Method and its device for garbage burning and flyash incinerating treatment

A waste incineration fly ash and calcination treatment technology, which is applied in the field of environmental engineering, can solve the problems of PCDD/Fs secondary pollution, loss of fly ash and calcination harmless treatment, etc., to prevent resynthesis, save energy, and have good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

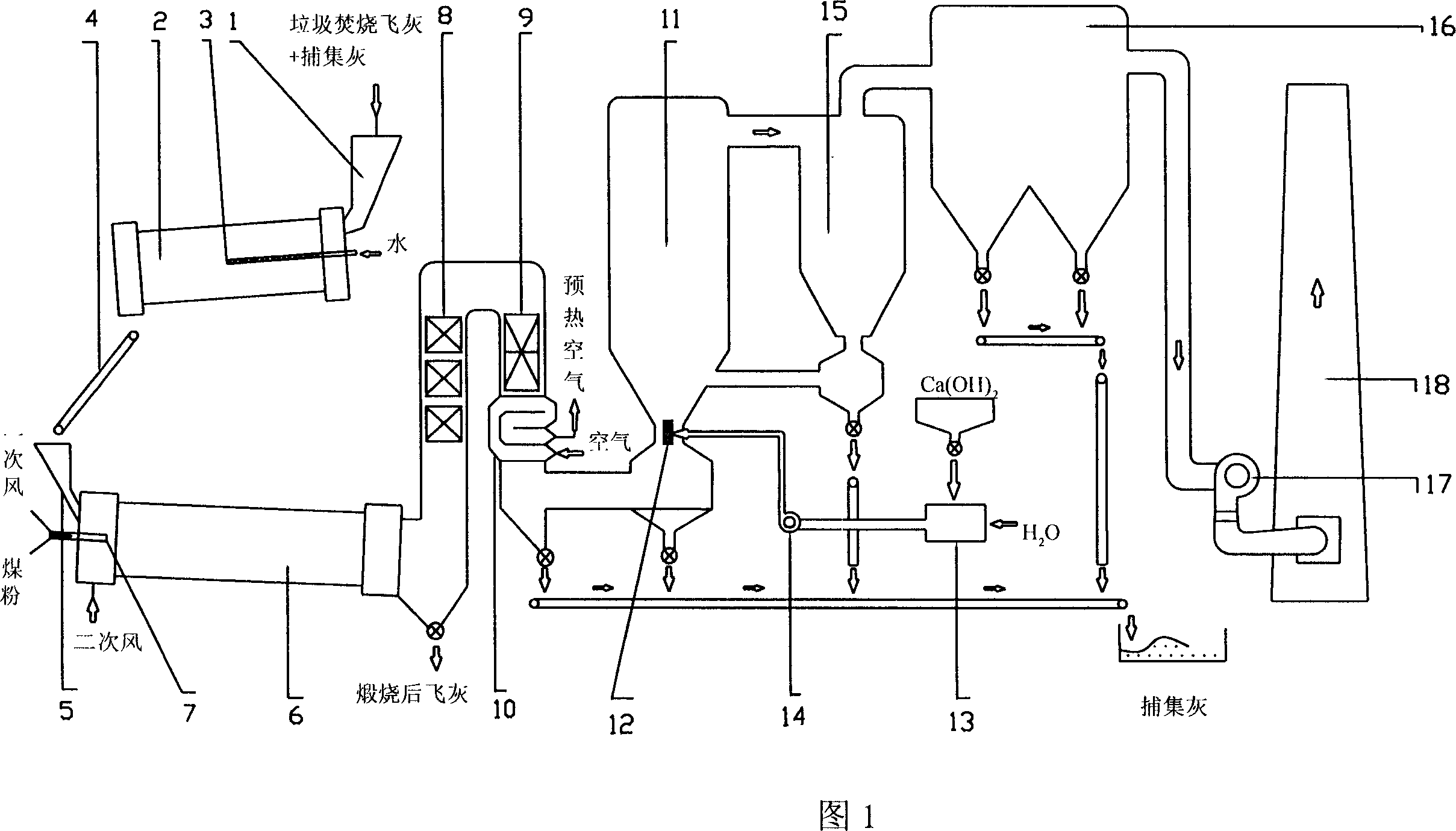

[0024] The waste incineration fly ash calcination treatment device is shown in Figure 1. The device includes: a drum granulator, a conveyor belt, a rotary calciner, a waste heat recovery system and a flue gas purification system. The rotary calciner is located behind the drum granulator, and a conveyor belt 4 is arranged between them. One end of the waste heat recovery system is connected to the rotary calciner, and the other end is connected to the flue gas purification system.

[0025] The drum granulator includes an ash hopper 1, a drum 2, and a water spray pipe 3. The ash hopper 1 and the water spray pipe 3 are arranged at the front end of the drum 2, and a conveyor belt 4 is provided below the rear end of the drum 2. .

[0026] Among them: there is a sealing baffle at the feed port of the drum granulator, and a semi-closed baffle at the discharge port to prevent fly ash from flying away.

[0027] The rotary calciner includes a feeding device 5, a burner 7, a secondary ai...

Embodiment 2

[0038] The difference from Example 1 is:

[0039] 1. Granulation stage: The fly ash stays in the drum granulator for 4±0.5 minutes, and the water content after granulation is 42+3%.

[0040] 2. Calcination stage: the temperature in the preheating zone is 200 - Preheat at 800°C for 7±1 minutes, after preheating at 800 - 1300°C (at 1100 - Calcination at 1200°C for 6 minutes, PCDD / Fs and other organic micro-pollutants in the fly ash can be completely decomposed) Stay in the high-temperature calcination zone for 12±1 minutes.

[0041] 3. Subsequent treatment stage: the flue gas temperature at the outlet of the air preheater is controlled at 225±5°C, and the lime injection rate is 1.0±0.1 g / standard cubic meter.

Embodiment 3

[0043] The difference from Example 1 is:

[0044] 1. Granulation stage: The fly ash stays in the drum granulator for 4.5±0.5 minutes, and the water content after granulation is 45±5%.

[0045] 2. Calcination stage: the preheating temperature is 200 - Preheat at 800°C for 8±1 minutes, after preheating, the temperature is 800 - 1200℃ (at 1000 - Calcined at 1100°C for 8 minutes, PCDD / Fs and other organic micro-pollutants in the fly ash can be completely decomposed) stay in the high temperature zone for 13±1 minutes.

[0046] 3. Subsequent treatment stage: the flue gas temperature at the outlet of the air preheater is controlled at 235±5°C, and the lime injection rate is 1.1±1 g / standard cubic meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com