Device for extracting fiber glass from non-metallic material of waste printed circuit boards and industrialized production process

A technology of non-metallic materials and glass fiber, which is applied in the direction of the device whose axis can be reversed, the swirl device, the removal of solid waste, etc., can solve the problems of undeveloped technology and achieve easy automation and long service life Long, accelerated flow velocity cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

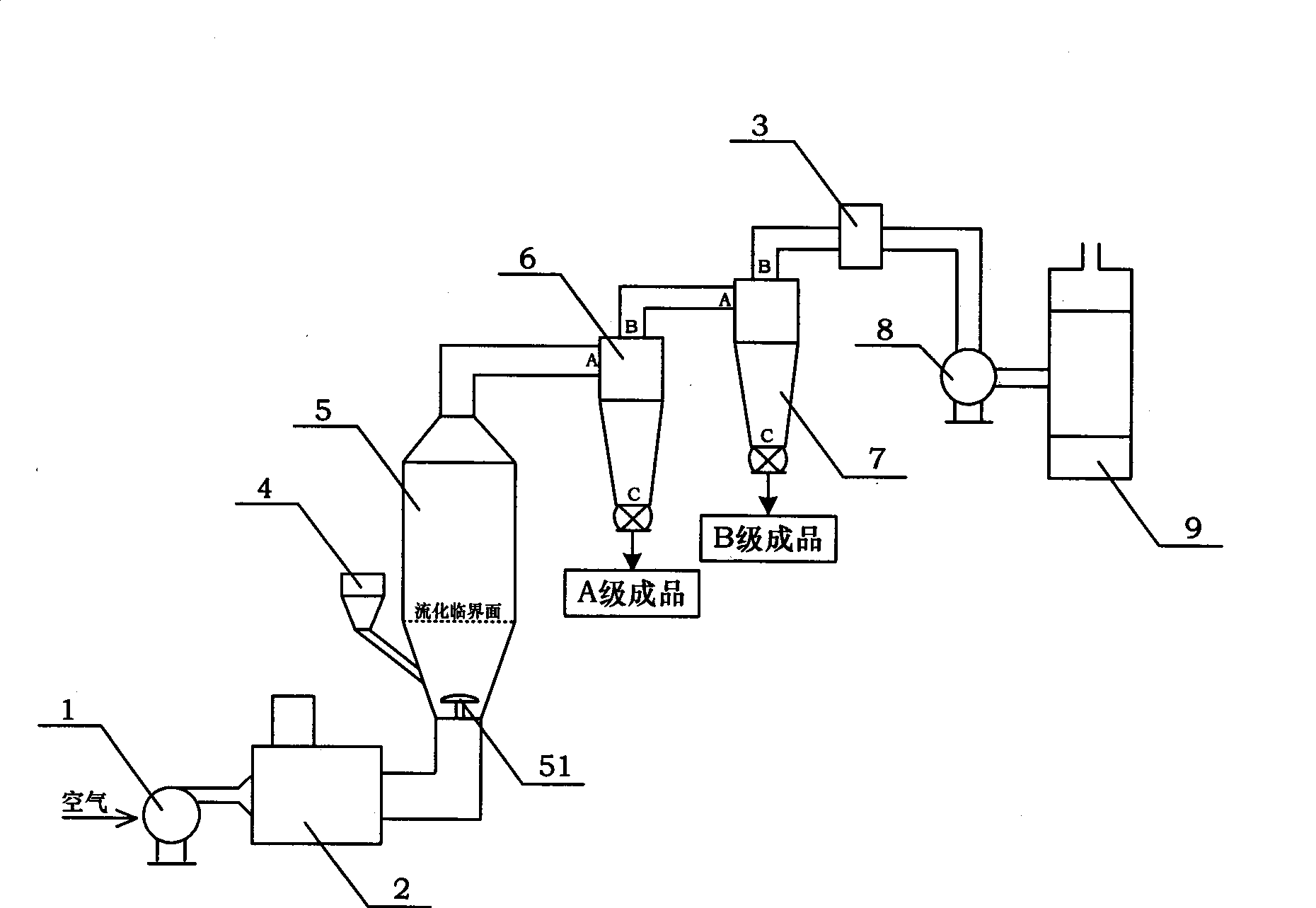

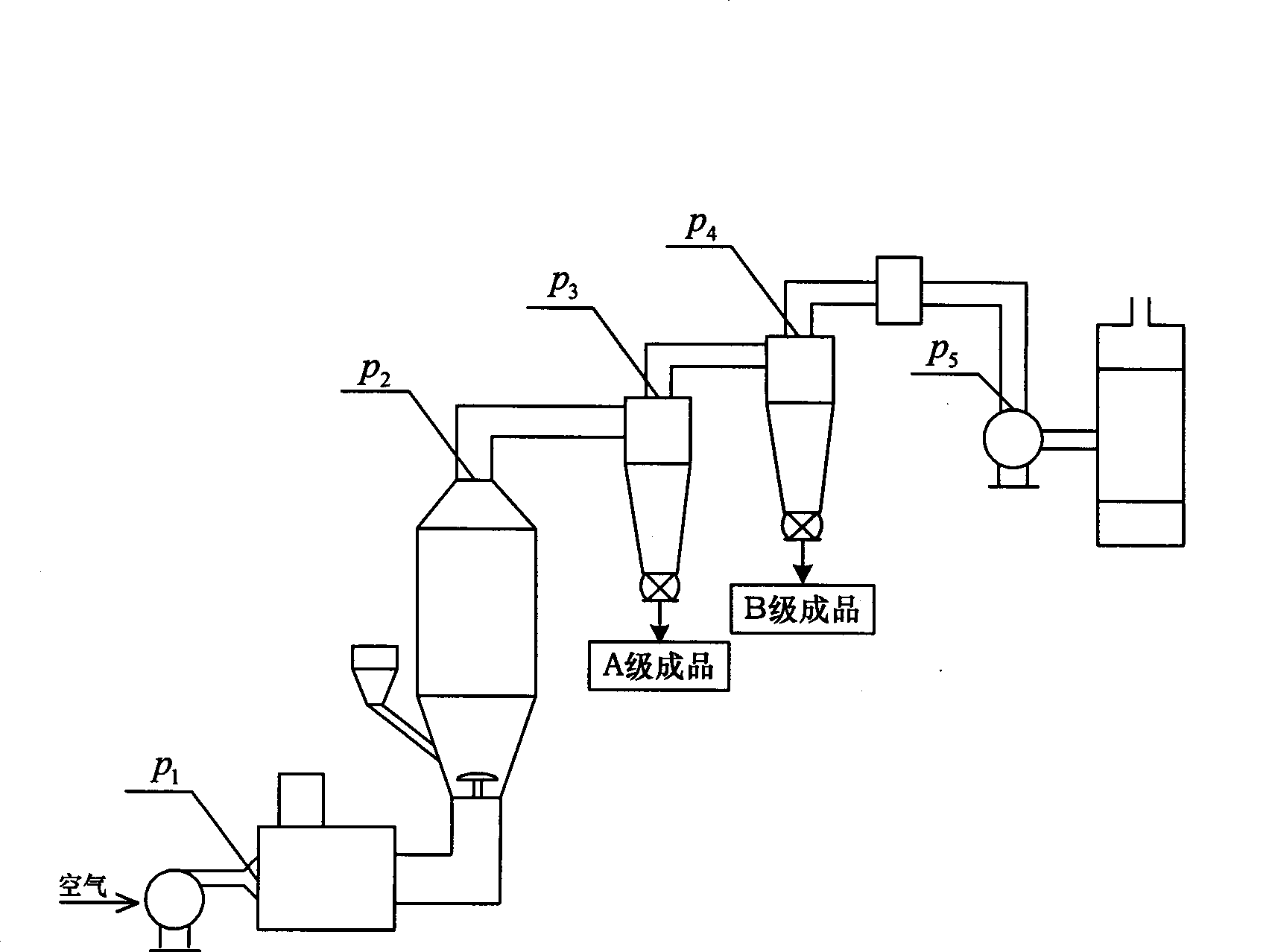

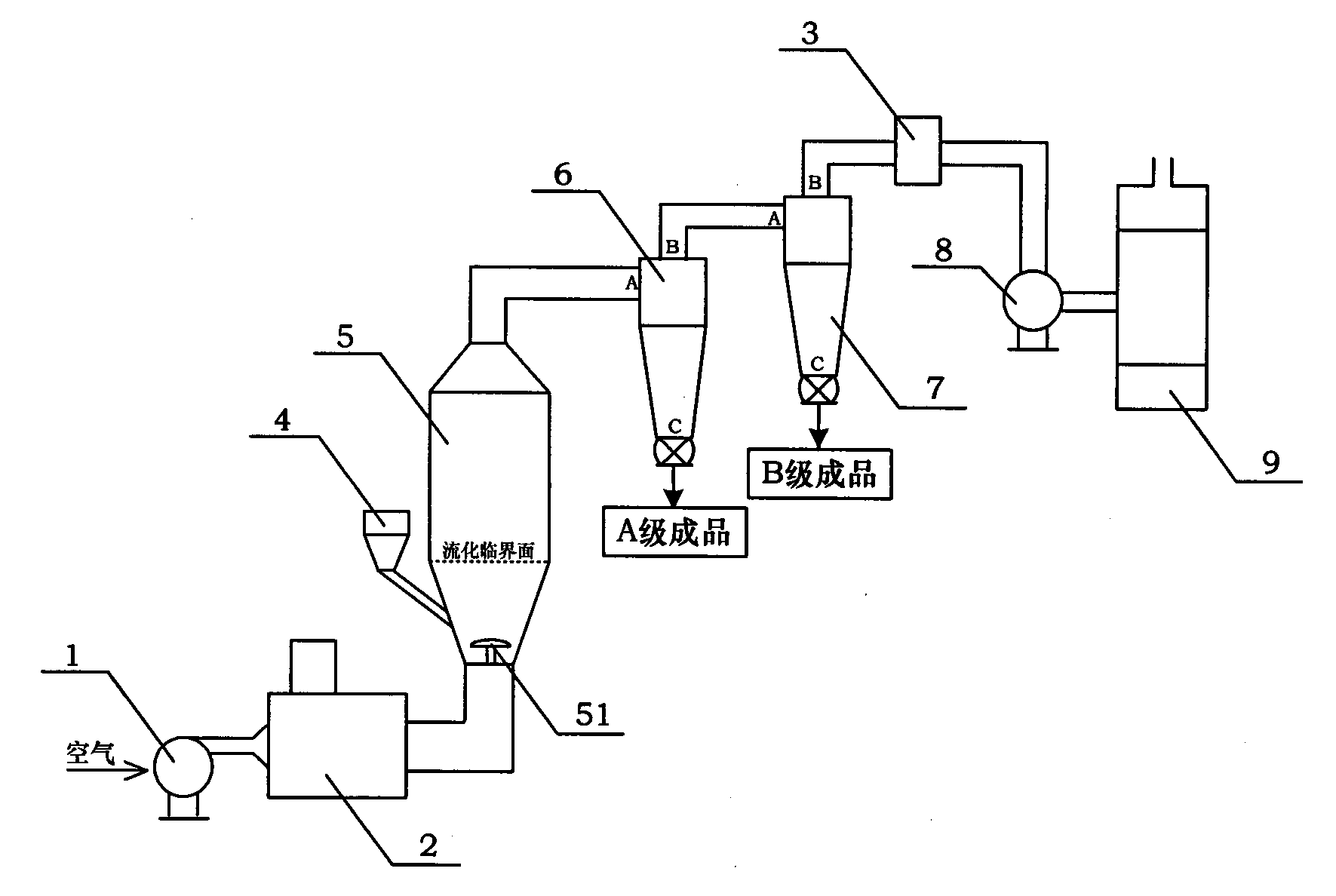

[0064] use as figure 1 The shown device, the industrialized production process of extracting glass fiber from the non-metallic material of waste printed circuit board is:

[0065] Step 1: Place quartz sand with a particle size of 0.5 to 1 mm at the air inlet of fluidized bed reactor 5, and the thickness of the quartz sand is 400 mm at rest;

[0066] The second step: the air is introduced into the electric heater 2 through the A induced draft fan 1 for heat treatment to form a hot air flow and output to the fluidized bed reactor 5;

[0067] The temperature of the hot air is 600°C;

[0068] The gas flow rate of A induced draft fan 1 is 1000m 3 / h, wind pressure is p 1 =10KPa;

[0069] The third step: transport the waste printed circuit board non-metallic materials with a particle size of 10-300 μm to the fluidized bed reactor 5 through the feeder 4; the conveying speed of the feeder 4 is 100Kg / h;

[0070] The fourth step: make the quartz sand placed in the first step and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com