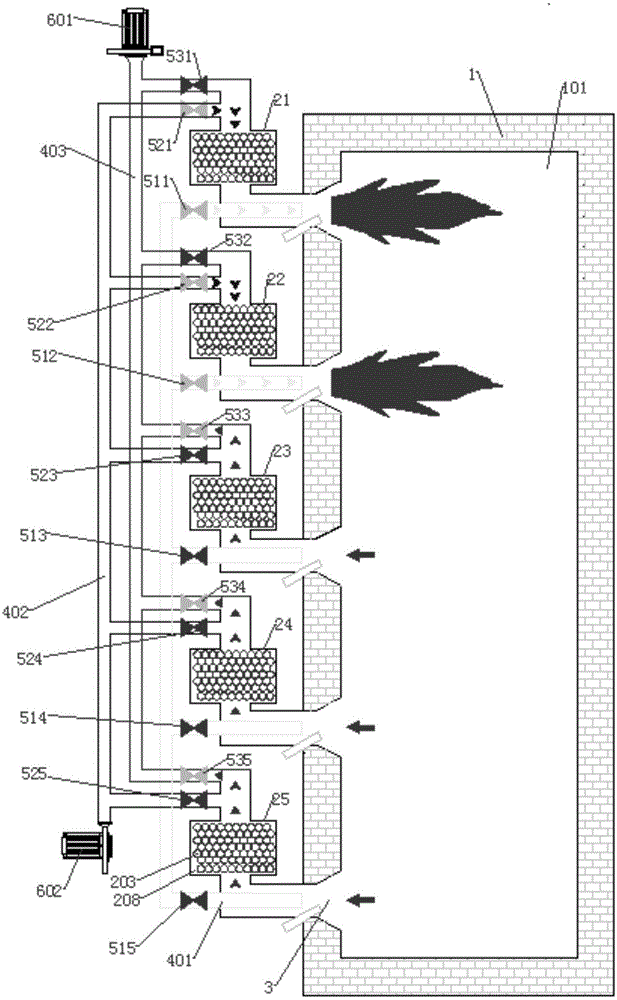

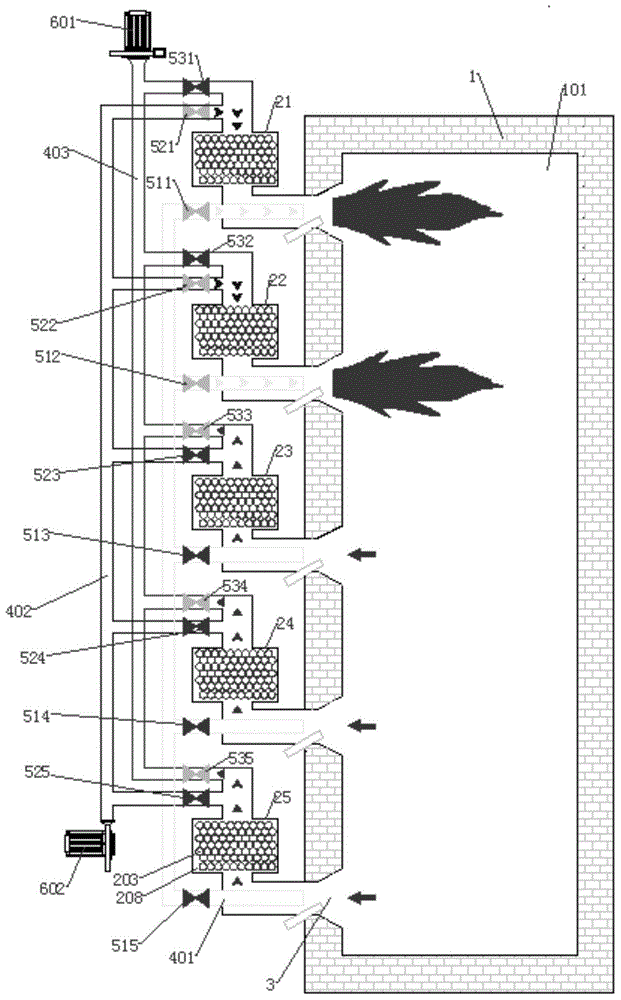

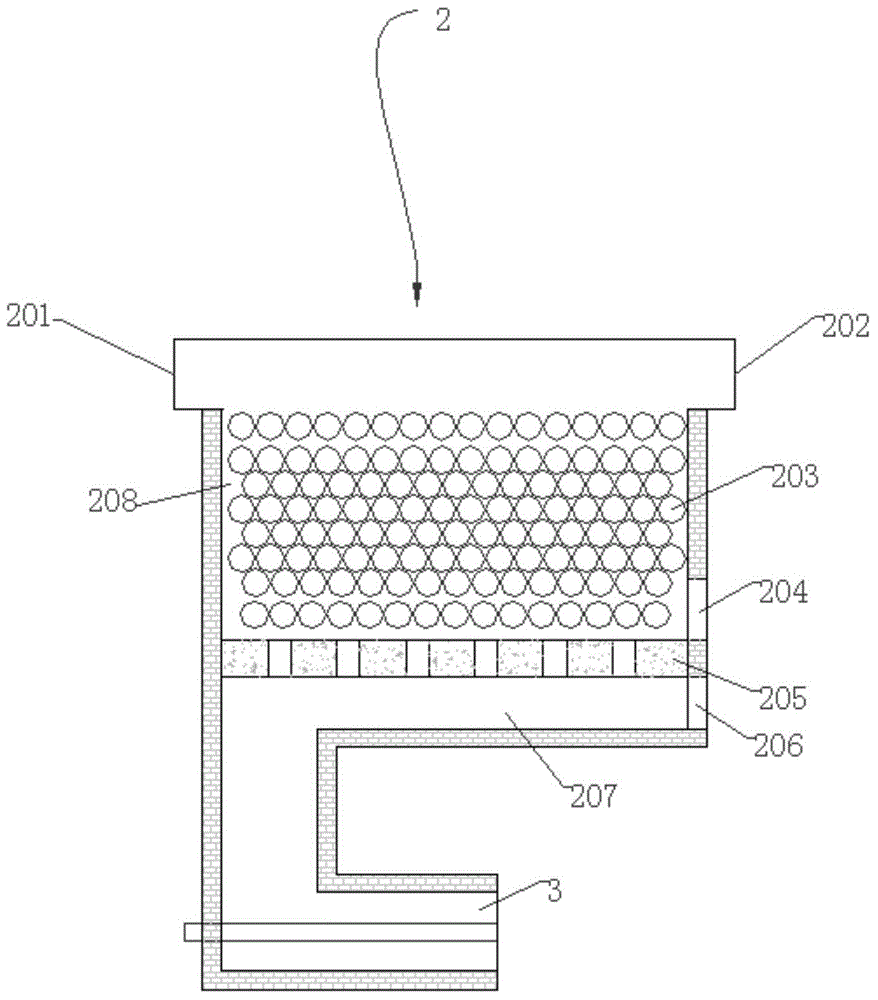

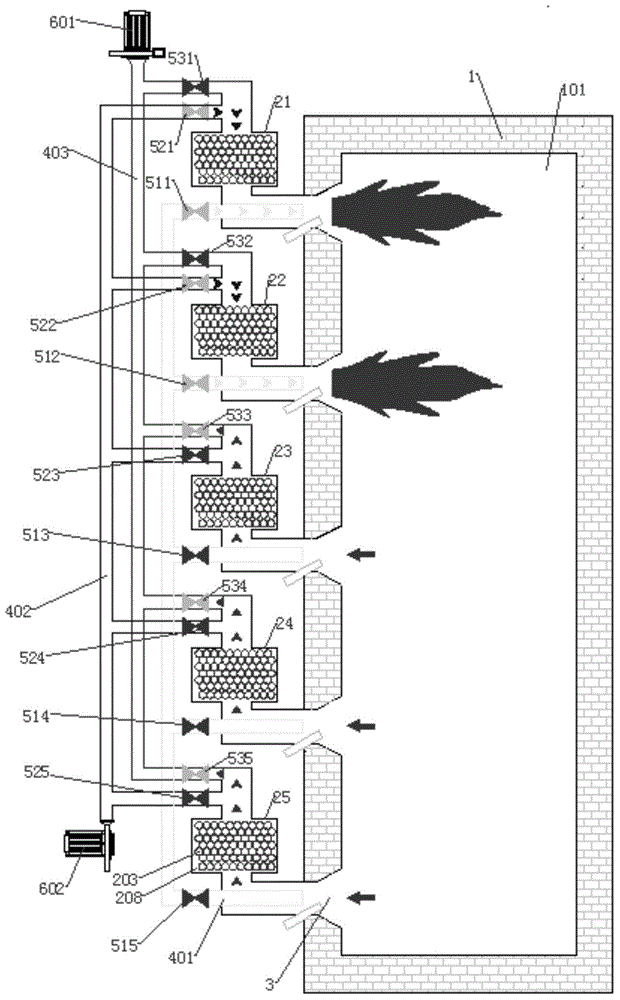

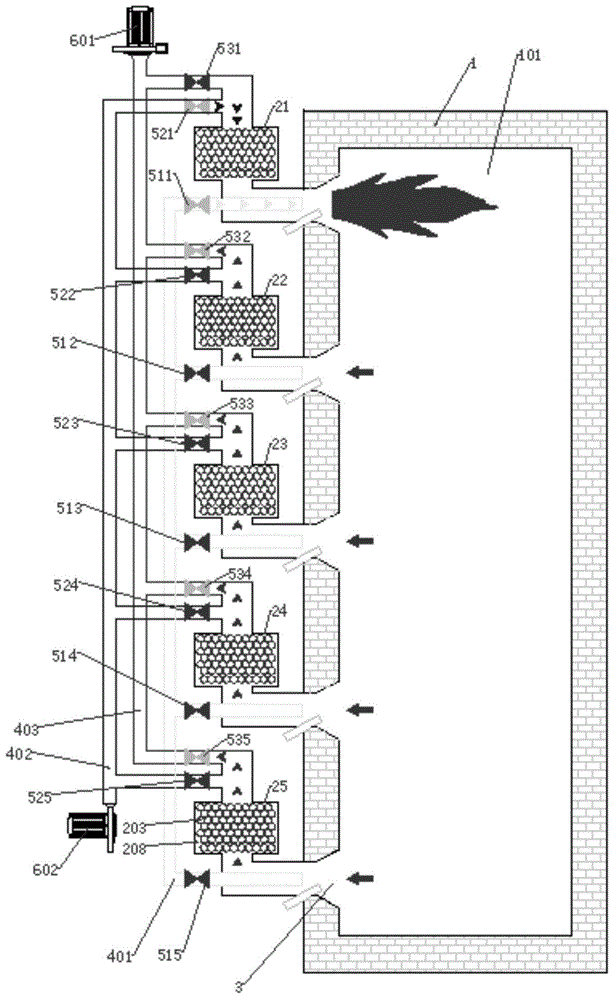

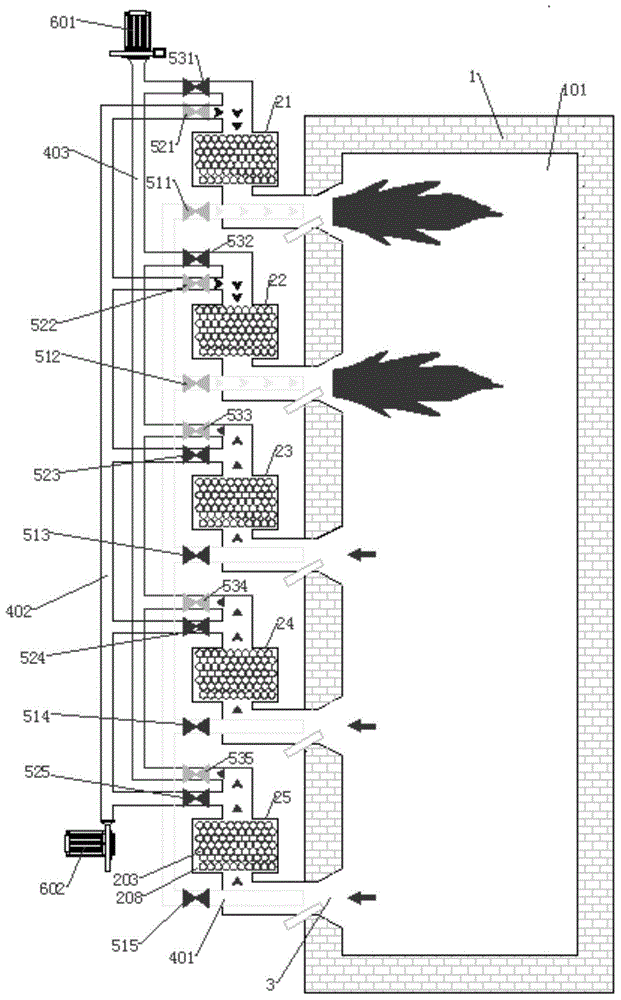

Progressive switchover heat storage type combustion device

InactiveCN104456569ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustor

The invention relates to a progressive switchover heat storage type combustion device. The progressive switchover heat storage type combustion device comprises at least five heat storage type combustors connected with a hearth and a controller capable of controlling the heat storage type combustors. The controller switches over the heat storage type combustors, so that the heat storage type combustors are alternately used for combustion or smoke exhaust, and the number of the heat storage type combustors used for smoke exhaust is made to be larger than that of the heat storage type combustors for combustion at any moment; in combustion production, when the controller switches over any heat storage type combustor, at least another heat storage type combustor maintains combustion work. Compared with the prior art, in the steering process of the device, the phenomena of detonation and furnace blast are effectively avoided, the safety performance is better, and the energy-saving effect is more obvious.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

Smoke purifying and waste heat utilizing system of waste incineration power plant

ActiveCN109395496AIncrease temperatureLow costGas treatmentDispersed particle filtrationDecomposerWaste heat recovery unit

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

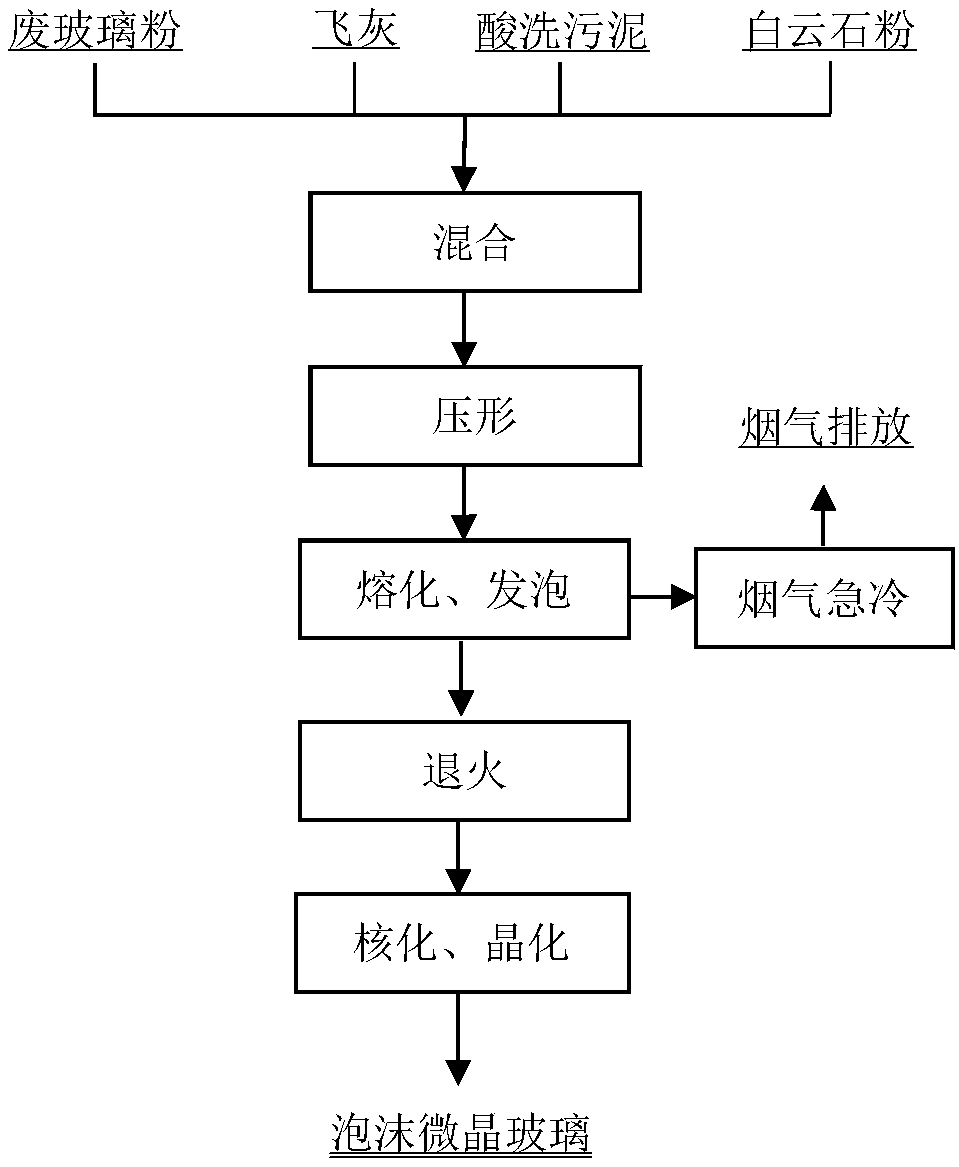

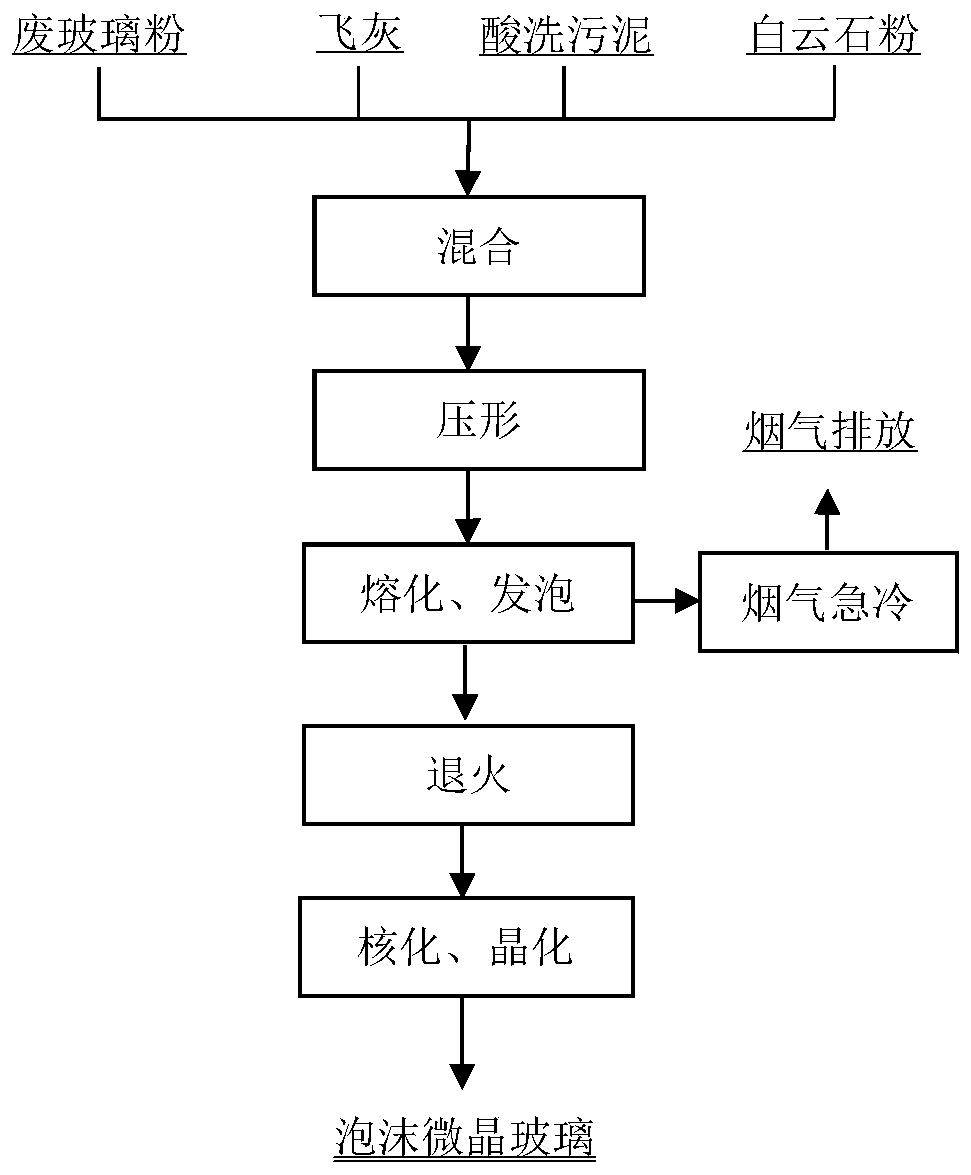

Harmless treatment method of garbage incineration fly ash dioxin

The invention discloses a harmless treatment method of garbage incineration fly ash dioxin, and belongs to the field of solid waste treatment and resource utilization. The method is characterized in that the garbage incineration fly ash is used as major raw materials to be mixed with waste glass powder, acid washing sludge and dolomite powder; shape pressing is performed; foam micro crystal glassis prepared through high-temperature fusion; meanwhile, dioxin in the fly ash is subjected to pyrolysis; chlorine atoms and alkaline earth metal oxides react to cure in the foam micro crystal glass; the generated smoke gas is fast cooled to the temperature of 200 DEG C or below through a sharp cooling device; and the synthesis of the dioxin again by residual chlorides is avoided. The harmless treatment and the high-value utilization in foam thermal insulation fireproof material of the garbage incineration fly ash dioxin can be realized; and the advantages of simple process and green and environmental-friendly effects are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Waste incineration system and high-efficiency incineration control method

PendingCN110878943AQuality assuranceGuaranteed effectIncinerator apparatusCombustion chamberEmission standard

The invention provides a waste incineration system and a high-efficiency incineration control method. The waste incineration system comprises a primary combustion chamber used for primary waste combustion. An exhaust gas outlet of the primary combustion chamber communicates with an exhaust gas inlet of a secondary combustion chamber through a first flue. An exhaust gas outlet of the secondary combustion chamber is connected with a spray tower used for spraying treatment on exhaust gas through a second flue. An outlet of the top end of the spray tower is connected with an exhaust gas purifyingsystem through a third flue. The waste incineration system can effectively control the waste incineration temperature, make use of flammable gas generated from incineration, meanwhile, controls the exhaust gas combustion temperature and the exhaust gas cooling rate to decompose dioxin and prevents resynthesis of dioxin to meet the treated waste emission standard. The high-efficiency incineration control method is high in intelligence degree, advanced, high in working efficiency, safe, reliable, energy-saving and friendly to environment.

Owner:YICHANG JIANGXIA MARINE MACHINERY +1

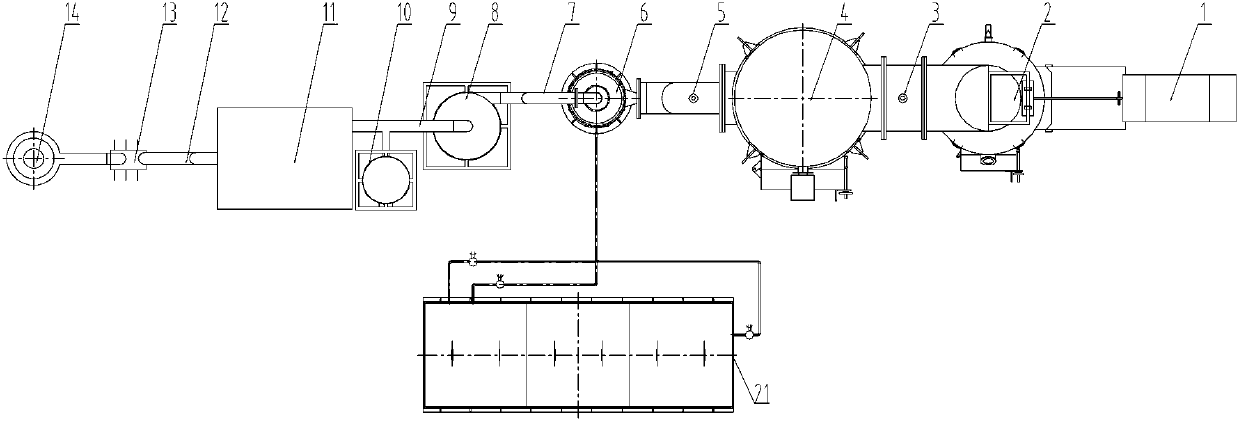

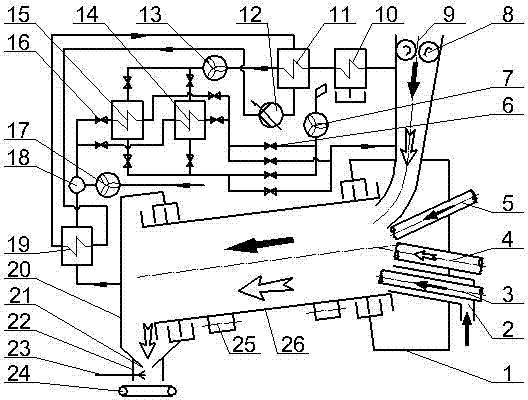

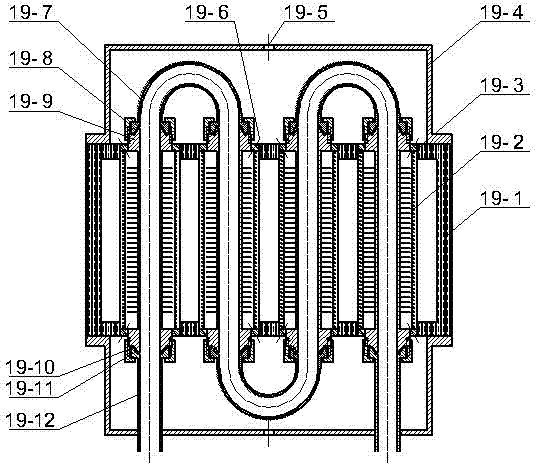

Garbage treatment rotary kiln system

InactiveCN104214782AAvoid resynthesisPrevent cryogenic emissionsIncinerator apparatusSlagHazardous substance

The invention provides a garbage treatment rotary kiln system which comprises a kiln tail seal chamber, a rotary kiln body, a kiln head seal chamber, a heat exchange device, a mixed gas cooling device and a dehumidifying device. The kiln tail seal chamber is arranged at a feeding end of the rotary kiln body, the kiln head seal chamber is arranged at a slag discharging end of the rotary kiln body, a garbage inlet flat pipe of the kiln tail seal chamber is communicated with the dehumidifying device, the kiln head seal chamber is communicated with the heat exchange device, the heat exchange device is communicated with the dehumidifying device, and a slag discharging device is arranged at the bottom of the kiln head seal chamber. The garbage treatment rotary kiln system is specially used for treating garbage and hazardous substances, garbage pretreatment requirements are low, and operating cost is further reduced.

Owner:刘继清

Three-stage dioxin emission reduction method in process of firing municipal sludge to prepare ceramsite

InactiveCN103936395AEquilibrium calorific valueUniform moistureDispersed particle filtrationCeramic materials productionThree stageSludge

The invention discloses a three-stage dioxin emission reduction method in a process of firing municipal sludge to prepare ceramsite, namely a three-stage emission reduction method including source prevention and control, control in a sintering process and tail end treatment of dioxin generated in the process of firing municipal sludge to prepare ceramsite. According to the method, a certain amount of an ammonium salt assistant is added at the source; a quench tower is additionally arranged in the sintering process; a dry type desulfurizing tower and a bag deduster are used together in tail end control. When dioxin is effectively removed, NOx, SO2, heavy metals and compounds of heavy metals can be further removed. Concentration of dioxin in outlet smoke is lower than 0.1ngTET / <m3>. The three-stage dioxin emission reduction method provided by the invention is high in practicality and simple to operate, and low-cost emission reduction control of dioxin can be effectively realized.

Owner:CHANGZHOU UNIV

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458BImprove current sharing effectGuarantee continuous and stable operationDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smokepurification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

High-temperature critical treatment method and system for dioxin in waste incineration flue gas

PendingCN112844015AEase of meeting emission standardsInhibitionCombination devicesGas treatmentFlue gasEmission standard

The invention discloses a high-temperature critical treatment method and system for dioxin in waste incineration flue gas. A first smoke pipe is mounted at the top of an incineration tower of the high-temperature critical treatment system for the dioxin in the waste incineration flue gas, and the end, away from the incineration tower, of the first smoke pipe is connected to one end of a spraying mechanism; a second smoke pipe is mounted at the top of the spraying mechanism, the end, away from the spraying mechanism, of the second smoke pipe is mounted at the top of one side of a cyclone separator in the tangential direction, a third smoke pipe is mounted at the top of the other side of the cyclone separator, and the end, away from the cyclone separator, of the third smoke pipe is connected to one end of an adsorption box; and the other end of the adsorption box is connected to an air inlet of an air blower, and an air outlet of the air blower is connected to one side of a smoke exhaust pipe. According to the high-temperature critical treatment system for the dioxin, generation of the dioxin in the waste incineration process can be restrained, the generated dioxin is effectively removed, smoke generated by waste incineration can easily reach the emission standard, the treatment effect of the dioxin is good, and the treatment cost is low.

Owner:利晟(杭州)科技有限公司

Apparatus and method for thermal plasma treatment of solid waste

Owner:安徽中科华炬环保科技有限公司

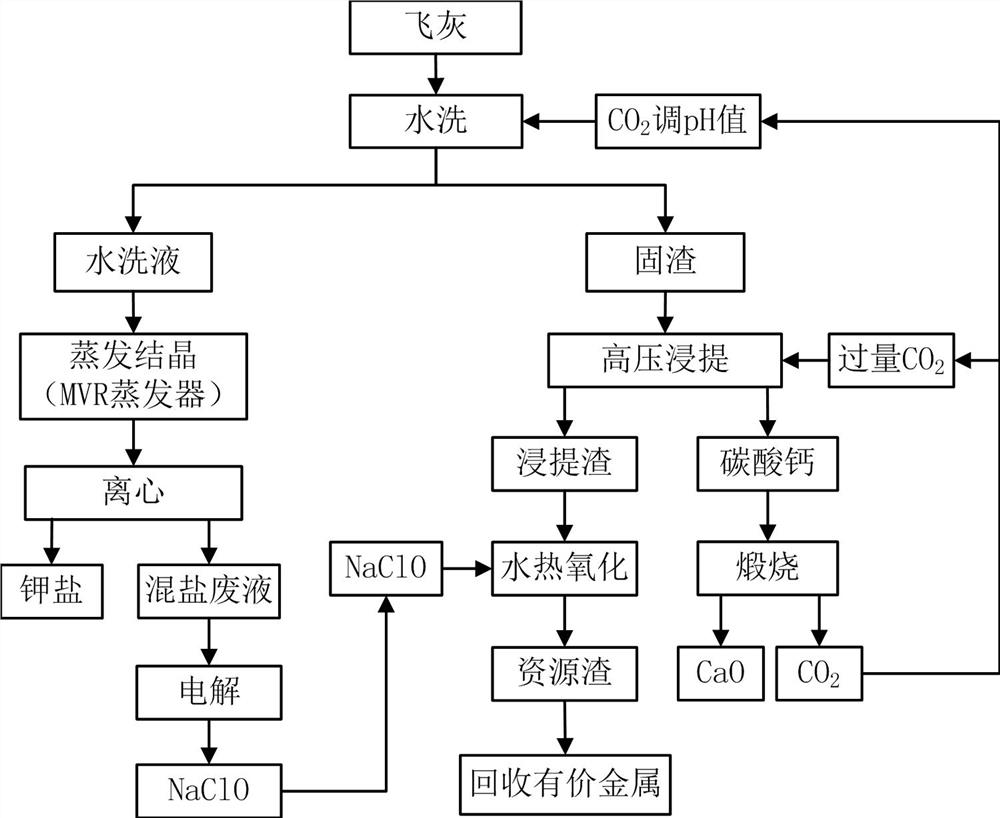

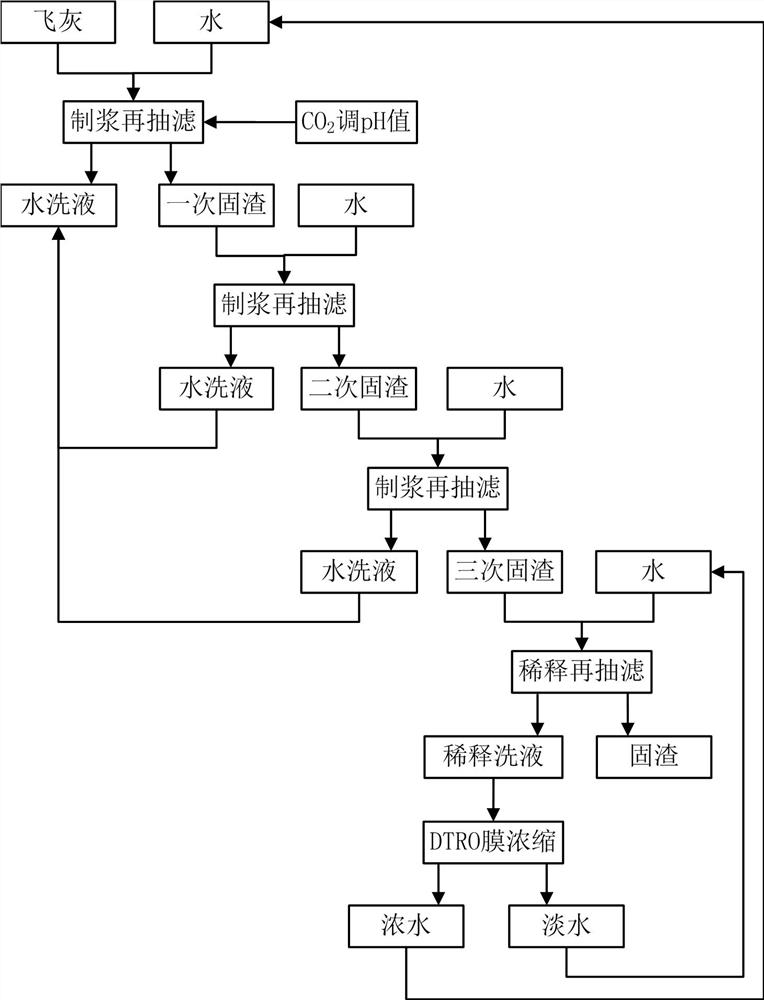

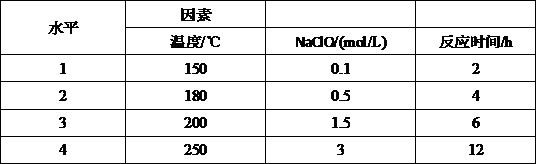

Process for removing dioxin in fly ash

PendingCN113955787AAvoid resynthesisReduce energy consumptionCalcium/strontium/barium carbonatesGas treatmentEnvironmental engineeringFly ash

A process for removing dioxin in fly ash is based on carbon dioxide high-pressure extraction of solid residues obtained after washing of the fly ash, then the extraction residues are washed with water and placed in a stainless steel reaction kettle under the high-temperature and high-pressure conditions, NaClO is added as an oxidizing agent for a reaction at the same time, and the dioxin is removed through a hydrothermal oxidation method. Compared with conventional high-temperature incineration, the hydrothermal oxidation method for removing dioxin saves more energy consumption, the washing liquid is subjected to evaporative crystallization and separation through an MVR evaporator to obtain sylvite and mixed salt waste liquid, NaClO can be obtained by electrolyzing the mixed salt waste liquid, an oxidizing agent does not need to be purchased additionally, on one hand, reagents are saved, on the other hand, NaClO has strong oxidizing property, the degradation efficiency on the dioxin is higher than the degradation efficiency of a common oxidizing agent, the hydrothermal oxidation effect is good, the recycling product of the fly ash is reused in the process link, the problem of product treatment such as export sales does not need to be considered, and the resynthesis of the dioxin can be effectively prevented.

Owner:JIANGXI GAIA ENVIRONMENTAL SCI & TECH CO LTD +1

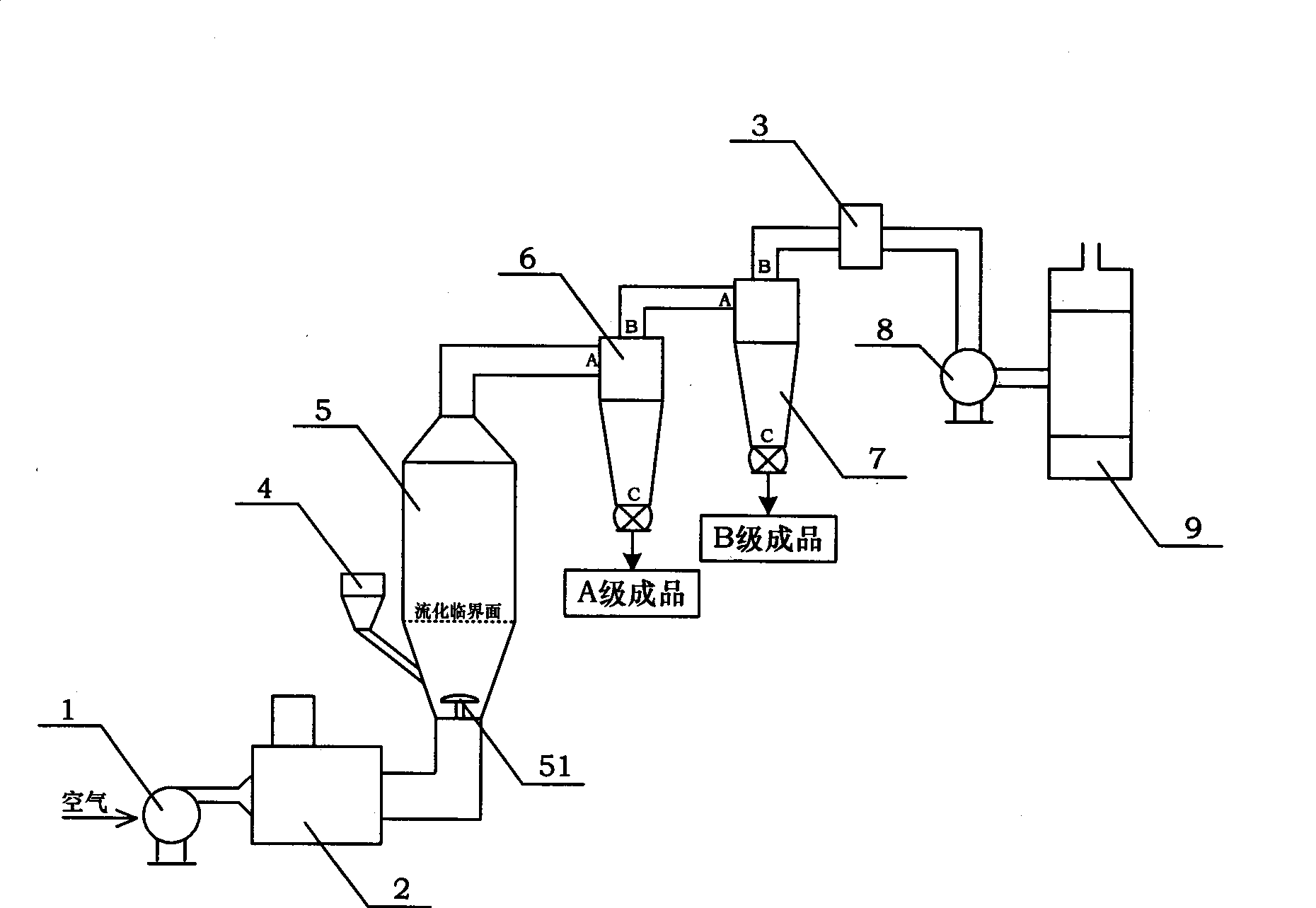

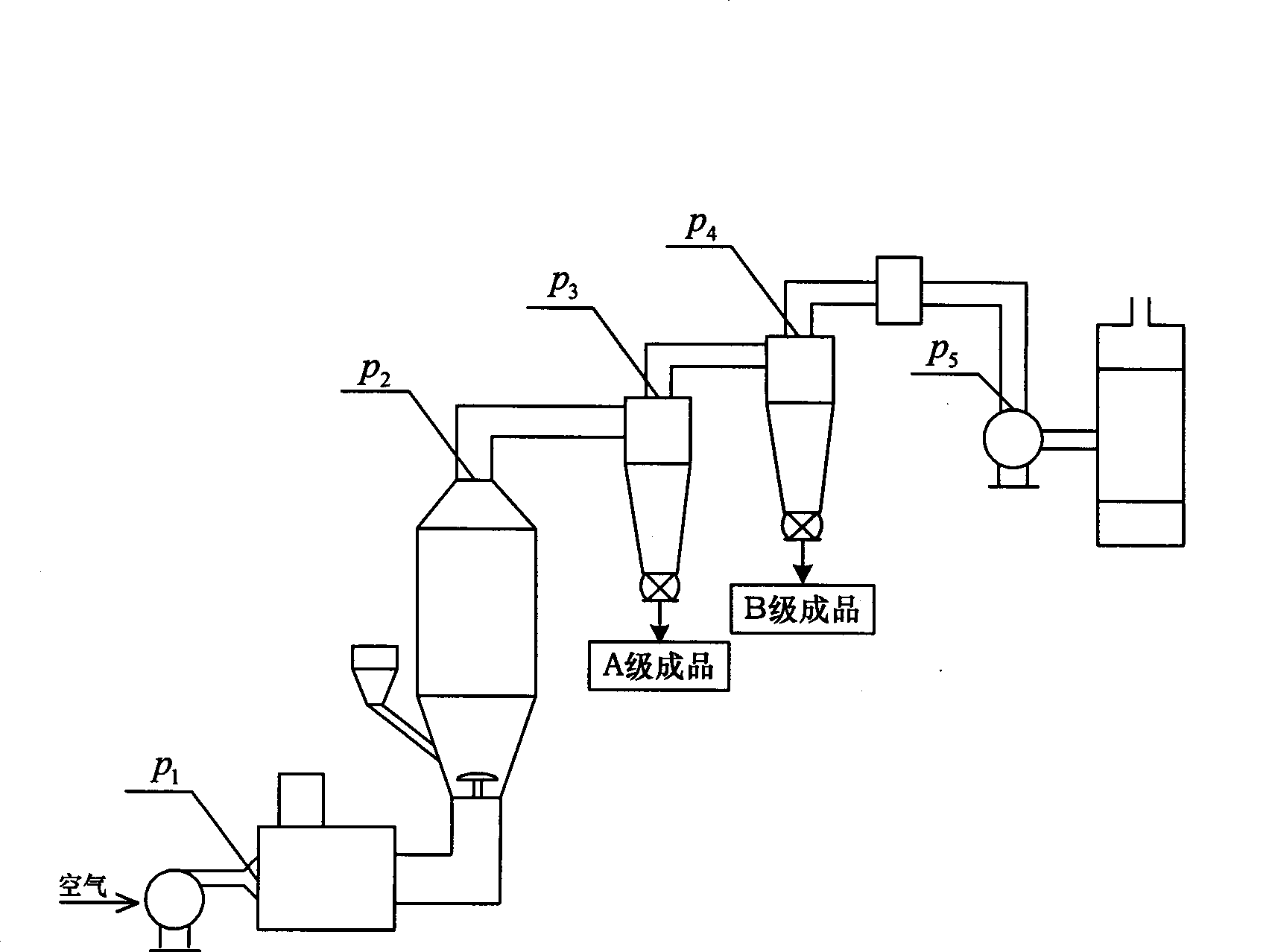

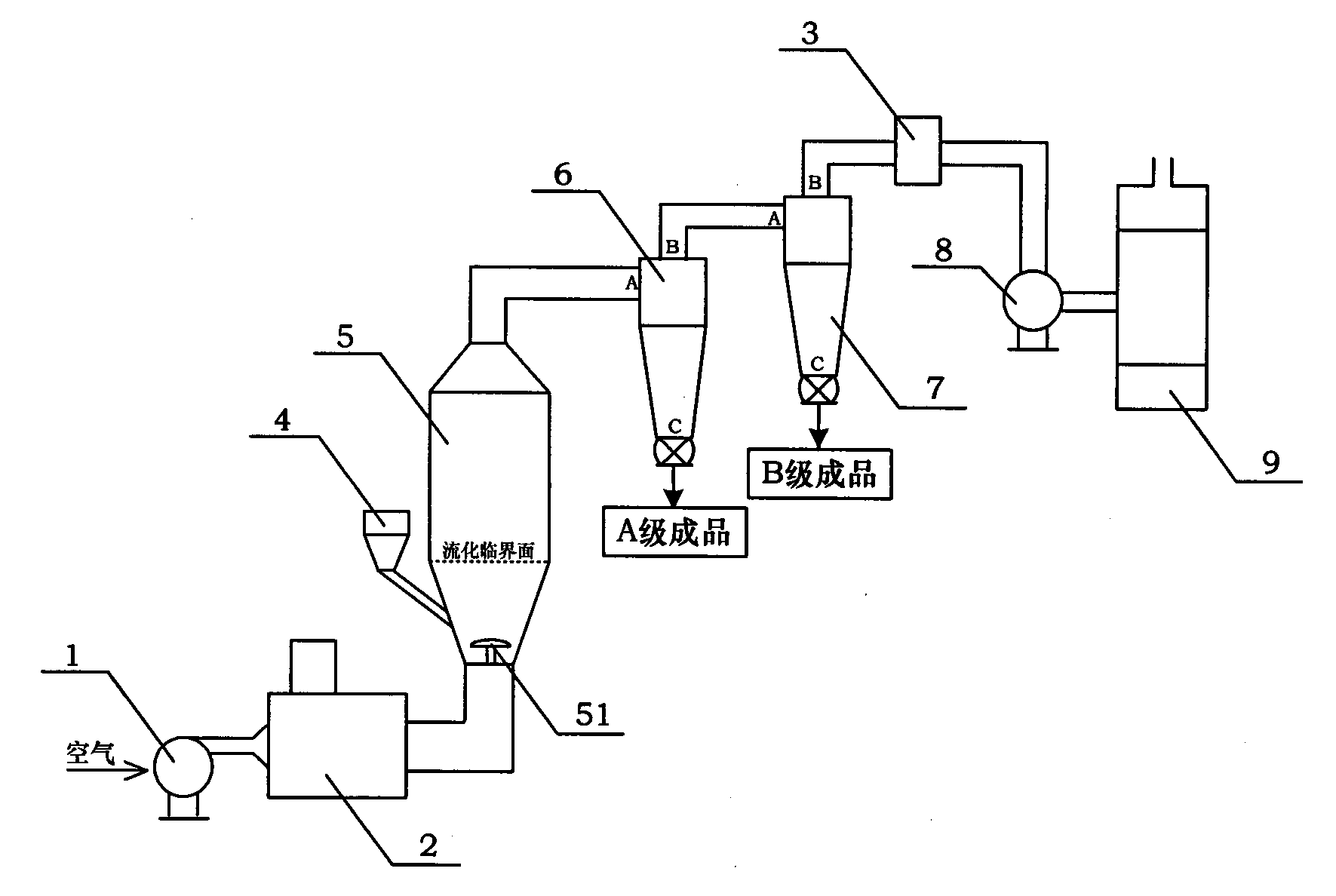

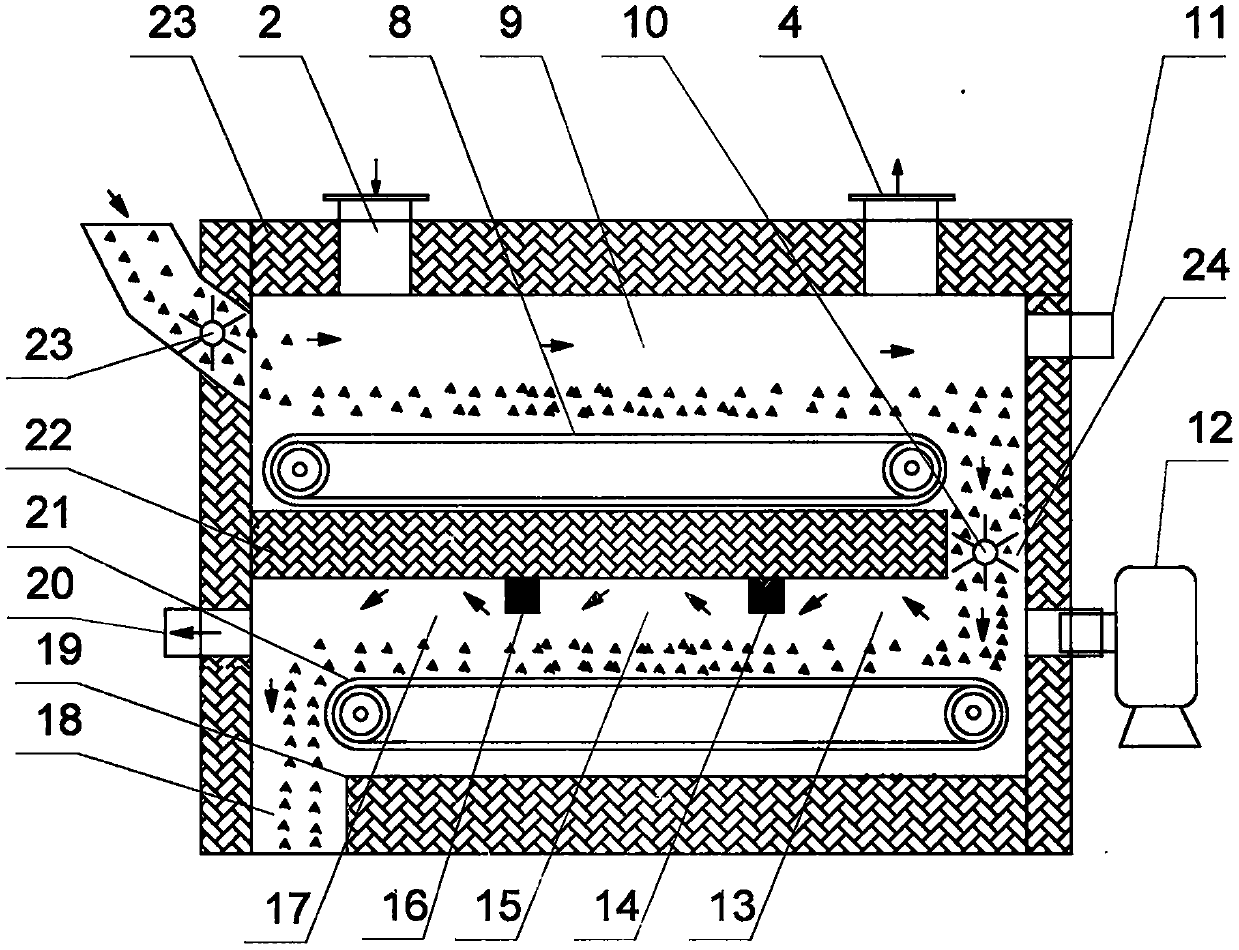

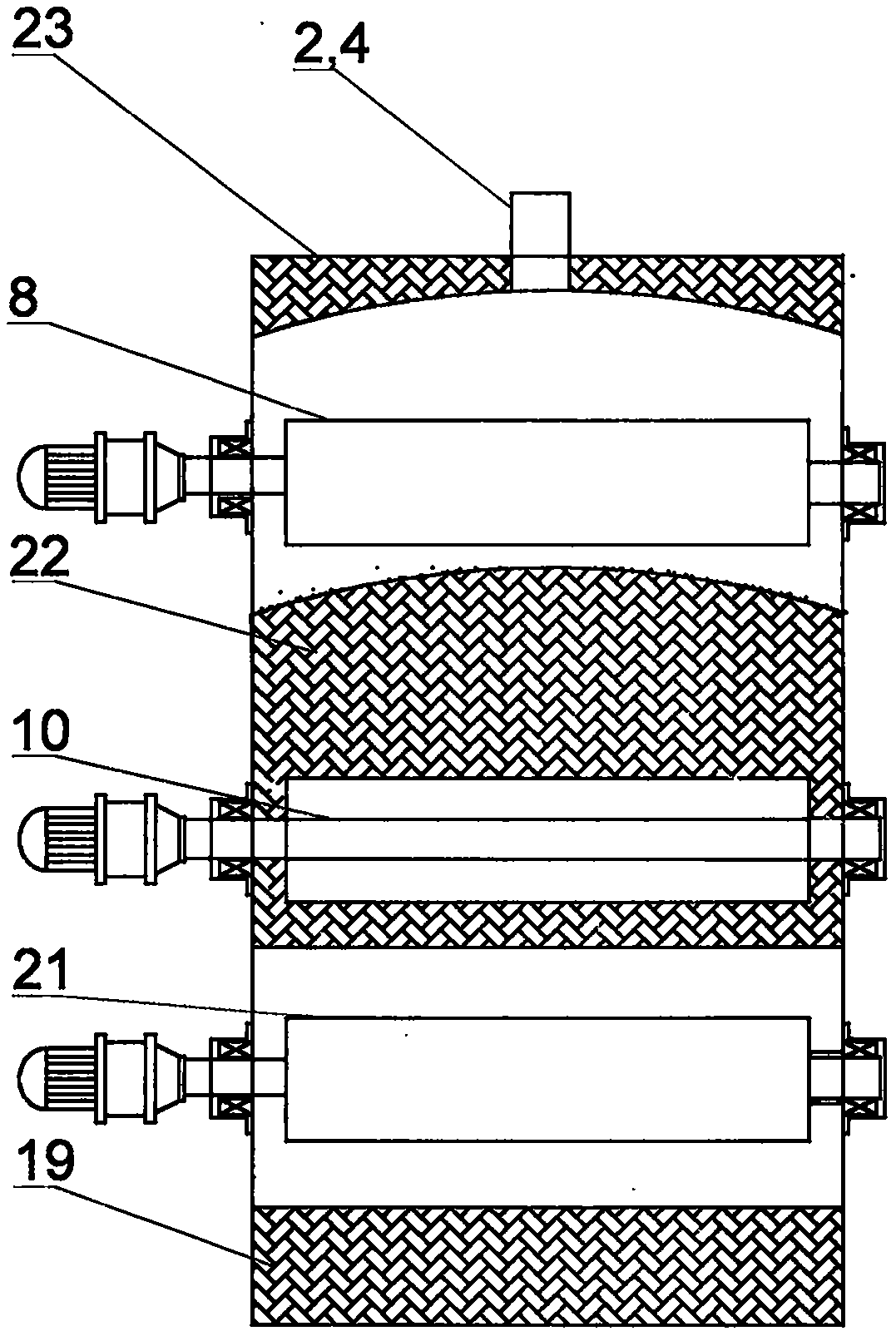

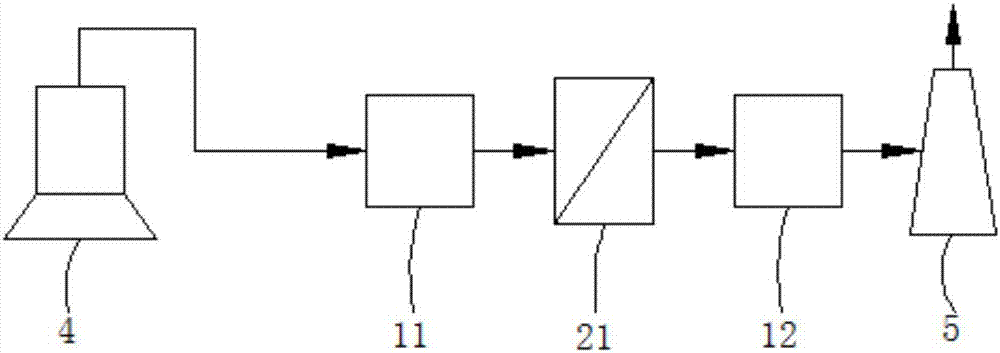

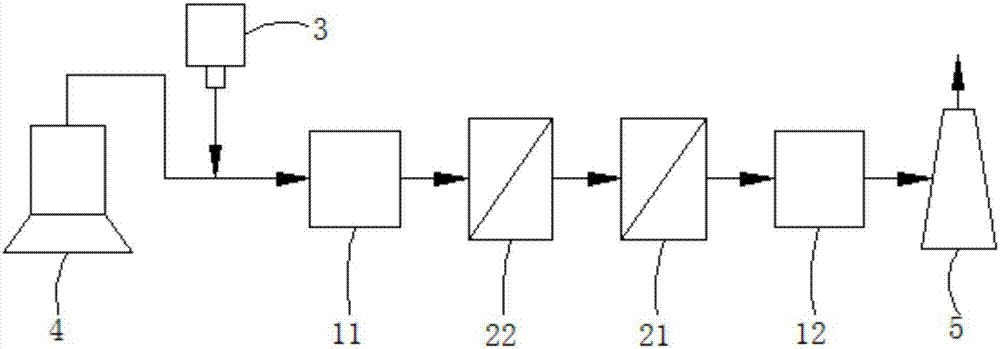

Device for extracting fiber glass from non-metallic material of waste printed circuit boards and industrialized production process

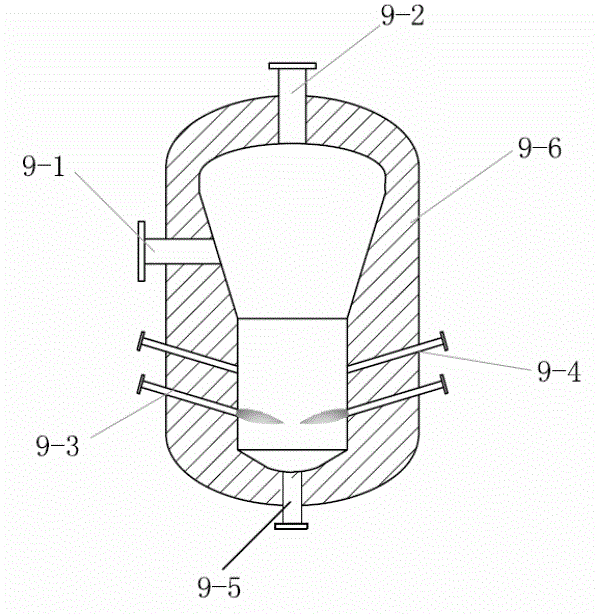

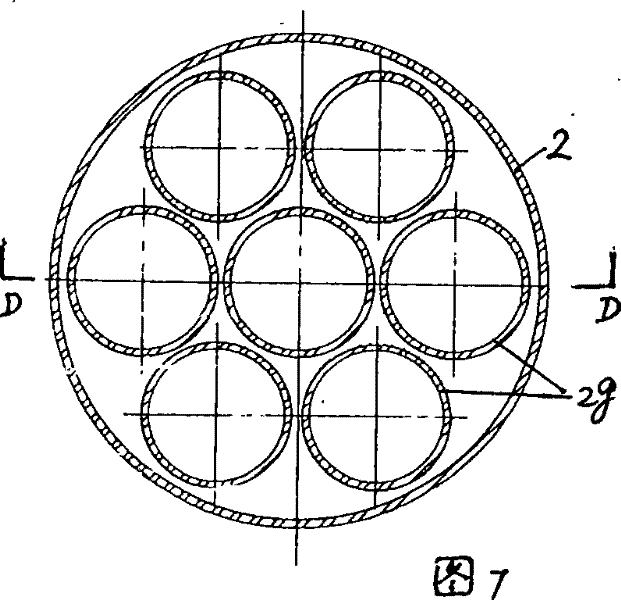

InactiveCN101380638BSimple structureIncreased durabilityReversed direction vortexSolid waste disposalCycloneGlass fiber

The invention discloses a device for extracting fiberglass from the nonmetallic materials of a waste printing circuit board as well as an industrial production technique. The device is connected with an electric heater (2), a fluidized bed reactor (5), a first grade cyclone separator (6), a second grade cyclone separator (7), an intermediate frequency heater (3) and a B draught fan (8) in sequence from an A draught fan (1) to a liquid dust remover (9); a feed device (4) is arranged on the fluidized bed reactor (5). In the technique for extracting fiberglass from the nonmetallic materials of awaste printing circuit board, firstly high temperature thermal decomposition is carried out in the fluidized bed; then multi-grade separation is carried out in the cyclone separator for obtaining thefiberglass; then high temperature decomposition is carried out on a gas product in the intermediate frequency heater; finally, a sharp quenching lye absorbing treatment is carried out; the technique can effectively push and promote the broad utilization of the nonmetallic materials in the waste printing circuit board. The fiberglass extracted by the industrial production technique can be used formanufacturing the compound materials of various fiberglasses for realizing the recycling of the nonmetallic materials of the waste printing circuit board with high added value.

Owner:BEIHANG UNIV +1

A rotary kiln gasification and plasma melting domestic waste graded gasification system

ActiveCN104976622BReduce energy consumptionReduce processing costsIncinerator apparatusAir preheaterCyclone

The invention discloses a household garbage classified gasification system with rotary kiln gasification and plasma fusion capability. The household garbage classified gasification system comprises a rubbish feeder, a rotary kiln type pyrolysis vaporizer, a metal sorting machine, a crusher, a high-temperature cyclone separator, an ash hopper, an ash feeder, a plasma fusion furnace and an air preheater; household garbage is sequentially subjected to the pyrolysis gasification, metal sorting and crushing of the rotary kiln type pyrolysis vaporizer and the further gasification treatment of the plasma fusion furnace; the low-temperature rotary kiln vaporizer and the high-temperature plasma fusion furnace can be effectively combined, and the ash generated by pyrolysis and gasification of the rotary kiln vaporizer is fused by virtue of taking plasma torch as a high-quality heat source; the household garbage classified gasification system can effectively take the heat of synthesis gas and the gas fume generated by the fusion furnace as an outer heat source of the rotary kiln vaporizer so as to heat the air entering in the plasma fusion furnace, the comprehensive energy use efficiency is improved, and the secondary pollution problem of dioxin and heavy metal is avoided.

Owner:中国东方电气集团有限公司

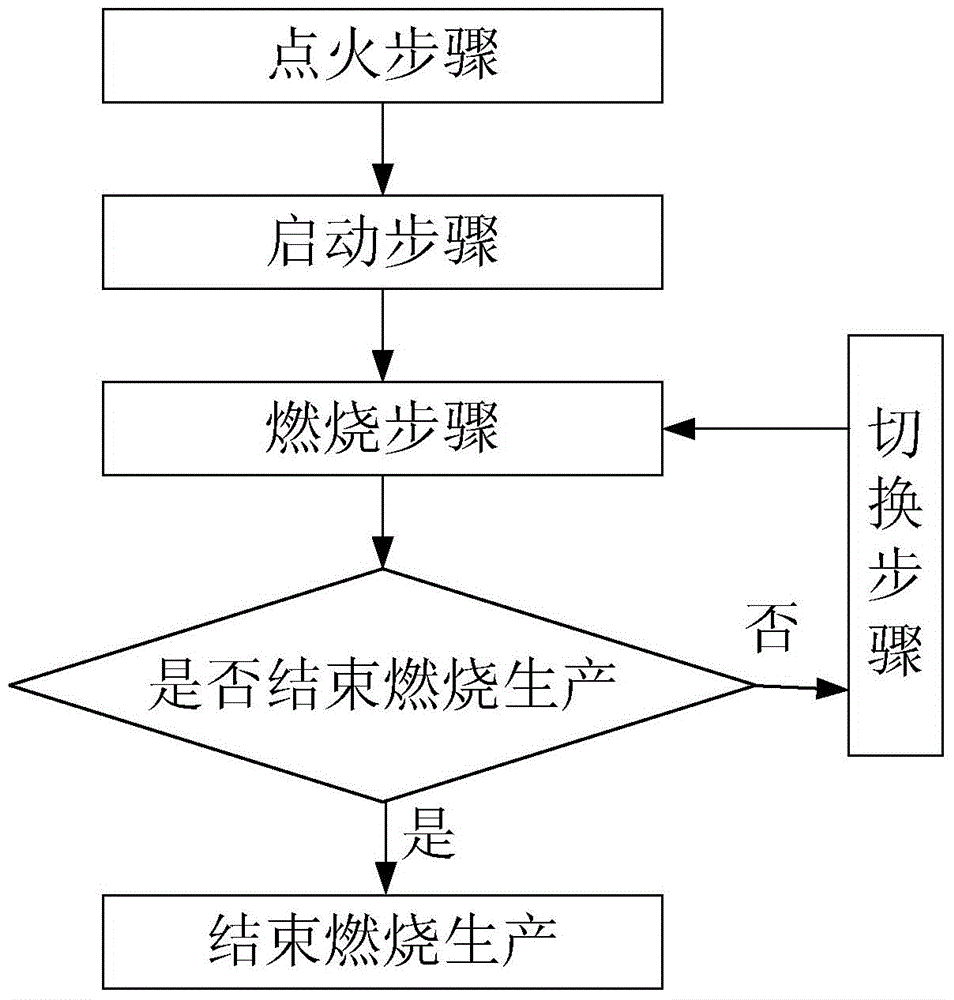

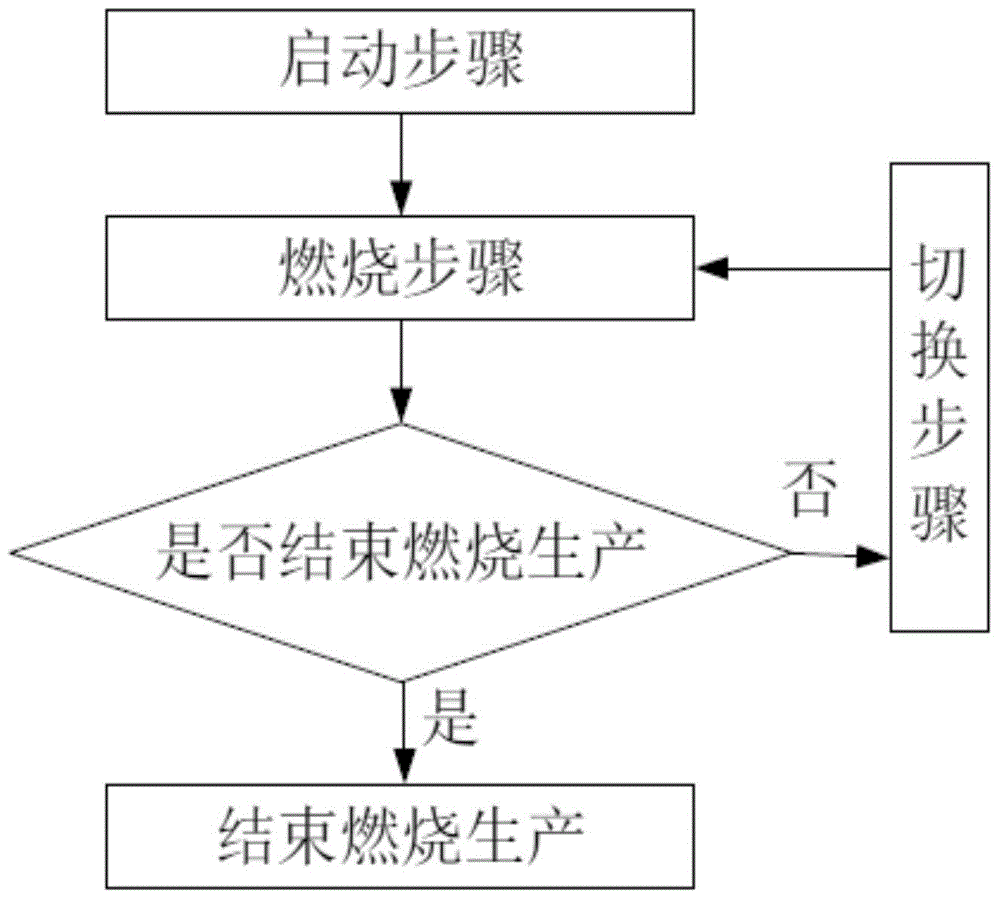

Control method of regenerative combustion equipment

ActiveCN104456616ADischarge in timeSmooth exhaustEnergy industryIndirect carbon-dioxide mitigationDetonationCombustion

The invention provides a control method of regenerative combustion equipment. The method includes an igniting step, a starting step, a combustion step and a switching step. The method overcomes the technical bias that the regenerative combustion equipment is controlled in pairs with a traditional method and achieves an unexpected energy-saving technical effect, and the phenomena that in an existing high-temperature air combustion technology, detonation and furnace explosion happen easily in the reversing process, and fuel waste is serious are effectively avoided.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

Fuel-free device for oil-sludge segmented drying, pyrolysis, incineration and secondary combustion of garbage sludge

InactiveCN109556118ACompact structureVersatileEmission preventionIncinerator apparatusExhaust gasElectrostatic precipitator

A fuel-free device for oil-sludge segmented drying, pyrolysis, incineration and secondary combustion of garbage sludge is composed of a quench cooler, a hot gas inlet, a multifunctional integrated furnace, a gas outlet, a denitrator, a desulfurizer and an electrostatic dust collector. The quench cooler is connected with and communicates with the hot gas inlet through a connecting pipe. The hot gasinlet is arranged on one side of the upper portion of the multifunctional integrated furnace and communicates with the multifunctional integrated furnace. The gas outlet is arranged on one side of the upper portion of the multifunctional integrated furnace and communicates with the multifunctional integrated furnace. The multifunctional integrated furnace is connected with and communicates with the denitrator through a connecting pipe. The denitrator is connected with and communicates with the desulfurizer through a connecting pipe. The desulfurizer is connected with and communicates with theelectrostatic dust collector through a connecting pipe. The multifunctional integrated furnace is connected with and communicates with the quench cooler through a connecting pipe. Multiple function areas are arranged in the multifunctional integrated furnace, drying, pyrolysis, incineration and secondary combustion are integrated, and environment protection treatment of garbage and the like is perfectly achieved by cooperating with the tail gas purification function.

Owner:李艺 +3

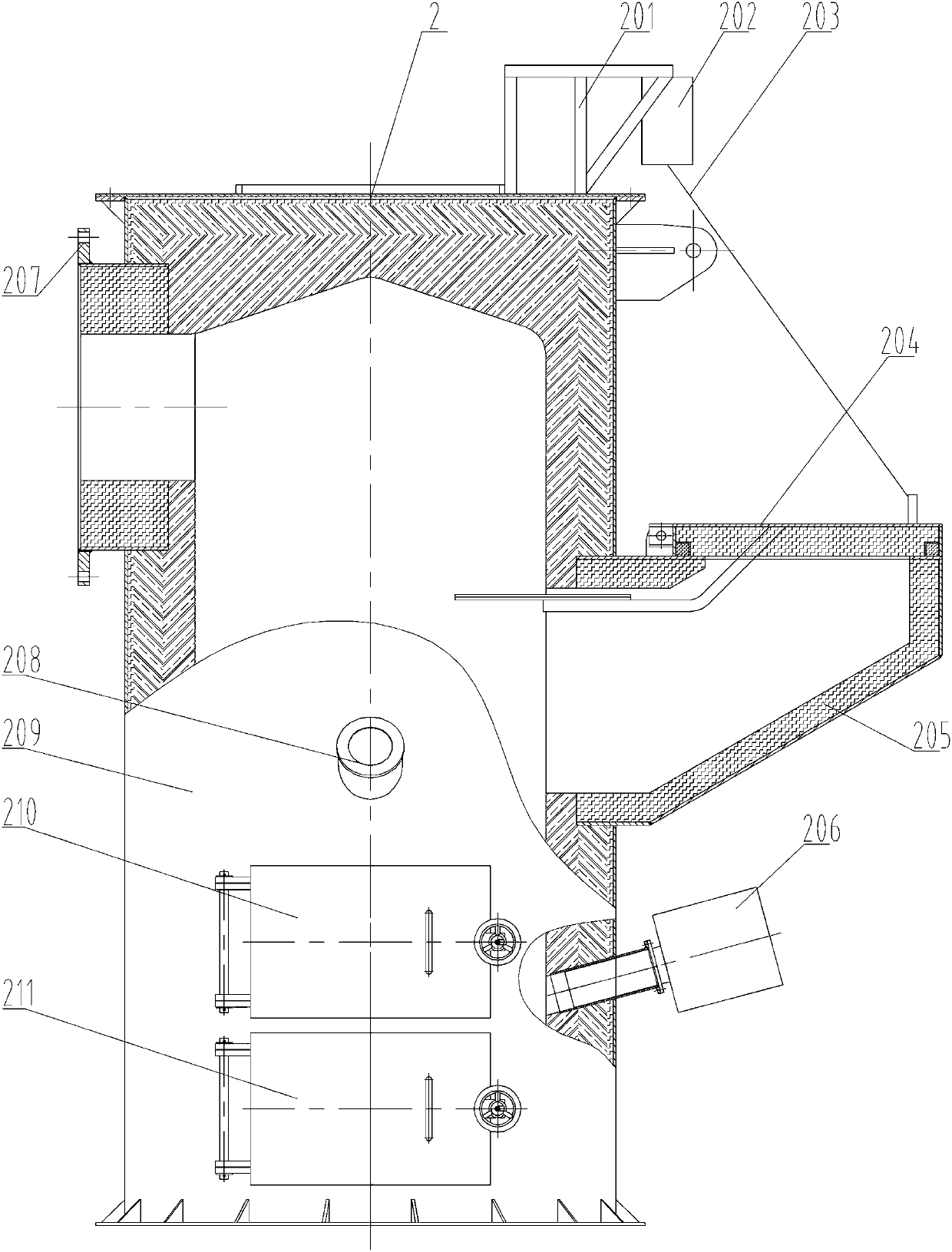

A method for harmless treatment of dioxin in waste incineration fly ash

ActiveCN109437573BChlorine reductionAvoid resynthesisGlass shaping apparatusSludgeThermal insulation

The invention discloses a harmless treatment method of garbage incineration fly ash dioxin, and belongs to the field of solid waste treatment and resource utilization. The method is characterized in that the garbage incineration fly ash is used as major raw materials to be mixed with waste glass powder, acid washing sludge and dolomite powder; shape pressing is performed; foam micro crystal glassis prepared through high-temperature fusion; meanwhile, dioxin in the fly ash is subjected to pyrolysis; chlorine atoms and alkaline earth metal oxides react to cure in the foam micro crystal glass; the generated smoke gas is fast cooled to the temperature of 200 DEG C or below through a sharp cooling device; and the synthesis of the dioxin again by residual chlorides is avoided. The harmless treatment and the high-value utilization in foam thermal insulation fireproof material of the garbage incineration fly ash dioxin can be realized; and the advantages of simple process and green and environmental-friendly effects are achieved.

Owner:UNIV OF SCI & TECH BEIJING

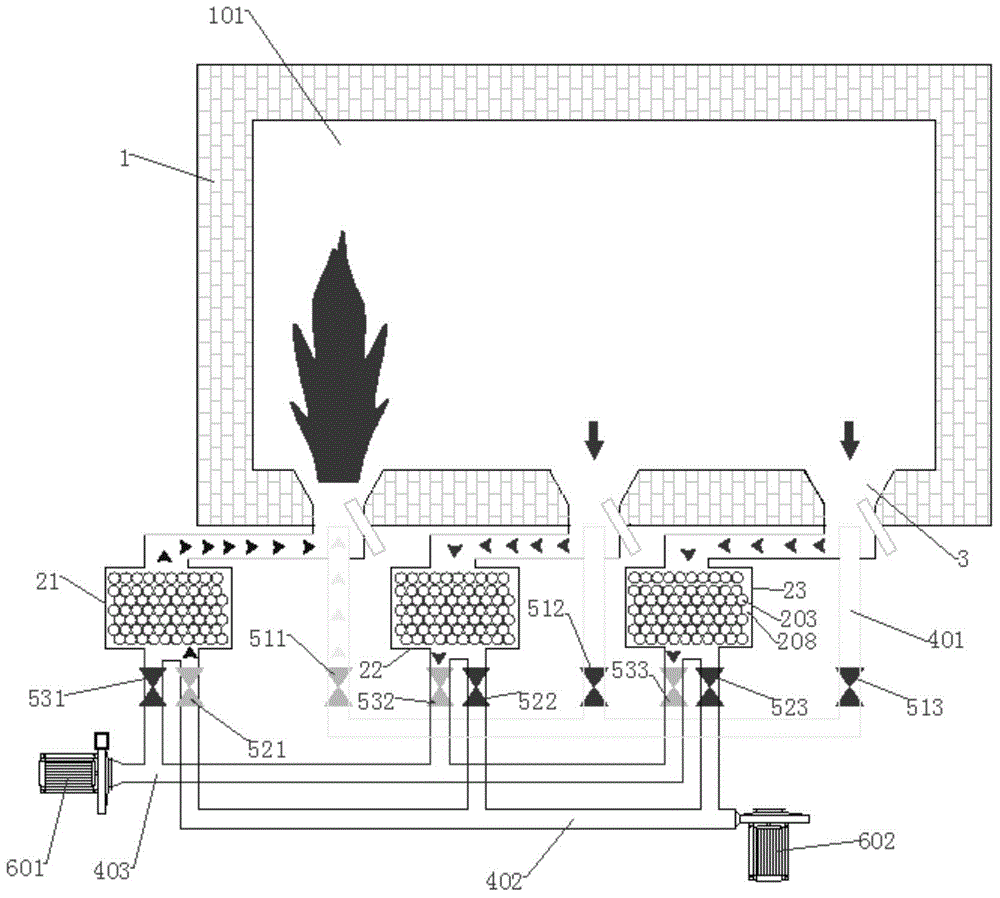

Effect improving method for progressive and classified pyrolysis and energy gathering of waste

ActiveCN105805755AAvoid resynthesisAvoid it happening againIncinerator apparatusGas phaseMedical waste

The invention discloses an effect improving method for progressive and classified pyrolysis and energy gathering of waste. The method aims to overcome the defects that in an existing waste pyrolysis process, dioxin is likely to be generated, the environment is polluted, the pyrolysis effect is poor, auxiliary energy consumption is needed, and the construction and operation cost of a project is high. The method comprises the steps that firstly, hot air at the temperature below 300 DEG C is introduced into waste for pyrolysis, and gas phase combustible organic matter is guided out; then the gas phase combustible organic matter is mixed with hot air at the temperature of 500 DEG C, obtained combustible smoke and the guided gas phase combustible organic matter are mixed with hot air at the temperature of 600 DEG C for incineration and pyrolysis, and heat exchange is conducted between obtained high-temperature flame gas and air; and the obtained hot air is input into the step a, the step b and the step c for utilization. The method is mainly used for harmless environment-friendly treatment of household waste and medical waste, the situation that the dioxin is generated during waste pyrolysis, and accordingly the environment is polluted can be avoided, and heat energy generated during waste pyrolysis is used for classified waste incineration and pyrolysis in the hot air mode; the energy is greatly saved, the effect is good, the efficiency is high, the investment is reduced, and the practicability is high.

Owner:周小华

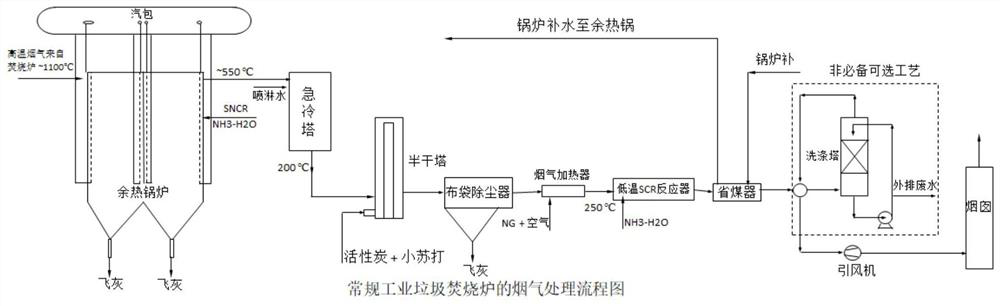

Purification system and purification method for flue gas from industrial incinerator

PendingCN111617632AImprove the efficiency of catalytic denitrificationDoes not consume energyCombination devicesPurification methodsEconomizer

The invention relates to a purification system and purification method for flue gas from an industrial incinerator, belonging to the technical field of industrial incineration flue gas treatment. Thepurification system comprises a waste heat boiler, a first-stage dry treatment unit, a quenching treatment unit and a second-stage dry treatment unit. According to the invention, high-temperature fluegas of the incinerator is cooled through the waste heat boiler, and heat is recycled; the flue gas is primarily purified by the first-stage dry treatment unit; then, the flue gas is rapidly cooled toa temperature within 200 DEG C through the quenching treatment unit, and therefore, the optimal dioxin synthesis temperature range of 500-300 DEG C is crossed, secondary synthesis of dioxin is avoided and saturated steam is by-produced to recover the heat of the flue gas; finally, the flue gas is thoroughly purified through the second-stage dry treatment unit; heat is continuously recycled through an economizer, and high-altitude emission is completed under the action of an induced draft fan and a chimney; and therefore, various problems caused by water spraying quenching are effectively avoided, the catalytic denitration efficiency of flue gas is improved, extra energy is not consumed, and meanwhile, heat generated in the flue gas purification process is recycled to the maximum extent.

Owner:亚德(上海)环保系统有限公司

Control method of regenerative combustion device

ActiveCN104456617ASmooth exhaustStable furnace pressureEnergy industryIndirect carbon-dioxide mitigationCoordination typePollutant emissions

The invention provides a control method of a regenerative combustion device. The method includes a starting step, a combustion step, a switching step and a circulation step. Compared with the prior art, the method has the outstanding technical effects of being smooth in smoke exhaust, stable in furnace pressure, small in temperature difference, good in heating quality, remarkable in energy-saving effect and little in pollutant discharge. Thus, the method belongs to an environment coordination type regenerative combustion technology.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

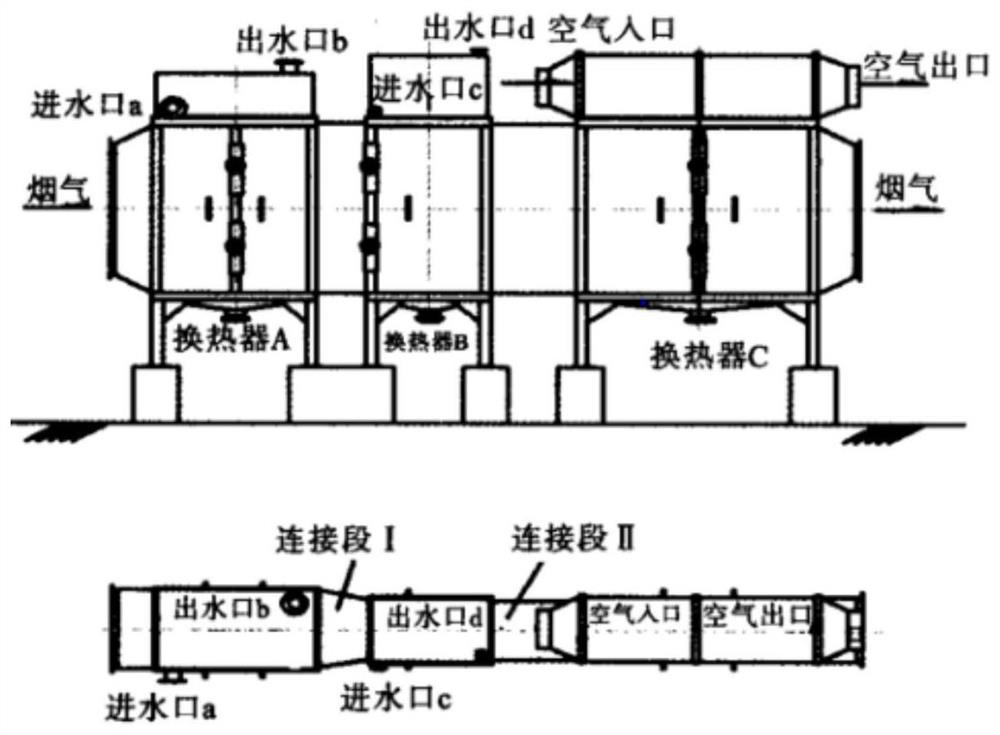

Method and equipment for reducing dioxin in smoke emitted in waste incineration

PendingCN107965775AStrong corrosion resistanceReduce energy consumptionMembrane filtersCombustion technology mitigationFilter materialEngineering

The invention discloses a method and equipment for reducing dioxin in smoke emitted in waste incineration. The method comprises the following steps: (1) reducing the temperature of the smoke to 450 to800 DEG C by adopting first afterheat recycling equipment, and treating the smoke by using the first afterheat recycling equipment to obtain first smoke; (2) filtering the first smoke at a temperature larger than or equal to 350 DEG C by adopting first filtration equipment, and making the first smoke pass through a filter material of the first filtration equipment to obtain second smoke of whichthe flying dust content is smaller than or equal to 20 mg / Nm<3>; and (3) reducing the temperature of the second smoke to 200 DEG C or below 200 DEG C by adopting second afterheat recycling equipment,and treating the second smoke by using the second afterheat recycling equipment to obtain exhaust smoke which can be directly exhausted, wherein the filter material of the first filtration equipment is a sheet composed of a metal porous material which takes a metal element of solid solution alloy and a face-centered cubic structure or the metal element of a body-centered cubic structure as a matrix phase.

Owner:CHENGDU INTERMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com