Membrane distillation process using hollow fiber membrane component to treat printing and dyeing wastewater

A printing and dyeing wastewater and fiber membrane technology, which is applied in the field of membrane distillation technology, can solve the problems of high power consumption and difficult treatment of concentrated water, and achieve the effects of reducing pretreatment requirements, simplifying the treatment process, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

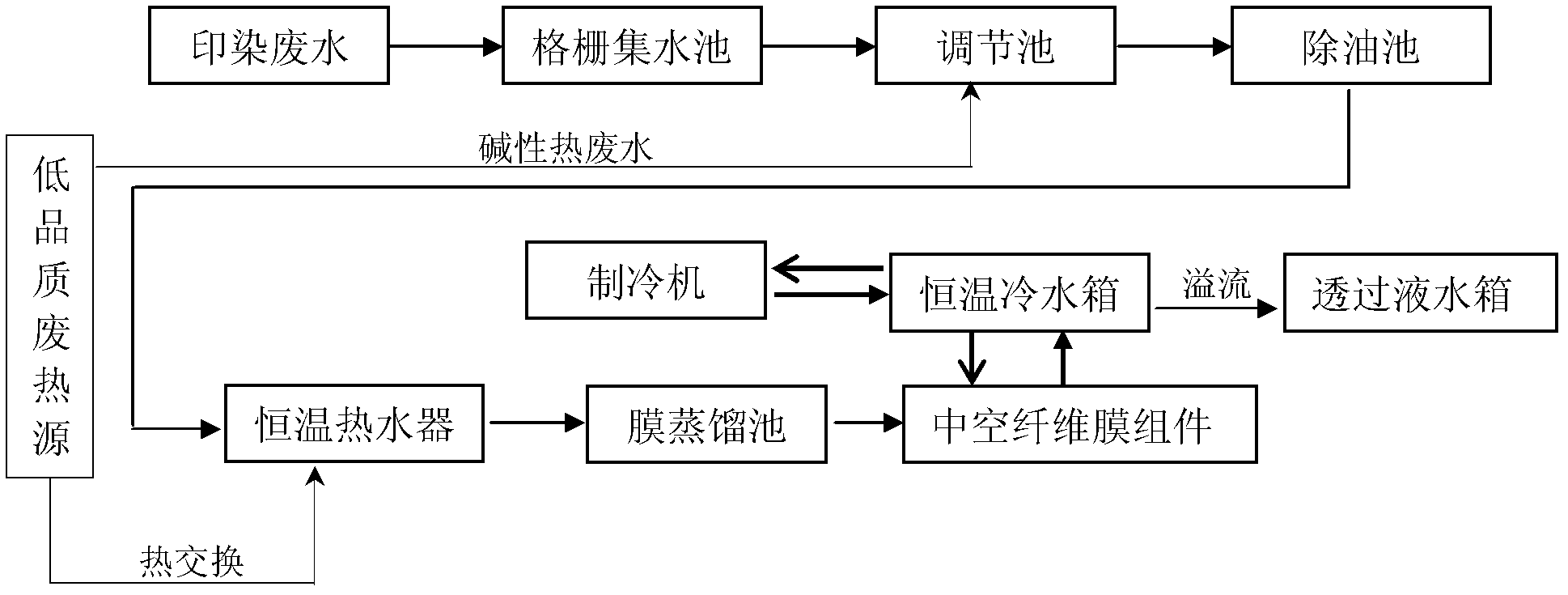

[0019] Such as figure 1 As shown, a membrane distillation process using hollow fiber membrane modules to treat printing and dyeing wastewater includes the following steps:

[0020] Step 1: Pretreatment of printing and dyeing wastewater: pass the printing and dyeing wastewater into the grid sump to remove large floating objects, then enter the regulating tank for water quality adjustment and continuously aerate to prevent precipitation, and then enter the degreasing tank to remove grease;

[0021] Step 2: Membrane distillation treatment: pass the pretreated wastewater into the constant temperature water heater, use the low-quality heat source generated in the printing and dyeing process to exchange heat with the constant temperature water heater, heat the wastewater to 50-60 degrees Celsius, and then pass it into the water heater equipped with hollow fibers In the membrane distillation tank of the membrane module, when the wastewater has not passed through the hollow fiber memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com