Patents

Literature

77results about How to "Low preprocessing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

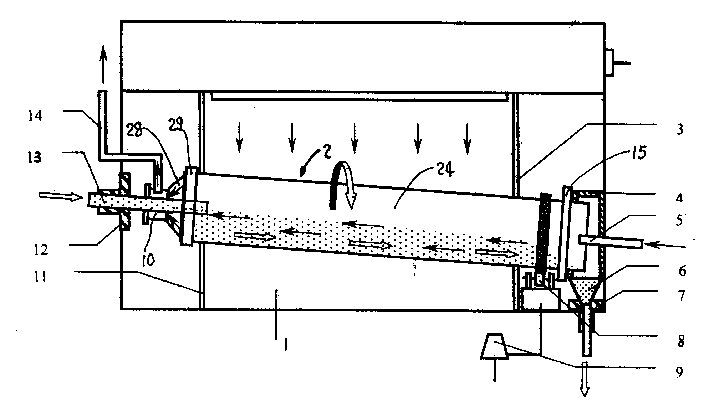

Incineration treatment method for domestic refuse

ActiveCN101761928AReduce dosageAchieve recyclingCement productionIncinerator apparatusSlagCalcination

The invention provides an incineration treatment method for domestic refuse. The method comprises: having an incinerator arranged between a rotary kiln and a decomposing furnace; introducing tertiary hot air into a wind tower of the incinerator and baking an incinerator body; crushing domestic refuse with the water content less than 20 percent into refuse material 50 to 80 millimeters in particle size and guiding the refuse material into the incinerator body through an electronic control feeder of the incinerator; allowing a material level meter to send a feedback signal to stop adding the refuse material when a refuse material layer is 50 millimeters away from a material separation body; drying the refuse material; burning, decomposing and gasifying organic substances in the refuse material through the tertiary hot air out of a multi-layer air outlet of a central air pipe; ensuring that the temperature in the incinerator body is above 850 DEG C; discharging produced flue gas to the decomposing furnace through a smoke outlet; ensuring that the decomposing furnace reaches a temperature of above 900 DEG C and is in an alkaline atmosphere; and further neutralizing acidic flue gas. Refuse ash-slag is discharged through an electrical vibrating material discharger, sent into the rotary kiln, and is taken as raw material burden for cement production to participate in calcination, so that the aim of treating domestic refuse in a 'harmless, amount-reducing and resource-recovering' way is achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

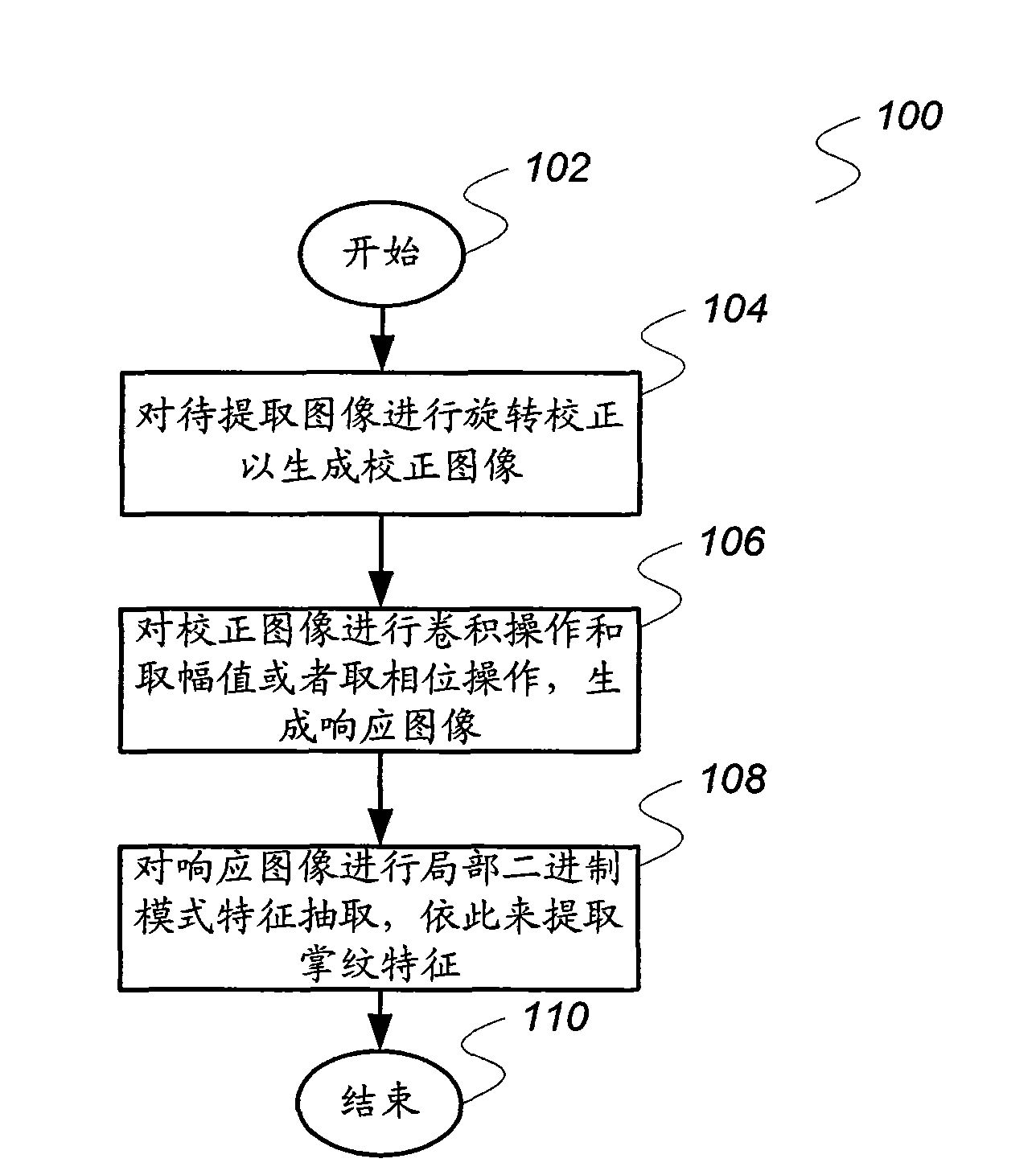

Palm print identifying method and palm print identifying device

InactiveCN101604385AReduce the impact of lightLow preprocessing requirementsCharacter and pattern recognitionPalm printComputer science

The invention relates to palm print identifying technology, and provides a palm print identifying method and a palm print identifying device aiming at the defects that the preprocessing requirement for the acquired palm print images is high in the prior palm print identifying technology, and the like. The palm print identifying method comprises the step of extracting the palm print characteristics of an image to be extracted, and the extraction specifically comprises the following steps: rotating and correcting the image to be extracted to generate a corrected image; carrying out convolution operation for the corrected image according to the preset Gabor wavelet, carrying out the operation of taking an amplitude value or a phase from the corrected image after the convolution operation, and generating a response image; and carrying out local binary mode characteristic extraction for the response image to acquire a local binary mode code of the image to be extracted so as to generate the palm print characteristics. The invention also provides the palm print identifying device. The technical proposal of the invention can provide rotational invariance and has high processing speed, so the technical proposal can achieve real-time palm print identification.

Owner:SHENZHEN UNIV

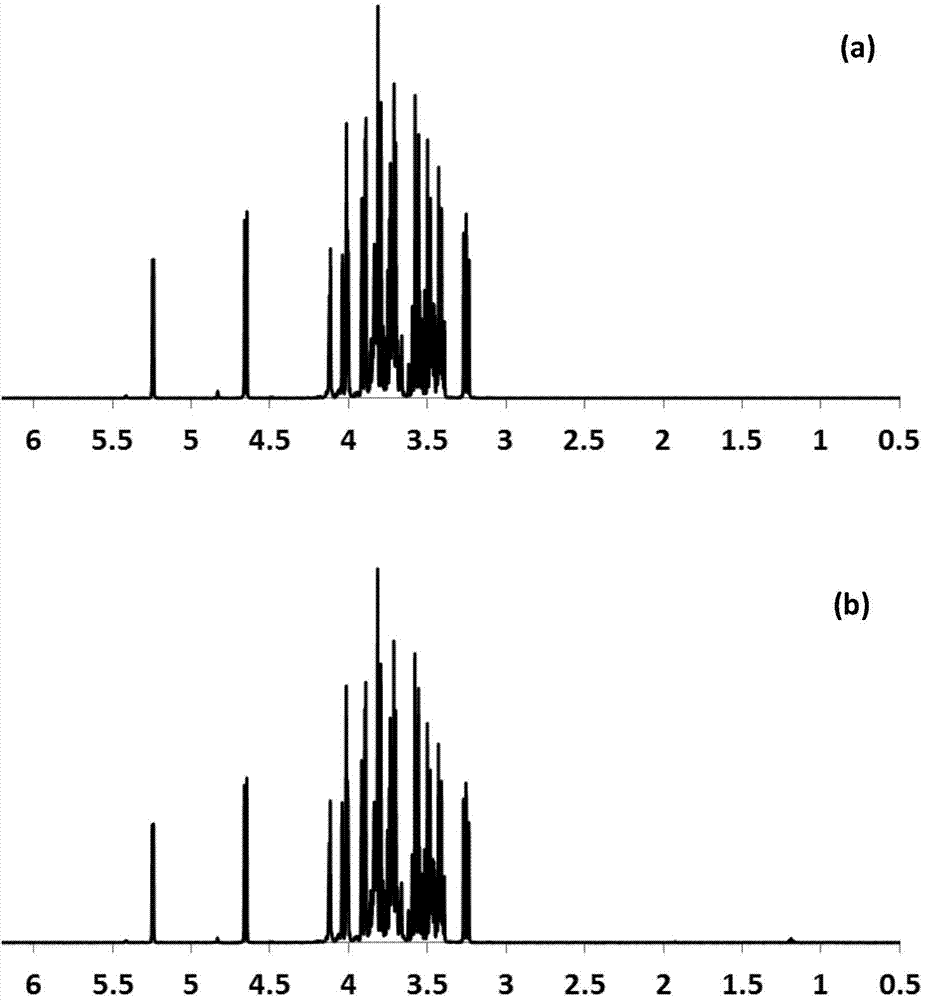

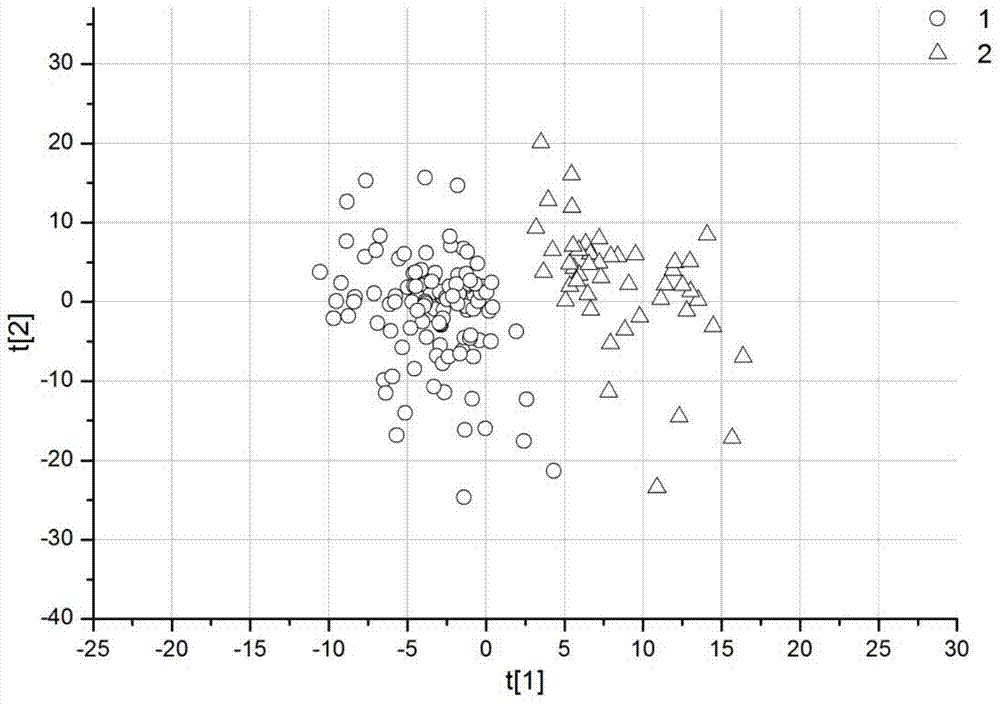

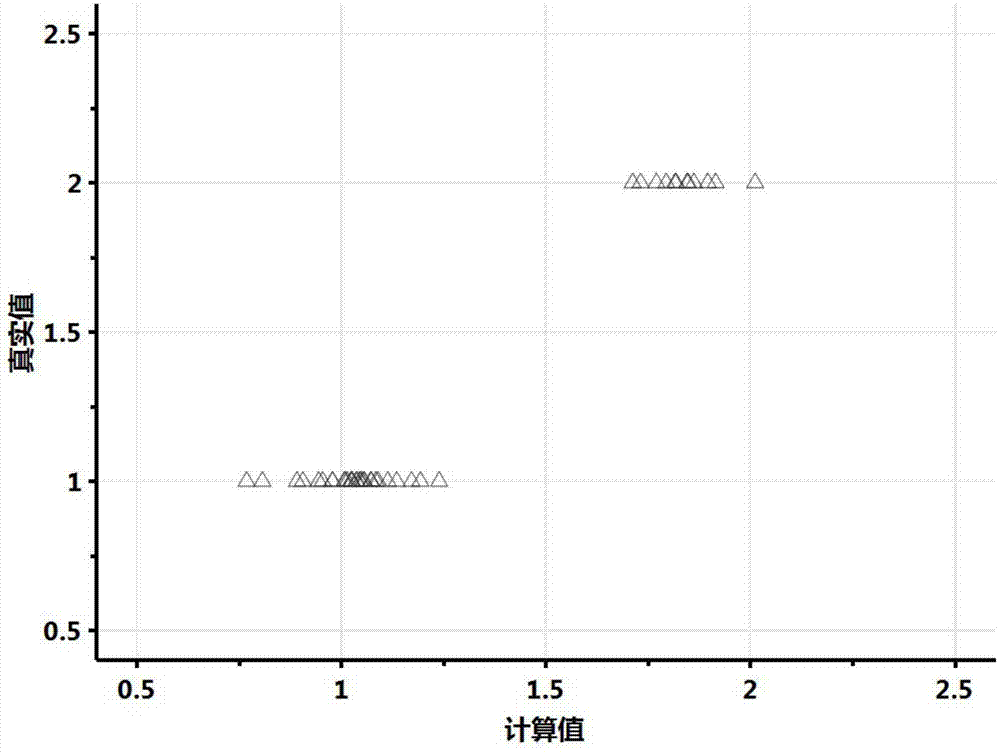

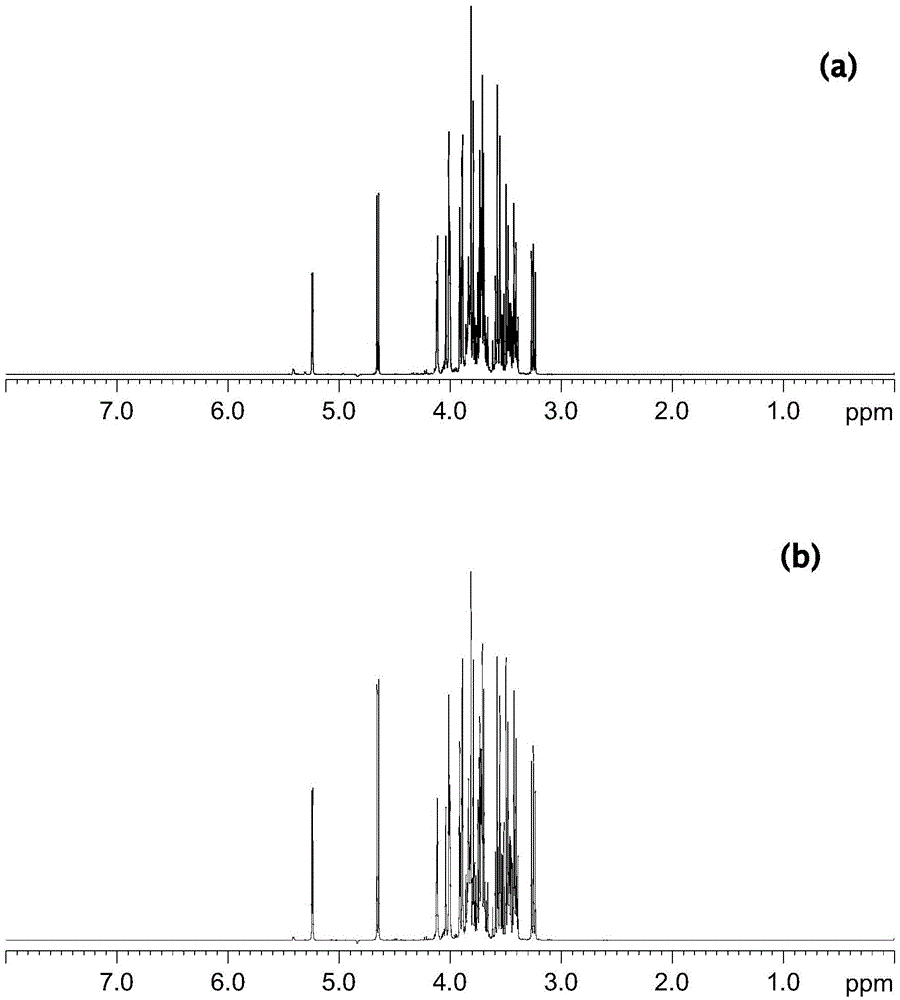

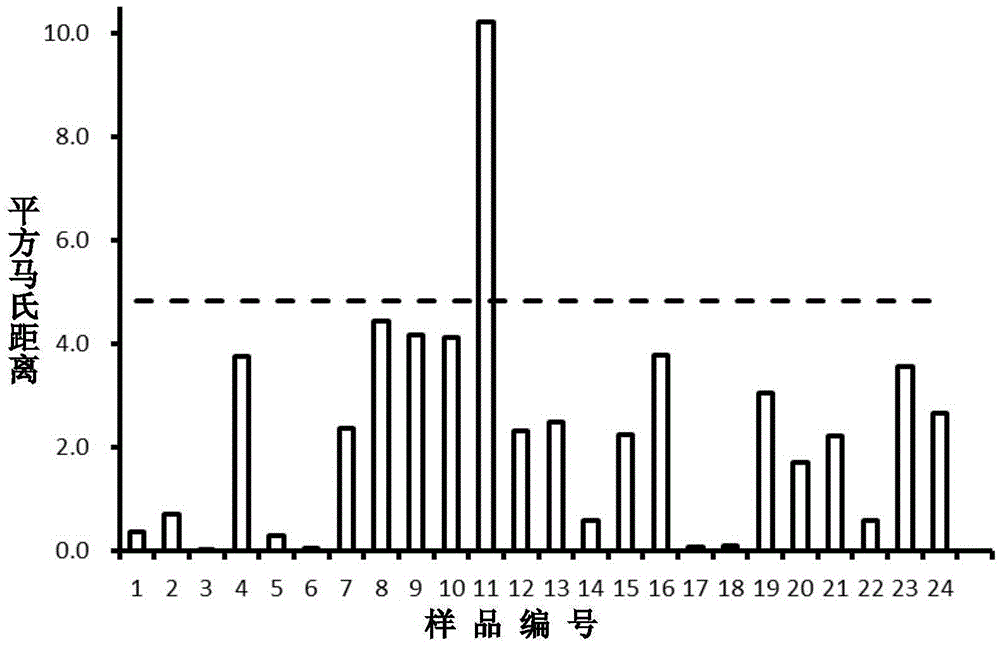

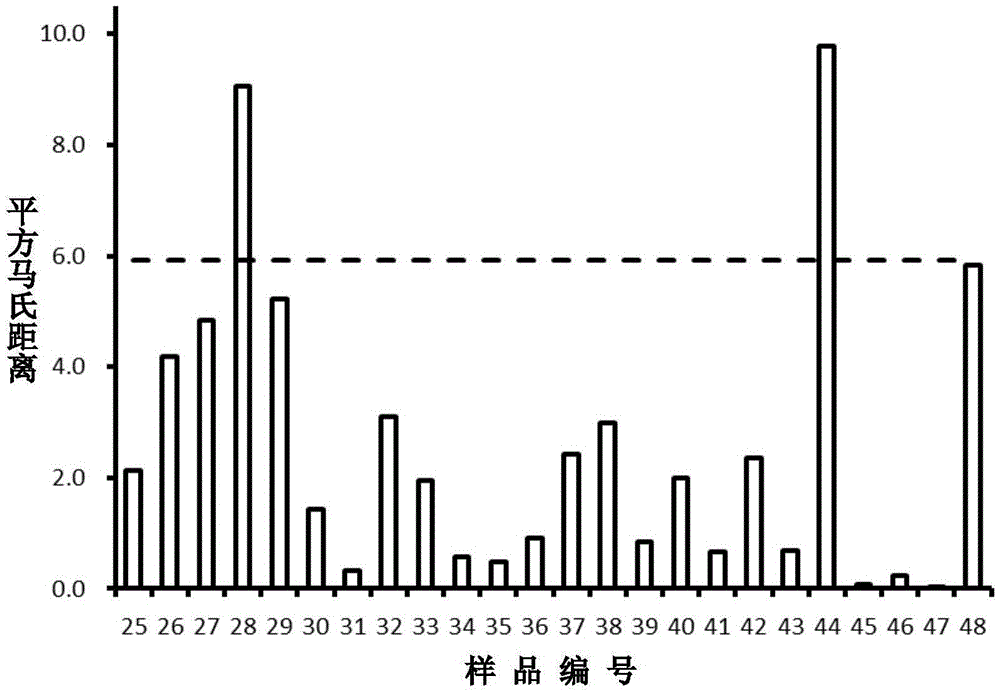

Method for distinguishing between pure and syrup-adulterated honey based on combination of hydrogen nuclear magnetic resonance and partial least square method

ActiveCN104713895ALow preprocessing requirementsMature and reliable technologyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceHydrogen

The invention discloses a method for distinguishing between pure and adulterated honey based on combination of hydrogen nuclear magnetic resonance and a partial least square method. The method relates to food detection, and application of a hydrogen nuclear magnetic resonance fingerprint to food detection. The method comprises the following steps: firstly, building a pure honey database and a syrup-doped honey database respectively; secondly, building a distinguishing model, and carrying out a reliability test on the identification model; finally, distinguishing honey samples to be detected, and expanding the databases with the distinguishing results to improve the representativeness of the samples and the distinguishing capability. The method has the advantages that the technique is reliable, the operation is simple, a large quantity of samples can be treated in a short time, the dubious honey samples can be quickly screened out, the subjective factors and the personal errors can be avoided, and the conclusion can be scientific and reliable.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

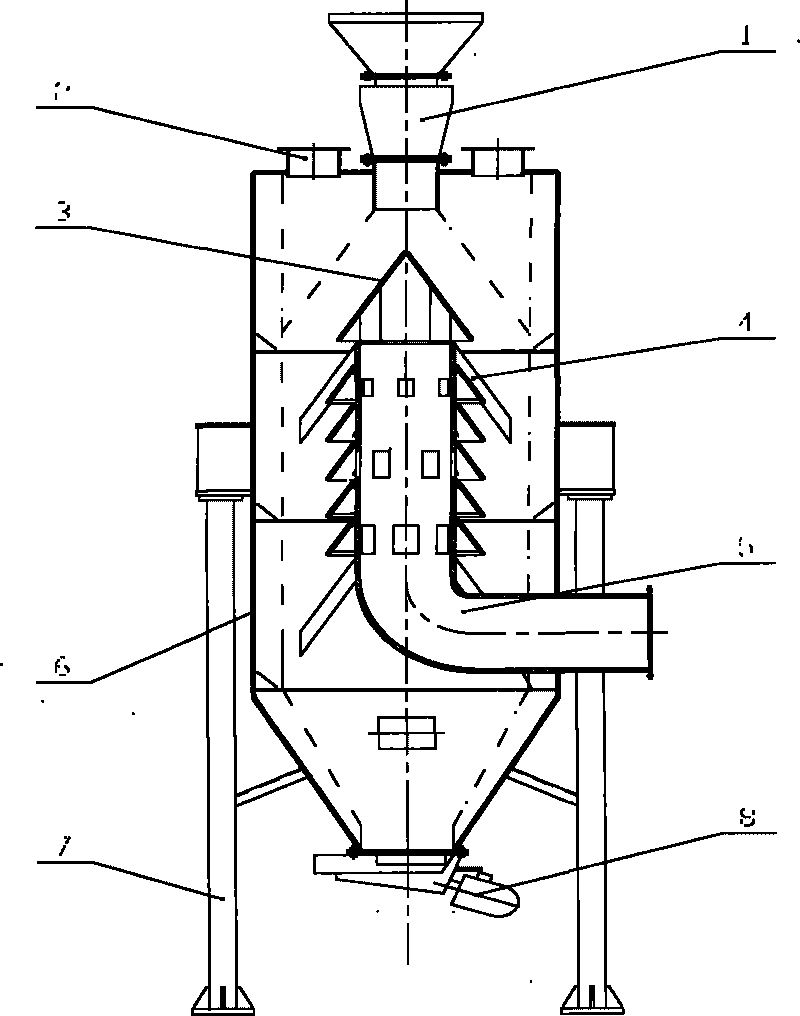

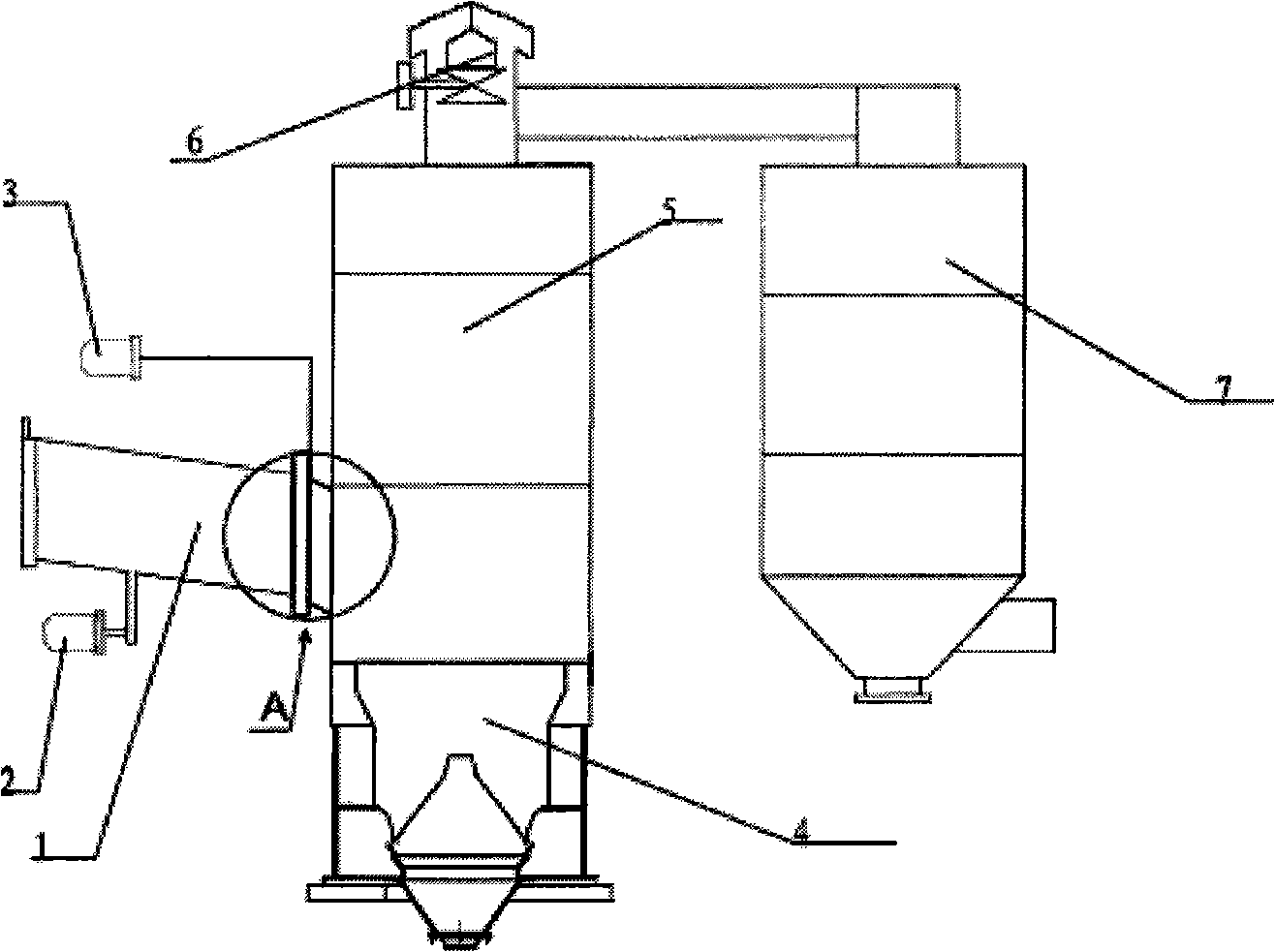

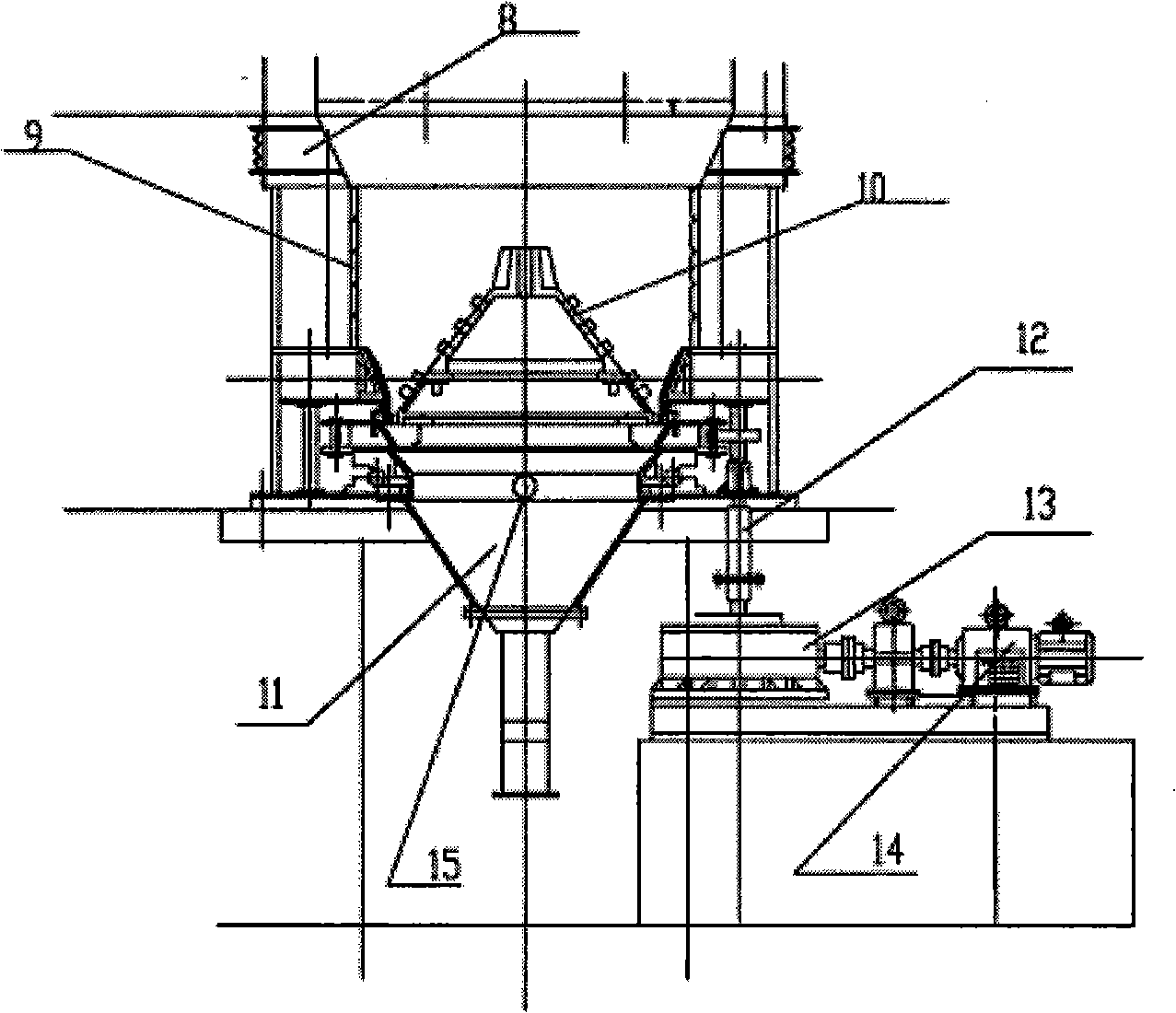

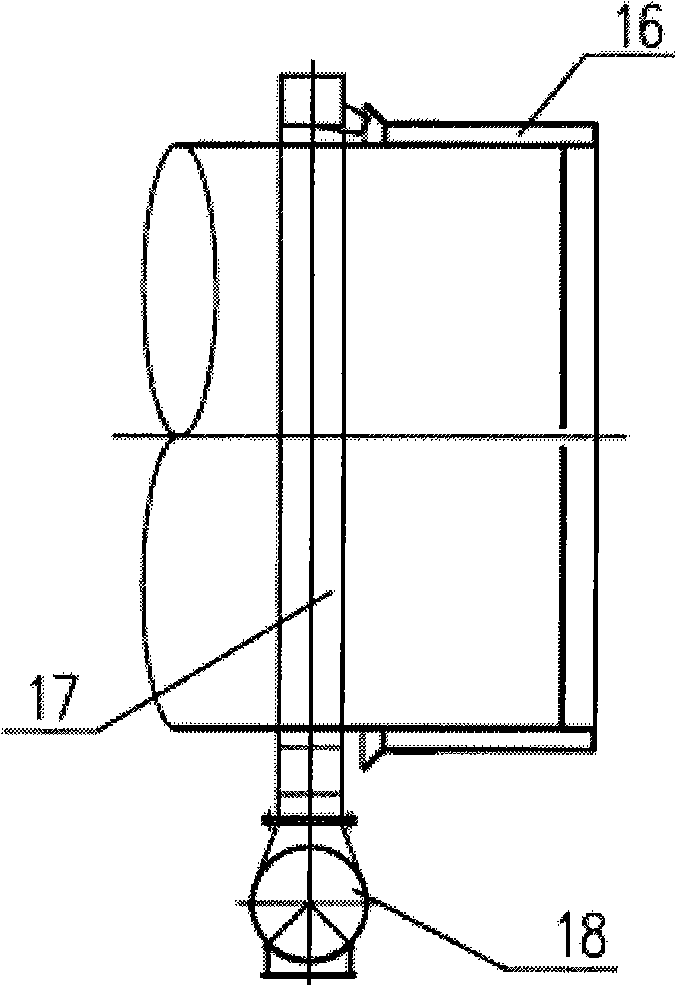

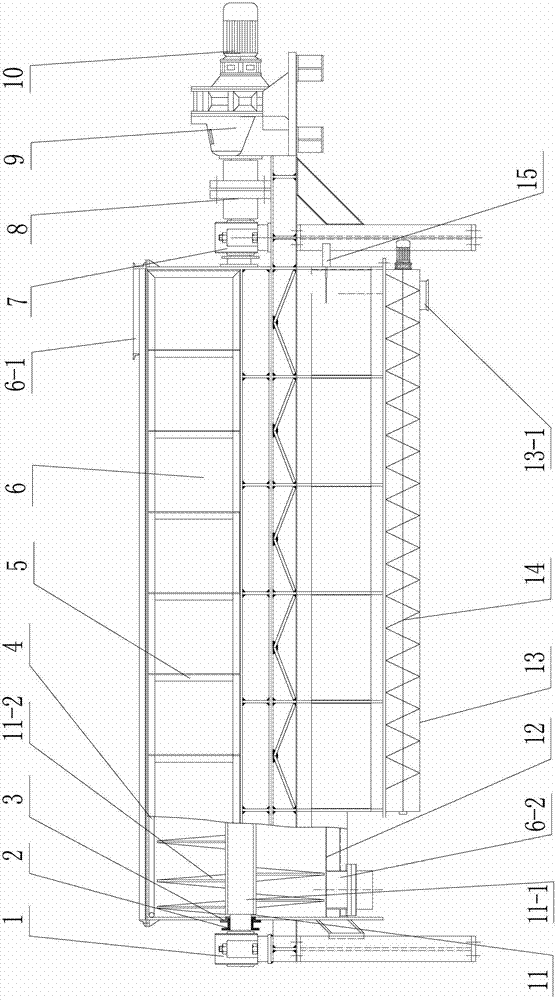

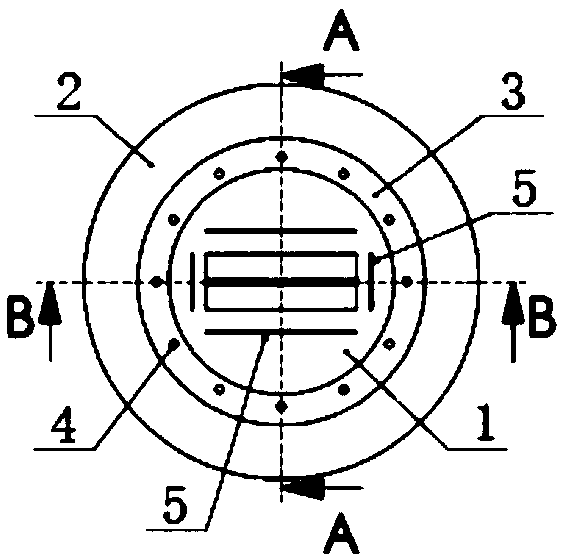

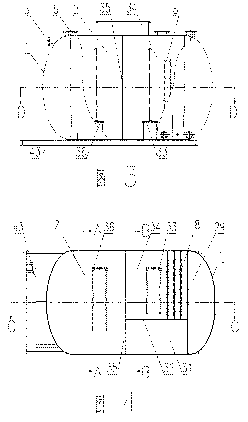

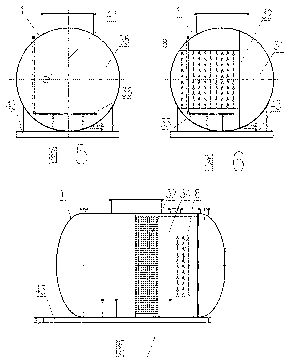

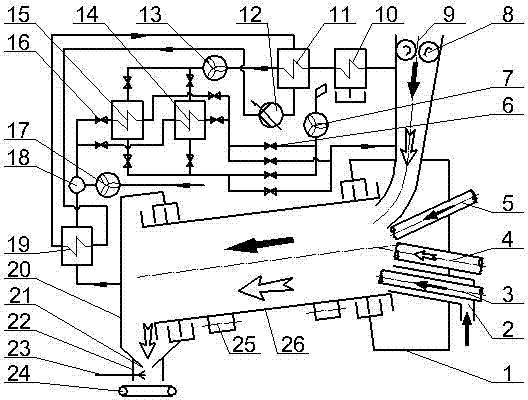

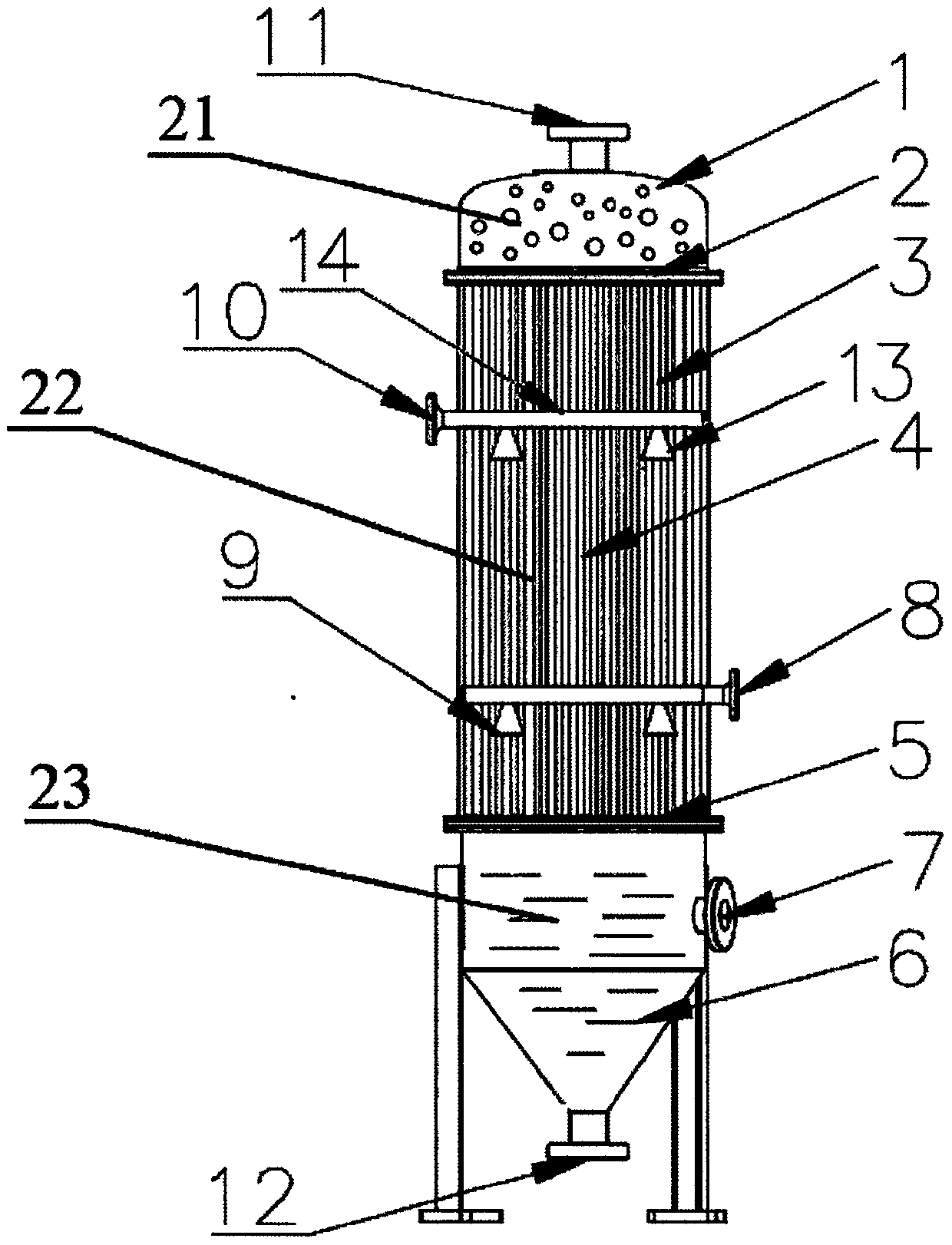

Danger waste material rotary type fluidization cold slag three-segment incinerator

ActiveCN101275743ALow preprocessing requirementsStrong adaptabilityIncinerator apparatusSlagCombustion chamber

The invention discloses a hazardous waste rotary type fluidizing cold slag three-stage incinerator, including a rotary kiln, a rotary kiln motor, a cooling fan, a fluidizing cold slag device, a three-burning chamber, an emergent discharge door, a quench tower, wherein the upper end of the fluidizing cold slag device is provided with a three-burning chamber, the top of which is connected with an emergent discharge door, a quench tower, the lower side of the three-burning chamber is connected with the tail of the rotary kiln provided with a cooling fan, and the rotary kiln is provided with a rotary kiln motor. The invention can process the hazardous waste of all forms, can burn the waste of liquid, solid and sludge etc., and has low requirement on the pretreatment. Under the rotation of the fluidizing cold slag device, the slag is further crashed, the slag heat loss ratio after burning is smaller than 3%; the thrice burning chamber further strengthens the burning, which makes the failure rate of the dioxin reach 99.99%, the temperature of the smoke from the three-burning chamber to the quench tower is reduced from 1100 degrees to 200 degrees.

Owner:ZHEJIANG UNIV

Method for discriminating acacia honey and rape honey on basis of H-nuclear magnetic resonance

InactiveCN105548233AMature and reliable technologyEasy to operateAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceFingerprint

The invention discloses a method for discriminating acacia honey and rape honey on the basis of H-nuclear magnetic resonance, belongs to the field of food detection, and relates to an application of H-nuclear magnetic resonance fingerprint in food detection. The method comprises the following steps: respectively establishing the H-nuclear magnetic resonance database of the rape honey and the H-nuclear magnetic resonance database of the acacia honey, constructing a discriminating model by using combination of a factor analysis technology and a discriminant analysis technology, discriminating a honey sample to be detected, and determining the honey to be discriminated as the rape honey or the acacia honey. The method has the advantages of reliable technology, simple operation, treatment of a large amount of samples in a short time, rapid discrimination of the kind of honey, avoiding of subjective factors and personal errors, and scientific and reliable conclusion.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

Tubular composite nanofiltration membrane

The invention discloses a tubular composite nanofiltration membrane which comprises four functional layers, namely a support layer, a base membrane layer, an interfacial polymerization layer and a protective layer. A tubular base ultrafiltration membrane is formed by carrying out blending modification on polyethersulfone and an inorganic nanometer material, and a tubular polyamide composite nanofiltration membrane is formed by carrying out interfacial polymerization reaction on piperazine hexahydrate as a water-phase solution and a trimesoyl chloride hexane solution. According to a preparation process, a process technology of preparing a tubular polyethersulfone ultrafiltration membrane by adopting a jelly and synchronously producing the tubular polyethersulfone ultrafiltration membrane by adopting reel pipe welding and membrane coating is adopted. The obtained tubular composite nanofiltration membrane disclosed by the invention has the advantages of different selective separation functions on a monovalent ion and a divalent ion, a higher interception rate on a small-molecular organic matter, lower requirements on the pretreatment of feed liquid, applicability on the separation of high-solubility high-granularity high-suspension matters, and very high economic values on deep separation, purification and soluble shrinkage of some specific materials.

Owner:泉州索爱膜科技开发有限公司

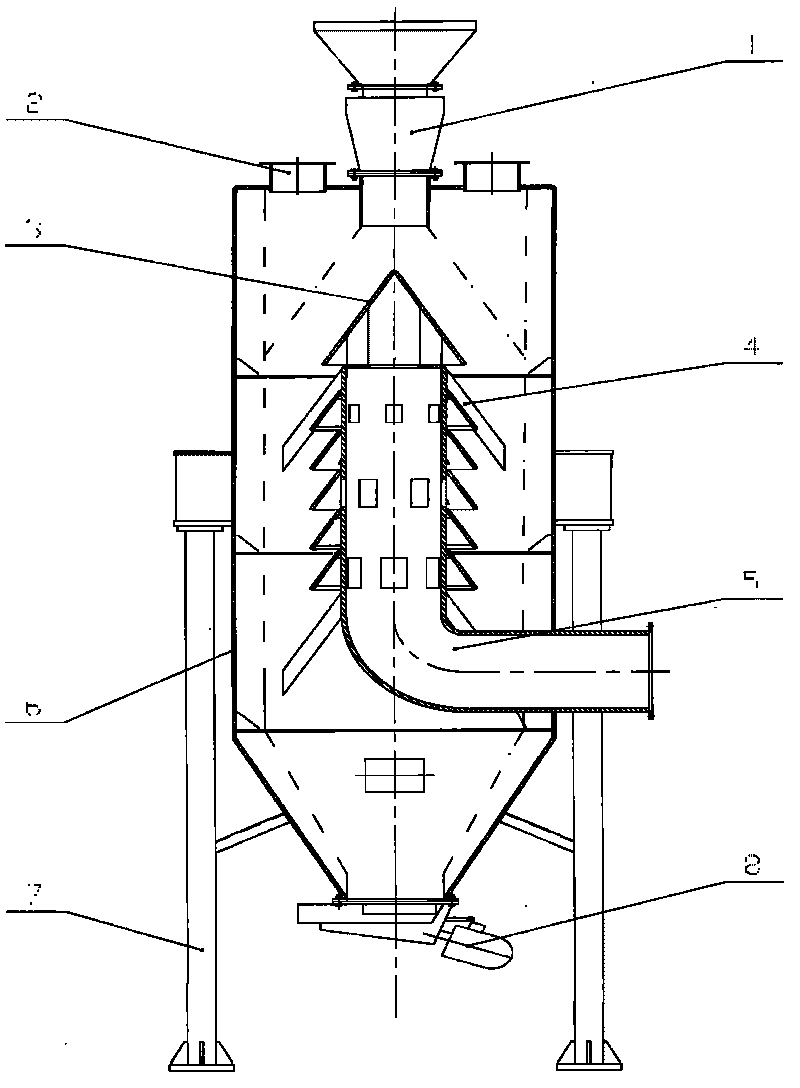

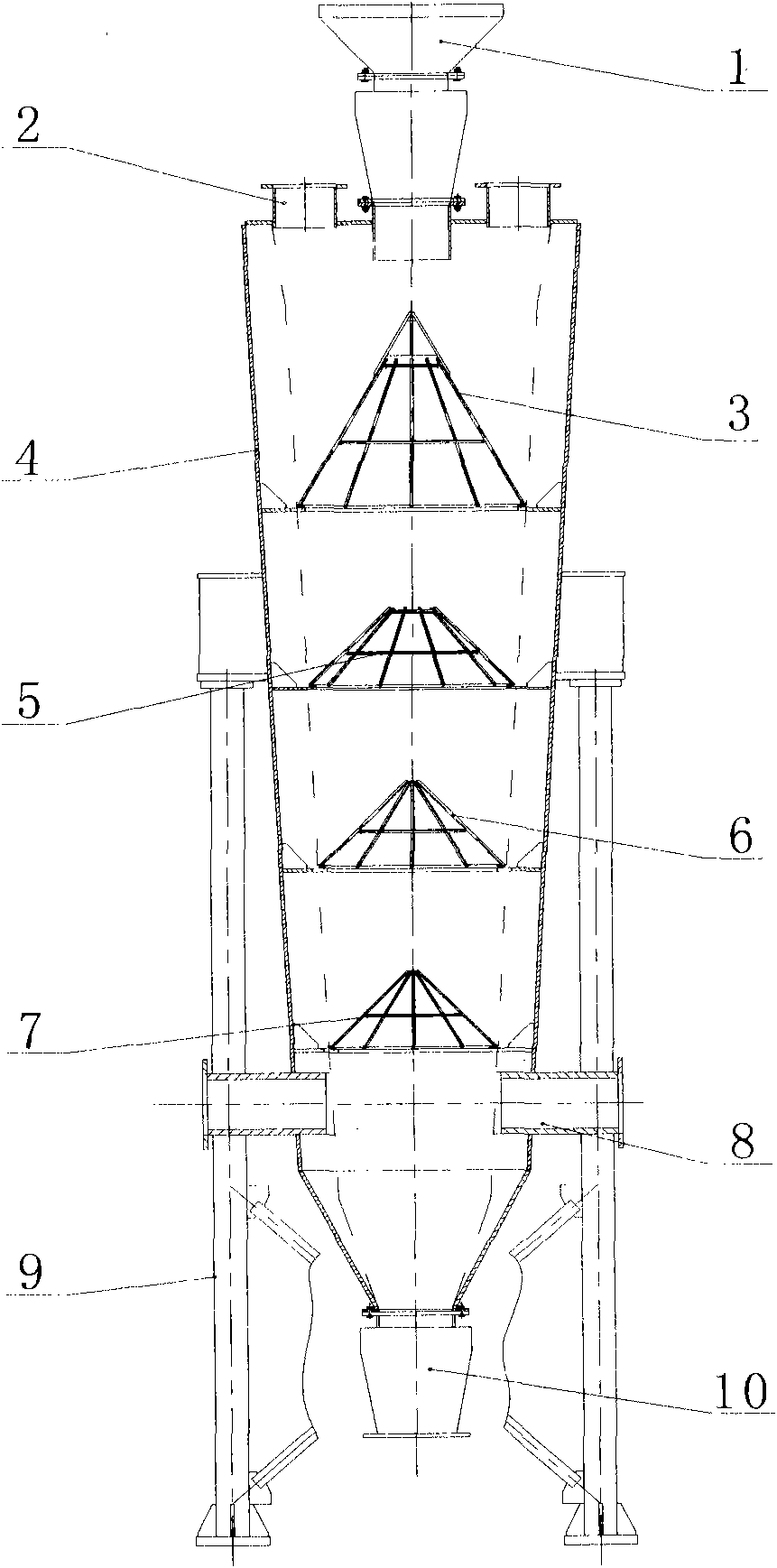

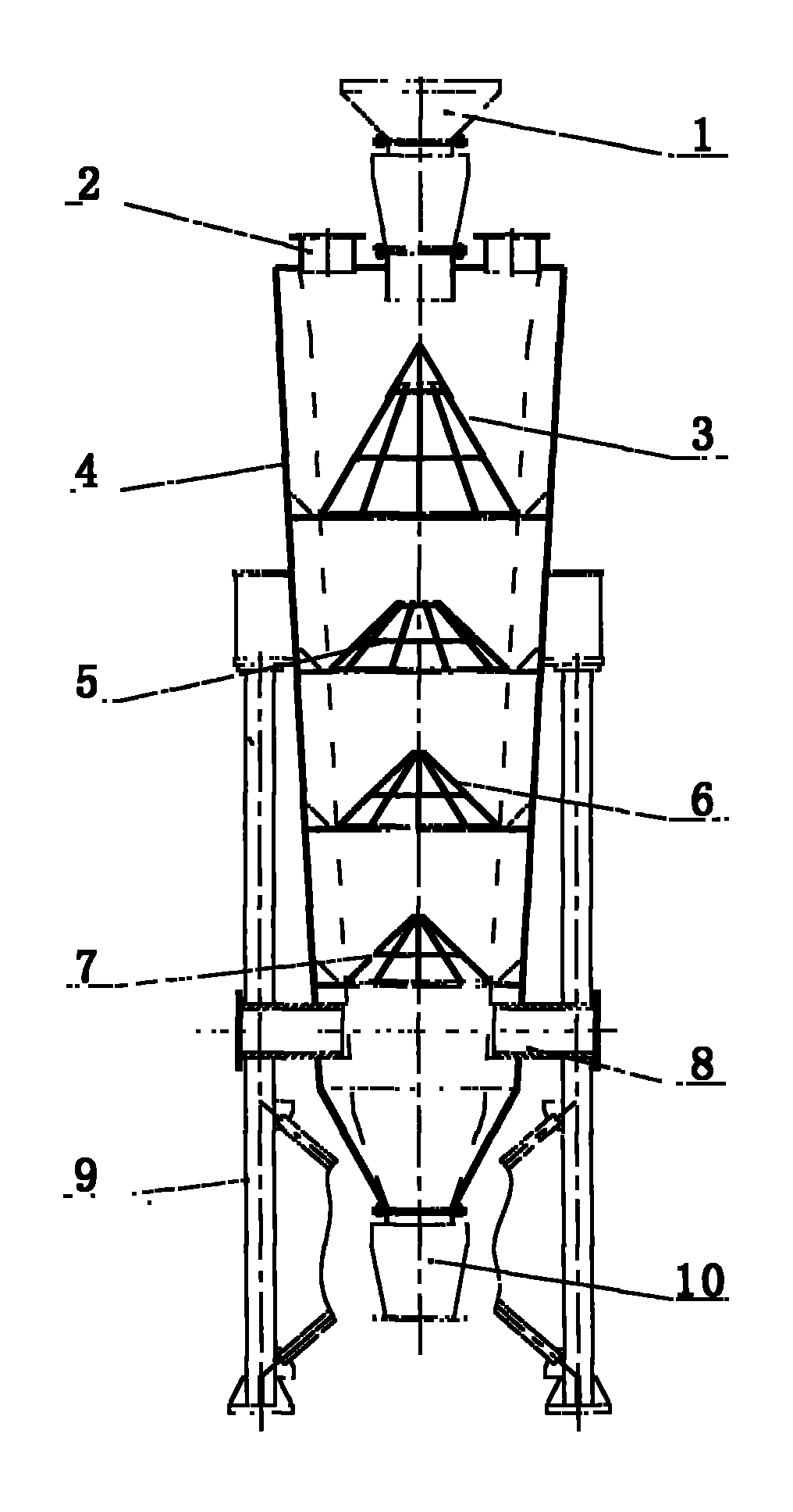

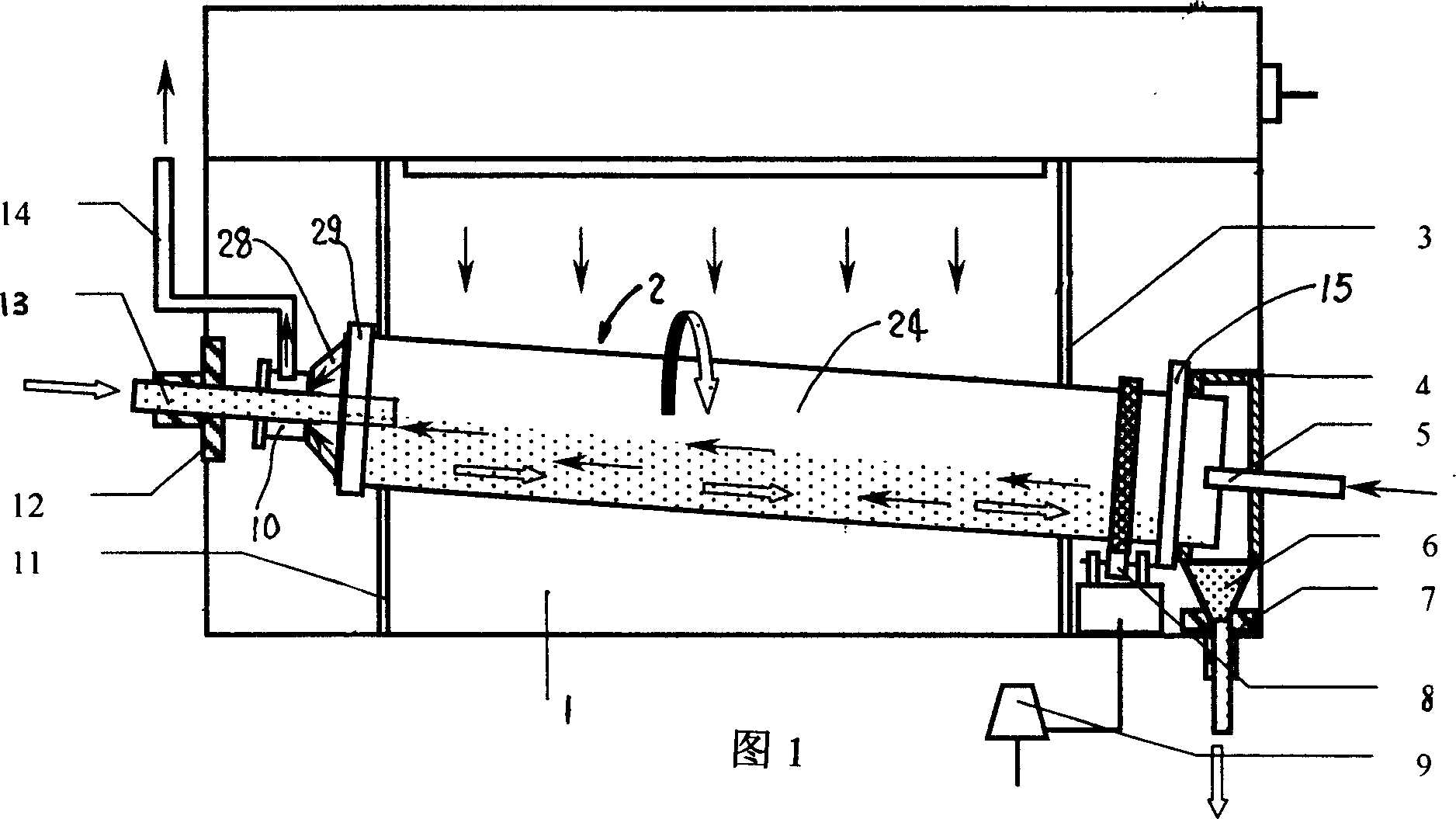

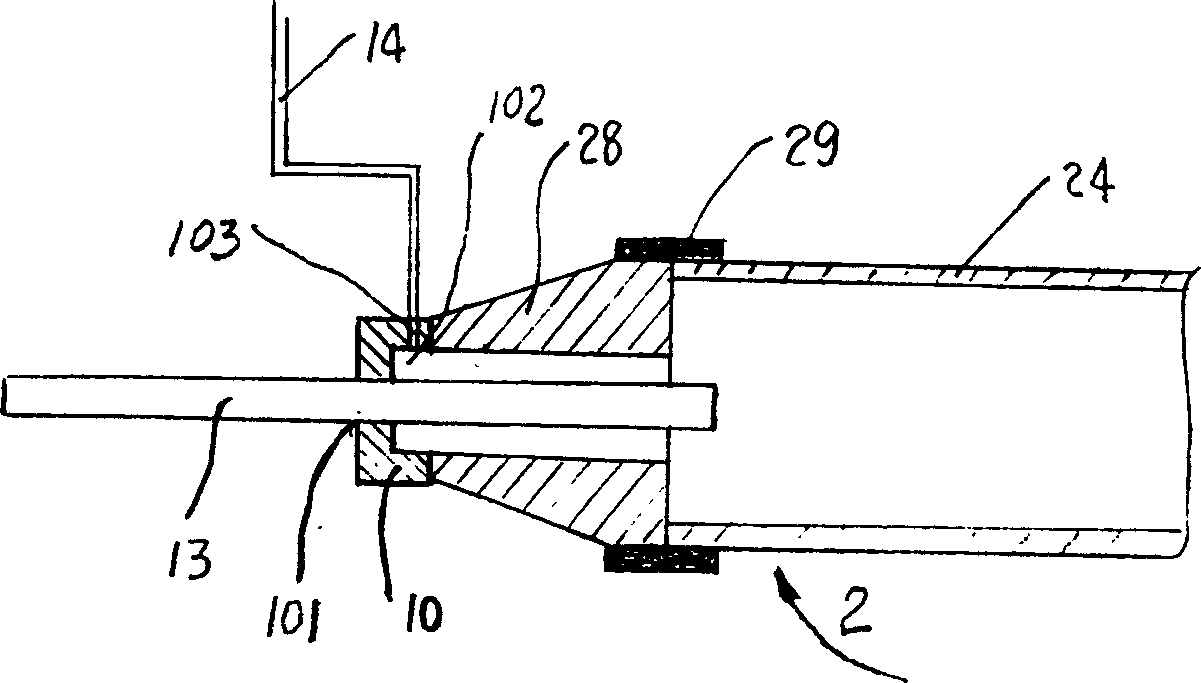

N-level incineration treatment technology for domestic garbage

InactiveCN101776269AAchieve full utilizationExtended stayCement productionIncinerator apparatusWater contentHot blast

The invention relates to an N-level incineration treatment method for domestic garbage, which comprises that: an N-level incinerator (N is more than or equal to 2) is arranged between a rotary kiln and a decomposing furnace; tertiary hot-blast air is introduced into the N-level incinerator, so that spiral upcurrent with the temperature of 850 DEG C is formed; the domestic garbage of which the moisture content is less than 10 percent is crushed into garbage materials of which the granularity is less than 30 millimeters, and a small quantity of the garbage materials are fed into a furnace body slowly through an air-lock feeder, and meet N-level dividing grates which are arranged from top to bottom to undergo the combustion, decomposition and gasification of organic matters; and generated acidic fume is discharged to the decomposing furnace through smoke outlets distributed at multiple positions uniformly, and after the decomposing furnace reaches the furnace temperature of over 900 DEG C and is in the state of alkalinity, the acidic fumes can be further subjected to neutralization treatment to reach discharging standards finally. Ash residues of the garbage are discharged out of the furnace body by a totally-enclosed electric vibrating discharger, are conveyed to a kiln hood of the rotary kiln by conveying equipment to enter the rotary kiln, and are used as a raw component for producing cement for calcination and solidified in the cement finally, so that the treatment aim of the 'harmlessness, reduction and recycling' of the domestic garbage is fulfilled.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

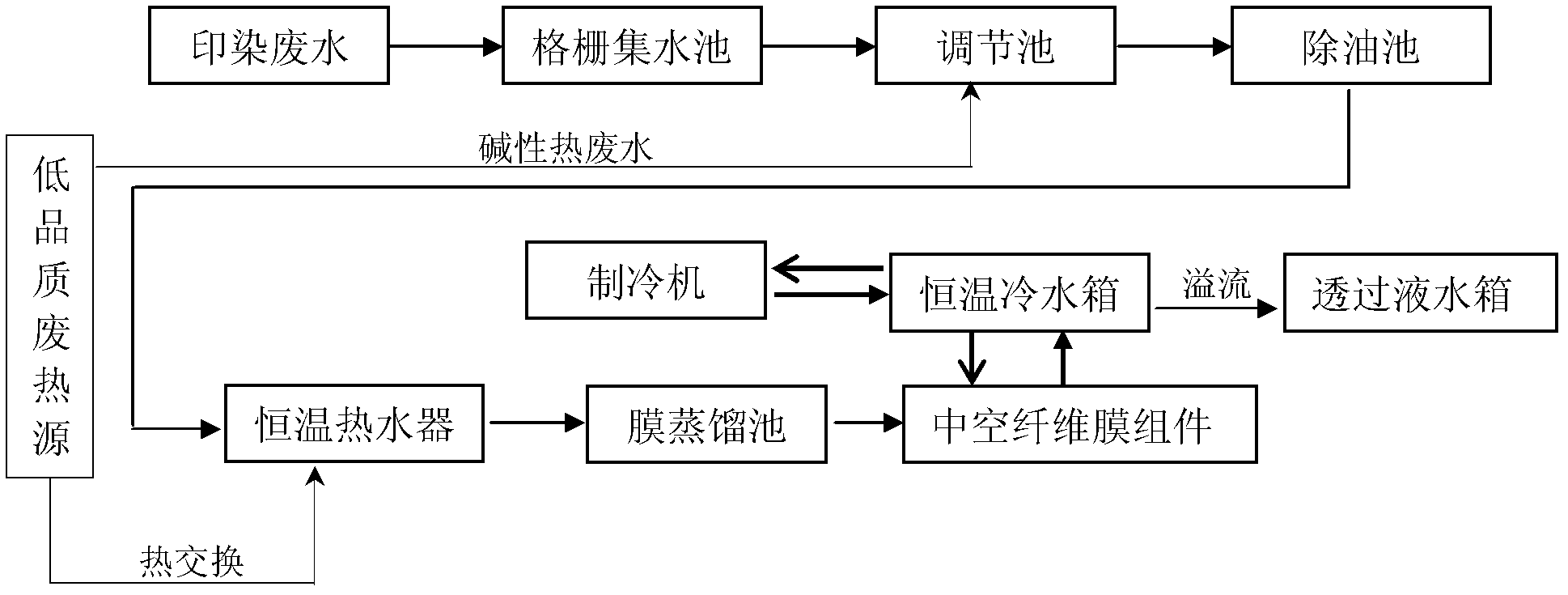

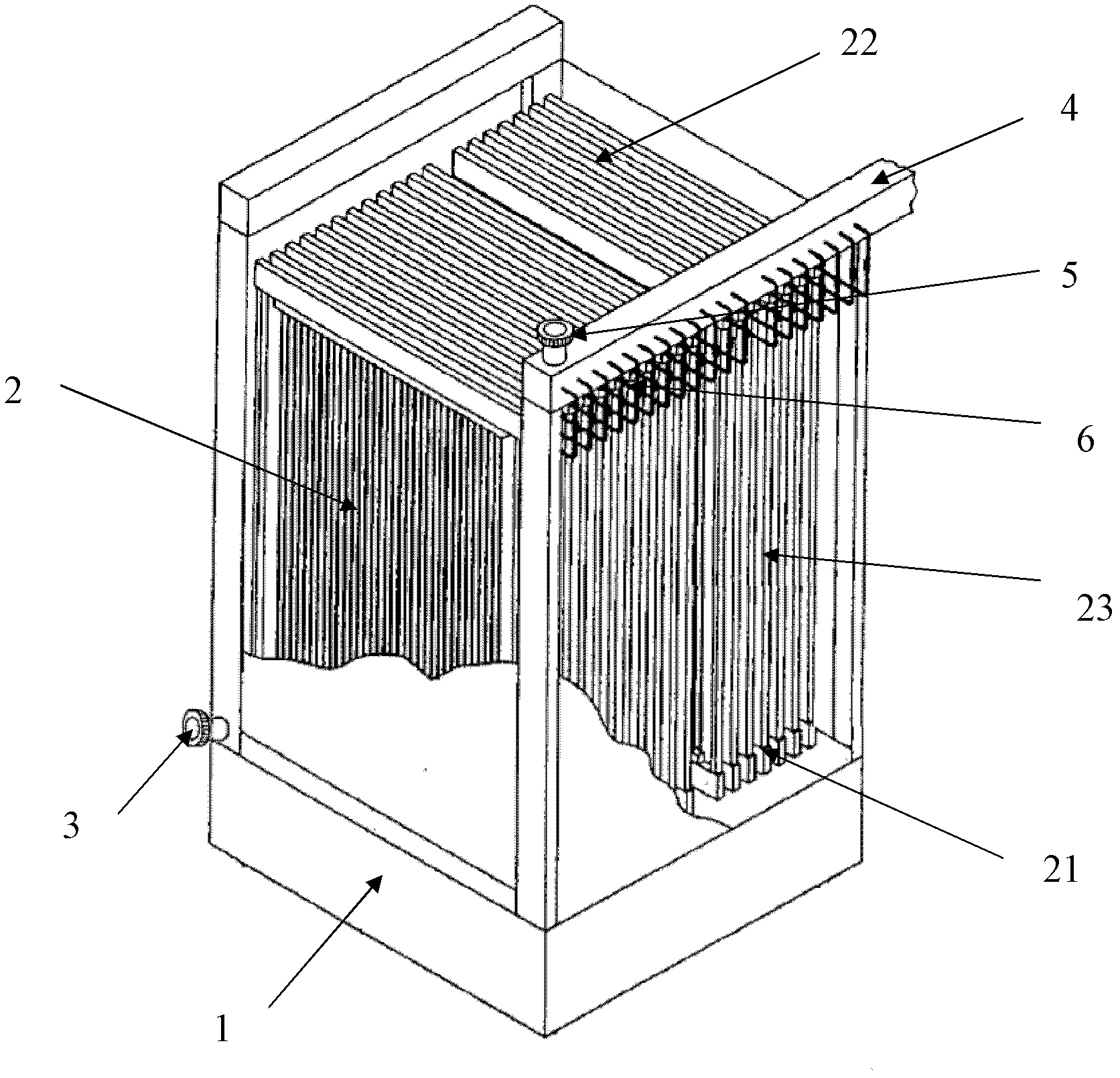

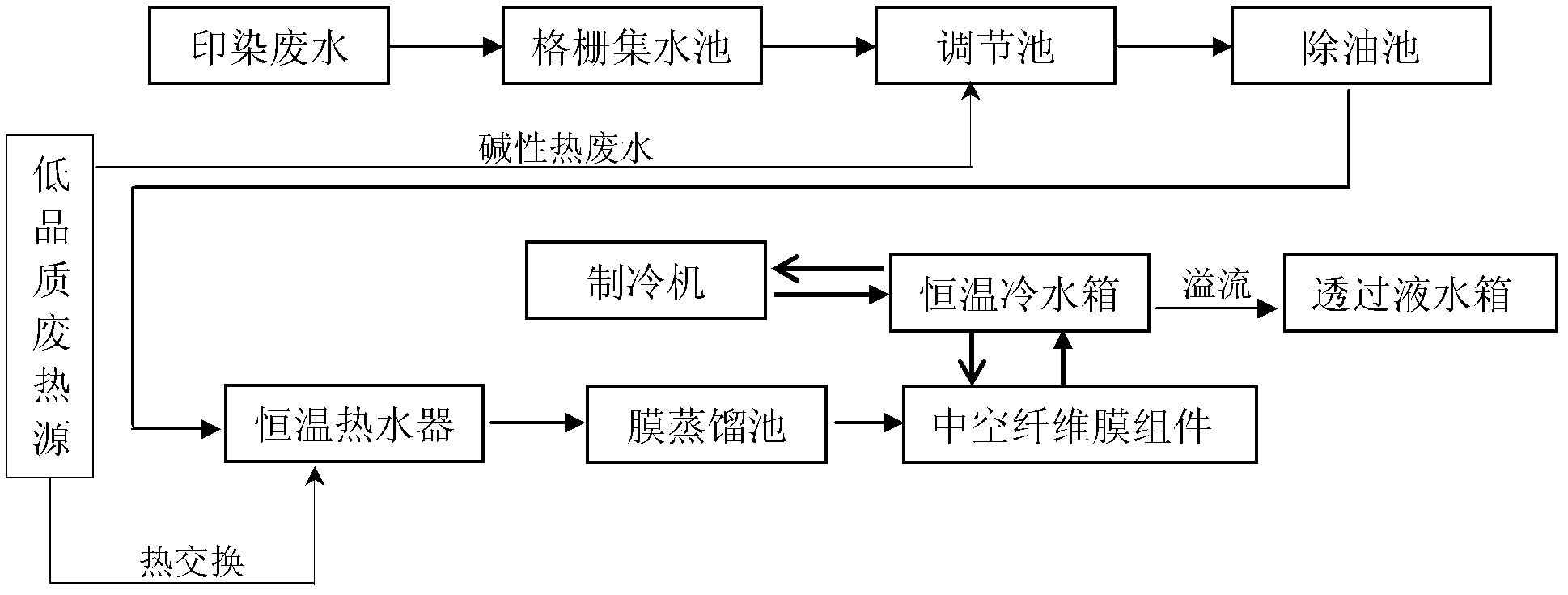

Membrane distillation process using hollow fiber membrane component to treat printing and dyeing wastewater

InactiveCN102553444AHigh desalination rateLow preprocessing requirementsGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater vaporMembrane distillation

The invention provides a membrane distillation process using a hollow fiber membrane component to treat printing and dyeing wastewater, which comprises the following steps of: 1, pretreatment of the printing and dyeing wastewater; and 2, membrane distillation: making pretreated wastewater flow into a constant-temperature water heater, heating the wastewater to 50-60 DEG C via heat exchange of a low-quality heat source produced in the printing and dyeing process and the constant-temperature water heater, making the wastewater flow into a membrane distillation tank with the hollow fiber membrane component, and making cold water of 10-15 DEG C flow into a hollow fiber membrane of the hollow fiber membrane component from a constant-temperature cold water tank when the hollow fiber membrane component is soaked in the wastewater so as to form a temperature difference between inside and outside the hollow fiber membrane. Therefore, water vapor in the wastewater can move from the outer side to the inner side of the fiber membrane and can be condensed by cold water on the inner side of the fiber membrane to be discharged. The desalination rate of wastewater treatment can be improved greatly. Meanwhile, the pretreatment requirements can be reduced, the treatment can be simplified, energy can be saved, emissions can be reduced, and the operating and maintenance costs can be decreased.

Owner:DD WATER GRP

Anaerobic digestion treatment method for organic garbages

ActiveCN102861762AReduce stabilityIncrease contact areaSolid waste disposalWaste based fuelAnaerobic reactorHydrolysis

The invention relates to an anaerobic digestion treatment method for organic garbages. The anaerobic digestion treatment method includes removing impurities such as large plastic bags and large metalware in kitchen garbages, lifting and dumping the kitchen garbages into a mechanical biochemical reaction to be subjected to hydrolytic acidification, discharging leaching residues through a residue outlet after squeezing and dewatering, feeding leaching liquid which is filtered roughly into a liquid groove and delivering the leaching liquid from a liquid outlet through a screw conveyor in the liquid groove, feeding the leaching liquid which is subjected to solid and liquid separation and filtering by a drum grill into an oil separating settling tank, enabling the leaching liquid which is subjected to oil and water separation to flow out of the oil separating settling tank, collecting oil and water mixed liquid by an oil collecting pipe and discharging the oil and water mixed liquid out of the settling tank, and lifting the oil-removed leaching liquid into an anaerobic reactor by a screw pump so as to carry out anaerobic digestion treatment. A part of outflow is used as spraying water, the other part of outflow is delivered by a drain pipe, and biogas generated is led into a gas pipe. The anaerobic digestion treatment method is reasonable in technology, capable of increasing hydrolysis and acidification efficiency of organic components and reducing content of residual organic components and low in treatment cost.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

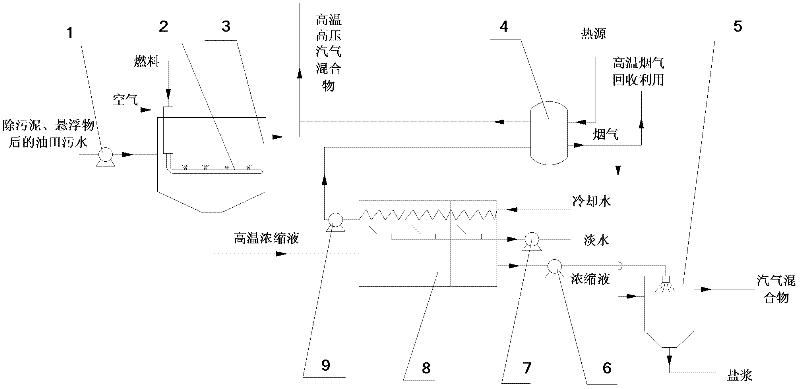

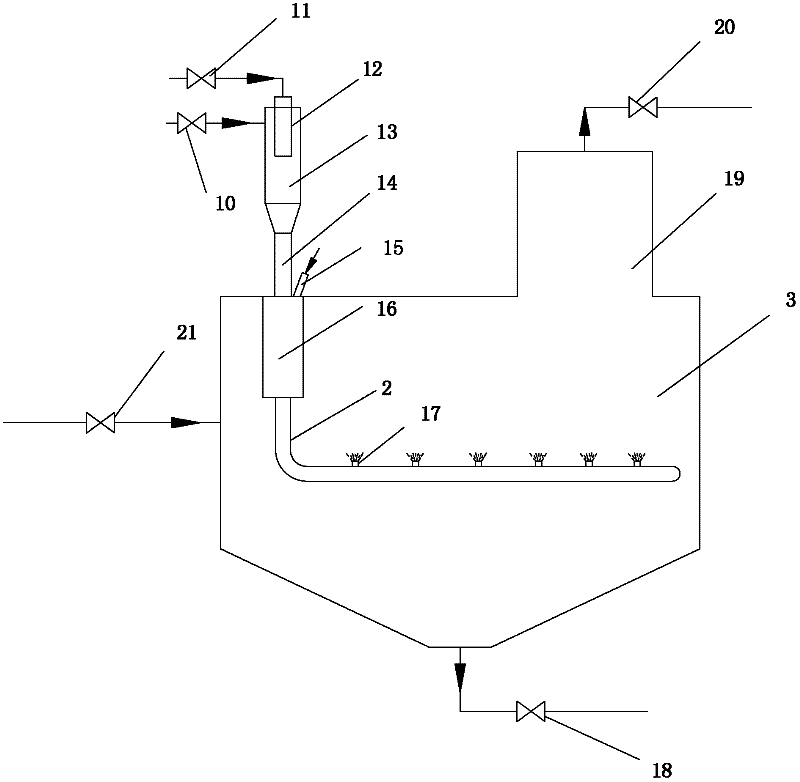

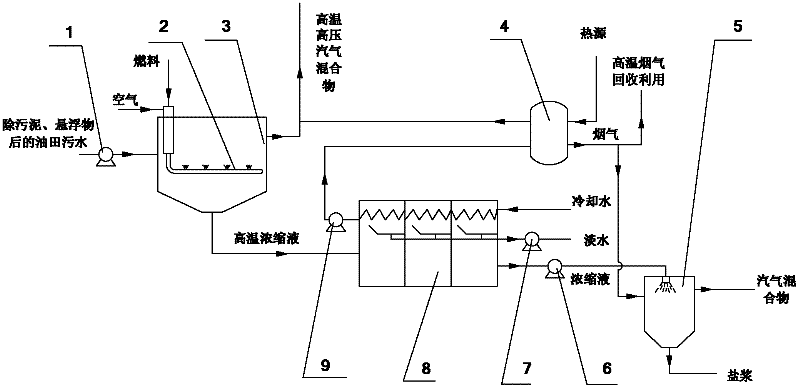

Device and technology capable of combining high-salt content oil field sewage treatment and viscous oil recovery

InactiveCN102351361AEasy to handleImprove heat transfer efficiencyFluid removalMultistage water/sewage treatmentWater productionHigh pressure water

The invention provides a device and a technology capable of combining high-salt content oil field sewage treatment and viscous oil recovery, and belongs to the technical field of sewage treatment. The device and the technology can be utilized for sewage treatment of a petroleum exploitation industry, a petroleum refining industry and chemical production processes, especially, realize high-efficiency treatment of high-salt content oil field sewage, and effectively combine high-salt content oil field sewage treatment and viscous oil recovery. The device is characterized mainly in that the device comprises a burning evaporator used in high pressure water, a multi-stage flash evaporation pot, a spray evaporator and a steam injection boiler. Through the device and the technology, advanced treatment of high-salt content oil field sewage is realized; fresh water and salt slurry can all be obtained; zero discharge is realized really; and waste water production is avoided. In addition, high-temperature high-pressure secondary steam and gas can be combined with boiler steam so that viscous oil can be recovered according to an optimal ratio and full utilization of energy is realized. The device has a compact structure, high efficiency and good economy. The technology is stable, reliable and novel oil field sewage treatment technology.

Owner:DALIAN UNIV OF TECH

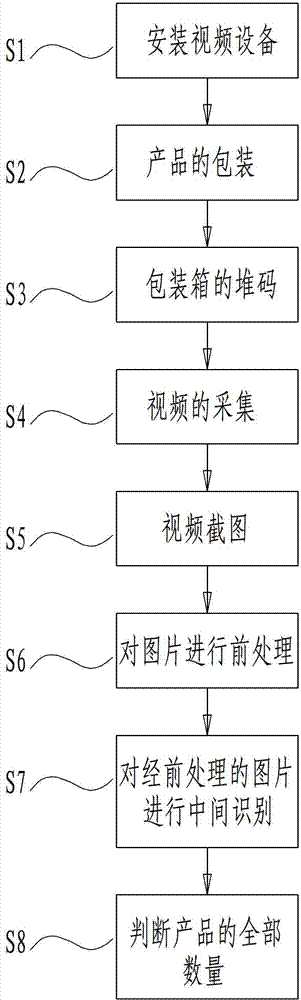

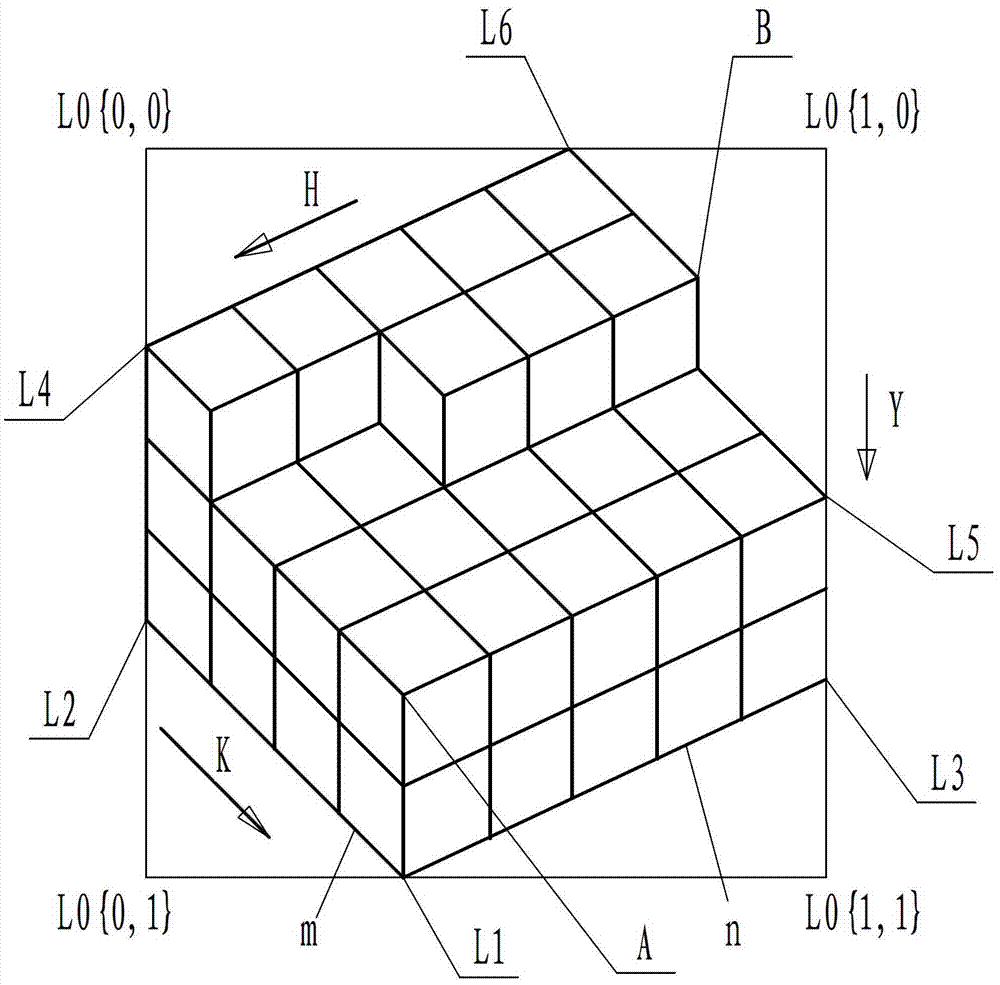

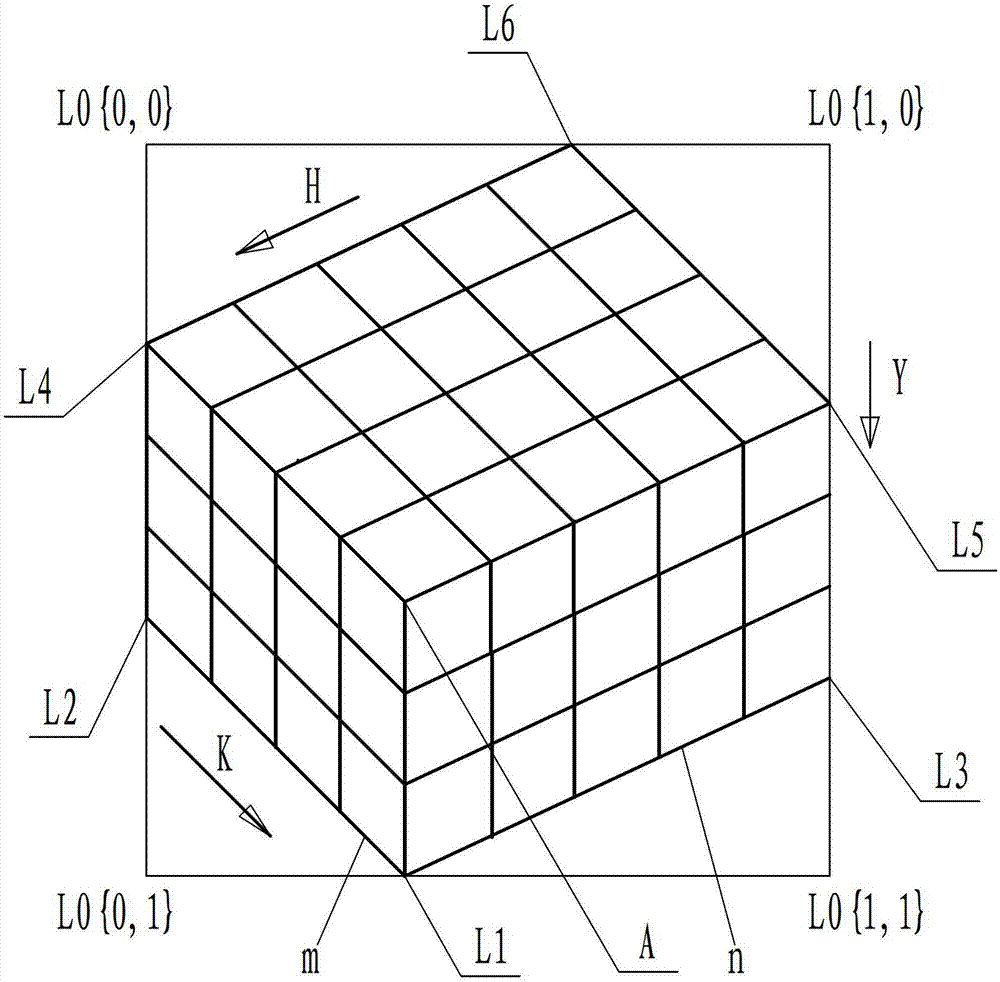

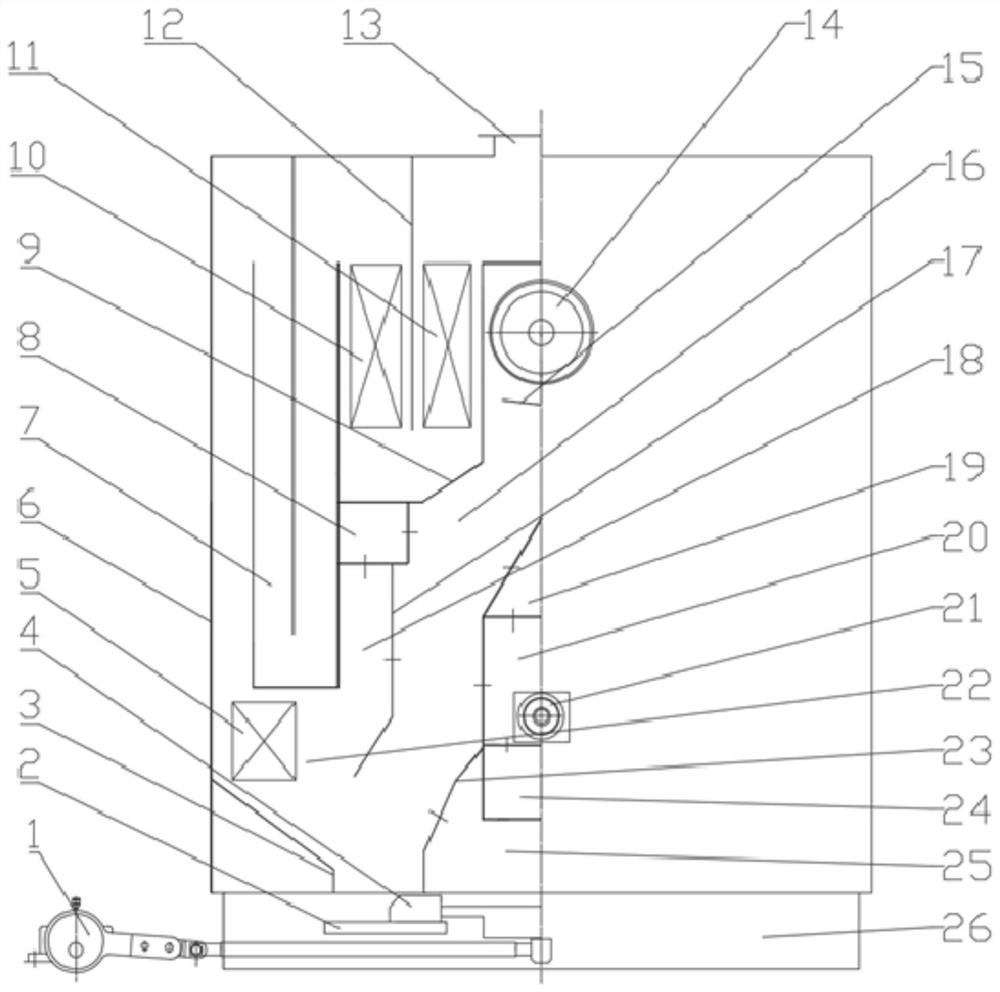

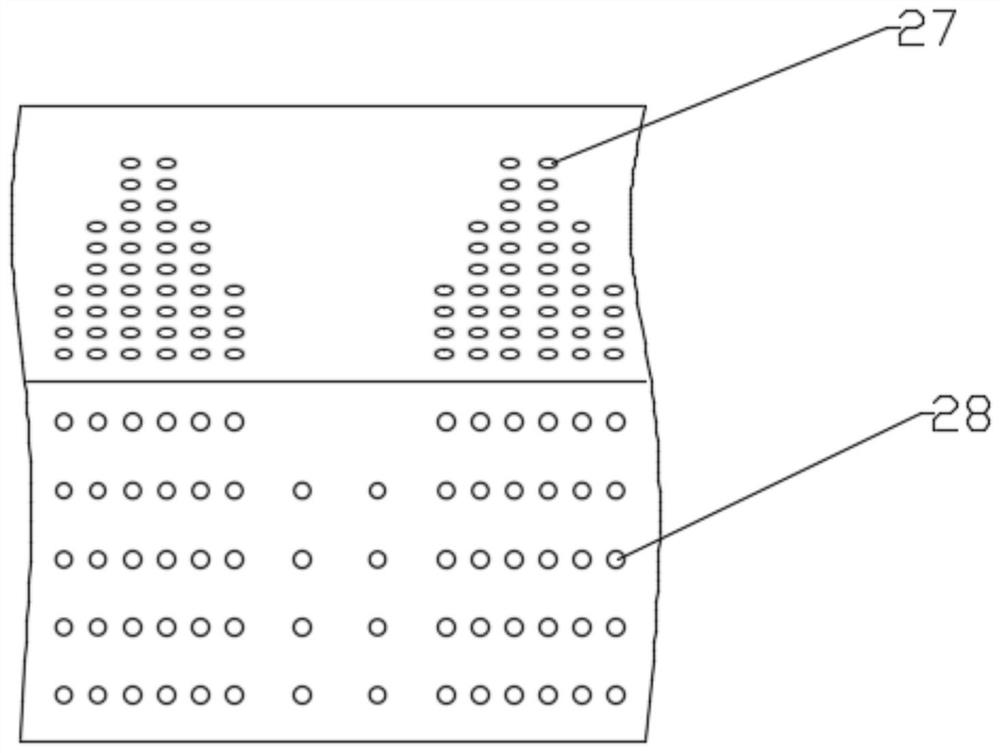

Image identification method for detecting product quantity

InactiveCN102930279ASimple methodImprove recognition accuracyCharacter and pattern recognitionPattern recognitionVideo equipment

The invention discloses an image identification method for detecting product quantity, and relates to an image identification method. The image identification method comprises the following steps of: S1, installing video equipment; S2, packaging products; S3, stacking packaging boxes; S4, acquiring videos; S5, performing video screenshot; S6, performing preprocessing on pictures; S7, performing intermediate identification on the preprocessed pictures; and S8, judging the total quantity of the products. The image identification method is simple and high in identification accuracy, the production cost can be reduced, labor intensity can be reduced, the production efficiency can be improved, and the image identification method can be popularized and applied to any just-in-time production enterprises.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

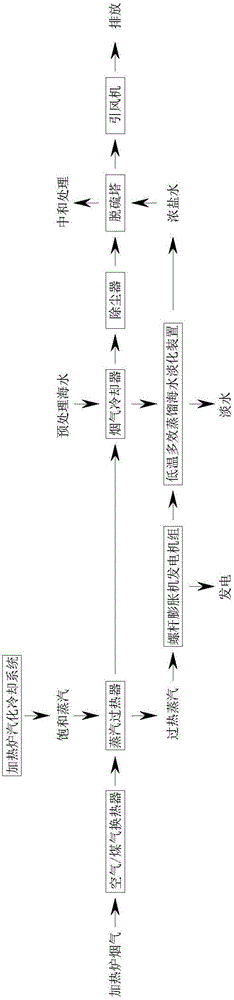

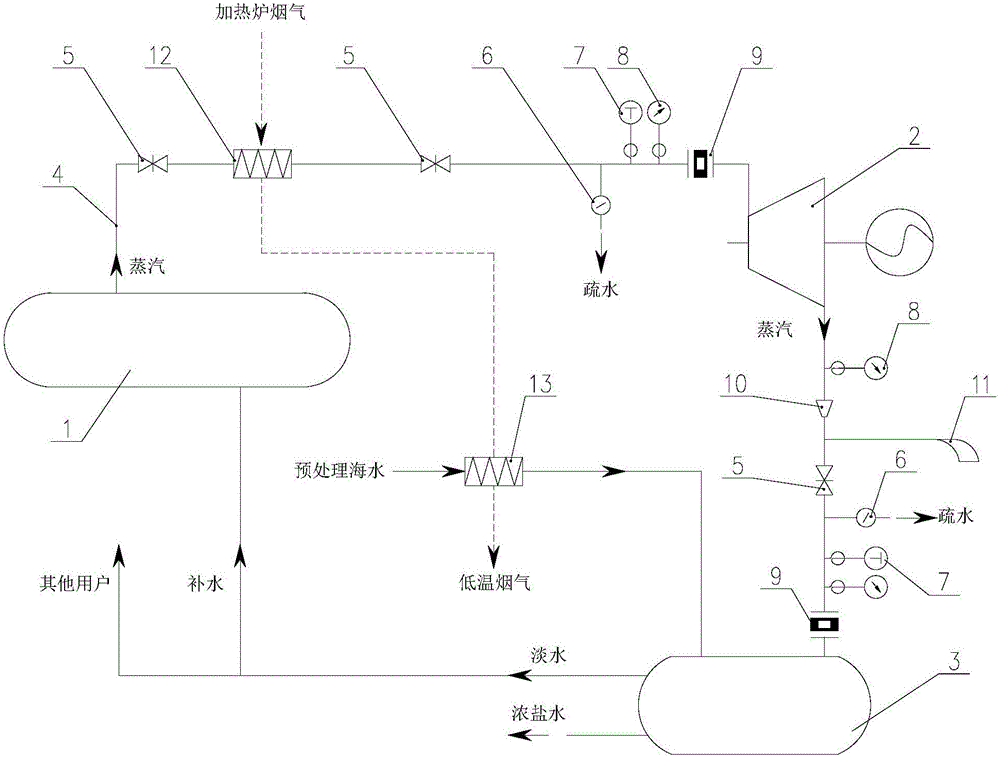

Heating furnace waste heat comprehensive utilization system and method

InactiveCN106052405ARealize cascade utilizationAddressing Adverse Effects of Power GenerationGeneral water supply conservationSeawater treatmentWater desalinationEngineering

The invention discloses a heating furnace waste heat comprehensive utilization system. The heating furnace waste heat comprehensive utilization system comprises a steam superheater, a power generator set and a sea water desalination device. The steam superheater is arranged in a heating furnace flue. Low pressure saturated steam generated by a heating furnace evaporated cooling system flows into the steam superheater and can be heated by heating furnace smoke to form superheated steam. The power generator set communicates with fluid of the steam superheater. The superheated steam generated in the steam superheater flows into the power generator set for power generation. The sea water desalination device communicated with fluid of the power generator set. The steam discharged by the power generator set flows into the sea water desalination device for sea water desalination. The invention further discloses a heating furnace waste heat comprehensive utilization method. Through the heating furnace waste heat comprehensive utilization system and method, gradient utilization of energy of the heating furnace steam is fully achieved, excessive pressure of the steam is used for power generation, and waste heat of the steam is further used for producing fresh water.

Owner:BERIS ENG & RES CORP

Rotary continuous microwave drier

The rotary continuous microwave drier includes one microwave drying oven with inner cavity with wall painted with one layer of PTFE, right and left parallel vertical baffles of metal plates surface painted with PTFE on the two sides of the oven, one 4-20 deg inclined rotary container with material feeding pipe and air exhaust pipe extending beyond the side oven all at the high end and material discharge pipe and air intake pipe extending beyond the side oven wall at the lower end, microwave suppressors set at the joints between each of the said pipes and the side oven wall. The apparatus dries material inside the container continuously and automatically, and the evaporated water vapor is limited inside the container and thus has no influence on the circuit, resulting in long service life and high operation safety of the equipment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

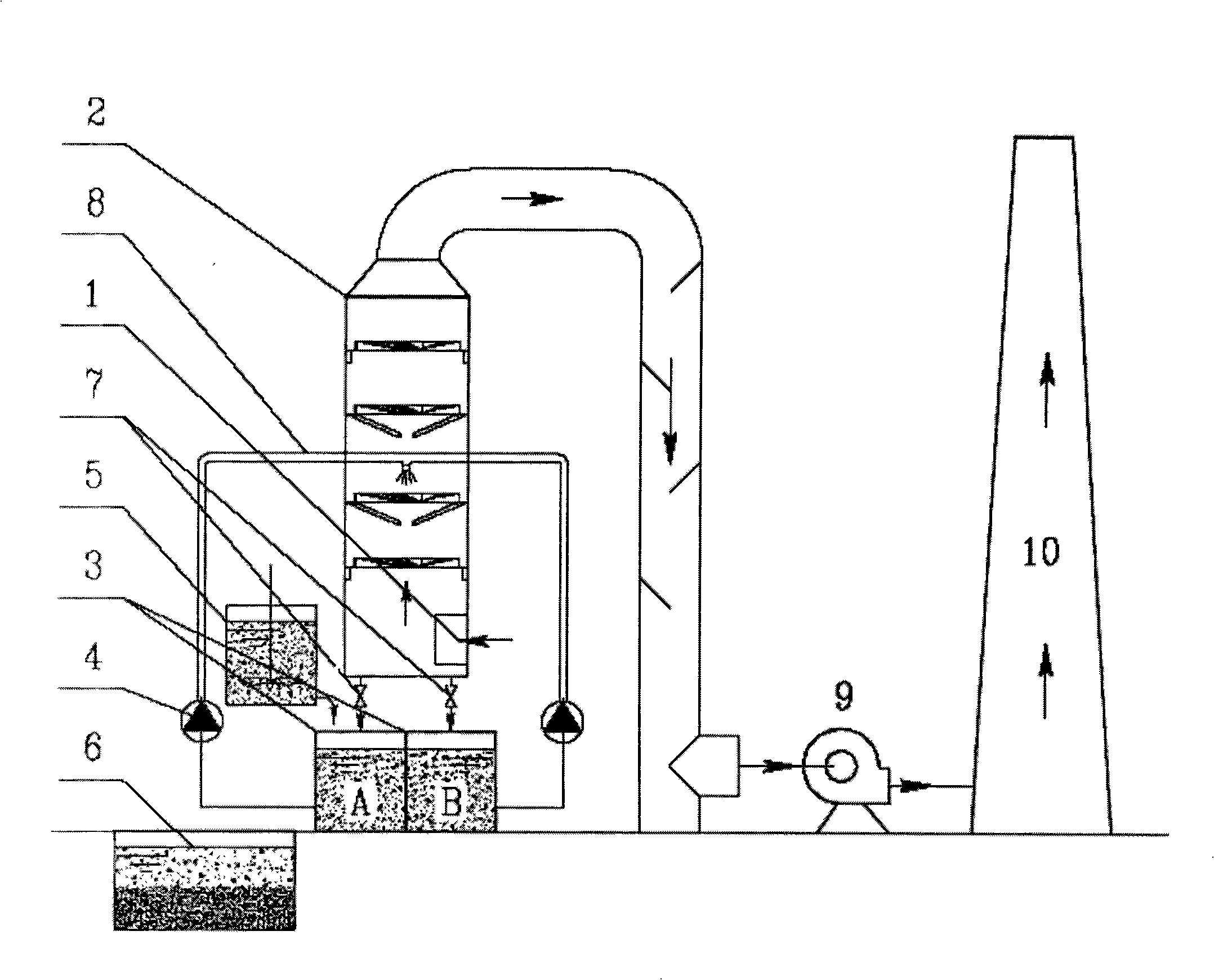

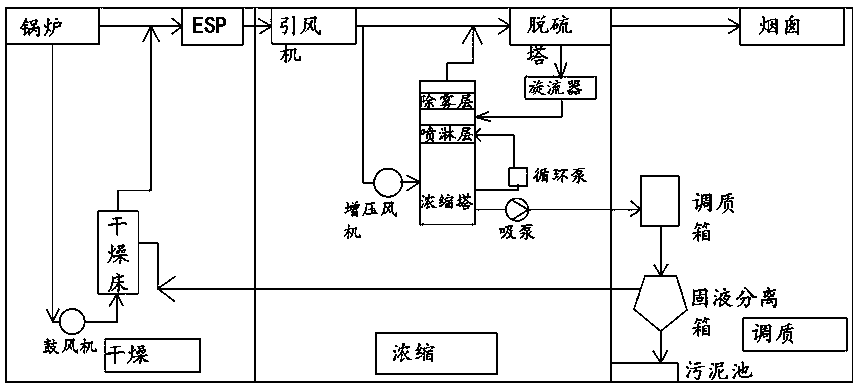

Sequencing batch limestone slurry wet desulfurization technique

InactiveCN101327395ASimple crafting systemLow by-product disposal requirementsDispersed particle separationSlagPH decrease

The present invention provides an order-batch-mode limestone mortar wet desulphurization process, in particular relates to a high-efficient limestone desulphurization process that adopts the limestone mortar as the desulphurization agent, and adopts the order-batch alternative absorption reaction, and adopts the high-efficient desulphurization tower as the desulphurization device, and adopts lower pH value, lower liquid-gas ratio and economical desulphurization rate, and adopts the desulphurization waste slag as the byproduct. Smoke enters into the high-efficient desulphurization device, and a group of limestone mortar is adopted as absorption agent for the smoke to be desulphurized, until the pH value is decreased to a pre-determined value, and the smoke is temporarily withdrawn and the absorption is stopped; the absorption solution is continued to be reacted with the tiny particle of CaCO3, until the pH value is returned to the original value, and then another group of limestone mortar is filled to be desulphurized until the pH decreases to the pre-determined value; the mortar is filled at one group by another group for alternative absorption and after the mortar is reacted with the CaCO3, a new group of limestone mortar is replaced; the waste mortar is discharged after being processed; the waste slag is processed after being dehydrated. The order-batch-mode limestone mortar wet desulphurization process saves the investment, and has low operation expense, and is simple to be operated and managed, and has wide application, and resolves the scale formation problem of the tower and pool.

Owner:贡有成

Method and mold device used for producing wide-width magnesium plates

InactiveCN109513762AAchieving continuous production requirementsHigh strengthExtrusion diesExtrusion control devicesMachiningDirect production

The invention relates to the technical field of magnesium plate production, in particular to a method and mold device used for producing wide-width magnesium plates. The mold device used for producingthe wide-width magnesium plates at least comprises an inner barrel which is provided with a blank material machining cavity; the blank material machining cavity comprises a mold cavity, a forward extruding area, a multi-corner equal-diameter angle extruding area and a magnesium plate outlet which sequentially communicate with one another from top to bottom; the forward extruding area is of a big-end-up conical structure; and the multi-corner equal-diameter angle extruding area is provided with at least two corners. According to the method and mold device used for producing the wide-width magnesium plates, the two manners of forward extruding and multi-corner equal-diameter angle extruding are combined, wide-width magnesium alloy medium thick plates and thin plates with high plasticity canbe directly produced in one machining travel, the continuity production requirement of the magnesium plates is met, the production efficiency is improved, and the rate of finished products of the magnesium alloy plates and the finished product quality are improved.

Owner:TSINGHUA UNIV

Continuous circulating pipe membrane bioreactor

ActiveCN102963972AIncrease concentrationExtended stayTreatment using aerobic processesSustainable biological treatmentSewageMembrane bioreactor

The invention discloses a continuous circulating pipe membrane bioreactor which comprises a reactor body, wherein at least one contact oxidation cabinet is arranged in the reactor body; the contact oxidation cabinet is connected with a circulating pipe membrane group through a water inlet pump; the circulating pipe membrane group at least comprises a pipe membrane and a circulating pump; the pipemembrane and the circulating pump are mutually connected in series through a backflow pipeline to form a circulating loop; a pipe cavity of the pipe membrane is communicated with a concentrate backflow pipe; a filtering cavity on the outer side of the pipe membrane is communicated with a discharge pipe; and when in work, the ratio V1 / V3 of the water inlet flow V1 flowing through the water inlet pump to the filtered clear liquid flow V3 of the circulating pipe membrane group is 2-10, and the ratio V2 / V3 of the circulating flow V2 flowing through the inner cavity of the pipe membrane to the filtered clear liquid flow V3 is 2-50. The pipe membrane bioreactor disclosed by the invention has the advantages of high efficiency in removing organic pollutants, difficulty in polluting a filter membrane and long service life, and is suitable for centralized treatment of domestic sewage of the ocean engineering equipment and ships as well as cities, houses or other people-intensive areas.

Owner:DONGTAI CITY DONGFANG MARINE FITTING

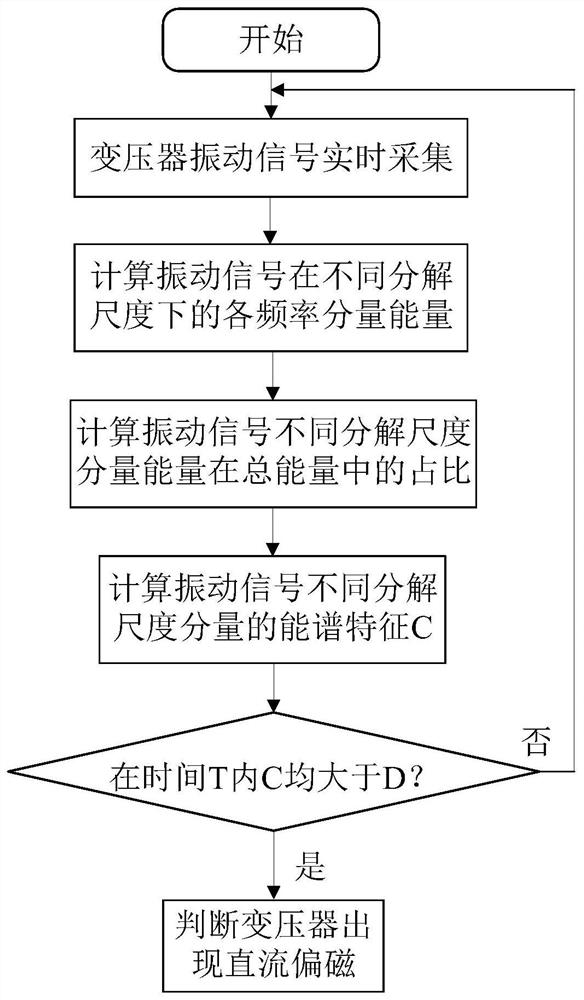

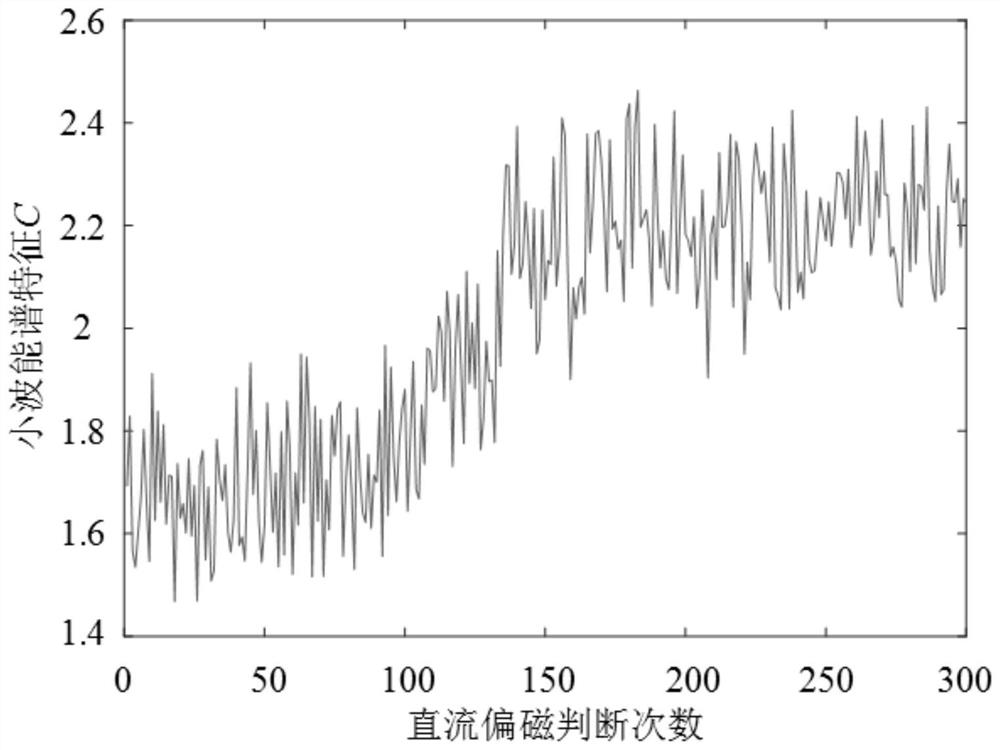

Transformer DC magnetic bias judgment method based on wavelet energy spectrum characteristics of vibration signals

ActiveCN111735533AAccurate extractionFast extractionSubsonic/sonic/ultrasonic wave measurementElectrical testingTransformerComputational physics

The invention discloses a transformer DC magnetic bias judgment method based on wavelet energy spectrum characteristics of a vibration signal. The method comprises the following steps: A, acquiring the vibration signal of a transformer and processing the acquired signal; B, judging the DC magnetic bias of the transformer according to the energy spectrum characteristics of the vibration signal frequency component energy distribution sequence; within the time T, if the wavelet energy spectrum characteristic C is always greater than the judgment threshold D, judging that DC magnetic bias occurs;otherwise, turning to the step 1. According to the invention, the technical problems that in the prior art, transformer DC magnetic bias judgment is high in requirement for effectiveness and accuracyof data, large in training amount, lack of theoretical basis, lack of evaluation on the DC magnetic bias state, prone to being disturbed by other factors, lack of persuasion, low in accuracy and reliability and the like are solved.

Garbage treatment rotary kiln system

InactiveCN104214782AAvoid resynthesisPrevent cryogenic emissionsIncinerator apparatusSlagHazardous substance

The invention provides a garbage treatment rotary kiln system which comprises a kiln tail seal chamber, a rotary kiln body, a kiln head seal chamber, a heat exchange device, a mixed gas cooling device and a dehumidifying device. The kiln tail seal chamber is arranged at a feeding end of the rotary kiln body, the kiln head seal chamber is arranged at a slag discharging end of the rotary kiln body, a garbage inlet flat pipe of the kiln tail seal chamber is communicated with the dehumidifying device, the kiln head seal chamber is communicated with the heat exchange device, the heat exchange device is communicated with the dehumidifying device, and a slag discharging device is arranged at the bottom of the kiln head seal chamber. The garbage treatment rotary kiln system is specially used for treating garbage and hazardous substances, garbage pretreatment requirements are low, and operating cost is further reduced.

Owner:刘继清

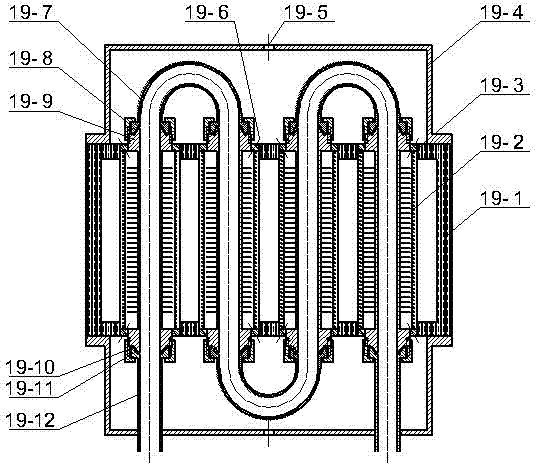

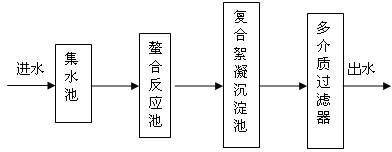

Method for removing nickel in chemical nickel-plating wastewater

InactiveCN102120659ALow preprocessing requirementsShorten the working cycleWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention discloses a method for removing nickel in chemical nickel-plating wastewater, comprising the steps of: (1) chelation reaction: reacting nickel in wastewater with a chelant to form a nickel chelate; (2) composite flocculation precipitation: subjecting a polymeric Mg-Fe composite flocculant and the nickel chelate obtained in the step (1) to composite flocculation precipitation; and (3) multimedium filtration: filtering the wastewater subjected to the composite flocculation precipitation in the step (2) by adopting a multimedium filter method. The treated wastewater is discharged when nickel content in outflow water reaches the standard. The method has the advantages of good treatment effect, simplicity for operation and management and low operation cost and is a good method for removing the nickel in the chemical nickel-plating wastewater.

Owner:无锡市霄鹰环境科技有限公司

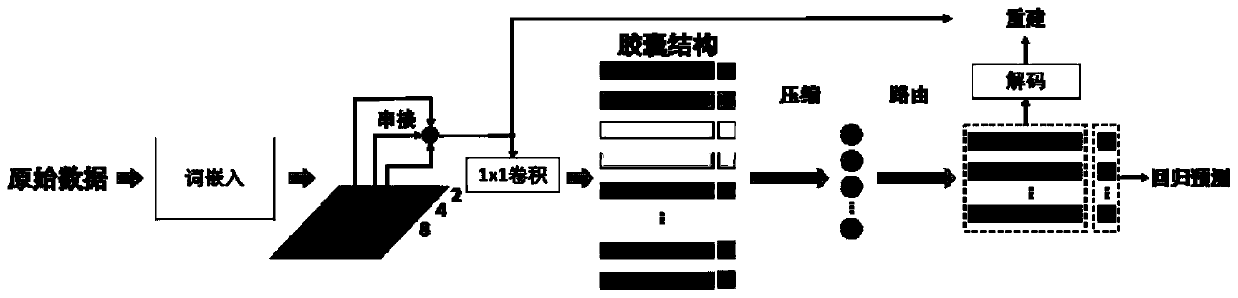

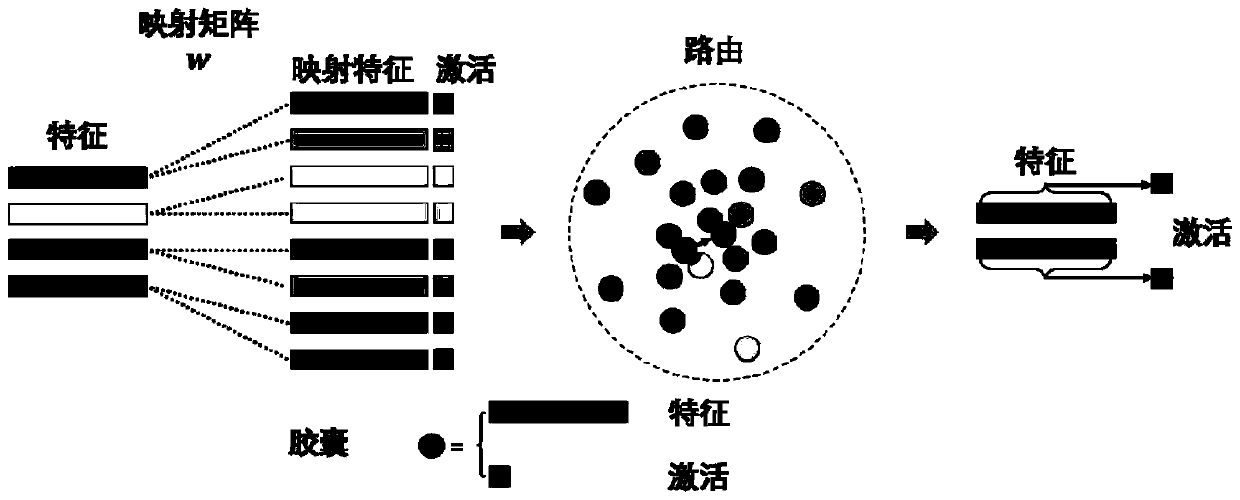

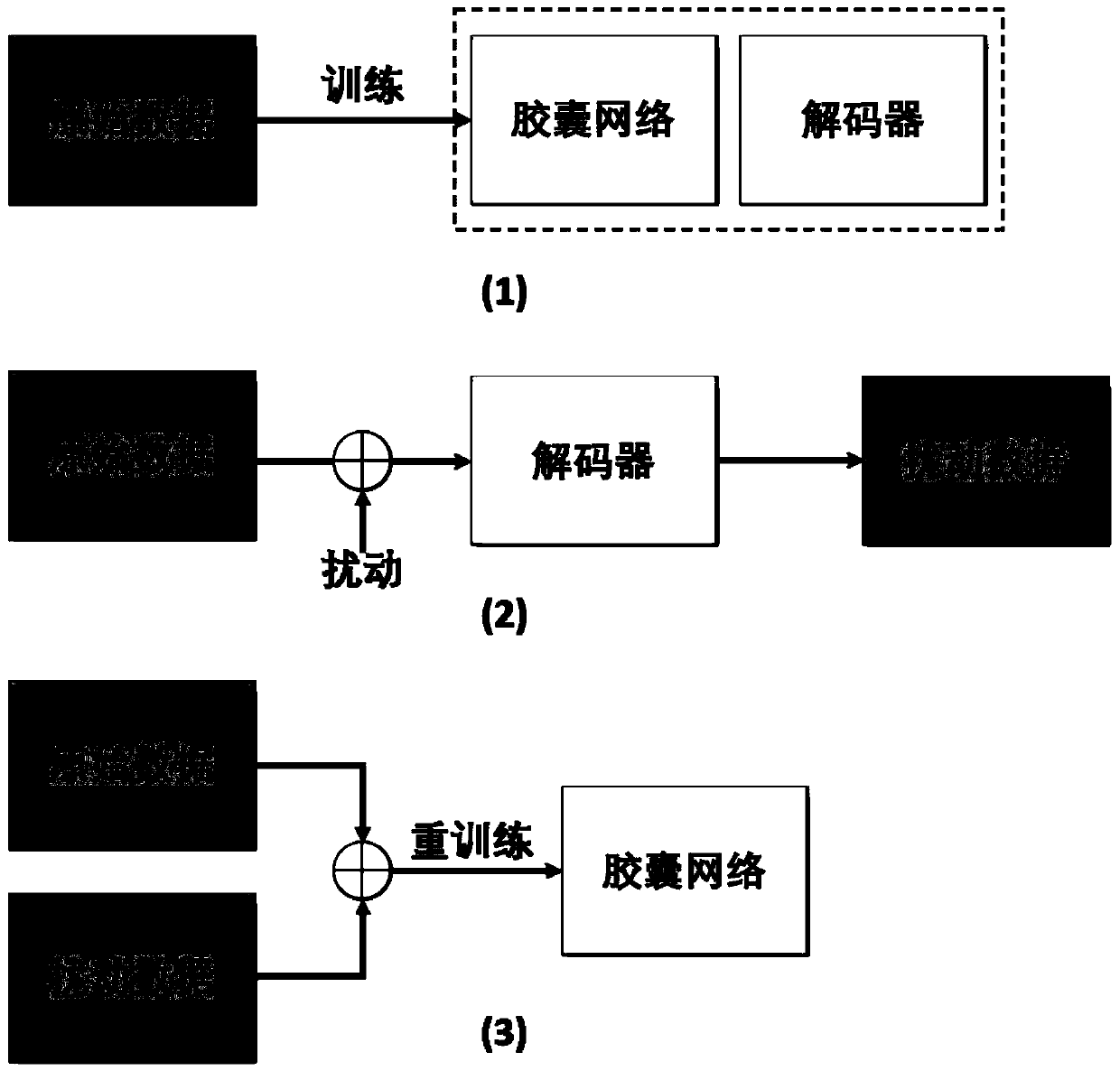

Electric power communication network equipment reliability evaluation method based on capsule network

ActiveCN111080168AImprove versatilityImprove completenessCharacter and pattern recognitionNeural architecturesFeature extractionAlgorithm

The invention discloses an electric power communication network equipment reliability evaluation method based on a capsule network. The method comprises the following steps: carrying out reliability evaluation on equipment through a trained electric power communication network equipment reliability evaluation model, wherein the model construction process comprises the following steps of processingthe text information of the operation and maintenance data through a word embedding method to obtain an input word vector; carrying out feature extraction on the input word vector by using convolution filters with different sizes, combining the extracted features in a serial connection manner, and further carrying out convolution filtering on each position where the features are obtained by usingthe convolution filter to form a capsule feature vector; binding an activation value to each capsule feature vector; compressing the number of capsules, and then obtaining a new capsule feature vector and a new activation value through a capsule routing method based on kernel density estimation, wherein the new activation value is used for regression prediction; and inputting the new capsule feature vector into a decoder to reconstruct an input feature. The method can conveniently and accurately evaluate the reliability of the power communication network equipment.

Owner:INFORMATION & COMM BRANCH OF STATE GRID JIANGSU ELECTRIC POWER +1

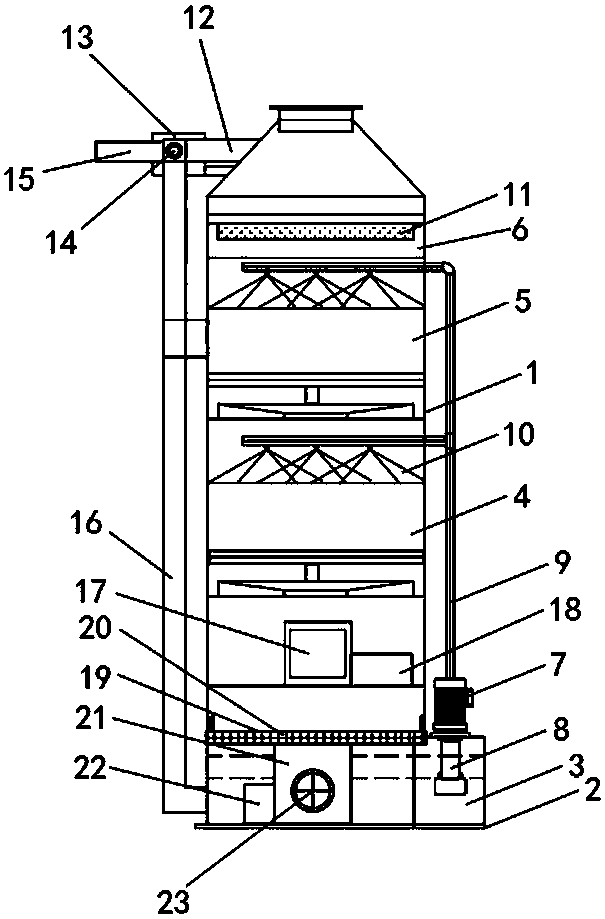

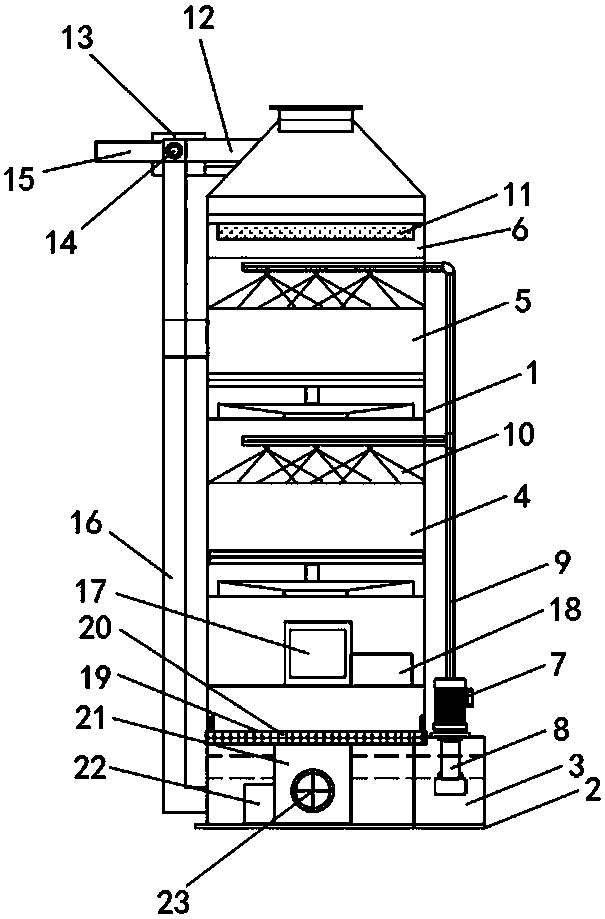

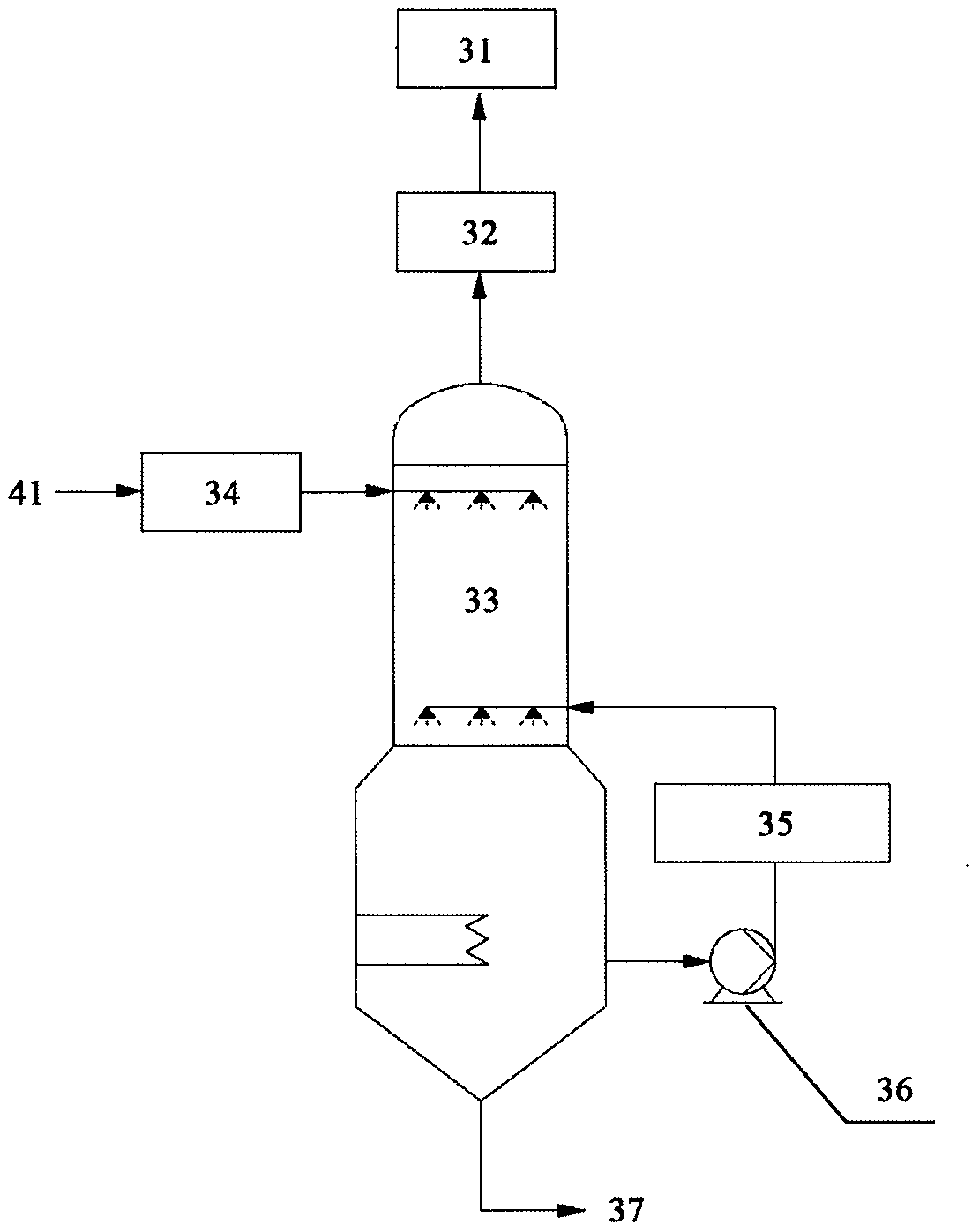

Zero-emission and low-energy-consumption concentration tower

InactiveCN111138016AReduce energy consumptionSolve the problem of energy consumptionTreatment involving filtrationWaste water treatment from gaseous effluentsCirculator pumpEngineering

The invention discloses a zero-emission and low-energy-consumption concentration tower. The zero-emission and low-energy-consumption concentration tower can solve the problems of high desulfurizationwastewater operation cost, complex treatment process and real zero emission of desulfurization wastewater, which are not solved by a traditional wastewater treatment method for a concentration tower.The zero-emission and low-energy-consumption concentration tower comprises a tower body and a bottom pool, wherein a first spraying layer, a second spraying layer and a demisting layer are sequentially arranged in the tower body from bottom to top; a demister is mounted in the demisting layer; a connecting pipe is connected with and arranged on the side wall of the top part of the demisting layer;one end of the connecting pipe is connected with a gas circulating pump; a guide pipe and a gas circulating pipe which are perpendicular to each other are connected with and arranged on the side wallof the gas circulating pump; the bottom end of the gas circulating pipe is guided into the bottom pool; an electromagnetic valve is installed at the joint of the guide pipe and the gas circulating pipe; a plurality of spray heads are installed in the first spray layer and the second spray layer; a tower tray is installed at the bottom part of the interior of the tower body; and a PLC is installedon the outer wall of the tower body.

Owner:LIBAO TECH

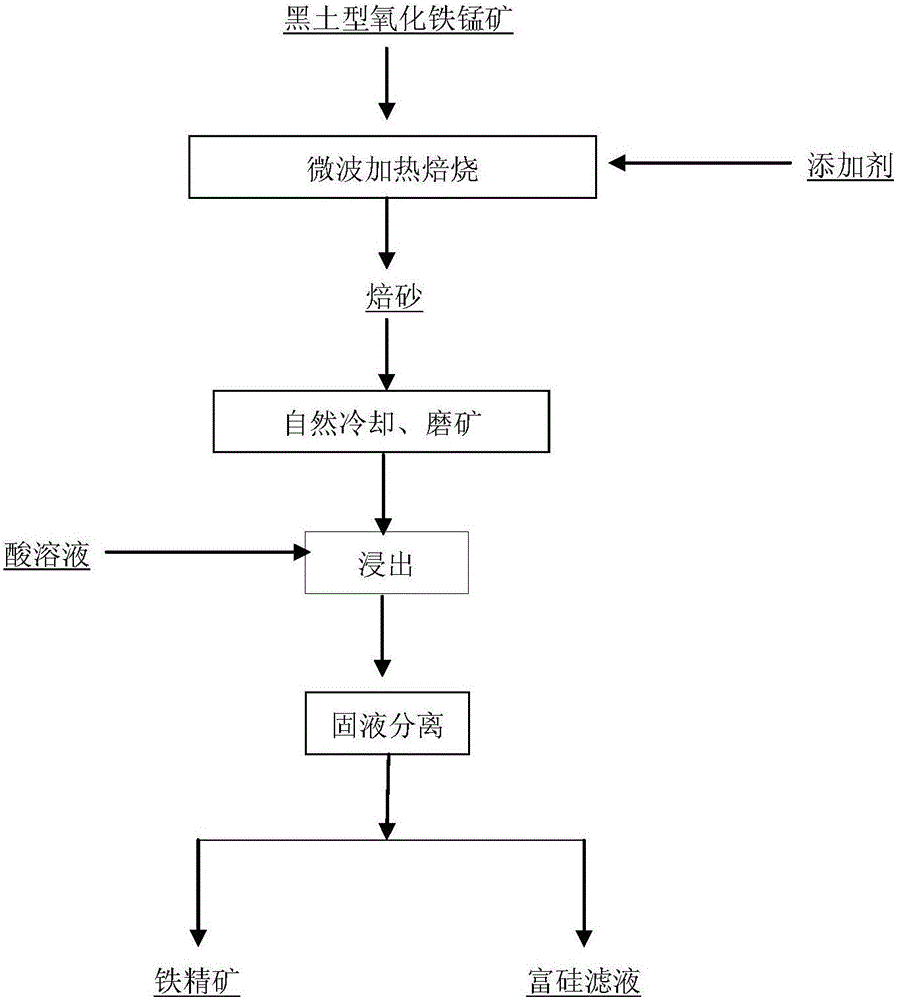

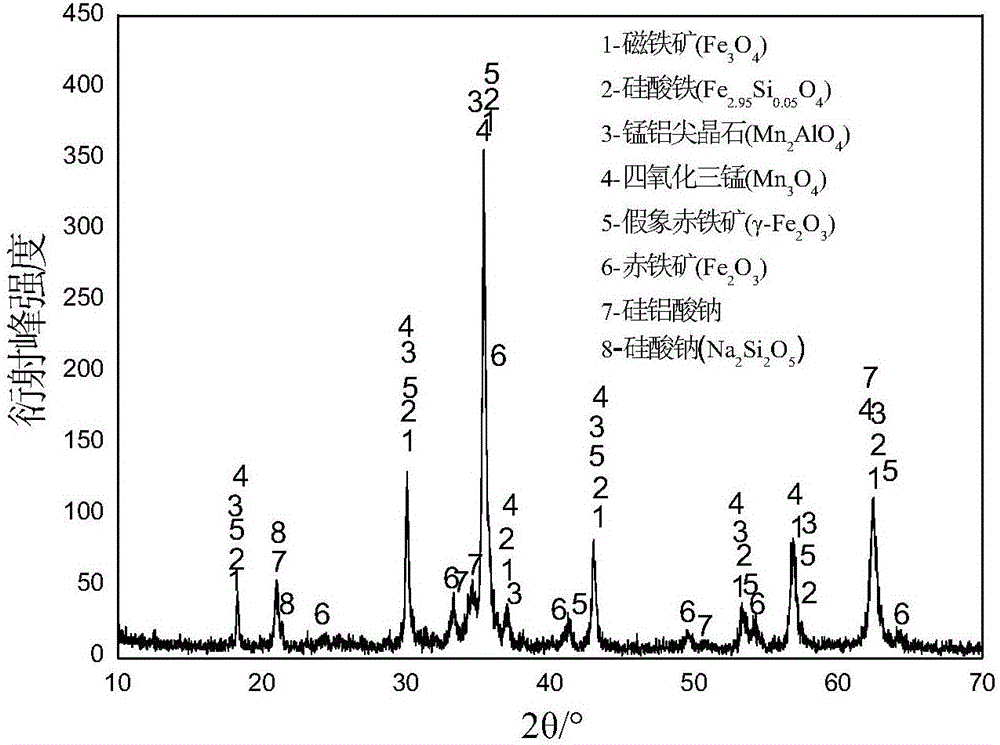

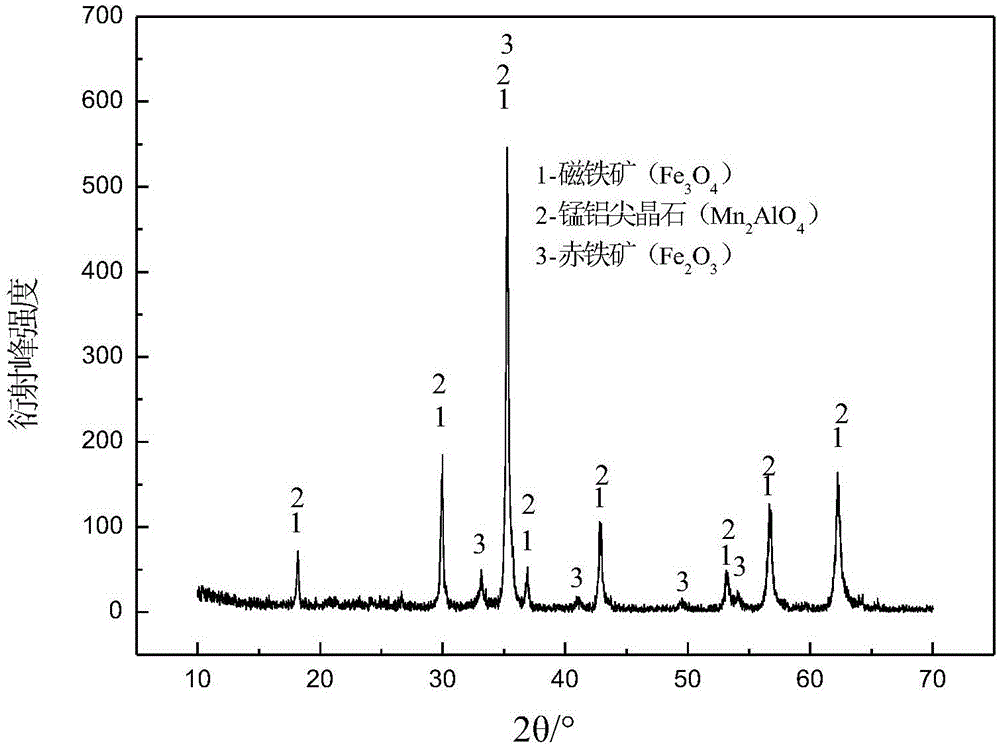

Chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation

ActiveCN106544502ARealize resource utilizationLow preprocessing requirementsSilicate mineralsPollution

The invention discloses a chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation. The chemical desiliconization method adopts microwaves to serve as a heating source so that silicon in silicate mineral can be quickly activated at the low temperature and then can react with alkali (soil) metallic oxide (salt) additives to generate acid-soluble salt, and the desiliconization purpose is achieved through an acid pickling process. The application of the chemical desiliconization method in black soil type iron oxide manganese ore beneficiation comprises the following steps that black soil type iron oxide manganese ore is crushed and ground to be 0.9 mm or less, then uniformly mixed with lignin additives and the alkali (soil) metallic oxide (salt) additives and put into a microwave reaction device for reducing roasting, and roasted ore is obtained; the roasted ore is cooled naturally and added into an acid solution to be subjected to stirring, leaching and desiliconization at the low temperature; and solid-liquid separation is conducted, and the obtained solid phase is iron ore concentrate. The chemical desiliconization method and application in black soil type iron oxide manganese ore beneficiation have the advantages of being low in pretreatment requirement, mild in reaction condition, high in desiliconization efficiency, small in acid consumption, high in iron recovery rate, free of pollution, controllable and the like and have wide application prospects.

Owner:CENT SOUTH UNIV

Sewage purification method for oil production

InactiveCN101113041AReduce dosageReduce dehydration costsWater/sewage treatment by flocculation/precipitationPurification methodsSludge

The invention relates to a purification and treatment technique field for polluted air. The oil extraction wastewater purification method of the invention is that: activated magnesia oxide 50 to 500mg / L is directly added to pretreated thick oil wastewater (oil content lower than 30mg / L, suspension lower than 1000mg / L); the mixture enters into an eddy reactor, after mixing and reaction for 1 to 15 minutes, inorganic aluminum salt and organic flocculating agent are added to water out and then enter into a sludge reactor; the sludge reactor generates return sludge by 1 to 6 times of the water in through top return pump or a lifting and stirring device, the return sludge fully mixes with water in for 10 to 60 minutes and comes into a clarification and precipitation device; after 30 to 90 minutes of clarification and precipitation, silicon dioxide and suspensions are removed, and the water out enters into the next stage treatment device, sludge is discharged from a sludge groove, thus reaching the target of silicon removing and water purification.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

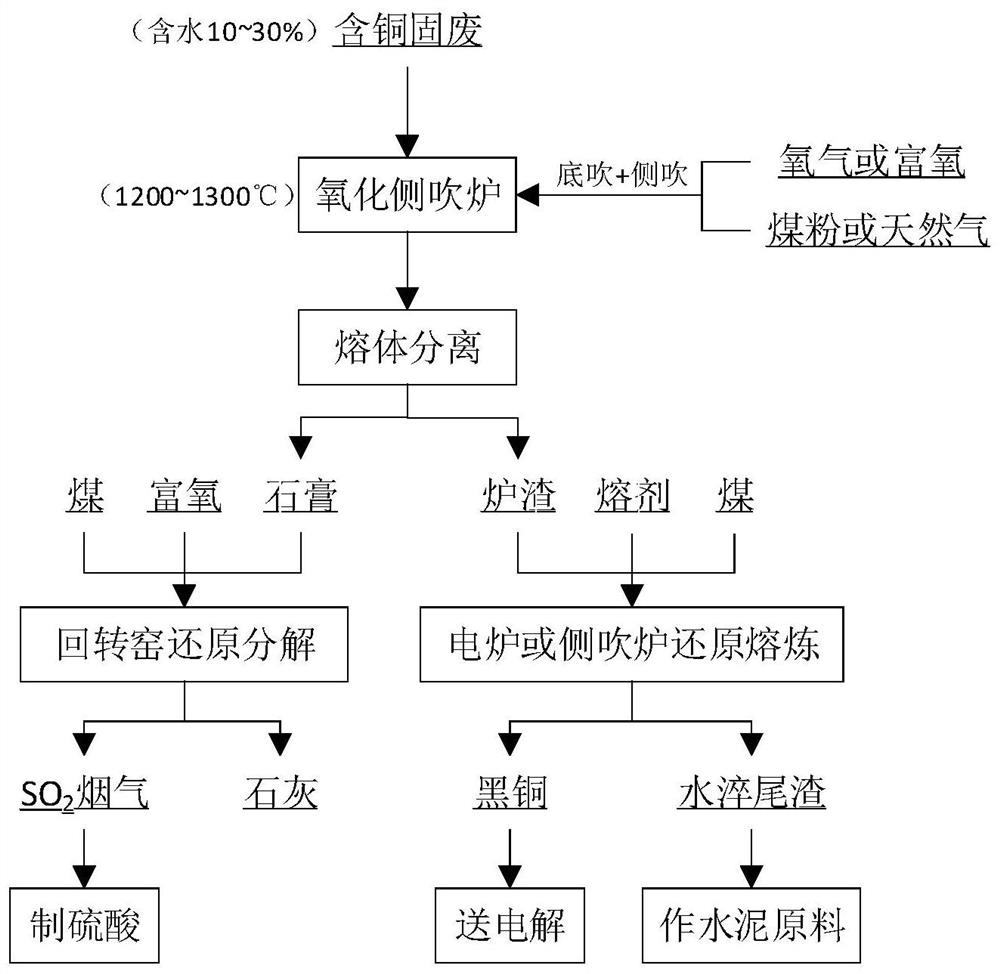

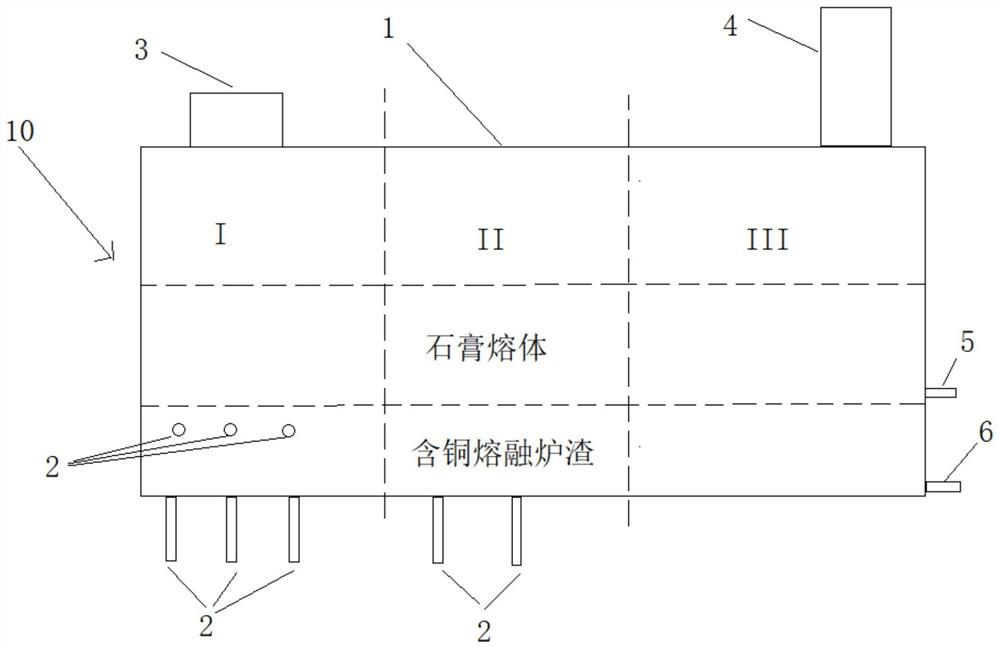

Method for separating copper-containing solid waste

ActiveCN111647749ALow preprocessing requirementsRemarkable effect of energy saving and consumption reductionProcess efficiency improvementCopperOrganic matter

The invention discloses a method for separating copper-containing solid waste. The method comprises the following steps of a, performing copper-containing solid waste granulation and drying pretreatment to obtain copper-containing solid waste particles; and b, placing the copper-containing solid waste particles into an oxidation side blown converter melting pool, wherein the oxidation side blown converter melting pool temperature is 1200-1300 DEG C, melting the copper-containing solid waste particles to obtain an upper-layer gypsum melt and lower-layer copper-containing molten slag. Accordingto the method, the copper-containing solid waste with high calcium, high sulfur, low silicon and low iron characteristics can be treated, the raw material pretreatment requirement is low, the problemsof high temperature, high energy consumption, a large amount of smoke, large organic matter volatilization amount and the like of deep drying pretreatment are avoided, and the method has the remarkable energy-saving and consumption-reducing effects, and has the high treatment capacity for the copper-containing solid waste.

Owner:CHINA ENFI ENGINEERING CORPORATION

Alga type hollow fiber ultrafiltration membrane filter device

InactiveCN101450283AStrong swingReduce foulingUltrafiltrationWater/sewage treatment bu osmosis/dialysisActivated sludgeFiber

The invention relates to an algae type hollow fiber ultrafiltration membrane filter device. Hollow fibers which are prior fixed on two ends are fixed on one end so as to form an algae floating type structure. A reticular support is adopted for the internal structure of a hollow fiber membrane silk, namely, a reticular support layer is added below a membrane silk separation layer of the hollow fiber ultrafiltration membrane. The algae type hollow fiber ultrafiltration membrane filter device is used for efficiently removing suspended matters, organic matters, colloids, microbes, and the like in water. The algae type hollow fiber ultrafiltration membrane filter device belongs to the technical field of membrane separation water treatment. The device is integrated with an activated sludge method to form a membrane bioreactor MBR without strict pretreatment. Therefore, the device can be applied to sewage treatment projects.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

Saline water membrane separation system for treating high-salinity high-organic substance waste water

PendingCN107792986AIncrease profitHigh salt and high utilization rateFatty/oily/floating substances removal devicesWater contaminantsSaline waterReverse osmosis

The invention discloses a saline water membrane separation system for treating high-salinity high-organic substance waste water. The system comprises a filter unit, a saline water membrane separator and a concentrated water circulation filter unit; the water inlet of the filter unit is connected with a to-be-treated high-salinity high-organic substance waste water inlet, the outlet of the filter unit is communicated to the saline water membrane separator, and the saline water membrane separator is provided with the concentrated water circulation filter unit; the saline water membrane separatorcomprises a top cover, an upper flange plate, a shell, a lower flange plate, a membrane component and a liquid collecting groove; the concentrated water circulation filter unit is arranged between acirculating water outlet and a circulating water spraying part. The saline water membrane separation system has a low requirement for pretreatment, and can be used for treating the high-salinity high-organic substance waste water which cannot be treated by reverse osmosis; the membrane has strong anti-pollution capacity, and the separator has the characteristics of high temperature resistance andcorrosion resistance; the system has a simple and compact structure, and is energy-saving, environment-friendly and easy to operate.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

Solid waste decoupling combustion device, solid waste decoupling combustion system device and combustion method of solid waste decoupling combustion device

PendingCN112879912AIncrease temperatureEasy to dry and heat up quicklyIncinerator apparatusCombustion systemFlue gas

The invention provides a solid waste decoupling combustion device, a solid waste decoupling combustion system device and a combustion method of the solid waste decoupling combustion device. The combustion device comprises a shell, wherein the interior of the shell is divided into a feeding combustion channel, a flue gas mixed combustion channel and a flue gas afterflame channel which are sequentially communicated through partition plates in the material flowing direction, and the feeding combustion channel is divided into a preheating drying area, a pyrolysis gasification area, a semi-coke area and a burnout area in the material flowing direction; an air distribution device is arranged below the feeding end in the feeding combustion channel, and vent holes are formed in the outer wall of the side, close to the preheating drying area and the pyrolysis gasification area, of the air distribution device; at least one deflection baffle is arranged in the flue gas afterflame channel, and a rotary deflection flue gas flow channel is formed in the flue gas afterflame channel through the deflection baffles; and an air-smoke heat exchanger is arranged in the flue gas afterflame channel close to the outlet. Through the reasonable flue and air distribution design and the optimized combustion process, materials are fully combusted, and the combustion device has the advantages of being compact in structure, small in pollutant emission and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Electroplating process for copper wires

The invention discloses an electroplating process for copper wires. The process comprises the following steps: (1) deoiling; (2) cleaning with running water; (3) baking; (4) electroplating; (5) carrying out water washing; (6) carrying out spin-drying, and packaging. According to the process, the requirements on pretreatment are low, the dispersing power is strong, and the current efficiency reaches over 95%; during electroplating, no precipitate is generated, and the consumption of electric energy is low; after electroplating, the combining power of a plated layer with a copper wire base body is good, and the plated layer is fine, purely white and glossy, so that the electroplating effect is good, and the service life is longer.

Owner:MINGGUANG XUSHENG TECH

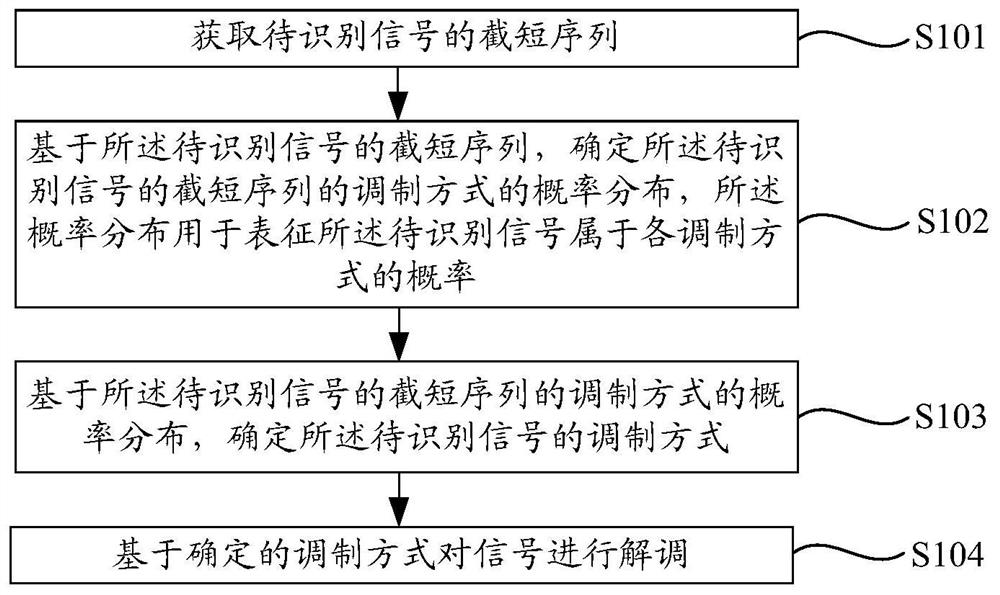

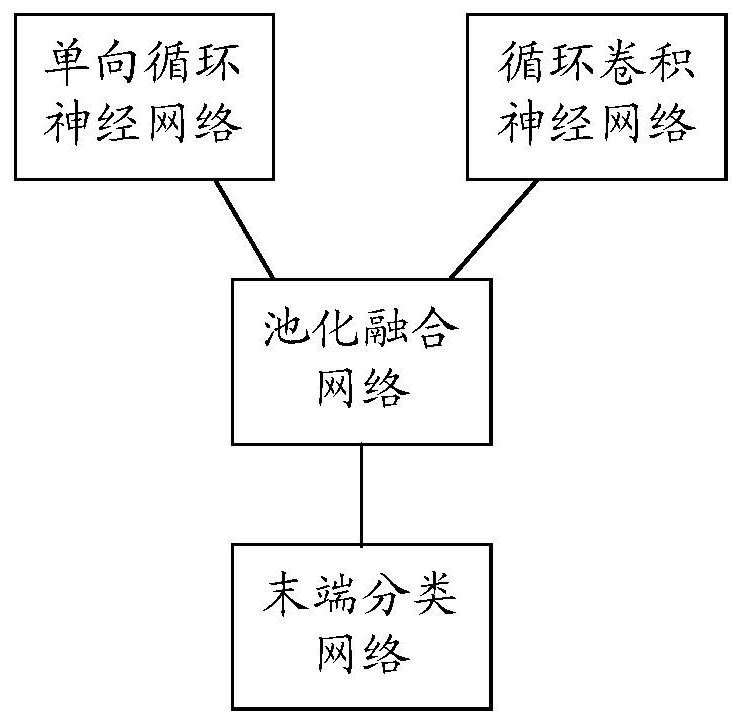

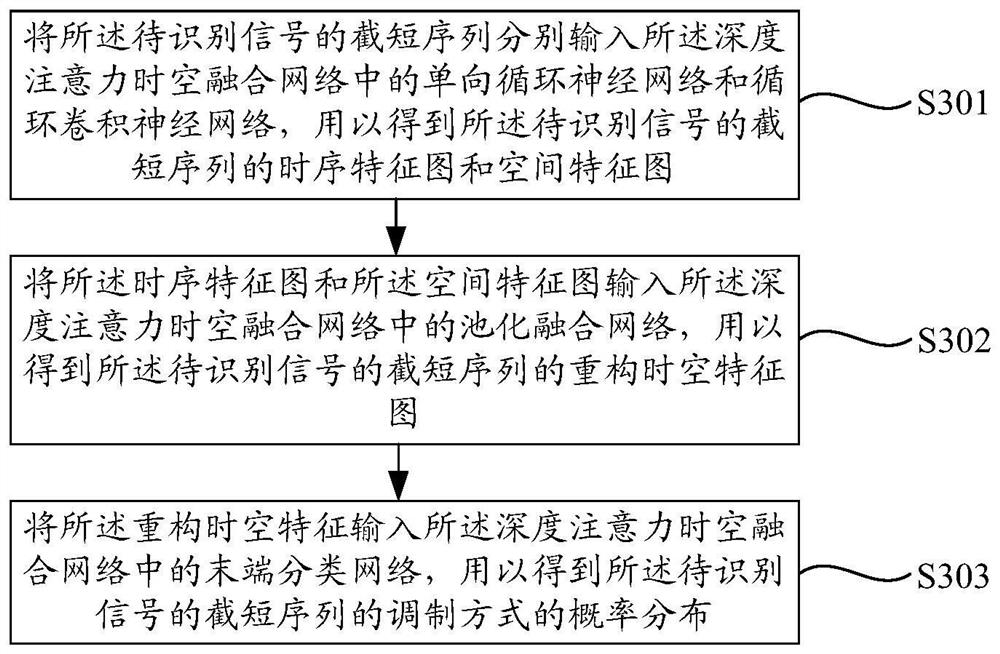

Signal modulation method and device and server

ActiveCN111865849AEffective blocking jammingLow preprocessing requirementsModulation type identificationTelecommunicationsInterference (communication)

The invention relates to the technical field of communication signal processing and discloses a signal modulation method, device and server. The method comprises steps of obtaining a truncated sequence of a to-be-recognized signal; based on the truncated sequence of the to-be-identified signal, determining probability distribution of modulation modes of the truncated sequence of the to-be-identified signal, the probability distribution being used for representing a probability that the to-be-identified signal belongs to each modulation mode; determining the modulation mode of the to-be-identified signal based on the probability distribution of the modulation mode of the truncated sequence of the to-be-identified signal; and demodulating the signal based on the determined modulation mode. According to the method, identification of a signal modulation mode with low preprocessing requirements and high identification precision can be realized under non-cooperative communication and non-ideal channel conditions, so that resources are more effectively concentrated to perform blocking interference on important signal parameters.

Owner:中国兵器科学研究院

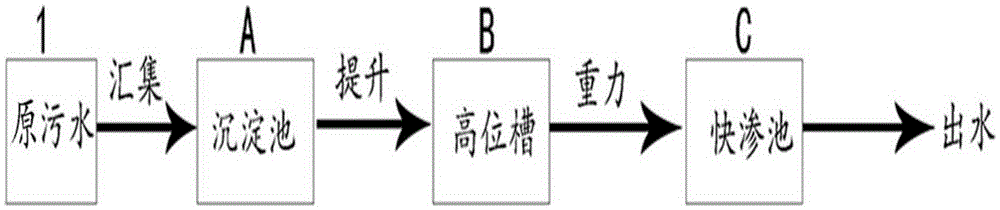

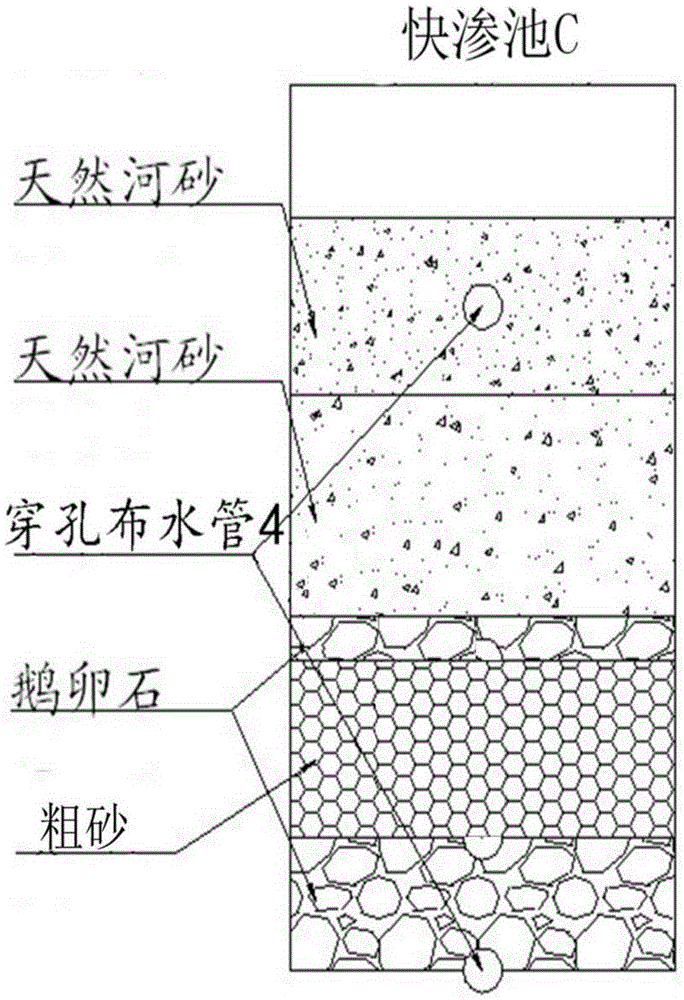

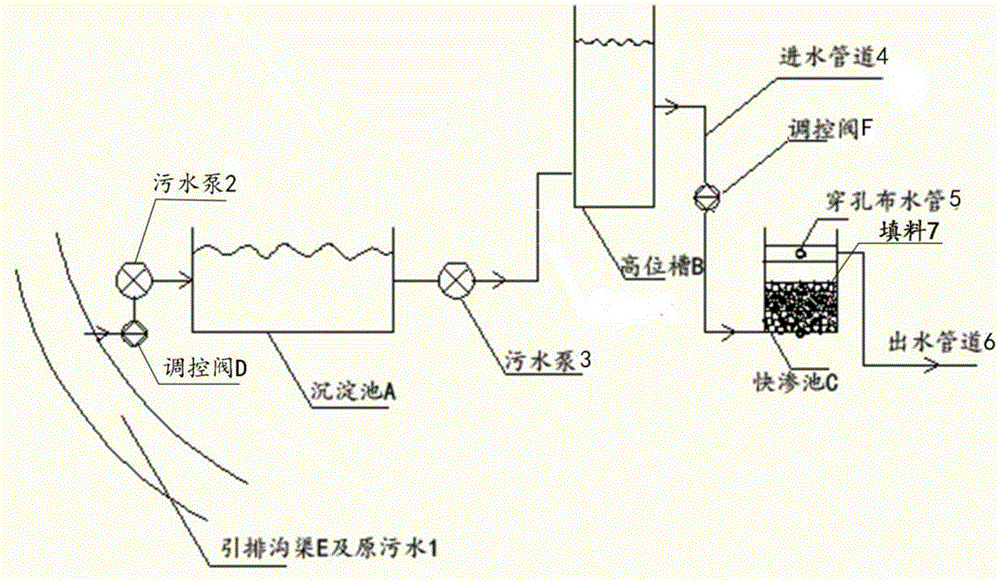

A water inlet method and device for improving the denitrification efficiency of an artificial percolation system

ActiveCN104176882BImprove nitrogen removal efficiencyRefining and Improving Processing EffectsMultistage water/sewage treatmentChemical oxygen demandSedimentation

The invention discloses a water feeding method and device for improving the nitrogen removal efficiency of a constructed infiltration system. The method comprises the following steps: A, collection and pretreatment of original sewage: pumping the original sewage in a drainage ditch into a sedimentation tank through a control valve and a sewage pump which are connected with the sedimentation tank, and removing suspended matters and sand from the original sewage in the sedimentation tank; B, water lift: lifting the pretreated original sewage in the sedimentation tank to an elevated tank by the sewage pump; and C, deep treatment: controlling the effluent in the elevated tank by the control valve, discharging the pretreated water to a packing layer of a rapid infiltration tank, thus achieving sewage treatment. The sedimentation tank is connected with the drainage ditch through the sewage pump and the control valve on a pipeline, the sewage pump is connected with the sedimentation tank, the effluent is connected with the elevated tank through the sewage pump, the elevated tank is connected with a water inlet pipeline, the water inlet pipeline is connected with the rapid infiltration tank through the control valve on the pipeline, and a perforated water distribution pipe is connected with a water outlet pipeline. Nitrogen, phosphorus and COD (chemical oxygen demand) can be removed by the CRI (Constructed Rapid Infiltration) system. The device is simple in structure and convenient to use, and can be used for realizing efficient purification of sewage.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com