Method for separating copper-containing solid waste

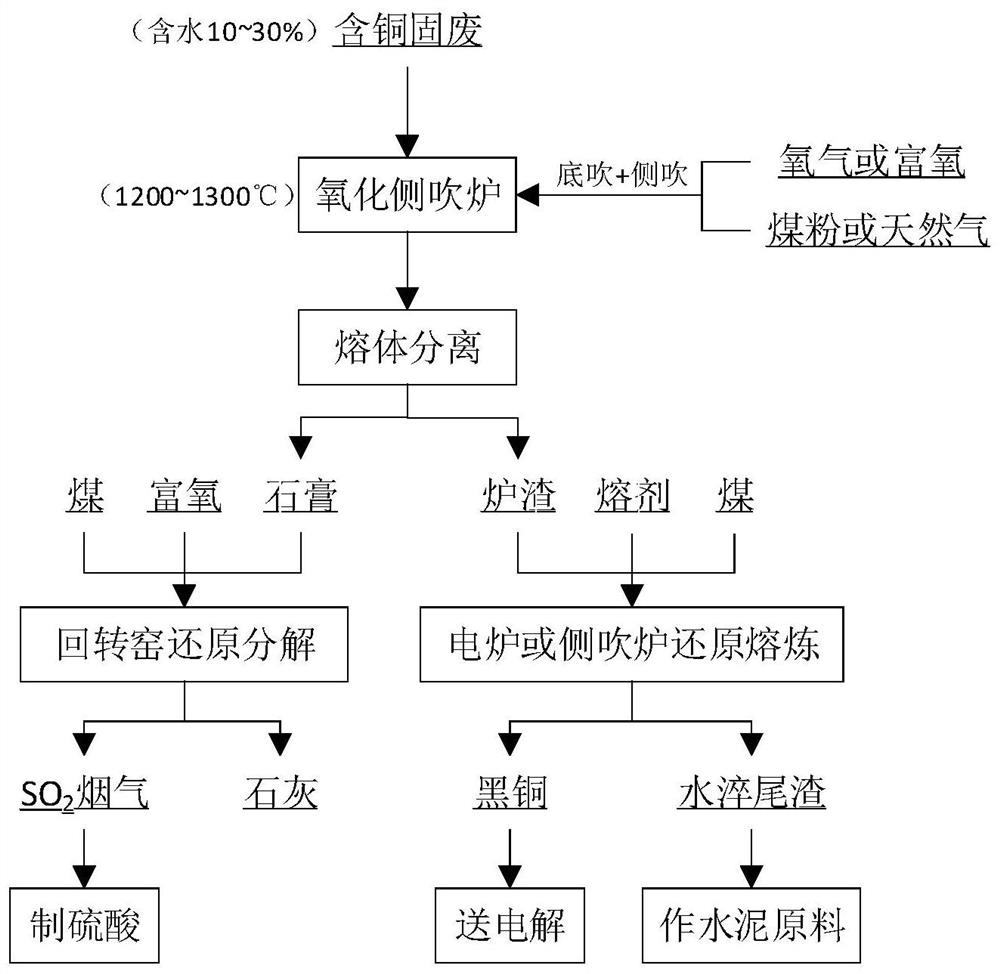

A separation method and technology of water content, applied in the direction of improving process efficiency, can solve the problems of limited processing capacity and poor adaptability of raw materials, and achieve the effect of reducing the amount of flux and reduction used, high recovery rate, and inhibiting decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

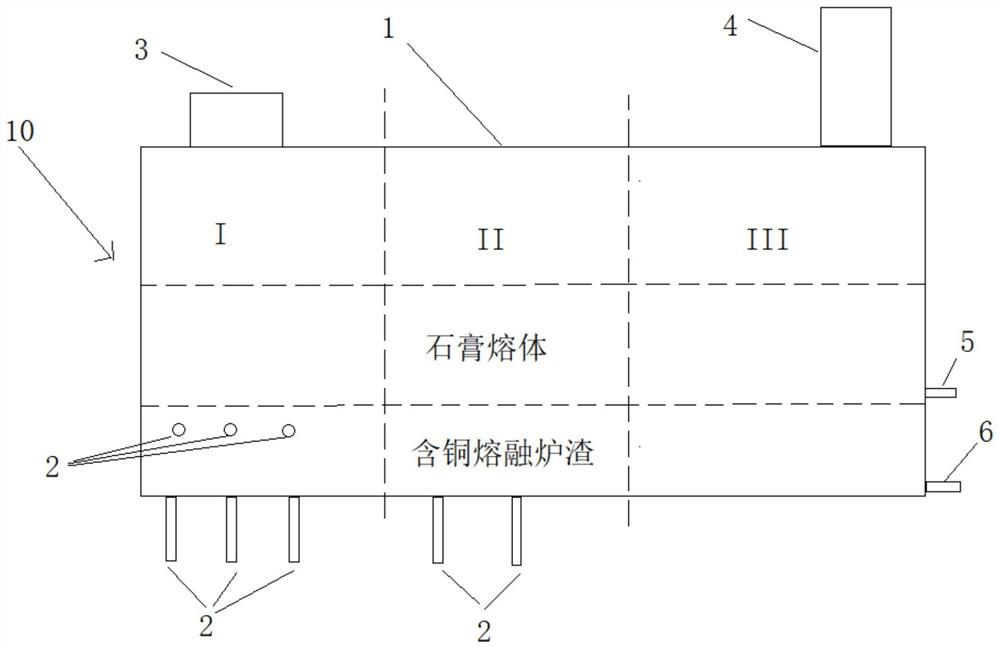

[0053] The pretreated copper-containing solid waste particles are directly dropped into the feeding area 1 of the melting pool 1 through the feeding port 3 of the oxidation side-blowing furnace 10, and the spray guns 2 on the side wall and bottom of the feeding area 1 spray coal powder and Oxygen-enriched (the volume concentration of oxygen is 86.96%), the temperature of the molten pool is 1200-1300 ° C, since the side wall and bottom of the feeding area I are equipped with spray guns, the number of spray guns is large, the heating intensity and the stirring intensity of the molten pool are large, and the copper is contained The solid waste melts in the feeding zone I of the molten pool 1, and then enters the intermediate transition zone II. The spray gun 2 at the bottom of the intermediate transition zone II injects coal powder and oxygen-enriched into the molten pool to maintain the temperature of the molten pool, and the agitation of the molten pool gradually tends to Relax,...

Embodiment 2

[0063] The same as the method of Example 1, the difference is that the blown oxygen-enriched volume concentration is 95.79%, and the O in the flue gas 2 The volume content is 7.3%.

[0064] 55kg of anthracite and 13Nm of air are consumed per ton of copper-containing solid waste 3 (partially used as anthracite carrier gas), oxygen 180Nm 3 , 270kg of gypsum melt and 400kg of molten slag can be produced. The main components of gypsum and slag are shown in Table 4, in terms of mass percentage.

[0065] Table 4

[0066] Element Cu Fe S Ni CaO SiO 2

upper plaster 4.77 2.54 17.66 0.22 40.61 0.75 lower slag 38.18 15.88 0.76 4.51 12.76 7.92

[0067] The molten slag in the lower layer is poured into the side-blown smelting furnace, and 120 kg of anthracite and 95 kg of silica are added to each ton of slag, and 450 kg of black copper and 480 kg of tailing slag can be obtained by reducing and smelting per ton of slag. Mass percentage ...

Embodiment 3

[0073] The same as the method of Example 1, the difference is that what the spray gun sprays is oxygen, and the O in the flue gas 2 The volume content is 9.76%.

[0074] 50kg of anthracite and 3Nm of air are consumed per ton of copper-containing solid waste 3 (as anthracite carrier gas), oxygen 160Nm 3 , 270kg of gypsum melt and 400kg of molten slag can be produced. The main components of gypsum and slag are shown in Table 6, in terms of mass percentage.

[0075] Table 6

[0076] Element Cu Fe S Ni CaO SiO 2

upper plaster 4.37 2.79 18.21 0.25 39.61 0.97 lower slag 38.72 14.81 0.96 4.87 13.98 8.76

[0077] The molten slag in the lower layer is poured into the side-blowing smelting furnace, and 110kg of anthracite and 85kg of silica are added to each ton of slag, and 460kg of black copper and 480kg of tailing slag can be obtained by reduction smelting per ton of slag. percentage meter.

[0078] Table 7

[0079] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com