High-temperature pyrolysis gasification treatment system and process for household garbage

A technology of domestic waste and treatment system, applied in the field of waste treatment equipment and technology, can solve the problems of easily causing pollution, clogging of filter cloth, large loss of pulse bag filter, etc., to reduce the content of harmful substances, avoid re-synthesis, and effectively The effect of using energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

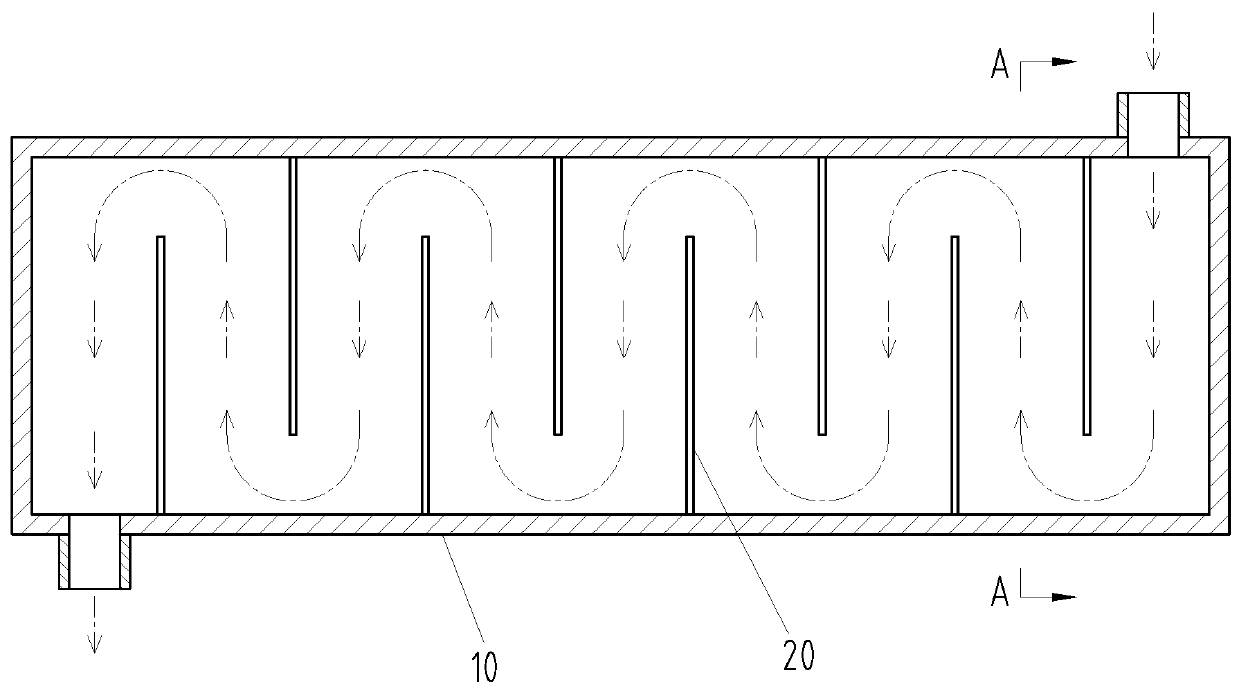

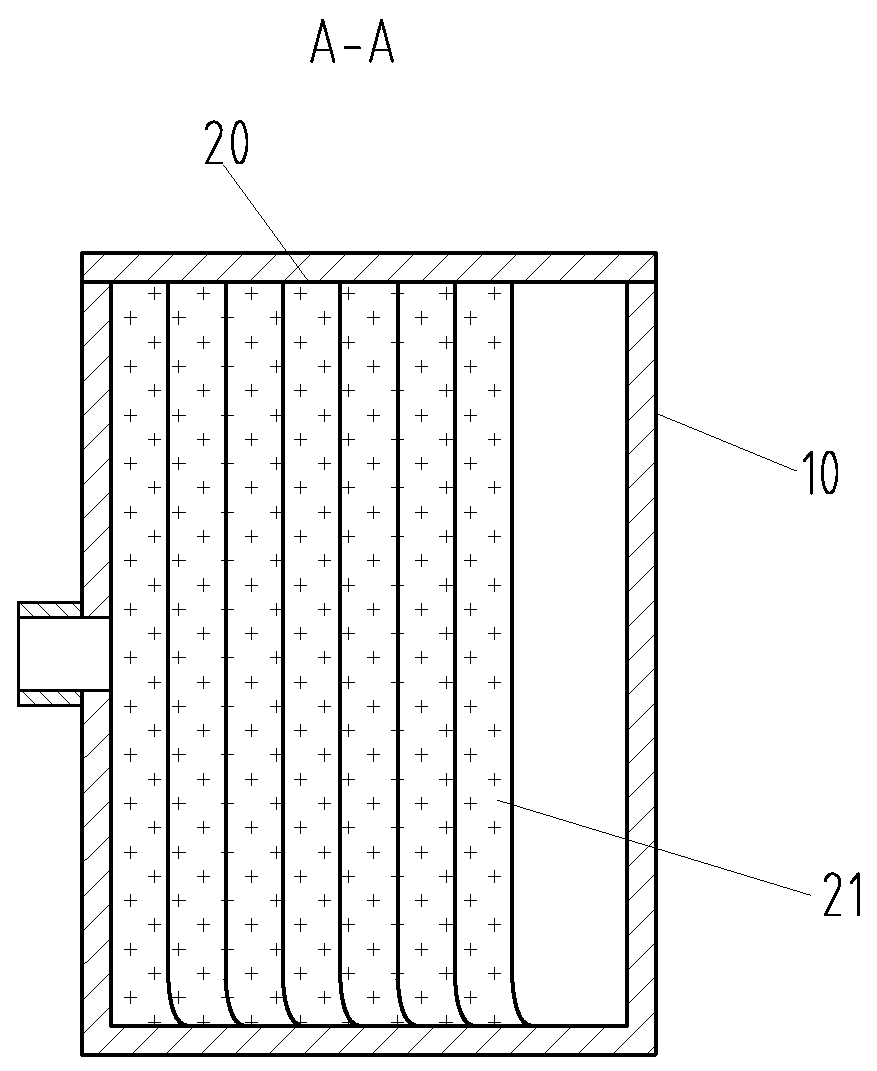

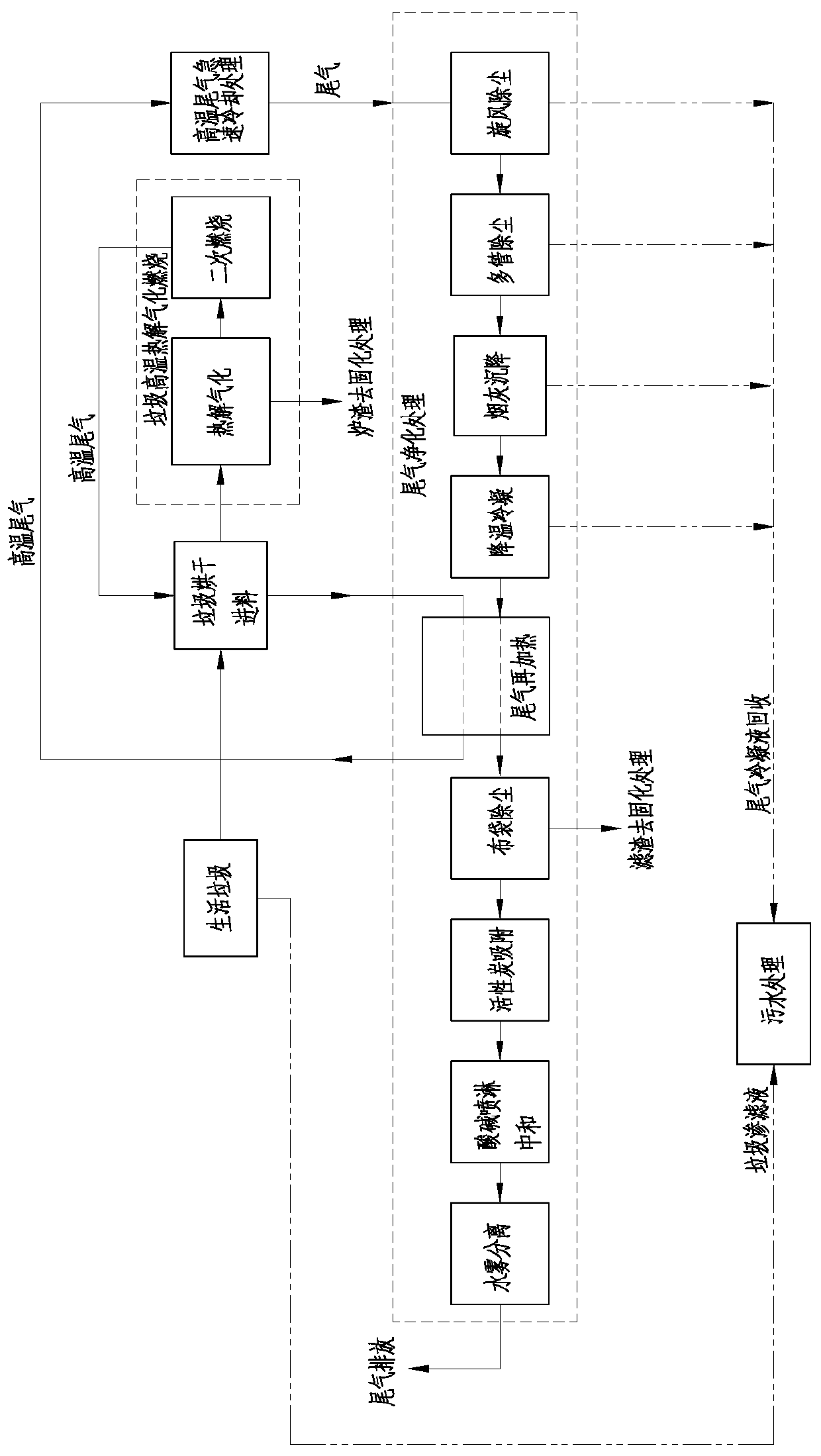

[0035] Such as figure 1As shown, on the one hand, the present invention provides a high-temperature pyrolysis gasification treatment system for domestic waste, including a garbage pool 1, a hydraulic grab bucket 2, a shaftless screw drying conveyor 3, a high-temperature pyrolysis gasification furnace, and a water-gas exchange system. Heater 6, cyclone dust collector 7, multi-pipe dust collector 8, primary exhaust fan 9, tail gas settling chamber 10, air cooler 11, gas-gas heat exchanger 12, pulse bag filter 13, secondary exhaust fan 14 , activated carbon absorber 15, spray neutralization tower 16, steam separator 17; shaftless spiral blades are used as the conveying mechanism in the conveying housing of the shaftless screw drying conveyor 3, and a heating chamber is provided on the outer wall of the conveying housing , the garbage in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com