Garbage treatment rotary kiln system

A technology for waste treatment and rotary kiln, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of corrosion, increase the amount of flue gas, inconvenient pretreatment, etc., to avoid high temperature chlorine corrosion, prevent resynthesis, reduce operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

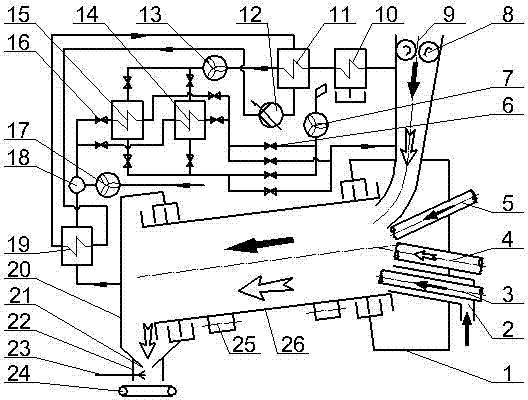

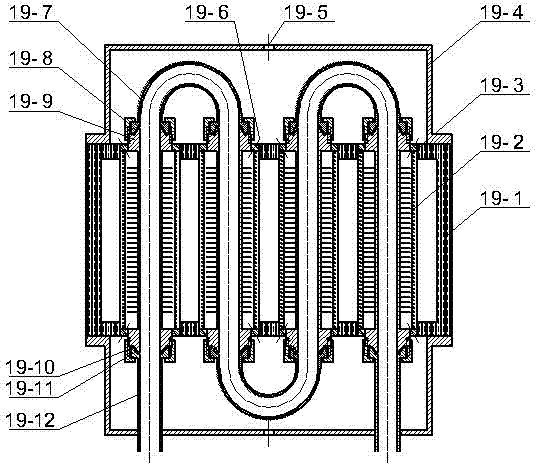

[0015] The present invention will be further explained below in conjunction with all the drawings. The preferred embodiment of the present invention is: see attached figure 1 And figure 2 , The rotary kiln system described in this embodiment is used for garbage incineration, such as figure 1 As shown, it is mainly composed of the kiln tail sealed chamber 1, the rotary kiln body 26, the kiln head sealed chamber 20, the removable double-walled heat exchanger 19, the air mixing chamber 18, the first and second regenerative heat exchangers 14, 15, the partition wall heat exchanger 11, the condenser 10, and the garbage flat pipe 9, the garbage crushing pinch roller 8, the sewage liquid pipe 5, the oxygen-enriched pipe 3, the fluid fuel sleeve 2, the solid fuel injection Tube 4, supporting roller 25, slag discharge necking 21, slag discharge port 22, slag spray mechanism 23 and slag discharge mechanism 24, mixed air blower 17, heat storage type heat exchanger valve group 16, drying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com