Method and equipment for reducing dioxin in smoke emitted in waste incineration

A waste incineration and dioxin technology, applied in the direction of combustion methods, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problems of short service life of equipment, high energy consumption, and unreasonable use of heat, and achieve high heat recovery efficiency , low energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

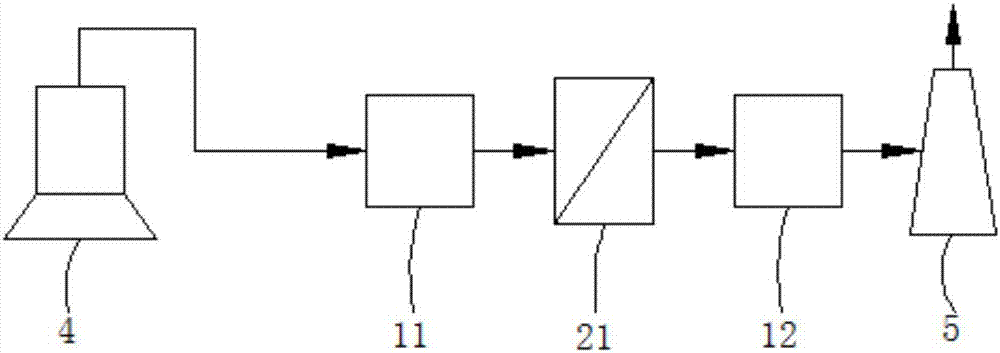

[0047] like figure 1 The shown device for reducing dioxins in the flue gas emitted by waste incineration includes a first waste heat recovery device 11, a first filter device 21 and a second waste heat recovery device sequentially arranged between the gas outlet of the incinerator 4 and the chimney 5 Recycling equipment 12.

[0048] The first waste heat recovery device 11 is a waste heat recovery device for processing the flue gas of the incinerator 4 to obtain the first flue gas with a temperature of 450°C-500°C.

[0049] The filter material of the first filtering device 21 is a sheet made of a solid solution alloy, a metal element with a face-centered cubic structure, or a metal porous material with a body-centered cubic structure as a matrix phase, and its thickness is 1mm, and the porosity is 60%, with an average pore size of 10 μm; the first filter device 21 filters the first flue gas to obtain a second flue gas with a fly ash content ≤ 10 mg / Nm3.

[0050] The second wa...

Embodiment 2

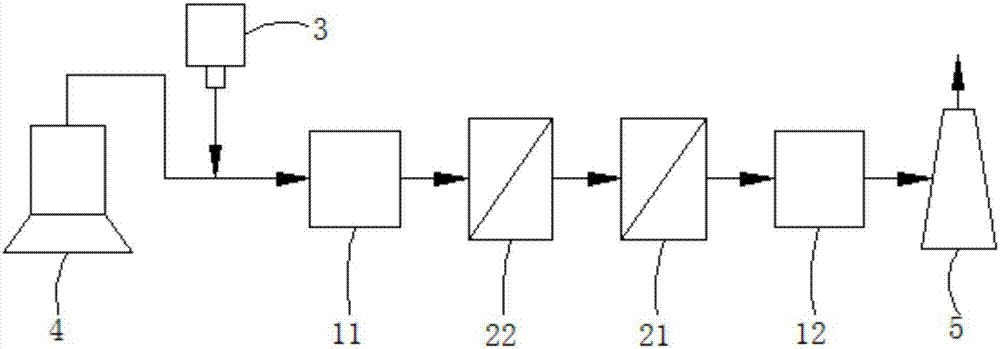

[0053] like figure 2 The shown device for reducing dioxins in the flue gas emitted by waste incineration includes a powder feeder 3, a first waste heat recovery device 11, and a second filter device 22 arranged in sequence between the gas outlet of the incinerator 4 and the chimney 5 , the first filter device 21 and the second waste heat recovery device 12 .

[0054] The function of the powder adding device 3 is to add modified powder to the flue gas, and the modified powder is diatomite with a particle size of 40 μm.

[0055] The first waste heat recovery device 11 is a waste heat recovery device for processing the flue gas of the incinerator 4 to obtain the first flue gas with a temperature of 450°C-500°C.

[0056] The filter material of the second filter device 22 is a metal alloy, its pore size is larger than that of the filter material of the first filter device 21, and the retention rate of the fly ash in the flue gas is ≥85%, and the modified powder The interception ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com