Mercury recovering and residue harmless treatment process for waste mercury catalyst

A harmless treatment, waste mercury catalyst technology, applied in the direction of gas treatment, process efficiency improvement, chemical instruments and methods, etc., can solve the problems of low mercury recovery rate, environmental pollution, mercury content leakage, etc., to reduce mercury content , reduce the effect of pollution and reduce stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

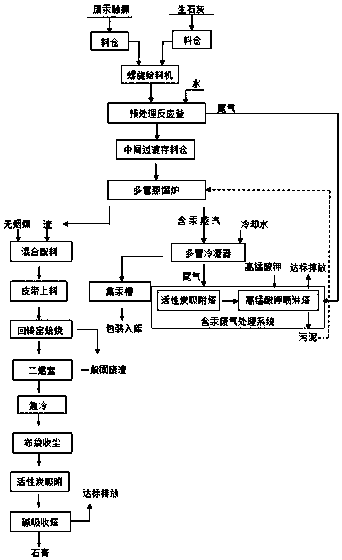

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0031] like figure 1 As shown, a waste mercury catalyst mercury recovery and slag harmless treatment process includes the following process steps:

[0032] (1) alkalization pretreatment

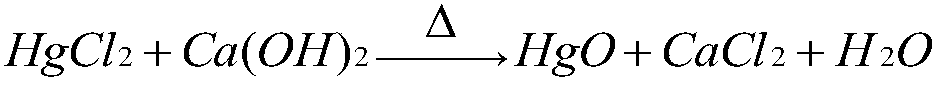

[0033] The waste mercury catalyst and quicklime enter their respective silos through the bucket elevator, and then enter the pretreatment reaction kettle after being fully mixed by the screw feeder, and at the same time add water to stir and mix well. Heat the mixed materials in the reaction kettle to a temperature of about 80°C, stir for 2 hours, and remove the HgCl in the waste mercury catalyst 2 Converted into HgO, the chemical reaction equation is:

[0034]

[0035] Note: The decomposition temperature of mercuric oxide is 500°C, and the temperature in the pretreatment reactor in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com