Danger waste material rotary type fluidization cold slag three-segment incinerator

A hazardous waste, rotary technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem that the thermal ignition loss rate of ash and smoke emission cannot meet the national environmental protection requirements, and the retention time of slag and smoke is difficult to guarantee, etc. problems, to achieve the effect of low pretreatment requirements, prolong residence time, and reduce thermal loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

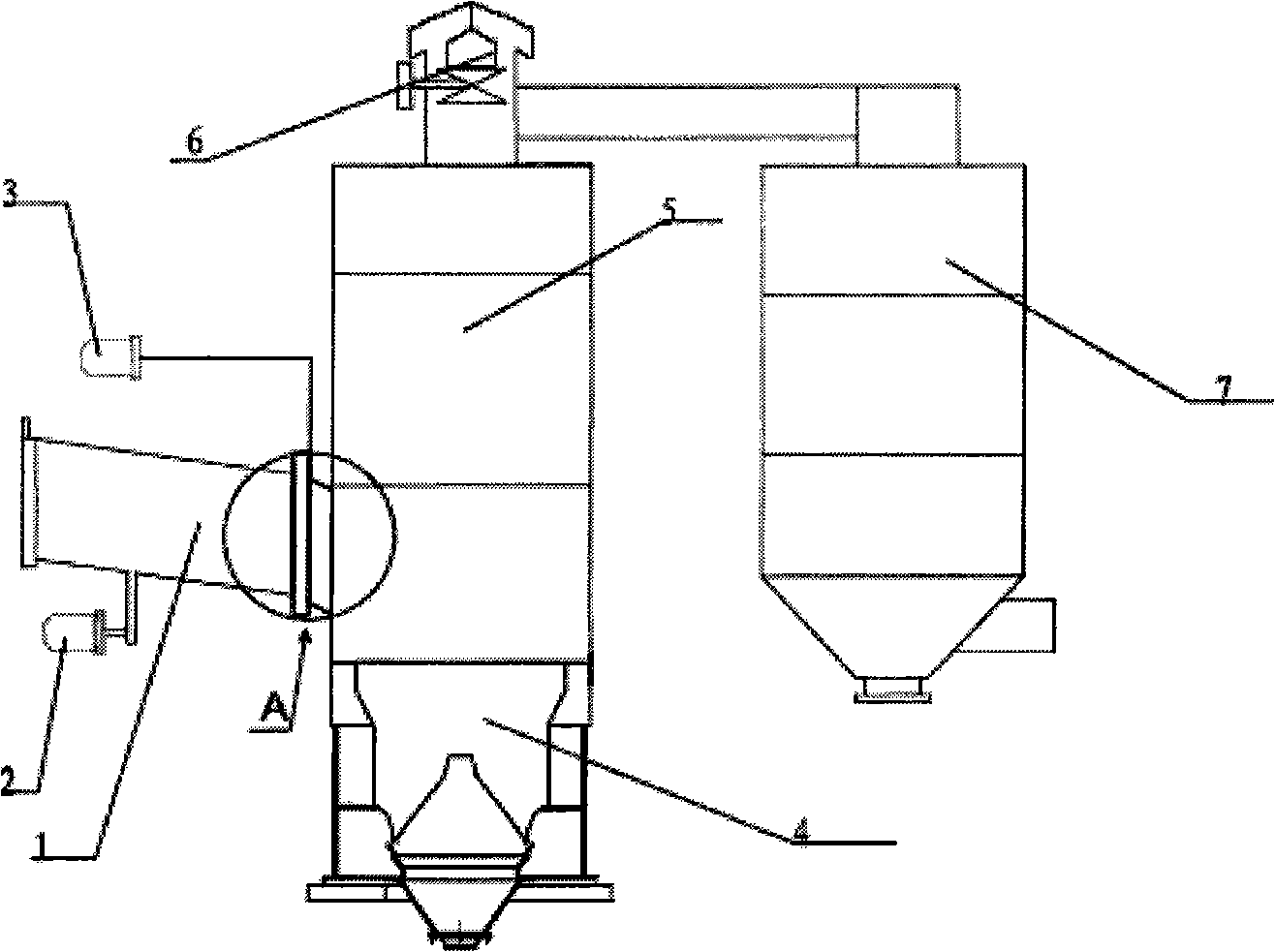

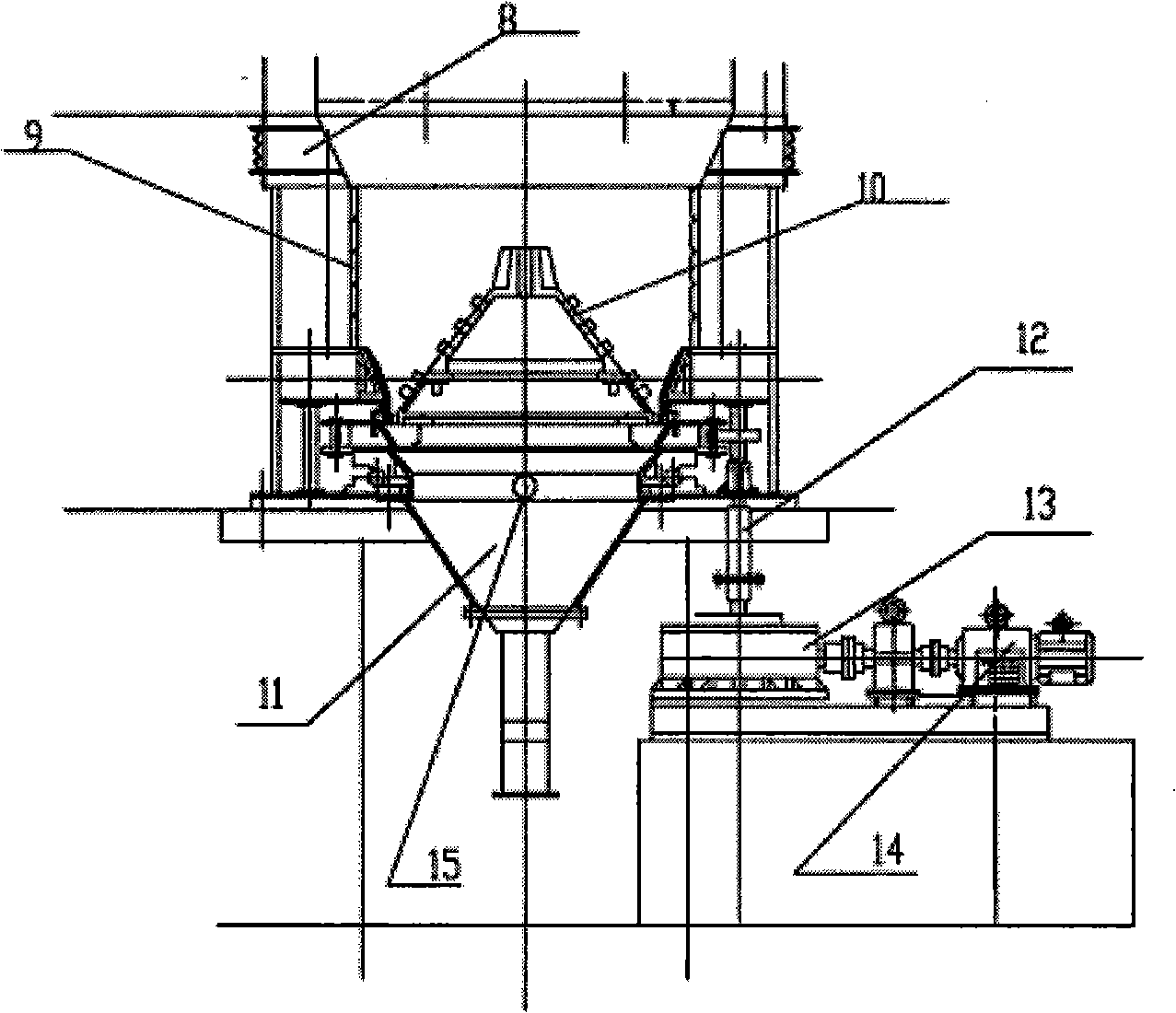

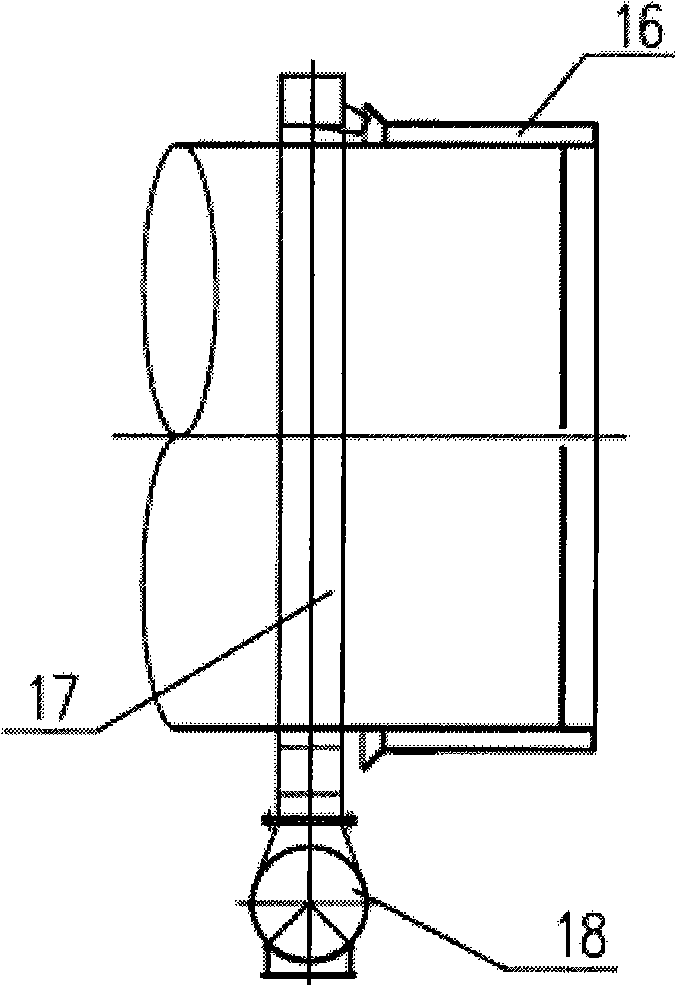

[0029] Such as figure 1 As shown, the hazardous waste rotary fluidized cold slag three-stage incinerator includes rotary kiln 1, rotary kiln motor 2, cooling fan 3, fluidized slag cold device 4, three combustion chamber 5, emergency discharge door 6, quench tower 7, The upper end of the fluidized slag cooling device 4 is provided with a three-combustion chamber 5. The top of the three-combustion chamber 5 is connected with an emergency discharge door 6 and a quench tower 7. The lower side wall of the three-combustion chamber 5 is connected with the tail of the rotary kiln 1, and the tail of the rotary kiln 1 There is a cooling fan 3, and the rotary kiln 1 is equipped with a rotary kiln motor 2.

[0030] The hazardous waste enters the first combustion chamber of the rotary kiln through the hazardous waste feed port, and the first combustion chamber is rotated by the main drive motor at a specific speed. The air used for incineration is sucked from the hazardous waste warehouse by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com