Solid waste decoupling combustion device, solid waste decoupling combustion system device and combustion method of solid waste decoupling combustion device

A combustion device and channel technology, which is applied in the field of solid waste decoupling combustion devices, can solve the problems of being unsuitable for small and medium-sized devices, occupying a large area, and complicated in process, so as to reduce temperature fluctuations, reduce high-temperature slagging, and improve laminar combustion. The effect of zone temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

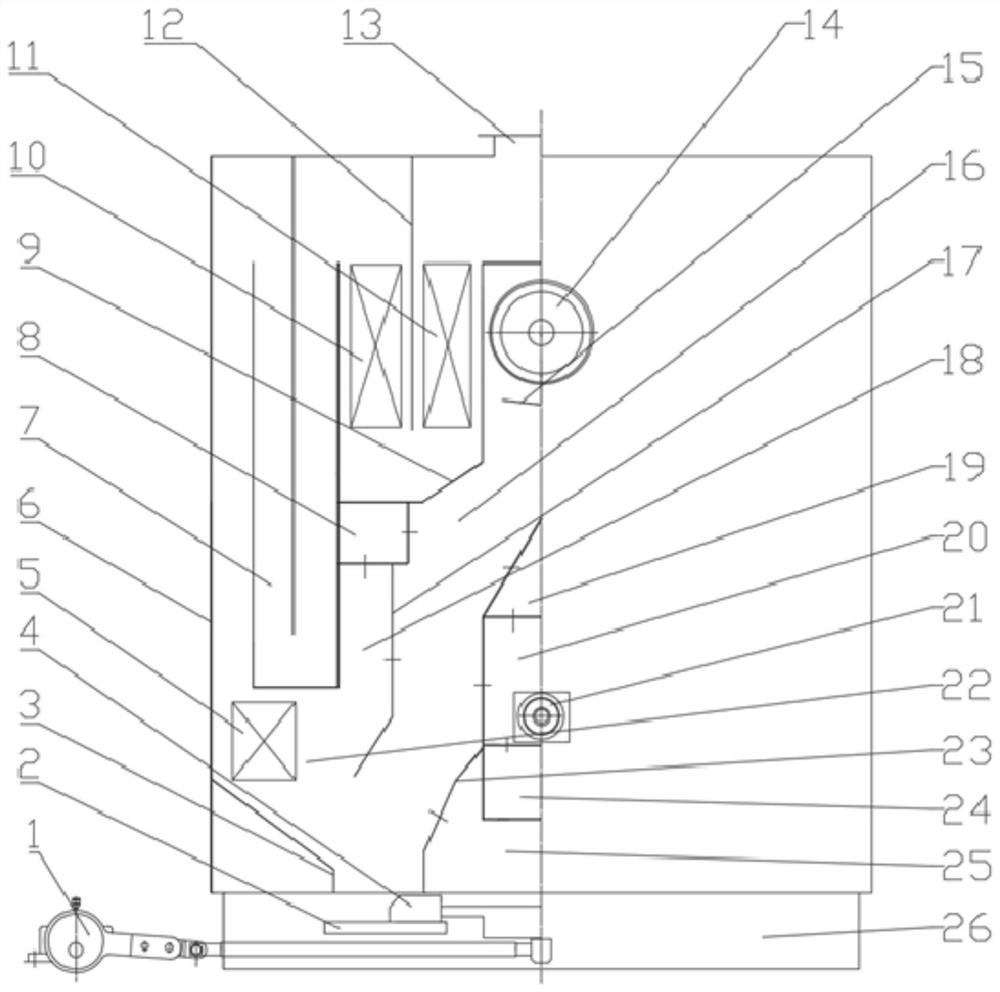

[0116] This embodiment provides a solid waste decoupling combustion system device, such as figure 1 As shown, based on the combustion system device described in a specific embodiment, wherein, two solid waste decoupling combustion devices are symmetrically arranged in the combustion system device, and the material of the heat-resistant metal is 310S, 316L, 304 or 1Cr18Ni9Ti, and the rest of the structure is the same as The combustion system devices described in a specific embodiment are identical.

[0117] This embodiment also provides a method for burning materials using the above-mentioned solid waste decoupling combustion system device, based on the combustion method described in a specific embodiment, wherein the temperature of the gas in the hot air chamber 19 in step (II) is 400°C; the gas entering the preheating drying zone in the hot air chamber 19 accounts for 70% of the total gas volume; the temperature of the gas in the auxiliary heating air chamber 20 is 500°C; the...

Embodiment 2

[0119] This embodiment provides a solid waste decoupling combustion system device, based on the combustion system device described in a specific embodiment, wherein the combustion system device includes three solid waste decoupling combustion devices, and the material of the heat-resistant metal is 316L , the rest of the structure is exactly the same as the combustion system device described in a specific embodiment.

[0120] This embodiment also provides a method for burning materials using the above-mentioned solid waste decoupling combustion system device, based on the combustion method described in a specific embodiment, wherein the temperature of the gas in the hot air chamber 19 in step (II) is 200°C; the gas entering the preheating drying zone in the hot air chamber 19 accounts for 50% of the total gas volume; the temperature of the gas in the auxiliary heating air chamber 20 is 700°C; the temperature in the flue gas co-combustion channel 22 is 1300°C; step (Ⅲ ) The tim...

Embodiment 3

[0122] This embodiment provides a solid waste decoupling combustion system device, based on the combustion system device described in a specific embodiment, wherein the combustion system device includes four solid waste decoupling combustion devices, and the material of the heat-resistant metal is 1Cr18Ni9Ti , the rest of the structure is exactly the same as the combustion system device described in a specific embodiment.

[0123] This embodiment also provides a method for burning materials using the above-mentioned solid waste decoupling combustion system device, based on the combustion method described in a specific embodiment, wherein the temperature of the gas in the hot air chamber 19 in step (II) is 600°C; the gas entering the preheating drying zone in the hot air chamber 19 accounts for 90% of the total gas volume; the temperature of the gas in the auxiliary heating air chamber 20 is 100°C; the temperature in the flue gas co-combustion channel 22 is 800°C; step (Ⅲ ) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com