Sludge filter pressing device of deep sludge filter-pressing dehydration system

A technology of sludge pressure filtration and depth, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as low work efficiency, need for manual operation, and high labor intensity of workers, and achieve The effect of reducing labor, avoiding sludge increment, and high degree of equipment automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

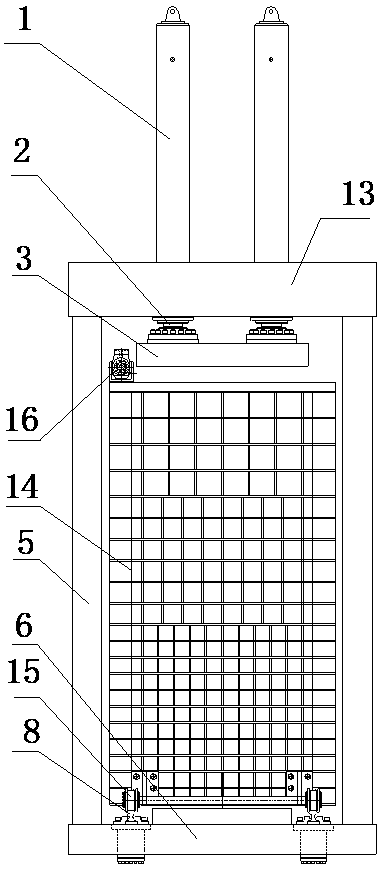

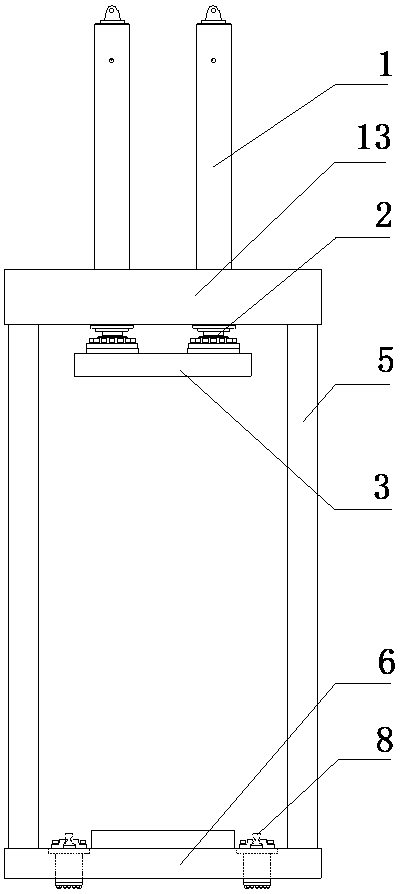

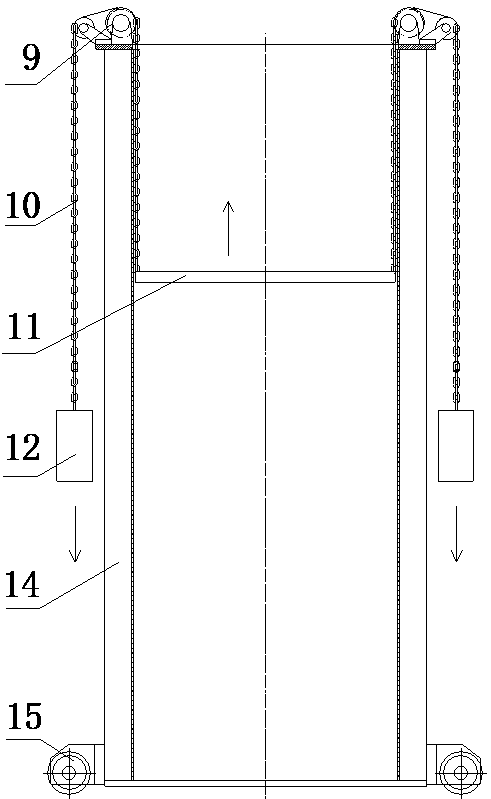

[0022] Embodiment 1: The sludge filter press includes: a filter press barrel and a press; the filter press barrel is placed under the filter press platform 3 of the press, and the press applies filtration pressure to the sludge in the filter press barrel.

[0023] The press comprises: a filter press cylinder 1, a filter press cylinder piston 2, a filter press platform 3, a filter press support 5, a filter press base 6, a filter bucket guide rail 8 and a filter press top seat 13; A filter press support 5 is connected with the filter press base 6; a filter press oil cylinder 1 is connected on the filter press top seat 13, and the filter press oil cylinder piston 2 of the filter press oil cylinder 1 passes through the filter press top seat 13. The end of the piston 2 is connected with a filter press platform 3; there is a filter barrel guide rail 8 on the filter press base 6, and the filter press barrel runs on the filter barrel guide rail 8.

[0024] The filter press barrel incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com