Thixotropic agent for polycarboxylate superplasticizer, thixotropic type polycarboxylate superplasticizer and application of thixotropic agent

A technology of water reducer and polycarboxylate, which is applied in the field of thixotropic agent for polycarboxylate water reducer and thixotropic polycarboxylate water reducer, can solve problems such as insufficient thixotropic performance, and achieve insufficient thixotropic performance , enhance thixotropy, improve the effect of early strength and thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

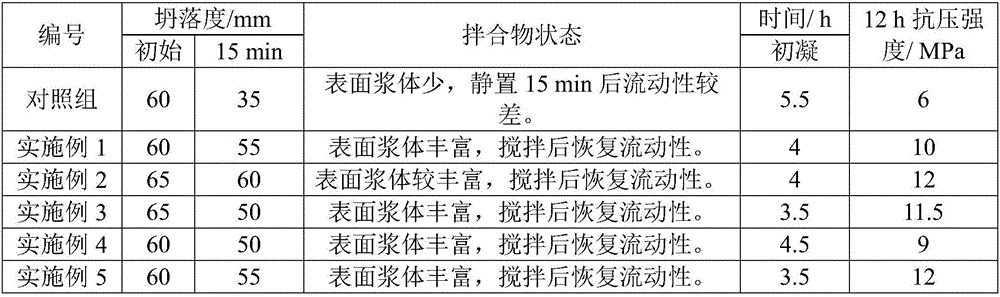

Examples

Embodiment 1

[0032] The thixotropic agent for polycarboxylate superplasticizer mainly includes 0.2 parts of white carbon black, 1 part of sodium carbonate, 2 parts of lithium carbonate and 1.5 parts of magnesium sulfate in parts by mass.

[0033]The application method of the above-mentioned thixotropic agent for polycarboxylate superplasticizer is as follows: fully mix the above-mentioned thixotropic agent with TPEG type polycarboxylate superplasticizer mother liquor in water to obtain good thixotropic performance in the application process of precast concrete Thixotropic polycarboxylate water reducer; wherein, the mass ratio of the thixotropic agent, polycarboxylate water reducer mother liquor effective solid content and water is 4.7:20:75.3, polycarboxylate water reducer mother liquor water reducing rate 30%.

[0034] Thixotropic polycarboxylate superplasticizer for precast concrete, composed of the following raw materials by mass percentage: white carbon black 0.2%, sodium carbonate 1%,...

Embodiment 2

[0039] The thixotropic agent for polycarboxylate superplasticizer mainly includes 0.5 parts of white carbon black, 9 parts of sodium carbonate, 3 parts of sodium sulfate and 1.5 parts of magnesium sulfate in parts by mass.

[0040] The application method of the above-mentioned thixotropic agent for polycarboxylate superplasticizer is as follows: fully mix the above-mentioned thixotropic agent with the VPEG type polycarboxylate superplasticizer mother liquor in water to obtain a good thixotropic performance in the application process of precast concrete. The thixotropic polycarboxylate water reducer; wherein, the mass ratio of the thixotropic agent, polycarboxylate water reducer mother liquor effective solid content and water is 7:15:28, the reduction of polycarboxylate water reducer mother liquor Water rate 30%.

[0041] Thixotropic polycarboxylate superplasticizer for precast concrete, composed of the following raw materials by mass percentage: white carbon black 0.5%, sodium...

Embodiment 3

[0046] The thixotropic agent for polycarboxylate superplasticizer, in parts by mass, its raw material components mainly include: 0.5 parts of white carbon black, 1 part of sodium carbonate, 1.5 parts of lithium carbonate, 0.5 parts of potassium carbonate, 0.5 parts of zinc sulfate, 1 part aluminum sulfate.

[0047] The application method of the thixotropic agent for the above-mentioned polycarboxylate superplasticizer is: fully mix the above-mentioned thixotropic agent with the mother liquor of the HPEG type polycarboxylate superplasticizer in water, and then a good thixotropic performance can be obtained in the application process of precast concrete. The thixotropic polycarboxylate water reducer; wherein, the mass ratio of the effective solid content of the thixotropic agent and the polycarboxylate water reducer mother liquor to water is 1:2:17, and the reduction of the polycarboxylate water reducer mother liquor Water rate 25%.

[0048] Thixotropic polycarboxylate superpla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com