Deep sludge filter-pressing dehydration device and dehydration method

A sludge filter press and dehydration device technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of manual operation, low work efficiency, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Embodiment 1: The deep sludge filter press dewatering of the present invention includes a filter press dewatering device and a filter press dewatering method based on the filter press dewatering device.

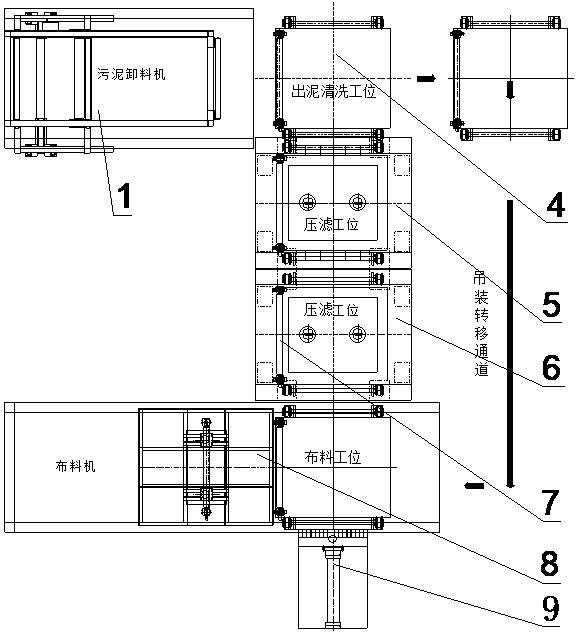

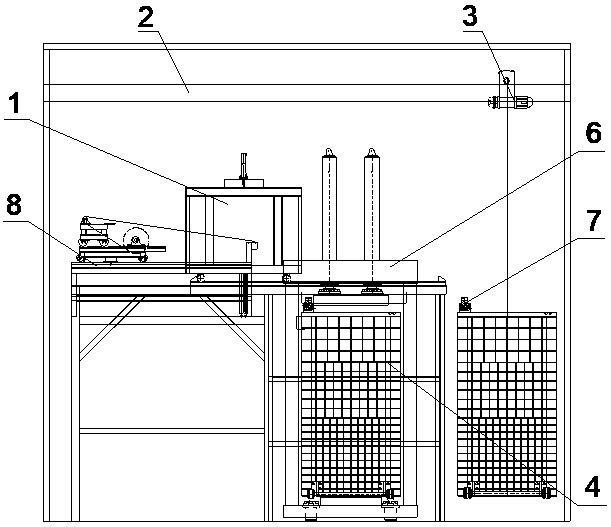

[0109] The sludge filter press dewatering device includes: sludge unloader 1, driving frame 2, driving car 3, filter press barrel 4, sludge filter press, filter cloth drum 7, sludge distributing machine 8 and filter barrel automatic cycle shifter Bit machine;

[0110] The sludge distributing machine and the sludge unloading machine are relatively installed and arranged. On the side of the sludge distributing machine and the sludge unloading machine, there are respectively a distributing station and a sludge cleaning station. The distributing station and the sludge cleaning station are located on the same axis;

[0111] There is a sludge filter press between the distributing station and the sludge cleaning station, there is at least one sludge filter press, and there i...

Embodiment 2

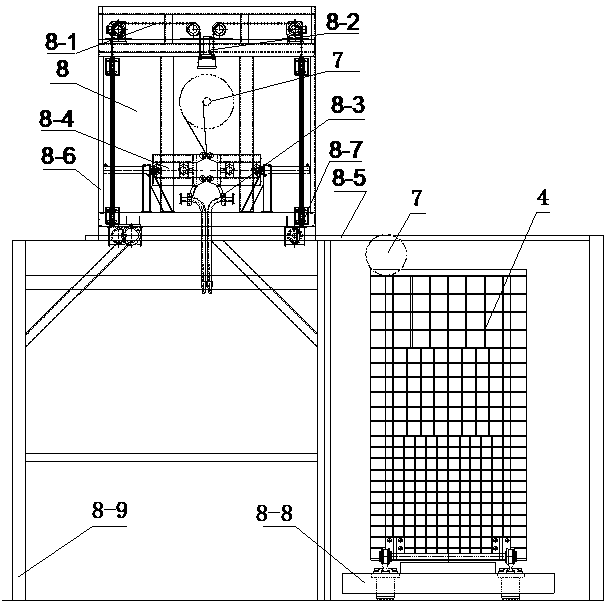

[0169] Example 2: Figure 17 and Figure 18 Among them, both ends of the lifting driven shaft 8-1-9 are connected with a driven connecting wheel 8-1-7 through a sleeve 8-1-6; a lifting chain 8-1-7 is bypassed on the sprocket 8. One end of the lifting chain 8-1-8 is connected to the pick-and-place device 8-2, and the other end of the lifting chain 8-1-8 is connected to the lifting hydraulic cylinder 8-1-11.

[0170] Others are the same as in Example 1.

Embodiment 3

[0171] Example 3: Figure 11 Among them, the filter cloth drum lifter 8-1 has two groups with the same structure, which are hydraulic lifting cylinders, the lower end of the hydraulic lifting cylinder is connected to the lifting plate 8-13, and the pick-and-place device 8-2 is connected to the lifting plate 8-13 The lower end moves up and down with the lifting plate 8-13 under the effect of the hydraulic lifting oil cylinder.

[0172] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com