Patents

Literature

84results about How to "Reduce dehydration costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

Method for conditioning and dehydrating residual sludge

ActiveCN103030259APromote moisture penetrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningPolymer dissolutionBiological cell

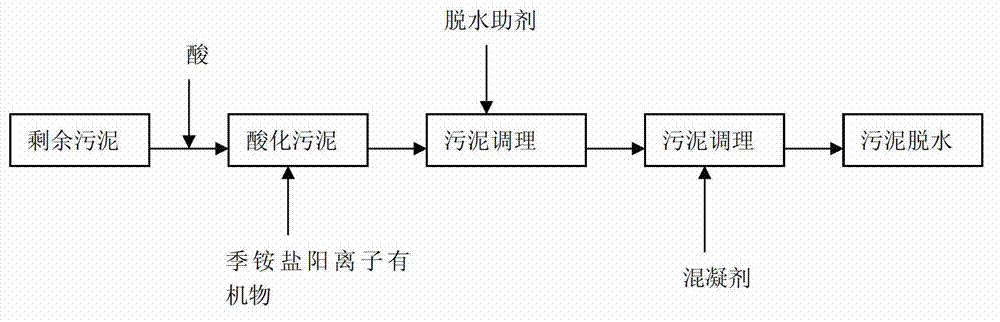

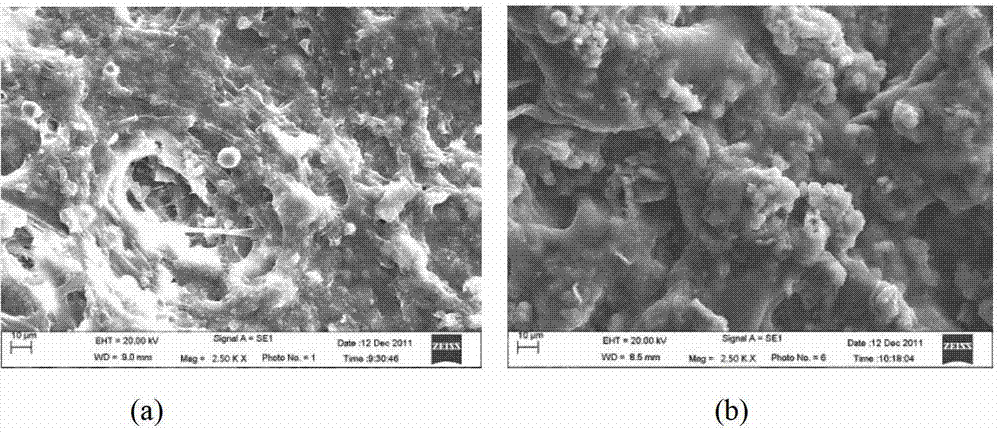

The invention relates to the technical field of residual sludge treatment, in particular to a process method for conditioning and dehydrating residual sludge. The method particularly comprises the following steps: (1) adding acid into the residual sludge to be treated and with the water content of 90 to 95 percent and adjusting until the pH value is between 4.0 and 6.0; (2) adding quaternary ammonium salt cationic organic matters into the conditioned sludge in the step (1) and performing hybrid reaction; (3) adding a dehydration aid into the conditioned sludge in the step (2) and stirring uniformly; and (4) adding coagulant into the conditioned sludge in the step (3) and mechanically dehydrating after mixing and stirring. The extracellular polymers on sludge flocs are stripped and partially hydrolyzed by a chemical conditioning mode, microbial cells are dissolved, a large amount of bound water is released, and the water permeability of the sludge is improved by utilizing the aid, so that the dehydration performance of the sludge is integrally improved, the water content of the sludge is reduced, the dehydration time is shortened and the dehydration cost is reduced.

Owner:北京方兴科创环境科技有限公司

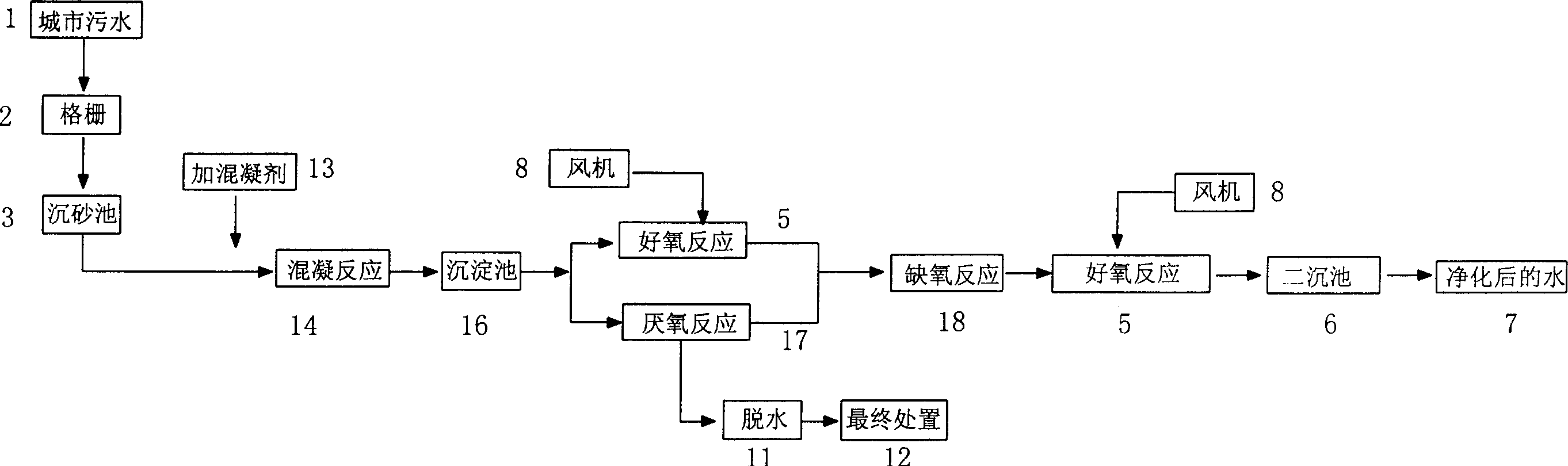

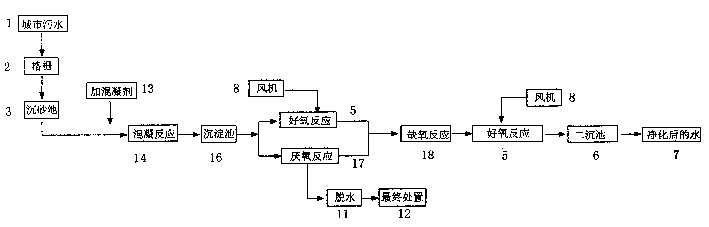

Urban domestic sewage treatment process and its method

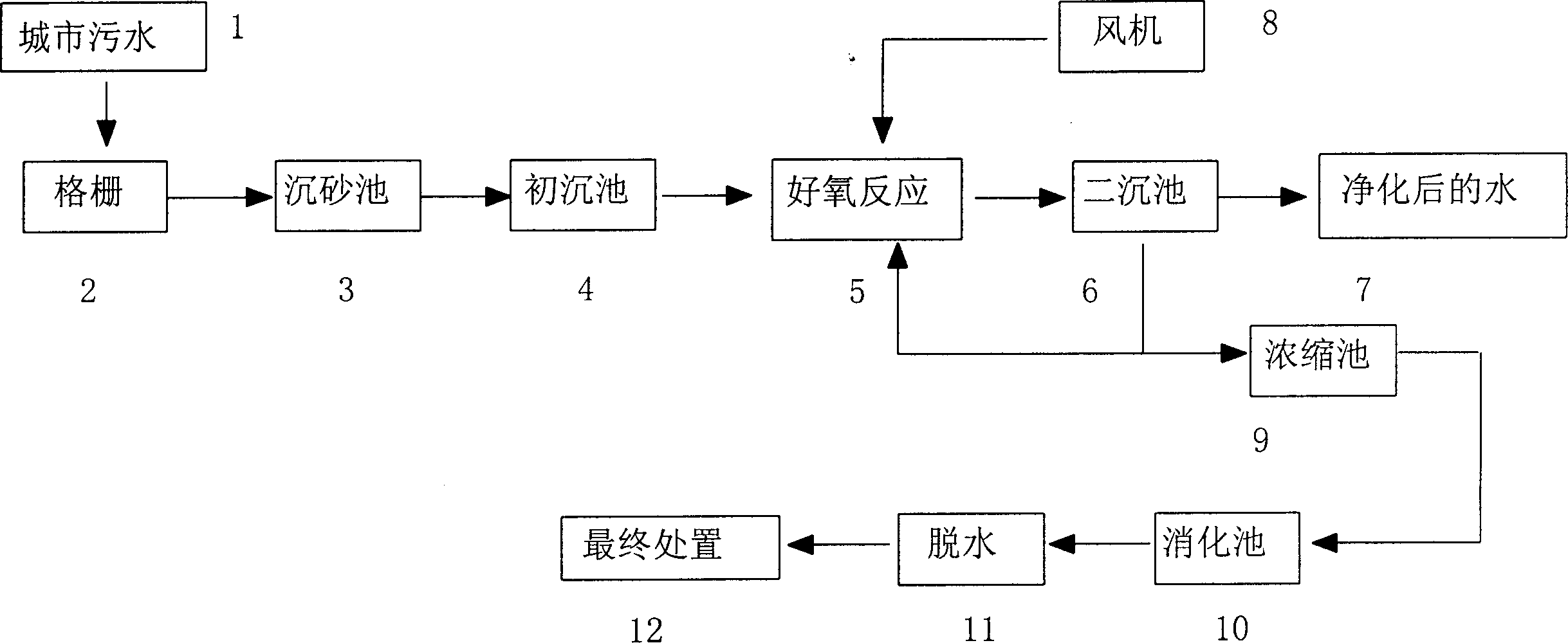

InactiveCN1412134AReduce contentReduce concentrationWater/sewage treatmentMultistage water/sewage treatmentWater qualitySmall footprint

The city sewage treatment process includes the following steps: utilizing grile and desilting basin to pretreat sewage, adding coagulating agent to make the phosphorus, heavy metal and orgnaic matters existed as colloid and suspended substances feed into anaerobic reactor in the form of sludge to make organic matter convert into impure methane, making the supernatant fluid pass through the next aerobic treatment reactor to remove organic matter and convert the ammoniacal nitrogen into nitric nitrogen, mixing anaerobic discharged water and aerobic discharged water, and making the mixture waterundergo the process of anaerobic treatment to make denitrifcation, finally utilizing secondary aeration and precipitation to completely remove organic matters from sewage so as to attain the goal of cleaning the sewage.

Owner:NANKAI UNIV

Soil conditioner prepared from sludge and preparation method thereof

InactiveCN106867544ASave landfill landResolve disposal issuesAgriculture tools and machinesOther chemical processesEcological environmentResource utilization

The invention belongs to the field of solid waste reclamation comprehensive utilization and particularly relates to a soil conditioner prepared from sludge and a preparation method thereof. The soil conditioner is prepared from river and lake bottom mud, conditioner, medium sand, agricultural and forestry residues, biological manure and plant ash, wherein the conditioner is 5% to 8% of the mass of the river and lake bottom mud, the medium sand is 5% to 10% of the mass of the river and lake bottom mud, the agricultural and forestry residues are 5% to 10% of the mass of the river and lake bottom mud, the biological manure is 1% to 5% of the mass of the river and lake bottom mud, and the plant ash is 1% to 3% of the mass of the river and lake bottom mud. The soil conditioner prepared from sludge disclosed by the invention achieves resource utilization of sludge, also fully utilizes sludge, tailings or river and lake sand, tailing sand, pipe network sand and agricultural and forestry residues at the same, achieves the purpose of treating waste through waste, avoids solid waste landfill, land occupancy and secondary pollution, reduces engineering cost of land reclamation, landscaping, forest land plant and the like and is beneficial to ecological environment; in addition, the river and lake sand, the tailing sand, the pipe network sand and the agricultural and forestry residues are separated and sorted from pipe network sludge.

Owner:SAFECLEEN TECH

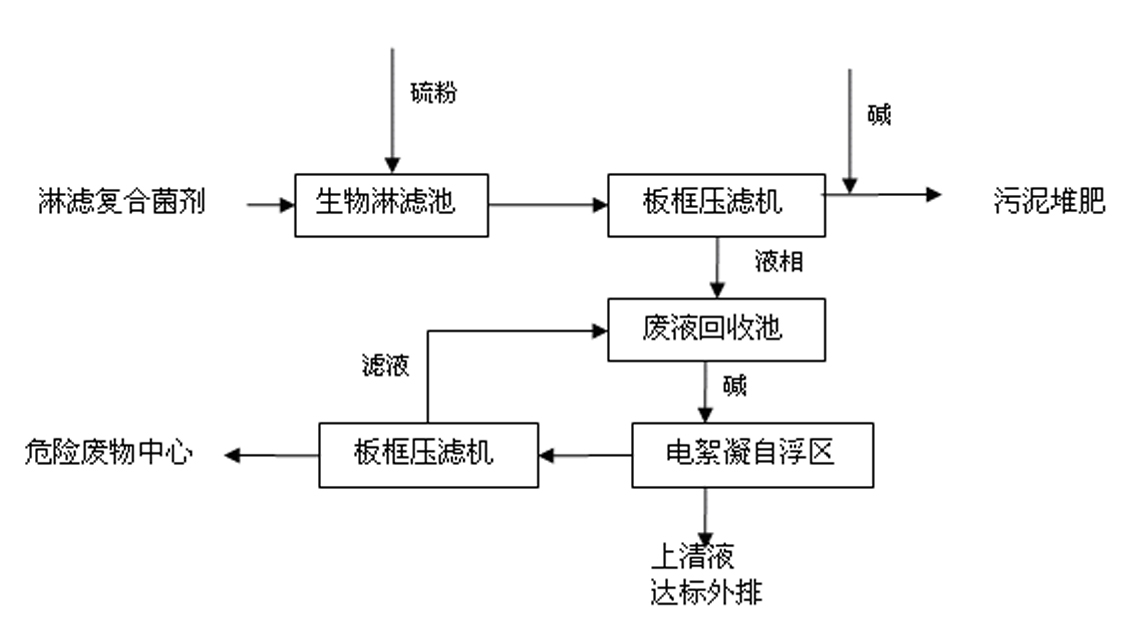

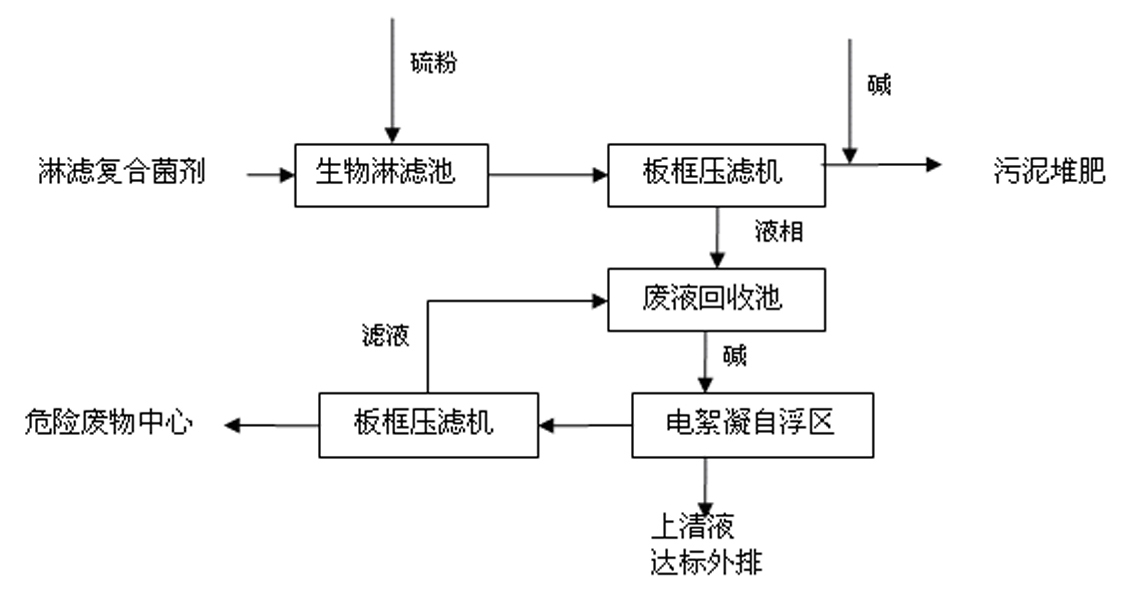

Process for removing heavy metal from sludge of sewage treatment plants

InactiveCN101913745AIncrease growth activityReduce dehydration costsClimate change adaptationWater contaminantsFlocculationSludge compost

The invention discloses a process for removing heavy metals from sludge of sewage treatment plants. The process comprises the following steps of: adding 0.5 to 30g of elemental sulfur in each litre of sludge in a bioleaching tank, respectively inoculating 1 to 5 percent of thiobacilli and 1 to 3 percent of acidophilus moulds in the bioleaching tank, carrying out aerated bioleaching on the obtained sludge for 2 to 6 days until the pH value of the obtained sludge in the bioleaching tank is less than 2, and pumping the sludge subjected to bioleaching treatment in a plate-and-frame filter press by using a pump to carry out filter press separation so as to obtain sludge from which heavy metal is removed and sewage containing the heavy metal; adding alkali into the sludge from which heavy metal is removed to neutralize the sludge and then transporting the sludge to a sludge composting plant for composting; adding alkali into the sewage containing the heavy metal until the pH value of the sewage is about 7, then putting the sewage into an electrolytic flocculation floatation device to carry out electrolytic flocculation and self-floatation treatments on the sewage, and after the obtained liquid supernatant reaches the standard, draining the liquid supernatant; and pumping the flocculated scum of the pollutant in water into the plate-and-frame filter press for separation to obtain corresponding filter liquor and sludge, wherein the filter liquor is drained to a waste liquor recovery tank, and the sludge is transported to a hazardous waste disposal center for treatment. The process of the invention has the advantages of shortening the lixiviation period, improving the lixiviation efficiency and the variety of lixiviated heavy metal, ensuring the stability of removing heavy metal, and saving equipment investment.

Owner:湖南德施普生物科技有限公司

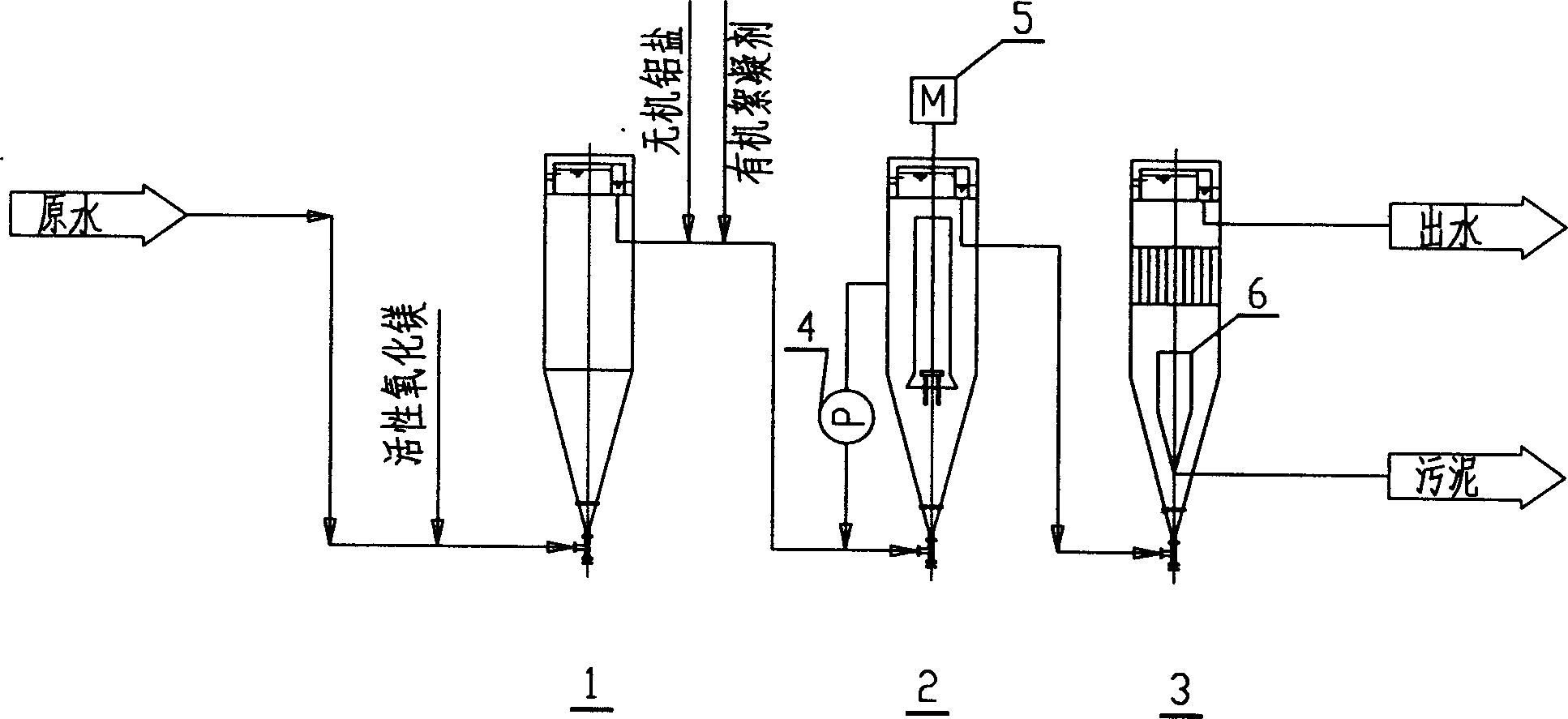

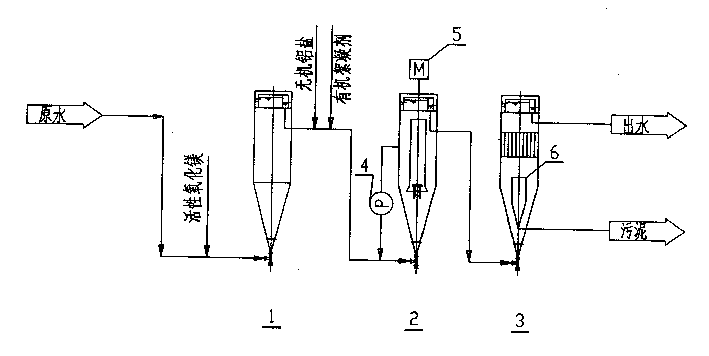

Oil field visous crude sewage silicone-removing and cleaning process

InactiveCN1412128ANon-fouling benefitsReduce dosageSedimentation separationWater/sewage treatment by flocculation/precipitationHigh concentrationSludge

The oil field viscous crude sewage silicone-removing cleaning technological process is characterized by that in the course ore moving silicone it has no need of regulating pH value of sewage, the active magnesium oxide can be directly added into the pretreated sewage, and after the sewage is passed through the vortex reactor and reacted, the inorganic aluminium salt anjd organic floccultant can be added in the discharge water, then fed into sludge reactor, said sludge reactor can provide high-concentration sludge, and said sludge can be fully reacted with feeding water, then fed into precipitation clearing device to implement sludge and water separation so as to obtain silicone dioxide and treated water in which the suspended matter content is lower.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

Sludge dewatering composite flocculant

InactiveCN101348318AEasy to dehydrateLow running costSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateChloride

The invention relates to a sludge dewatering composite flocculating agent, in particular to an inorganic-organic composite flocculating agent capable of effectively improving dewatering efficiency and reducing dewatering cost. In order to realize the goal, the invention adopts the following technical proposal that the sludge dewatering composite flocculating agent comprises the compositions of polymeric aluminum ferric chloride and cationic polyacrylamide, wherein the chemical general formula of polymeric aluminum ferric chloride is [Al2 (OH)n Cl6-n]m , [Fe 2(OH)n Cl6-n] m; moreover, n is less than 5, and m is less than 10; and the content ratio of the polymeric aluminum ferric chloride to the cationic polyacrylamide is between 2 to 1 and 5 to 1. The sludge dewatering composite flocculating agent is mainly used in sludge dewatering.

Owner:四川省水处理及资源化工程技术研究中心

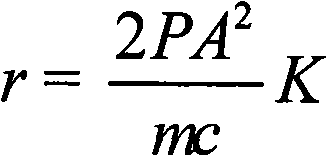

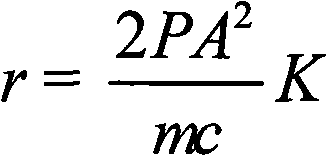

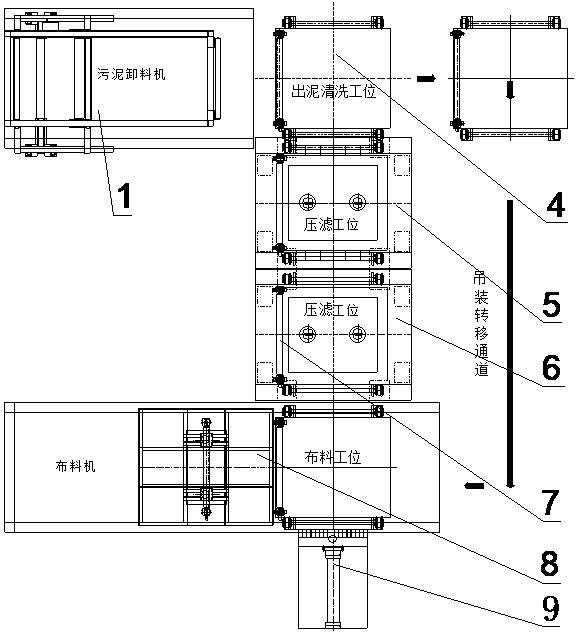

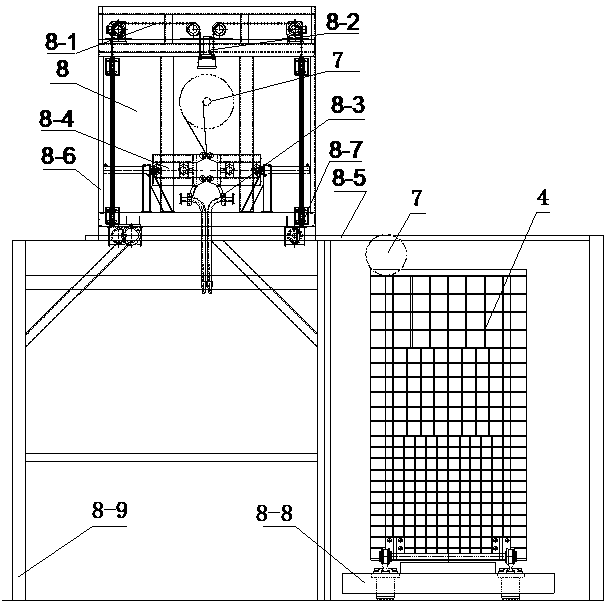

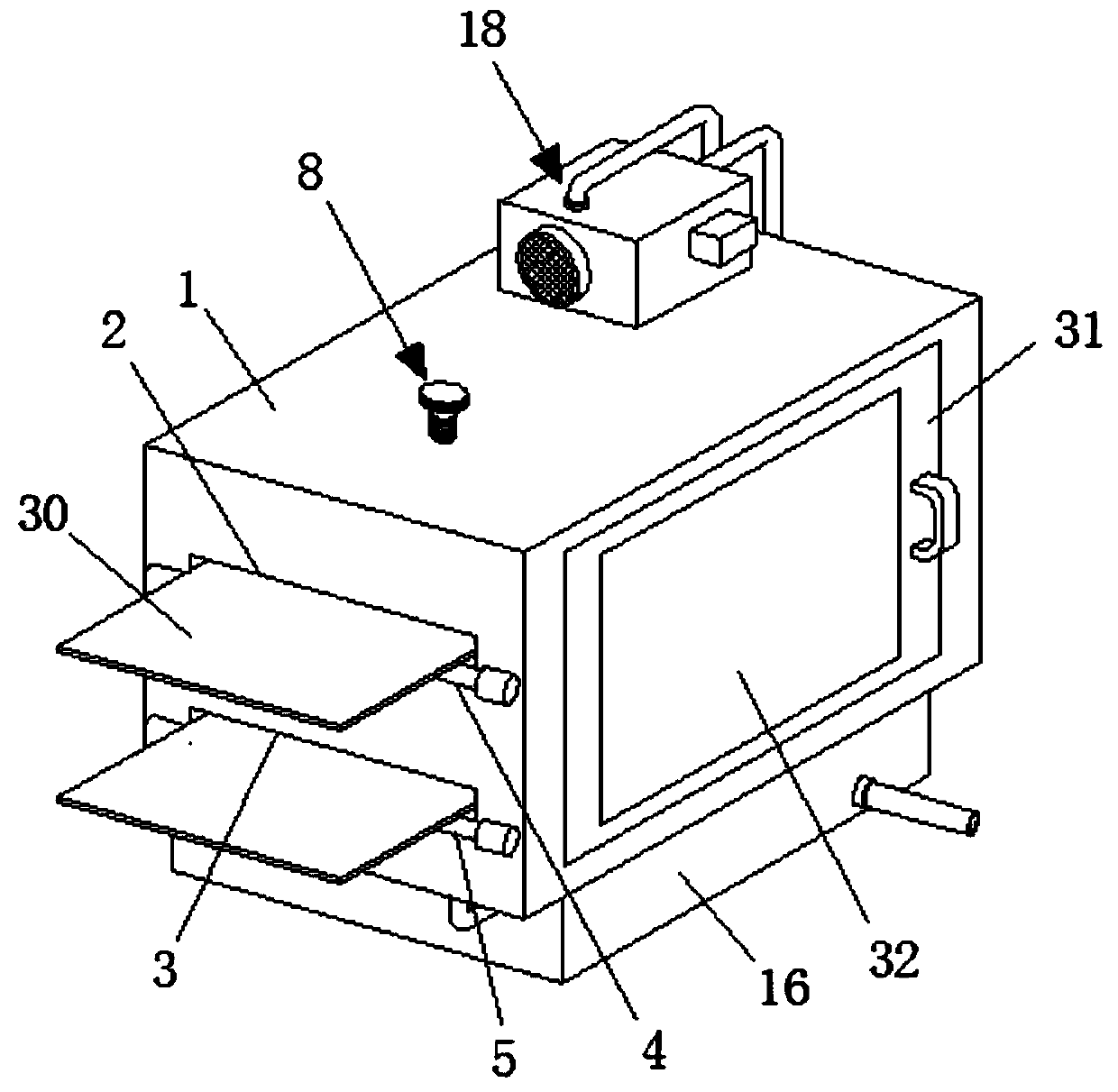

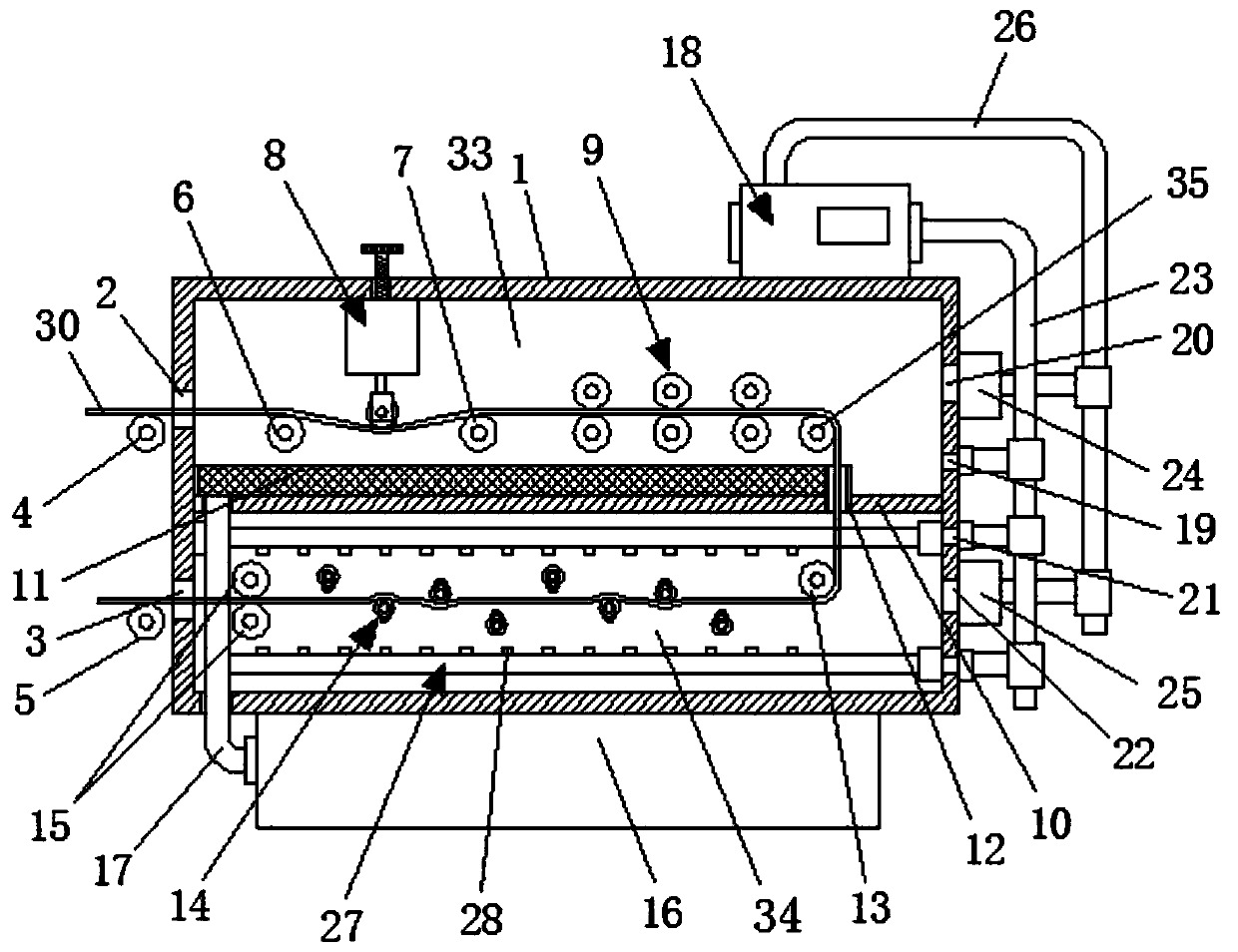

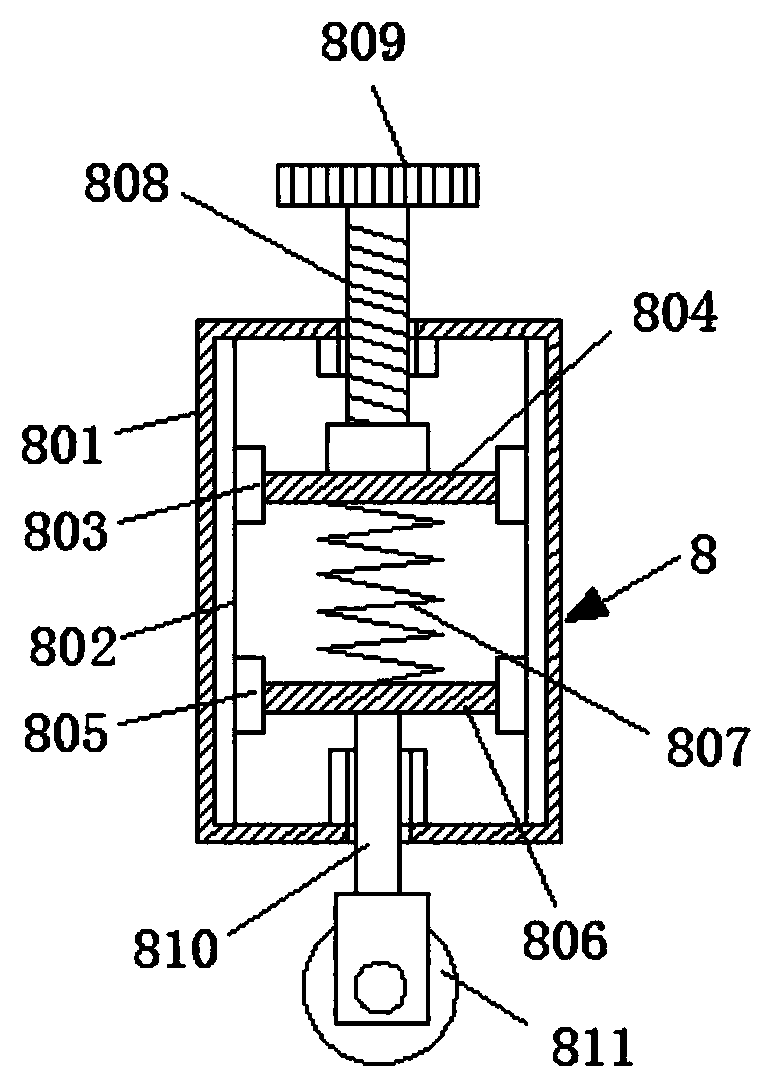

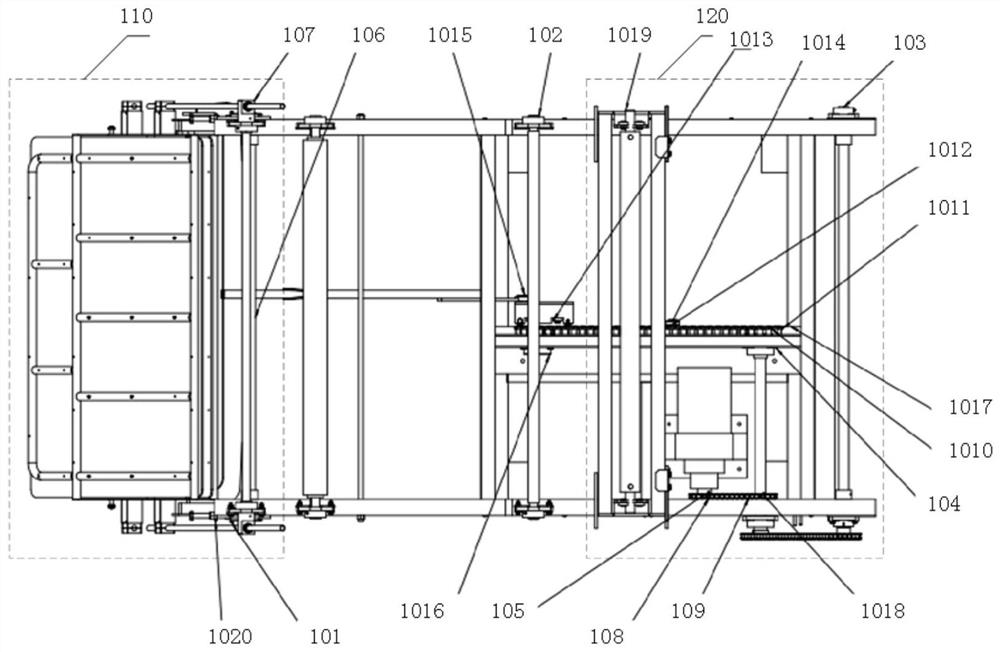

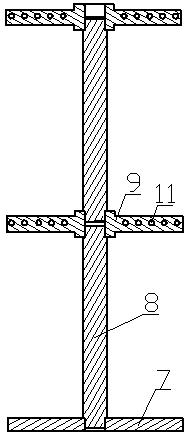

Deep sludge filter-pressing dehydration device and dehydration method

PendingCN111087158AHigh efficiency and energy saving dehydration effectReduce labor intensitySludge treatmentSludgeProcess engineering

The invention discloses a deep sludge filter-pressing dehydration device and a dehydration method, and belongs to a filter-pressing dehydration device and a dehydration method. According to the device, a sludge distributing machine and a sludge discharging machine are oppositely arranged; a material distributing station and a sludge discharging and cleaning station are arranged on one side of thesludge distributing machine and one side of the sludge discharging machine respectively; a sludge filter press is arranged between the material distribution station and the sludge discharging and cleaning station; a filter pressing station is correspondingly arranged below the sludge filter press; the filter pressing station, the material distributing station and the sludge discharging and cleaning station are positioned on the same axis; filter pressing barrels are arranged on the filter pressing station, the material distributing station and the sludge discharging and cleaning station; a filter barrel automatic circulating shifter is arranged above or on one side of the filter pressing station, the material distributing station and the sludge discharging and cleaning station; and the filter barrel automatic circulating shifter is positioned on the moving tracks of the filter pressing station, the material distributing station and the sludge discharging and cleaning station. Accordingto the invention, no chemical additive is required to be added during dehydration and filter pressing of sludge, so that the cost is effectively reduced, and the operation is stable and reliable; andthe automation degree of equipment is high, and operators are not required to operate on site;

Owner:XUZHOU KUANGYUAN UNDERFLOW PUMP IND CO LTD

Compounded sludge dewatering conditioner and application method thereof

InactiveCN105948457ARich sourcesLow priceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCompound aAluminium chloride

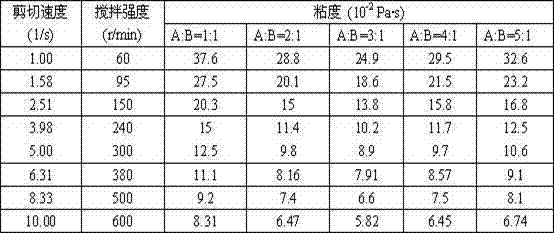

The invention discloses a compounded sludge dewatering conditioner and belongs to the technical field of sludge treatment. The compounded sludge dewatering conditioner is prepared through compounding a sludge conditioner A and a sludge conditioner B, wherein the sludge conditioner A is prepared through compounding the following ingredients in parts by weight: 20-30 parts of fly ash, 10-20 parts of quicklime powder, 10-20 parts of magnesia, 20-30 parts of polyaluminum ferric chloride; the sludge conditioner B is an acetic solution of chitosan. The invention further discloses a method of application of the compounded sludge dewatering conditioner.

Owner:河南永泽环境科技有限公司

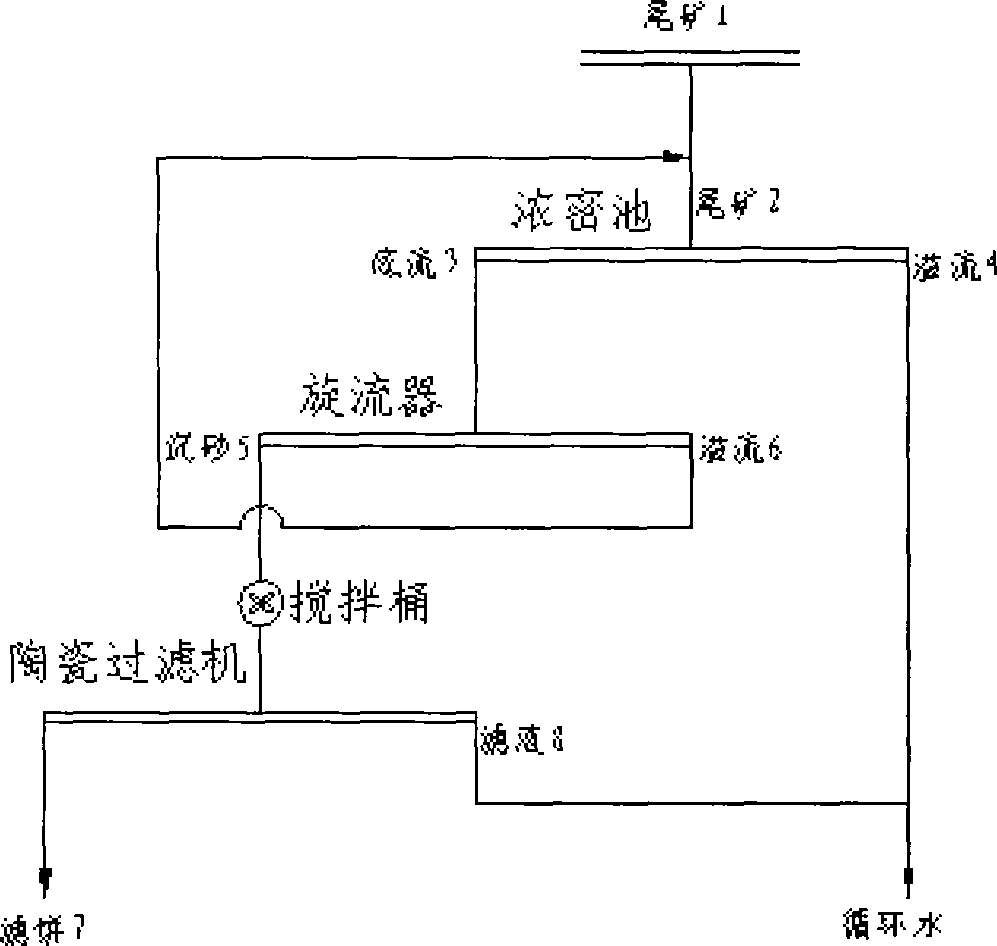

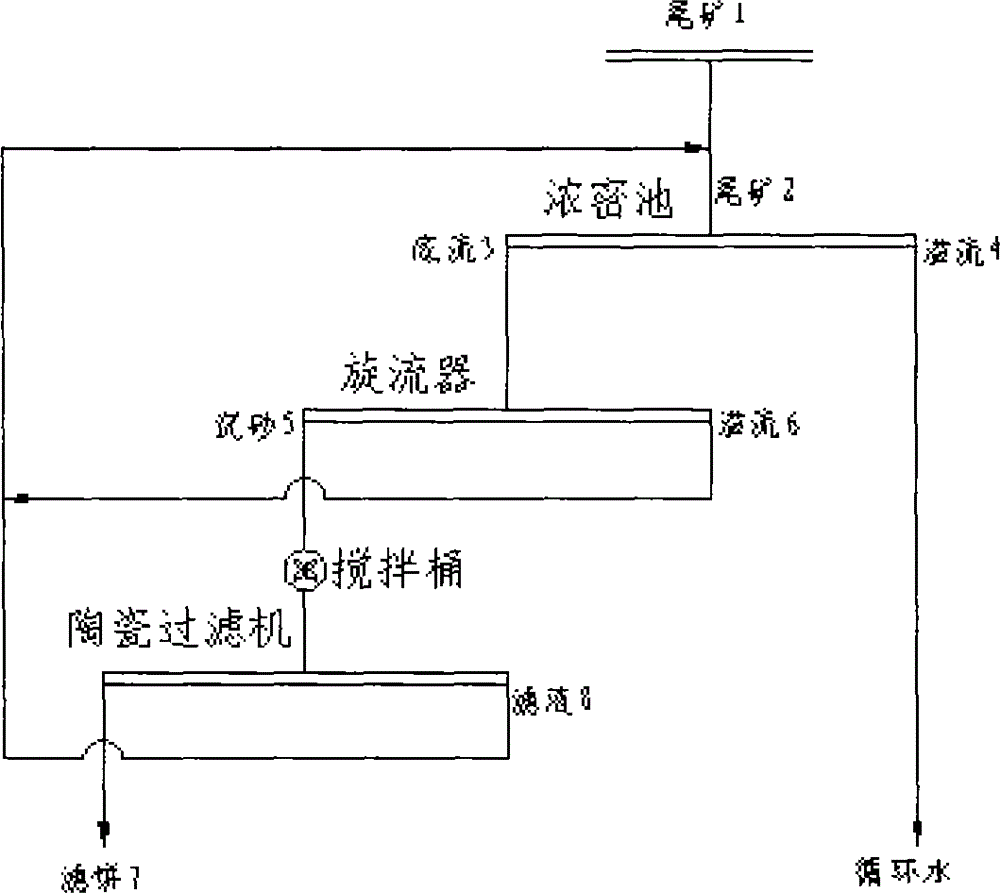

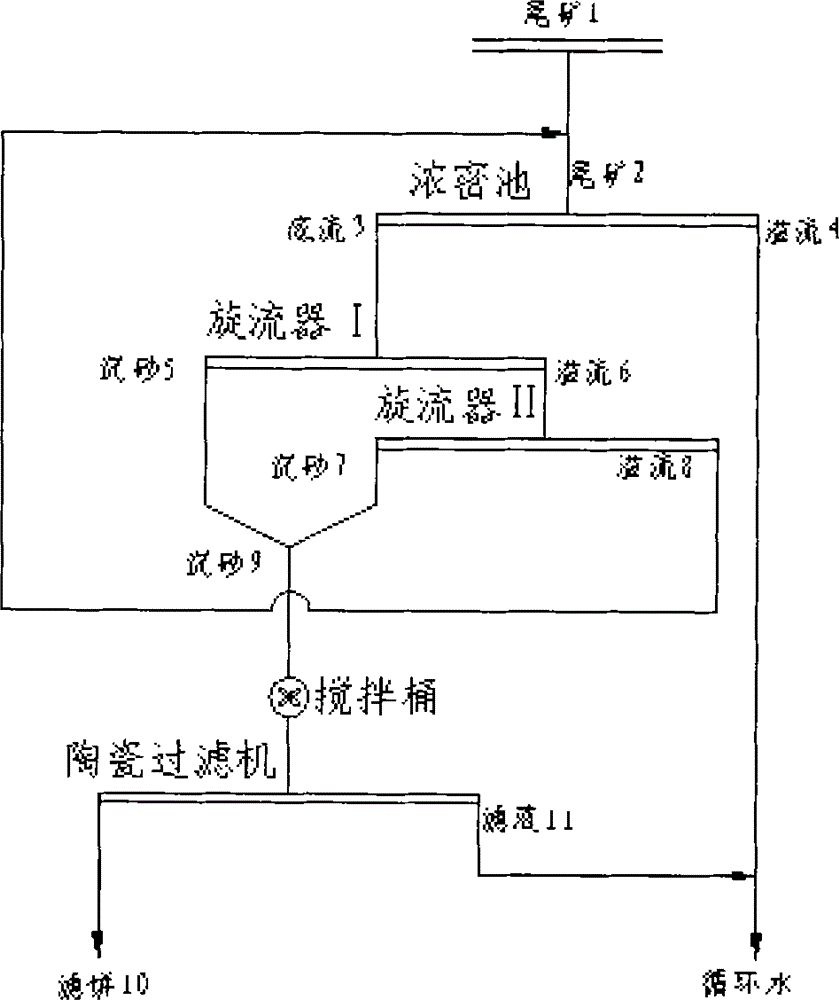

A thickening and dewatering method for tailings and applications thereof

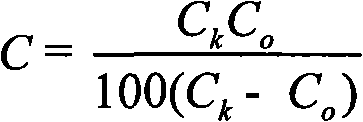

InactiveCN105363275AIncrease feed concentrationImprove dehydration efficiencyFiltration circuitsMaterials scienceTailings

The invention relates to a thickening and dewatering method for tailings. The method is suitable for thickening and dewatering fine-granule tailings adopting dry stockpiling or a comprehensive utilization plan. According to the method, tailings fed into a stirring barrel are subjected to secondary thickening by adopting a hydrocyclone so as to increase the concentration of tailings fed into a ceramic filter, overflow of the hydrocyclone and filtrate of the ceramic filter are returned to a thickening pond and mixed with fine-granule tailings discharged from an ore dressing process so as to reduce the concentration of the tailings and to increase the deposition speed of the tailings, thus finally achieving the objectives of increasing the efficiency of the ceramic filters and reducing the cost of dewatering.

Owner:范思远 +1

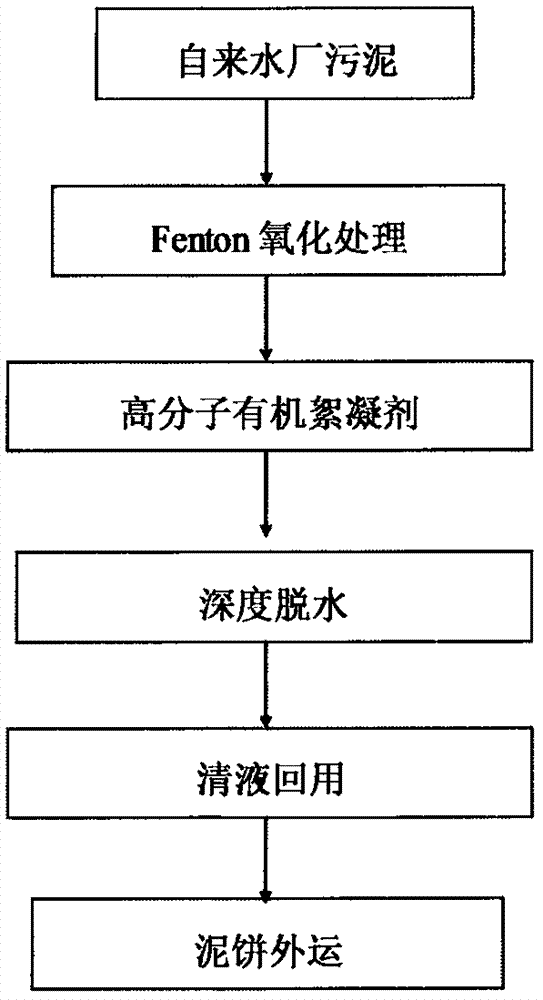

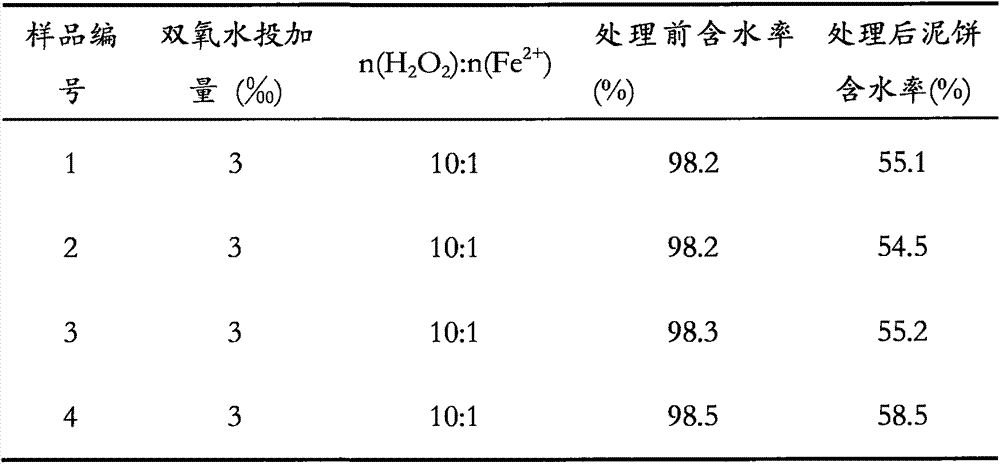

Safety recycling method for solid-liquid separation of sludge water of water supply plant

InactiveCN107089787AImprove dehydration effectImprove the efficiency of dewatering machinerySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeHigh pressure

The invention discloses a safety recycling method for solid-liquid separation of sludge water of a water supply plant. The method sequentially comprises a chemical conditioning process, a high-pressure filtering process and a membrane press filtering process, and comprises the following specific steps of (1) concentrating sludge of running water through gravity and treating by adopting a Fenton oxidation technology; (2) conditioning through the Fenton oxidation technology, generating flocs in the sludge and adding a few of organic macromolecule flocculants to carry out secondary construction of the flocs; (3) carrying out deep dehydration on conditioned sludge of the running water by adopting a filter device; and (4) recycling a clear liquid as inlet water of the water supply plant and transporting a mud cake outward. The dehydration effect of the sludge is improved, and reflux recycling of the sludge water is achieved.

Owner:北京尚水清源水处理技术有限公司

Low temperature demulsifier and preparation method thereof

InactiveCN104293376AReduce the cost of demulsification and dehydrationReduce dehydration costsDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierOleic Acid Triglyceride

The invention relates to a low temperature (30 DEG C) demulsifier and a preparation method thereof. The demulsifier comprises by 40-45% of multiple block polyether, 1.5-2% of triethanolamine, 2-2.5% of oleic acid and 20-50% of methanol and the balance of water, calculated by the weight of the demulsifier being 100%. The low temperature demulsifier of the invention has dehydration rate of 91.6% to crude oil of Changqing ultralow permeability reservoir under the conditions of 50 ppm and temperature of 30 DEG C.

Owner:PETROCHINA CO LTD

Rapid dewatering device for printing and dyeing processing

InactiveCN110029464ADehydration fastImprove dehydration effectLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater collectionWater pipe

The invention discloses a rapid dewatering device for printing and dyeing processing. The device comprises a dewatering box, a third guiding roller, a fourth guiding roller, a tension adjusting device, an extruding roller set, a fifth guiding roller, a partition plate, a water collection groove, a material guiding channel, a sixth guiding roller, a fabric flapping device, a leveling roller set, awater collecting tank, a water pipe, a heat supply device, a first air inlet, a first air outlet, a second air inlet, a second air outlet, an air supply pipe, a first exhaust fan, a second exhaust fan, a heat supply pipe assembly and an air jet head; one side wall of the dewatering tank is correspondingly provided with a fabric inlet and a fabric outlet up and down. The rapid dewatering device canachieve the purpose of repaid dewatering by adopting a combination mode of extruding roller dewatering and hot air drying for conducting dewatering operation on textile fabric, the dewatering effectis good, and the efficiency is high; by adopting an integral structure design, the structure is compact, the occupation space of the dewatering device is greatly reduced, the structure is stable, theeffect of energy saving is achieved, and the dewatering cost during printing and dyeing processing is reduced.

Owner:朱斯

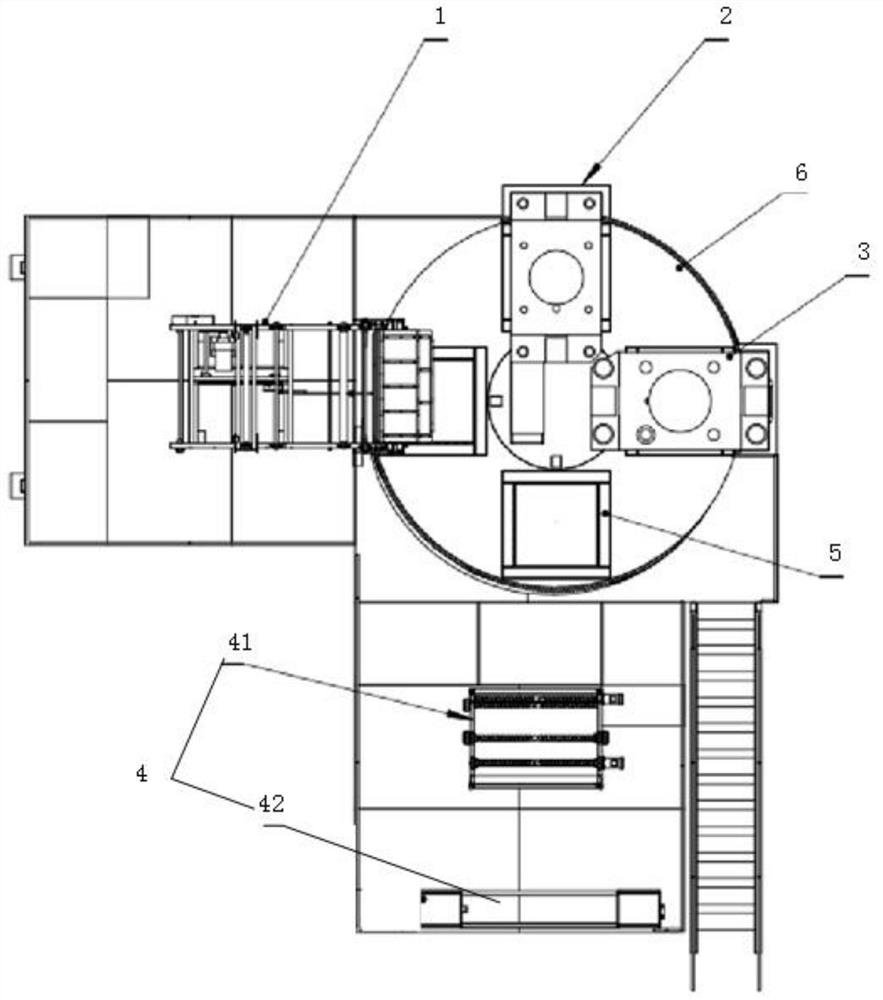

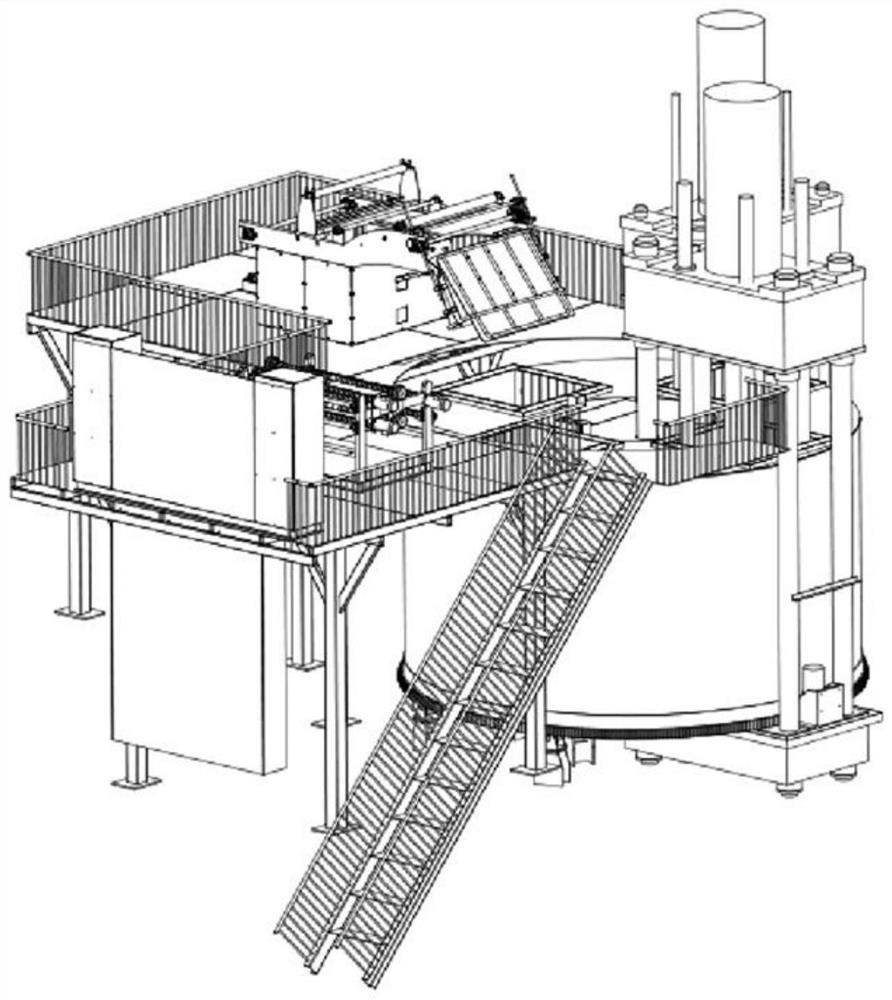

Sludge continuous dewatering system

ActiveCN112607995AReduce dehydration costsHigh degree of automationSludge treatmentProcess engineeringSludge dewatering

The invention relates to a sludge continuous dewatering system which is characterized by comprising a feeding device, a pre-dewatering device, a deep dewatering device and a sludge discharging device, sludge is conveyed to the feeding device through a pipeline, the sludge is evenly distributed in the two layers of filter cloth through the feeding device, and the two layers of filter cloth wrapped with the sludge are folded and fed into the station cylinder through the feeding device to serve as materials in the station cylinder. the station cylinder is moved to a pre-dewatering device; the pre-dewatering device is used for squeezing and maintaining the pressure of materials in the station cylinder through a low-tonnage hydraulic machine; the station cylinder is moved to the deep dewatering device; the deep dewatering device carries out squeezing and pressure maintaining on the materials in the station cylinder again through the high-tonnage hydraulic machine; the station cylinder is moved to the sludge discharging device; the sludge discharging device is used for separating the sludge and the filter cloth in the station cylinder, the two layers of separated filter cloth are recycled, and the separated sludge is transmitted to a designated position. Through the system, the automation degree of the system is improved, the dewatering performance is improved, and the dewatering cost of different types of sludge can be effectively reduced.

Owner:芜湖海创环保科技有限责任公司

Treatment method for electroplating sludge

InactiveCN108383343ARealize resource utilizationReduce resource utilizationSludge treatment by de-watering/drying/thickeningWater treatment compoundsSlagSludge

The invention provides a treatment method for electroplating sludge. The method comprises the following steps: (1) adding a composite additive into the electroplating sludge in a mass ratio of 100 to(5-7), mixing uniformly, then putting the mixture in an ultraviolet irradiation condition, and stirring and processing for 1-1.5h at a revolving speed of 110-120r / min; (2) adding coke powder into themixture obtained in step (1), maintaining the added amount of the coke powder to be 20% of the mass of the mixture, mixing uniformly, then performing filter pressing treatment, collecting mud cakes, and meanwhile, discharging filtrate subjected to purification treatment; (3) smashing the mud cakes collected in step (2), drying the smashed mud cakes until the moisture content is less than or equalto 8%, keeping the smashed mud cakes in a condition that the temperature is 1,100-1,200 DEG C so as to perform smelting treatment, enabling exhaust gas, which is generated through smelting, to be subjected to purification treatment, then discharging the exhaust gas, and refining and separating materials subjected to smelting to obtain melted slag and metal alloy.

Owner:重庆康达实业有限公司

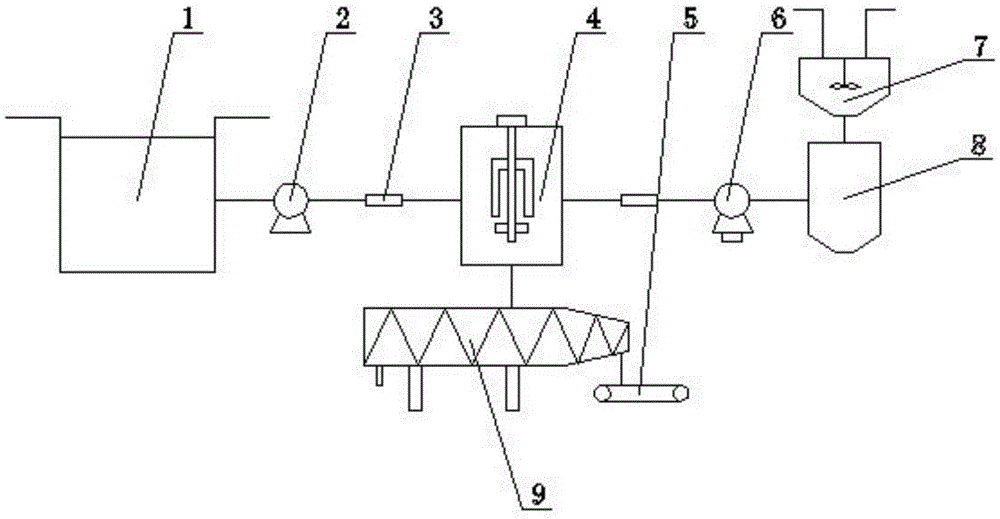

Centrifugal sludge dewatering type small-sized innocent sludge treatment system

InactiveCN105481223AAchieve a fast dehydration processScientific and reasonable structure designSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemical storageCentrifugal extractor

The invention relates to a centrifugal sludge dewatering type small-sized innocent sludge treatment system. The centrifugal sludge dewatering type small-sized innocent sludge treatment system comprises a sludge storage pool, a sludge intake pump, a flowmeter, a mixing reactor, a chemical manufacturing tank, a chemical storage tank, a chemical intake pump and a sludge centrifugal extractor, wherein the sludge storage pool is connected with an inlet of the mixing reactor by the sludge intake pump and the flowmeter; the chemical manufacturing tank is connected with another inlet of the mixing reactor by the chemical storage tank, the chemical intake tank and the flowmeter; the outlet of the mixing reactor is connected with the sludge centrifugal extractor. The centrifugal sludge dewatering type small-sized innocent sludge treatment system is scientific and reasonable in design, high in processing effect, convenient to manage and strong in operability, and effectively reduces the sludge dehydration cost.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Method for preparing edible mushroom culture medium from potato residue

InactiveCN104557258AFully realize the potential valuePrevent acid fermentationCalcareous fertilisersOrganic fertilisersCompostMoisture

The invention discloses a method for preparing an edible mushroom culture medium from potato residue. The method comprises the following steps: removing rotted potato residue, spreading the potato residue on an iron net and dehydrating, enhancing the ventilation force so that the moisture content of the potato residue is evaporated, and grinding and sieving the air-dried potato residue; evenly mixing 15-20 parts of potato reside, 10-15 parts of saw dust, 4-5 parts of soybean cake powder, 62-66 parts of straw powder and 1-2 parts of gypsum, and adding water until the moisture content is 60-62% and then stirring evenly; bagging and sterilizing, thereby obtaining the edible mushroom culture medium. According to the method, the leftovers of agricultural and forestry products are taken as the major compost needed by cultivating the edible mushrooms, so that the edible mushroom culture cost is reduced; especially, the dosage of the potato residue and other raw materials is optimized so that the biological conversion rate can be increased and the potential value of the potato residue can be developed thoroughly; besides, the environmental pollution caused by the waste potato residue in the potato processing process is solved, the agricultural product processing industry chain is expanded, excellent ecological benefit is generated and considerable economic benefit is generated.

Owner:GANSU ZHENGYANG FOOD

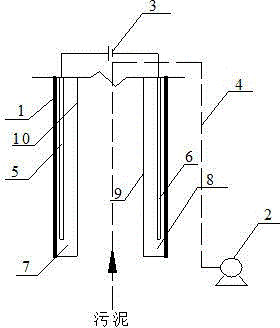

Device for removing heavy metals in sludge by using electro-dynamic method and synchronously and deeply dehydrating sludge

ActiveCN104909526AHigh power utilizationSimple processSludge treatmentIon-exchange membranesChemistry

The invention relates to a device for removing heavy metals in sludge by using an electro-dynamic method and synchronously and deeply dehydrating sludge in a process of conveying digested sludge. The device comprises a sludge conveying pipeline, a sludge pump, a direct-current power supply, electrodes and ion exchange membranes / porous medium membranes, wherein the treatment object of the device is anaerobic digestion sludge; the electric remediation is implemented in the sludge conveying process in the pipeline; a positive electrode and a negative electrode are arranged on the inner wall of the pipeline; a positive chamber and a negative chamber are formed in two sides of the pipeline; the ion exchange membranes / porous medium membranes are arranged in the positive chamber and the negative chamber; the gap between the electrodes and the ion exchange membranes / porous medium membranes is filled with an electrolyte solution; the positive electrode and the negative electrode are connected with the power supply by virtue of a lead. By virtue of the device, the heavy metals in the sludge are removed by electrodialysis and electrolysis techniques in the process of conveying the anaerobic digestion sludge via the pipeline; meanwhile, the partial water in the sludge can be removed under the action of the ion exchange membranes / porous medium membranes; the device can be used for effectively utilizing the conveying power, and is convenient to operate; the subsequent resource utilization of the sludge can be facilitated.

Owner:TONGJI UNIV

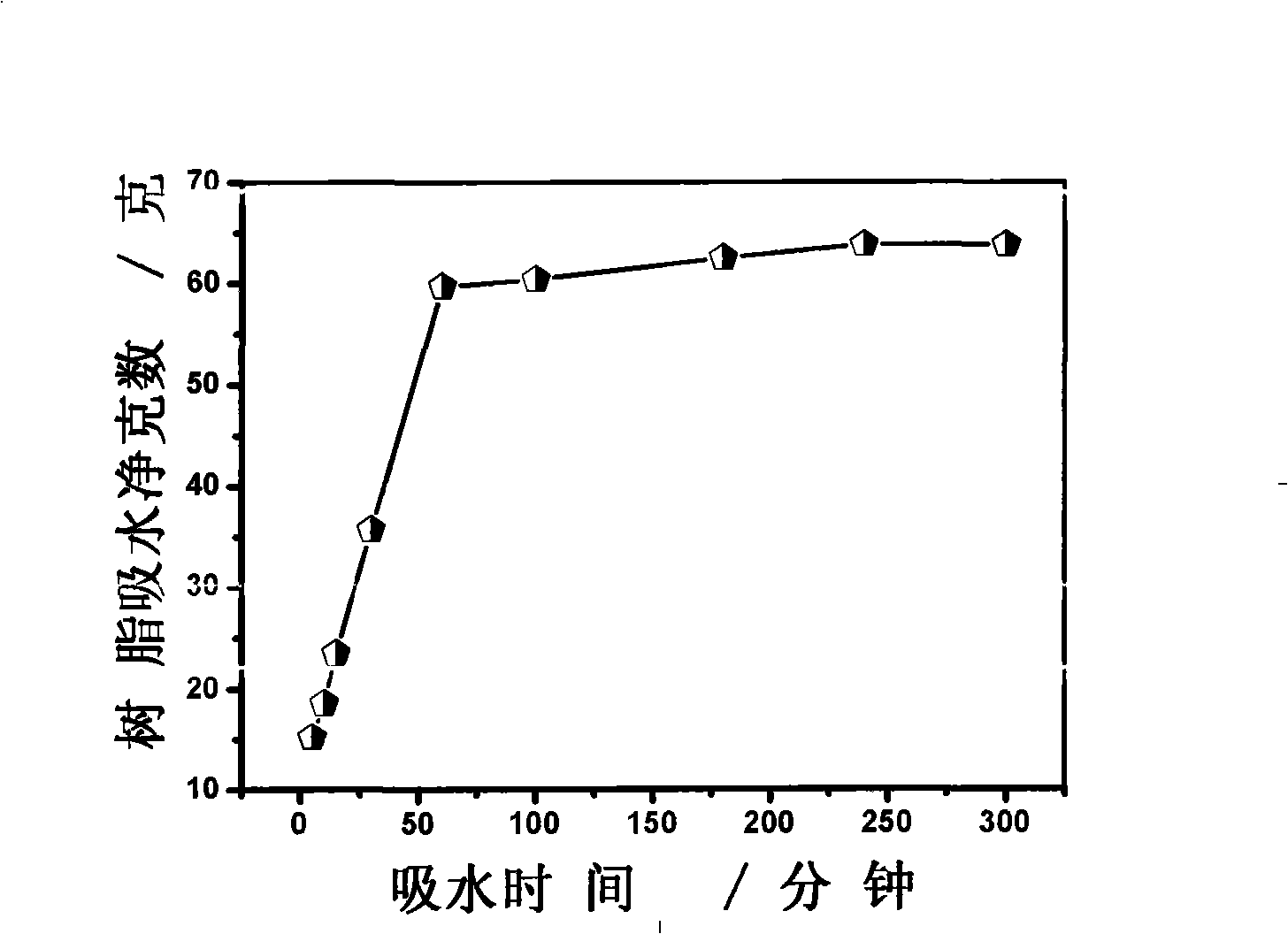

Room temperature dehydration method for hogwash oil with high-water uptake resin

InactiveCN101270319AReduce dehydration costsEnhance the destructive effectFatty oils/acids recovery from wasteOther chemical processesSodium BentoniteCooking oil

The invention provides a method for dehydrating waste cooking oil with super absorbent resin at room temperature. The super absorbent resin is the copolymer of sodium bentonite, acroleic acid and starch. The super absorbent resin is prepared by adding sodium bentonite to the graft copolymer of starch and acrylic acid. The dry graft copolymer of acroleic acid and starch accounts for 58 percent by weight and the sodium bentonite accounts for 42 percent by weight. The super absorbent resin absorbs 120 times distilled water. The particles of 50 to 200 meshes of the super absorbent resin are used as the dehydrator of waste cooking oil containing water for dehydrating waste cooking oil containing water with the density from 0.880g / cm3 to 0.934g / cm3. The single dehydration efficiency can exceed 50 percent; the method substitutes for common method for heating and dehydrating waste cooking oil containing water in vacuum or under reduced pressure, thus solving the problems of high cost, large energy consumption and unfriendliness to the environment of industrial dehydration of waste cooking oil.

Owner:CHANGCHUN UNIV OF SCI & TECH

Deodorization method for sludge composting fermentation

InactiveCN104496582AReduce dehydration costsHigh in nutrientsBio-organic fraction processingSludge treatment by de-watering/drying/thickeningActivated carbonFungicide

The invention discloses a deodorization method for sludge composting fermentation. The method comprises the following steps: (1) performing primary deodorization, and spraying by adopting a deodorization agent while dewatering during sludge dewatering, wherein the deodorization agent comprises 10-15 parts of activated carbon, 15-20 parts of zeolite, 8-10 parts of pomace and the balance of water; and (2) performing secondary deodorization, and adding a beneficial fungicide into the materials while sludge mixing and composting, wherein the effective microbial community comprises trichoderma viride, bacillus subtilis and aspergillus niger, and the mass part ratio of the trichoderma viride to bacillus subtilis to aspergillus niger is 2:2;1. In the mode, the deodorization method disclosed by the invention has the advantages that the deodorization effect can be improved, the sludge dewatering efficiency is improved, the sludge dewatering cost is reduced, and nutritional ingredients in the sludge are increased.

Owner:CHANGSHU TIANYUAN ENVIRONMENTAL PROTECTION SCI & TECH

Purified gas dehydration technology applied in natural gas with high sulfur content

The invention discloses a purified gas dehydration technology applied in natural gas with high sulfur content. The purified gas dehydration technology applied in natural gas with high sulfur content contains steps of: removing moisture from wet purified gas, regenerating a dehydration solution and the like. The invention can be used to effectively dehydrate purified gas and reduce dehydration cost, and requires simple processes.

Owner:袁俊海

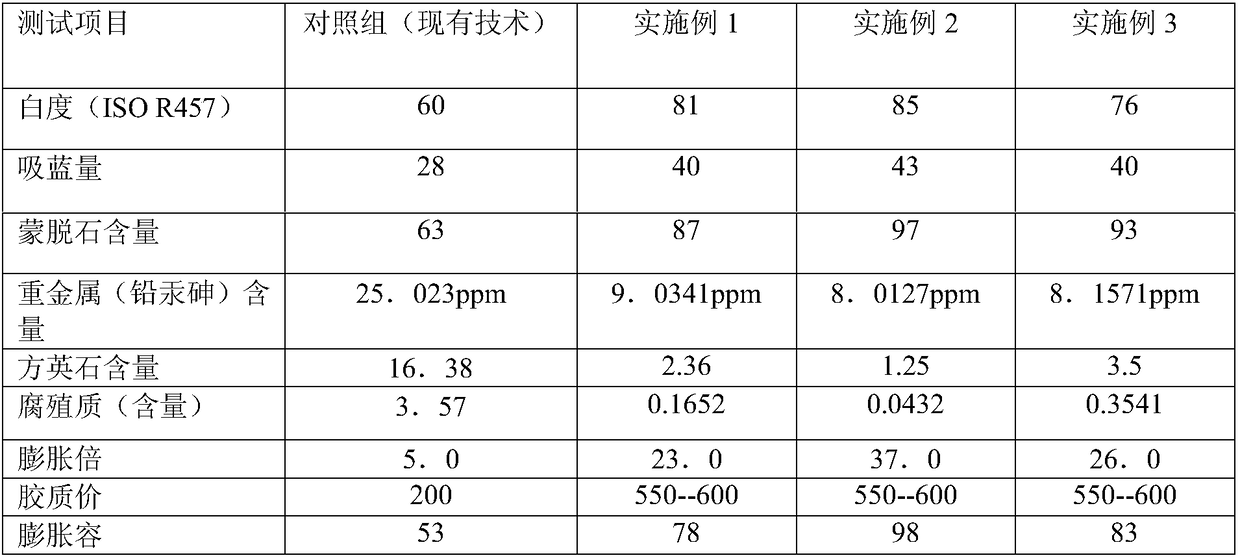

Process for producing refined montmorillonite by using bentonite

The invention relates to the field of bentonite purification processes, particularly to a process for producing refined montmorillonite by using bentonite. The process comprises: raw ore pulping, sieving, modifying, flocculation dehydration, acid neutralization, flocculation dehydration, washing, pulp adjusting and peeling, concentrating, spray drying, dispersing, and packaging. With the production process of the present invention, impurities, alkali insoluble impurities and acid insoluble impurities can be removed from raw ore, and the new generated impurities after the modification can be removed so as to further improve the product purity.

Owner:杭州柏科立新材料有限公司

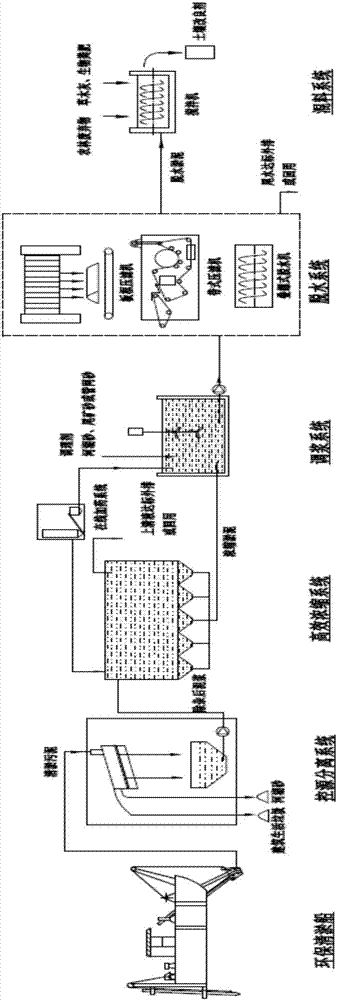

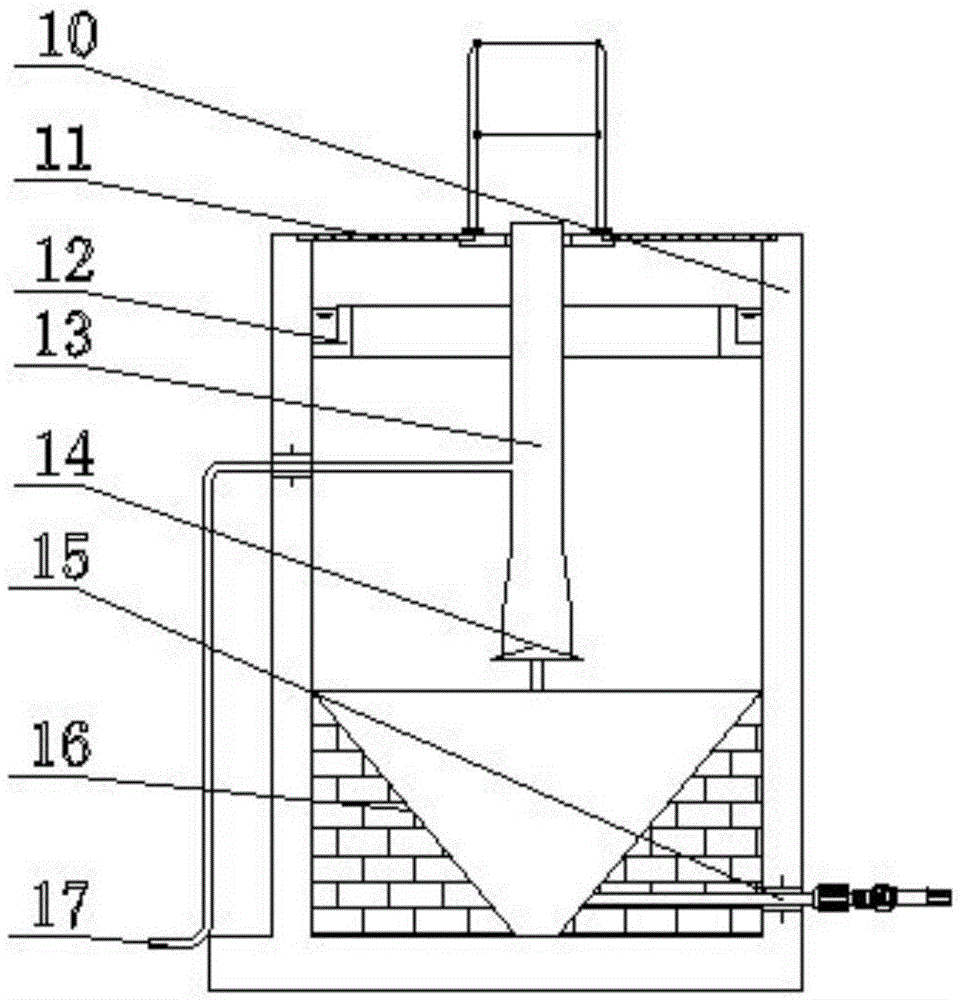

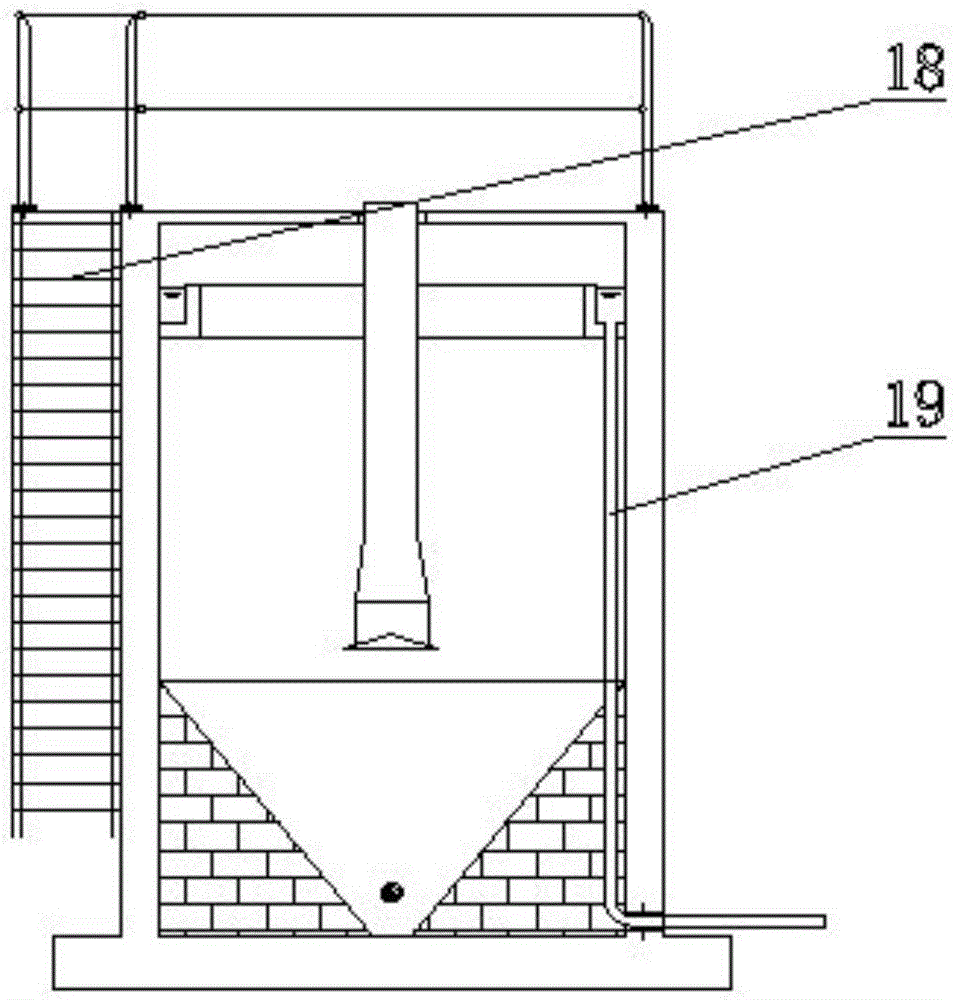

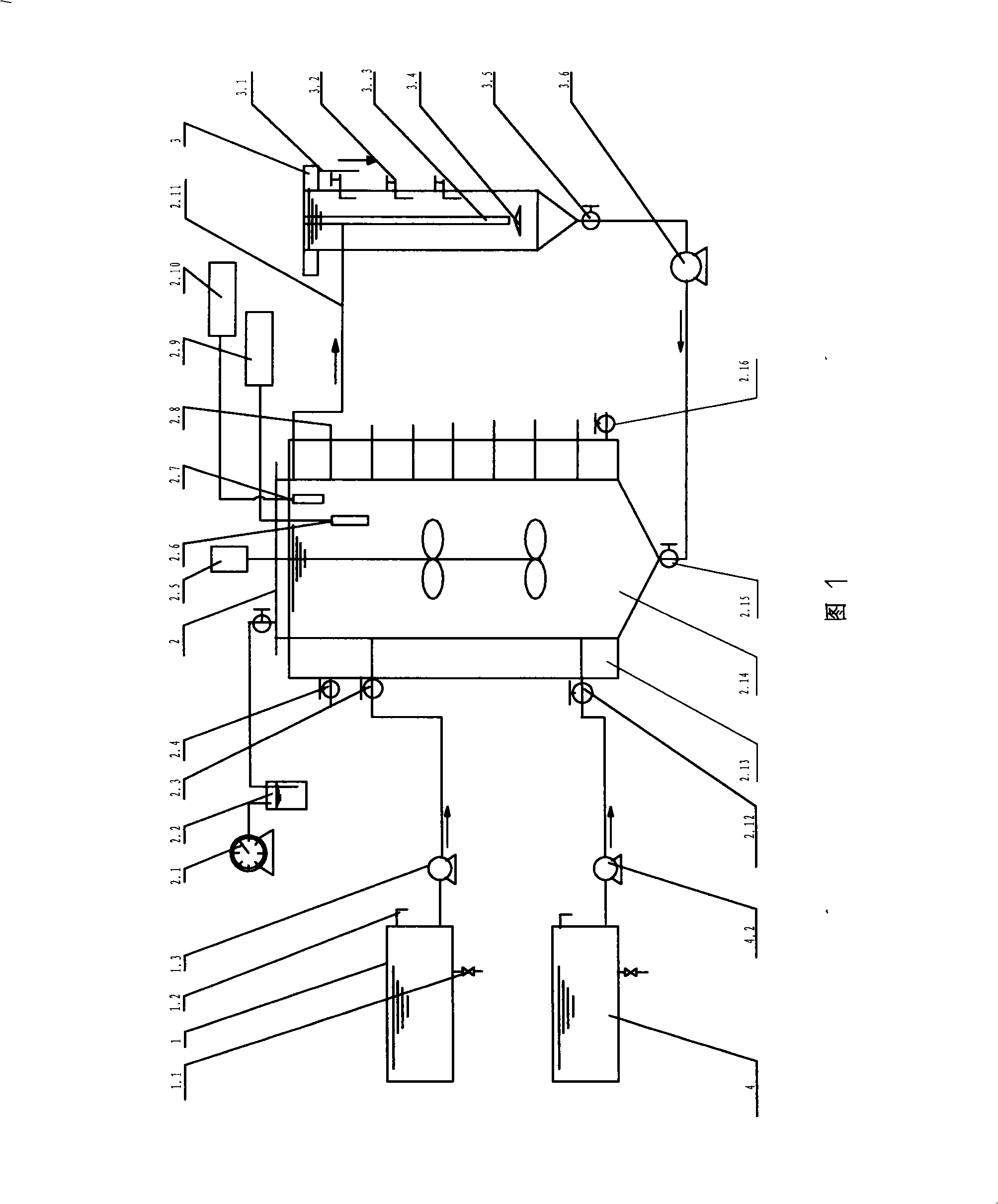

Apparatus and method for synchronous denitrification and development of sewage sludge internal carbon source of urban sewage

ActiveCN101318741ASolve the problem that it is difficult to improve the nitrogen removal efficiencyAchieve reductionTreatment with aerobic and anaerobic processesWater bathsSludge

The invention discloses a synchronous urban sewage denitrogenation and in-sludge carbon source development device and a method using the same. The device is provided with a nitration liquid raw water tank, a sludge denitrification reactor (SDR), a sedimentation tank and a sludge pool, wherein the SDR consists of a reaction chamber and a water bath heating sleeve arranged at the periphery of the reaction chamber; the sedimentation tank is provided with a central pipe and a conical baffle board; and the method making use of the device comprises the steps of starting and reaction cycle operation, etc. The synchronous urban sewage denitrogenation and in-sludge carbon source development device and the method using the same are suitable to be used in urban sewage treatment, and save carbon source along with high degree of automation, high efficiency and good effects.

Owner:BEIJING DRAINAGE GRP CO LTD

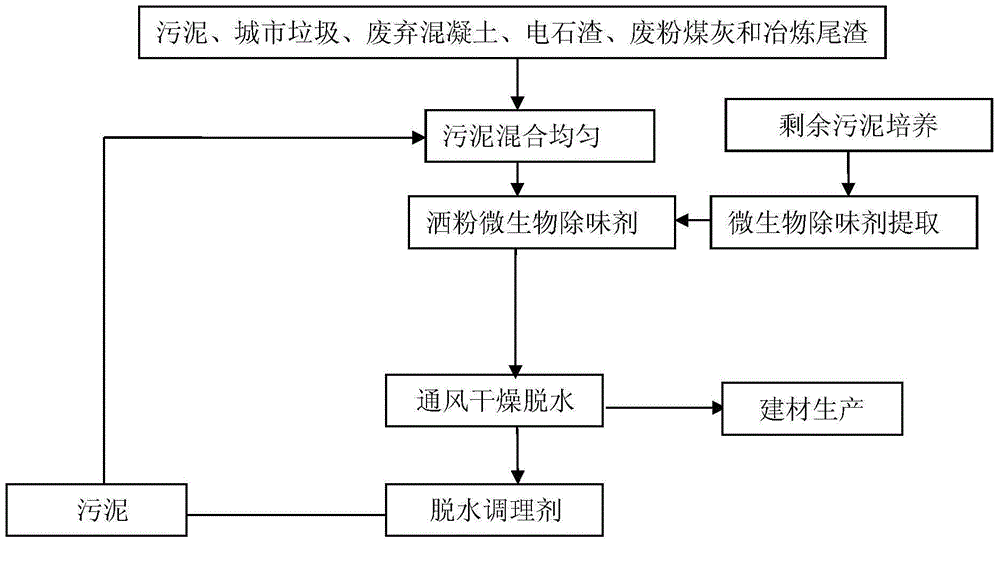

Compound sludge dewatering conditioner adaptable to technology for production of building materials from excess sludge as well as preparation method and application of conditioner

InactiveCN104891777ALow cost of dehydrationCause secondary pollutionSludge treatment by de-watering/drying/thickeningBrickSlag

The invention relates to a compound sludge dewatering conditioner adaptable to a technology for production of building materials from excess sludge as well as a preparation method and an application of the conditioner. The conditioner comprises components in percentage by mass as follows: 20%-60% of SiO2, 5%-20% of Al2O3, 1%-15% of Fe2O3, 5%-15% of CaO, 5%-30% of C and 0.25-2% of N. The preparation method comprises steps as follows: mixing waste concrete, carbide slag, waste fly ash and smelting tailings in proportion to obtain a mixture, mixing the mixture with sludge, spraying a microorganism odor absorber, and performing ventilation and heat preservation for 3-7 days to obtain the conditioner. The conditioner has the dewatering effect and can be used as an important component of raw building materials. When the conditioner is applied to deep sludge dewatering, the method is simple, the dewatering rate can be adjusted according to the comprehensive utilization application of the sludge, the moisture content can be decreased to be lower than 5%, preparation of the building materials such as ceramsite, bricks and the like is facilitated, and the cost for preparation of the building material from the sludge is reduced.

Owner:DONGHUA UNIV

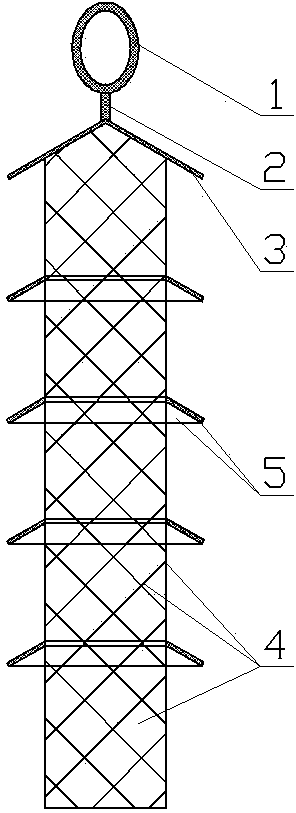

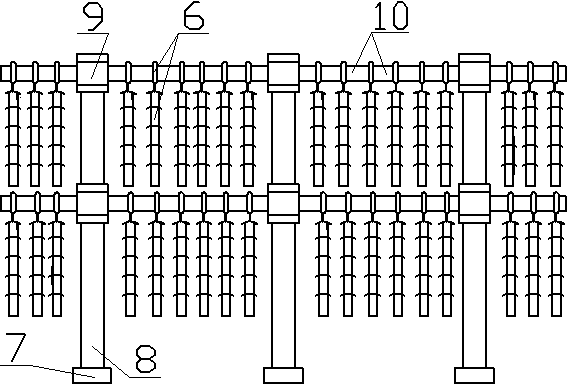

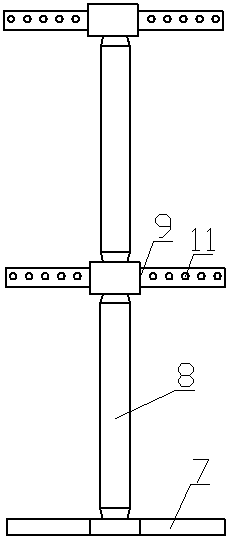

Tuber natural wind dehydration device

The invention discloses a tuber natural wind dehydration device. Each base of the tuber natural wind dehydration device is fixed in the mode that an inner taper hole in the middle of the base is matched with an outer conical face of the lower end of a supporting column. Each transverse frame is fixed in the mode that a longitudinal taper hole of the transverse frame is matched with the upper end face or the outer conical face at the lower end of the corresponding supporting column. A transverse bearing position is arranged on each transverse frame. A transverse load bearing rod is inserted into bearing position holes or bearing position grooves of the transverse bearing positions. A hanging handle is arranged on the lower portion of each bag hanging piece. A rain shielding cover is arranged on the lower portion of each hanging handle. One end of each mesh bag is fixed to the corresponding rain shielding cover. At least one rain shielding eave is fixed to the periphery, in the longitudinal direction, of each mesh bag. The tuber natural wind dehydration device is simple in structure and brings convenience to wind dehydration and airing, wind hydration can be conducted on rubber on a large scale without skewering the tubers onto one skewer, labor intensity is lowered, wind dehydration time is shortened, labor is saved, rapidness is achieved, and production efficiency is improved; a tuber natural wind dehydration frame and the tuber natural wind dehydration mesh bags can be repeatedly used, so that wind dehydration cost is reduced.

Owner:JIANGSU LIGONG FRUIT & VEGETABLE MACHINERY

Integrated method for collaborative treatment of sludge and algal mud

InactiveCN110342779AHigh organic contentIncrease the calorific value of incinerationSludge treatment by de-watering/drying/thickeningIncinerator apparatusBiologyDehydration

The invention discloses an integrated method for collaborative treatment of sludge and algal mud. According to the integrated method, the technical problems ofalgal mud lacking of skeleton agents difficult dehydration alone and the low calorific value of sludge incineration alone can be simultaneously solved, and so that algal mud and sludge disposal can realize industrial application. The integrated method for collaborative treatment of the sludge and the algal mud comprises the following steps of dilution, conditioning, dehydration, drying and incineration,is characterized in that mixing stepsare arranged before dilution steps, and the mixing steps comprise the sludge and the algae mud are mixed according to the ratio of 1:1-1:3of absolute dry capacity.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

Method for electrochemically preparing trifluoromethylsulfonyl fluoride from methylsulfonyl chloride

ActiveCN112760672ARaw materials are easy to getSimple and fast operationElectrolysis componentsElectrolytic organic productionElectrolytic agentSulfonyl chloride

The invention relates to a method for electrochemically preparing trifluoromethylsulfonyl fluoride from methylsulfonyl chloride, and belongs to the field of fine chemical engineering. The method comprises the following steps: adding methylsulfonyl chloride, a conductive agent and anhydrous hydrogen fluoride into an electrolytic bath to form an electrolyte; subjecting the electrolyte to electrolytic dehydration for 2-10 h under the conditions that the temperature ranges from -10 DEG C to 20 DEG C and the voltage ranges from 3 V to 4.5 V; and under the conditions that the temperature ranges from -10 DEG C to 20 DEG C and the voltage ranges from 5 V to 7.5 V, conducting eletrolysis to obtain electrolysis gas, wherein the electrolysis gas contains trifluoromethylsulfonyl fluoride. According to the method, methylsulfonyl chloride is used as a raw material, a conductive agent and anhydrous hydrogen fluoride are added, an electrochemical fluorination reaction is carried out at a constant voltage, trifluoromethylsulfonyl fluoride can be obtained, wherein the anhydrous hydrogen fluoride is a solvent and a fluorinating agent of the electrolyte. The electrochemical preparation method of trifluoromethylsulfonyl fluoride provided by the invention is simple and convenient to operate, low in cost and suitable for large-scale application.

Owner:PERIC SPECIAL GASES CO LTD

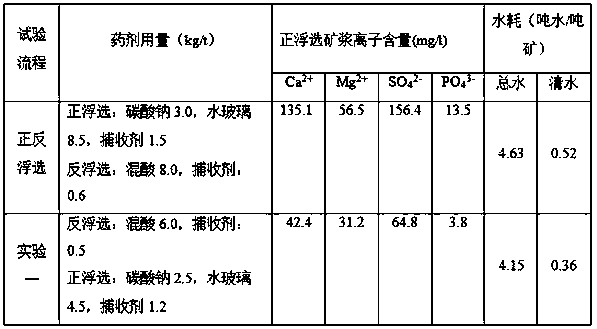

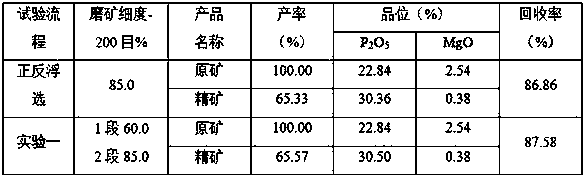

Reverse-direct flotation method for siliceous-calcareous collophanite

The invention relates to a reverse-direct flotation method for siliceous-calcareous collophanite. According to the method, after raw ore is ground, a flotation process sequentially comprising reverseflotation magnesium removal and direct flotation desilicication operation is adopted, reverse flotation return water enters a reverse flotation water return pool and then returns to reverse flotationmagnesium removal so as to be used, direct flotation return water enters a direct flotation water return pool and then returns to direct flotation desilicication operation, and surplus direct flotation return water is fed into the reverse flotation water return pool so as to be used for reverse flotation. According to the invention, with the method, water can be saved, all wastewater can be recycled, and the treatment cost is low; by using a flotation process sequentially comprising reverse flotation and direct flotation, less water is needed, and reverse flotation return water enters the reverse flotation return water pool and then is reused for reverse flotation; and on the premise that the indexes of the concentrate yield, the grade and the recovery rate are similar to those in the prior art, the dosage of chemicals is small, the ion content of ore pulp in direct flotation operation is low, and water consumption is small.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

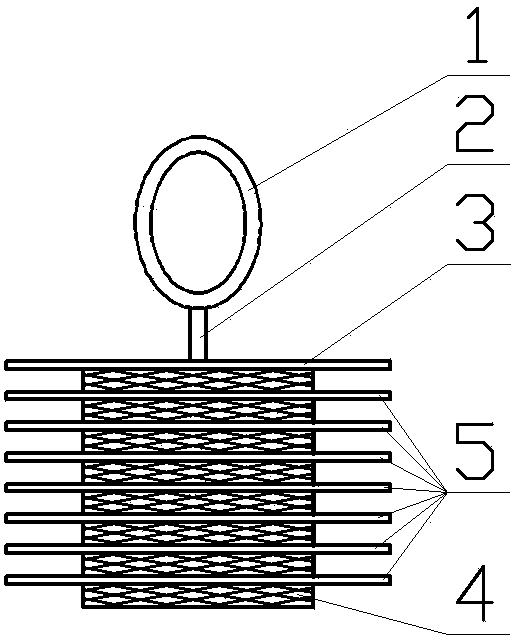

Natural tuber mustard airing dehydration equipment

The invention discloses natural tuber mustard airing dehydration equipment. A base of the equipment is fixed by virtue of the matching of a middle triangular hole and a triangular column at the lower end of a supporting rod, a transverse frame is fixed by virtue of the matching of a triangular hole in the transverse frame and a triangular column at the upper end of the supporting column or the triangular column at the lower end of the supporting column, a transverse support is arranged on the transverse frame, and a transverse connection bearing rod is inserted into a support hole or a support groove of the transverse support. A hanging handle is arranged below a bag hanger, a rain sheltering cover is arranged below the hanging handle, one end of each mesh bag is fixedly arranged on the rain sheltering cover, and at least one rain sheltering brim is fixedly arranged on the periphery of the longitudinal direction of each mesh bag. The natural tuber mustard airing dehydration equipment is simple in structure and has a convenient airing dehydration function; tuber mustard can be subjected to airing dehydration on a large scale without stringing, so that the labor intensity is reduced, the airing dehydration time is shortened, the effects of labor saving and quickness are achieved, and the production efficiency is improved; a tuber mustard airing dehydration frame and the tuber mustard airing dehydration mesh bags can be reused, and therefore the airing dehydration cost is reduced.

Owner:杜金潞

A kind of comprehensive utilization treatment method of aluminum ash

ActiveCN105347361BHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com