Patents

Literature

62results about How to "Achieve dehydration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

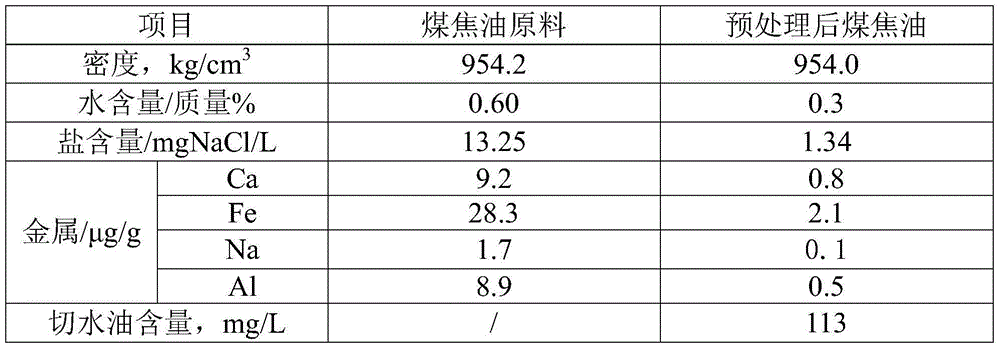

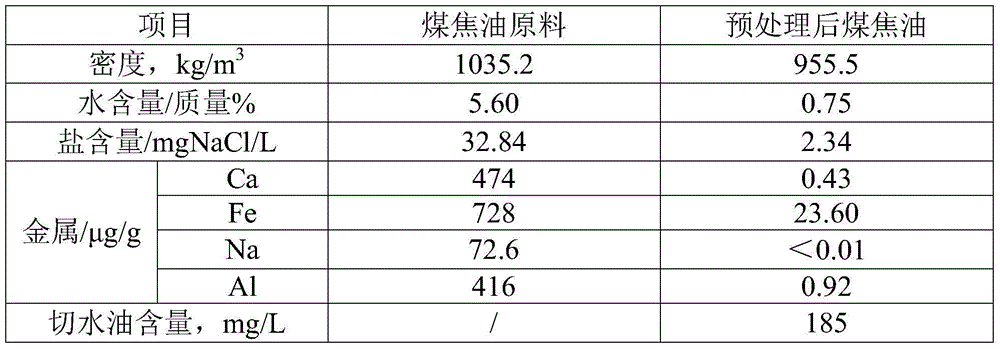

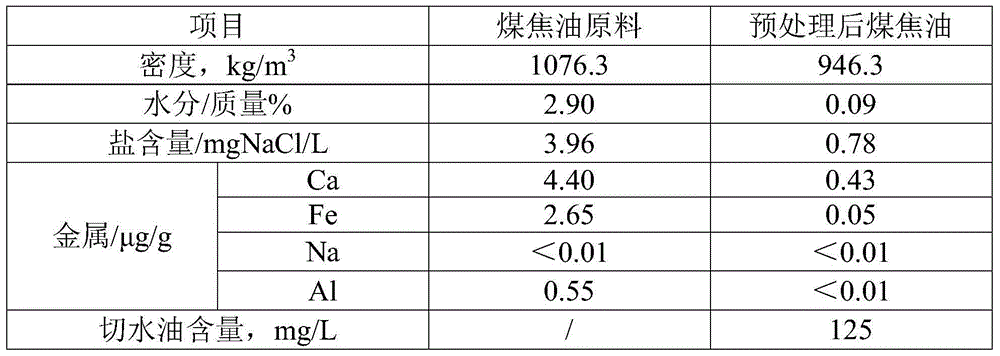

Coal tar pretreatment method

InactiveCN105623698AAchieve dehydration effectTar working-up by chemical refiningPretreatment methodOil water

The invention discloses a coal tar pretreatment method. The coal tar pretreatment method comprises that coal tar and a metal removal agent aqueous solution undergo a contact reaction in a fiber liquid film contactor and the reaction product is subjected to oil-water separation. The coal tar pretreatment method has simple processes, greatly saves power consumption, reduces a chemical agent use amount, reduces water pollution, reduces a pretreatment cost, realizes cut water recycle, saves resources and realizes the invention purpose.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

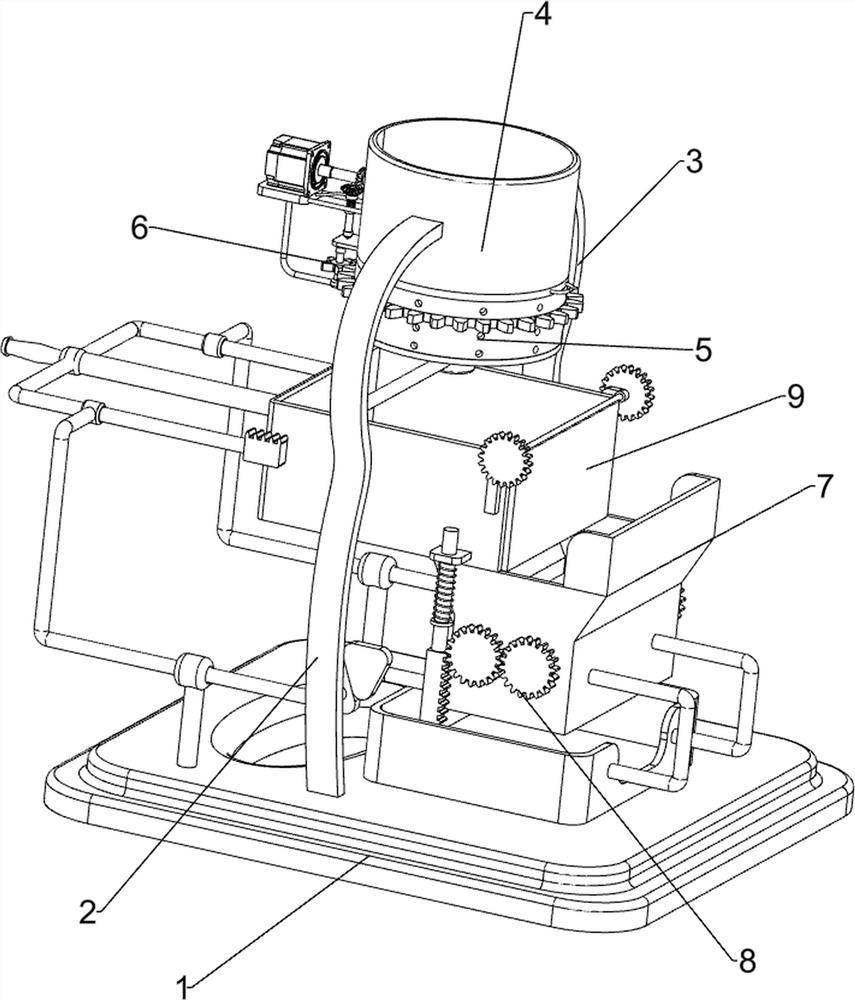

Edible potato cleaning device

InactiveCN112425798AAchieve cleaningAchieve dehydration effectCleaning using toolsFood treatmentMotor driveBiochemical engineering

The invention relates to a cleaning device, in particular to an edible potato cleaning device, and provides the edible potato cleaning device which consumes less water resources, is high in working efficiency and is simple and easy to collect. The edible potato cleaning device comprises a first fixing plate, wherein a first supporting rod is arranged in the middle of the left side of the first fixing plate; a second supporting rod which is arranged in the middle of the right side of the first fixing plate; a cleaning mechanism which is arranged between the first supporting rod and the second supporting rod; a dehydration mechanism which is arranged between the upper parts of the first supporting rod and the second supporting rod. Potatoes are put into the first discharging frame, then clear water is poured into the first discharging frame, the motor is started, and the output shaft of the motor drives the first rotating shaft to rotate so that the brush is driven to rotate to clean thepotatoes.

Owner:傅世秋

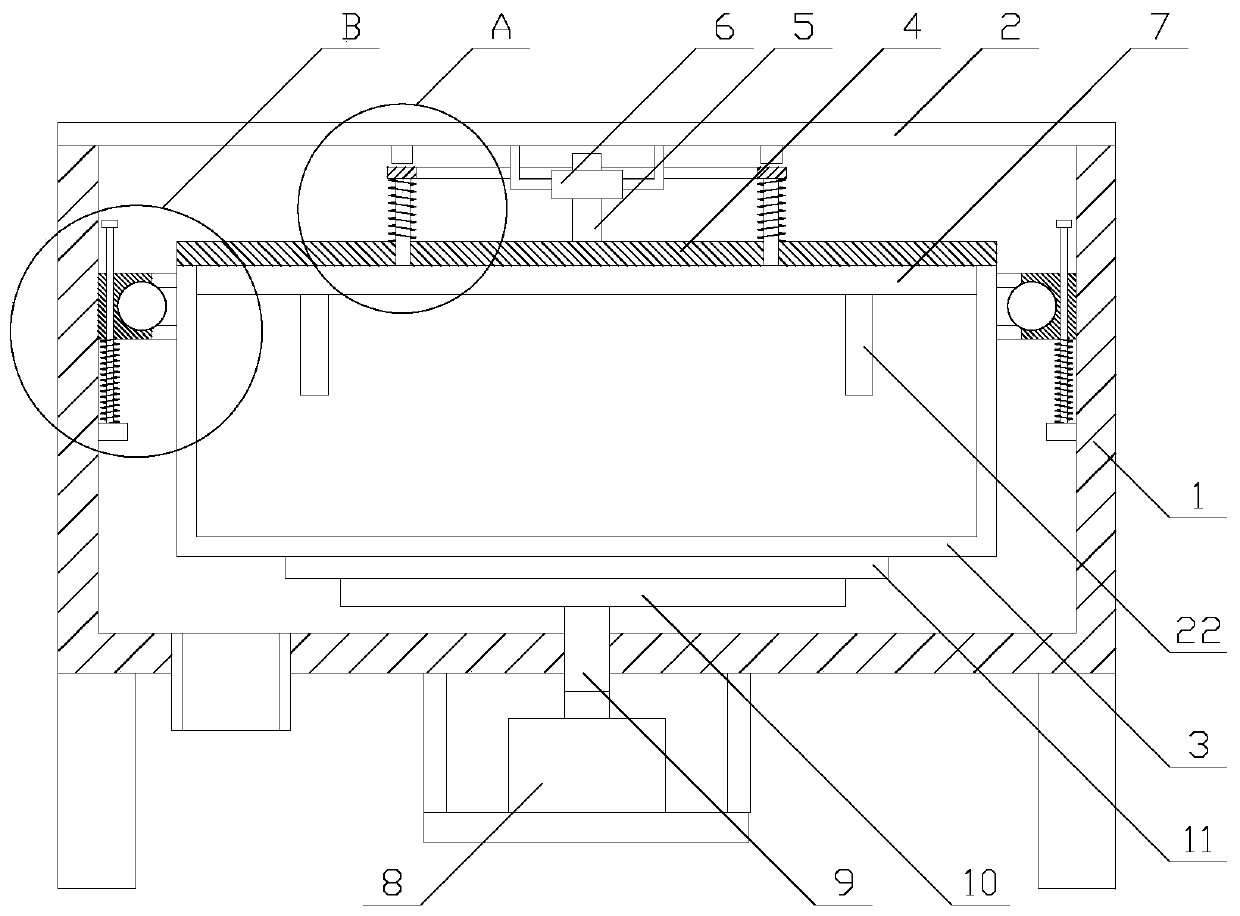

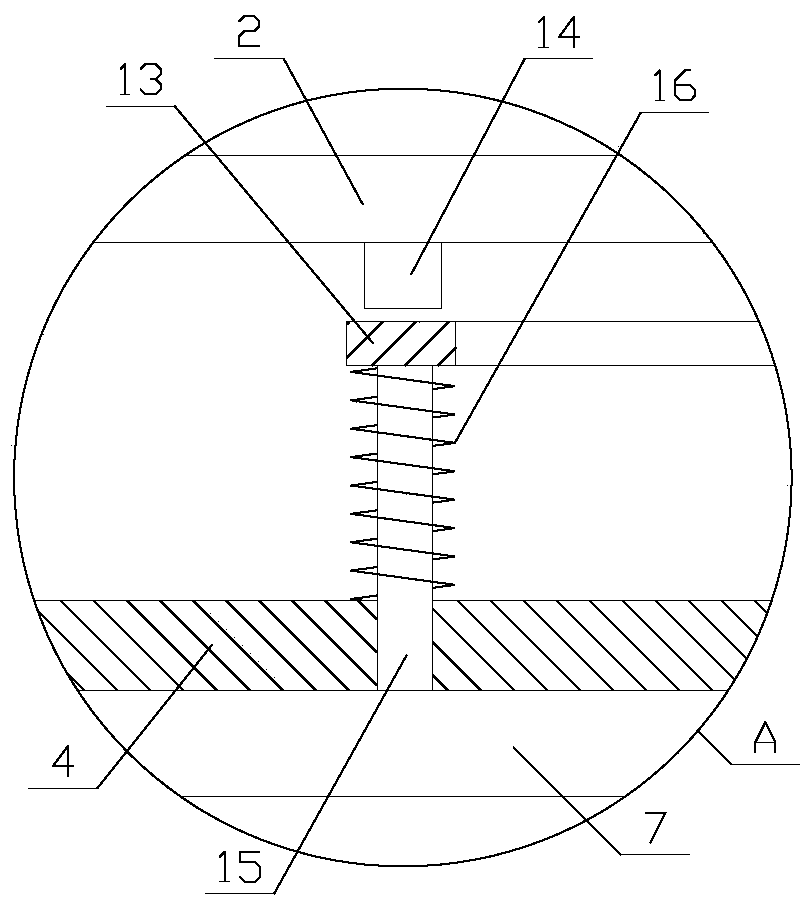

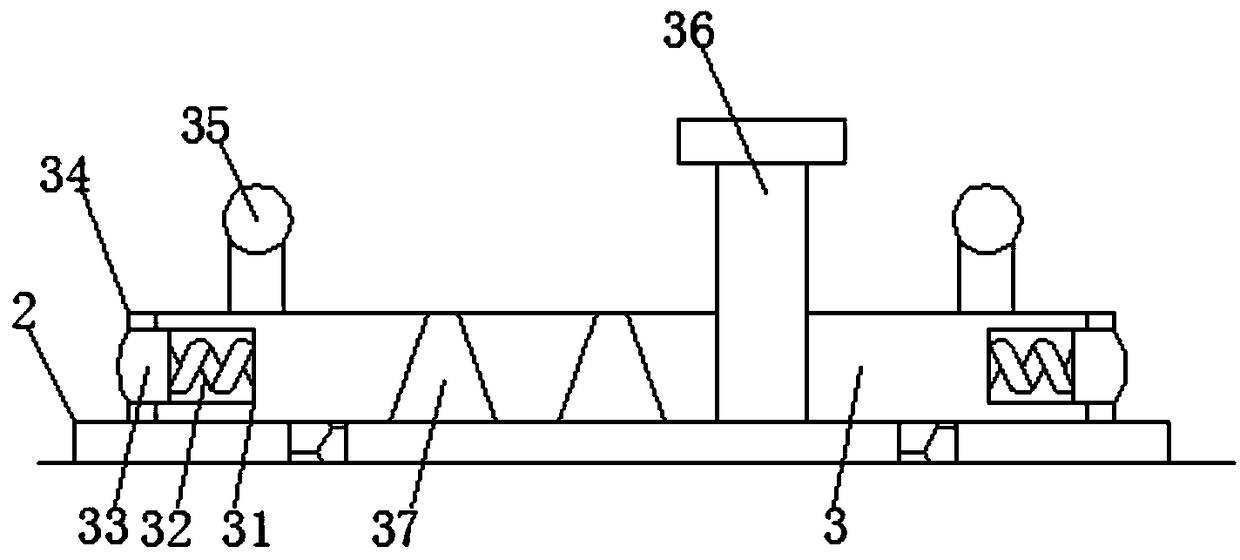

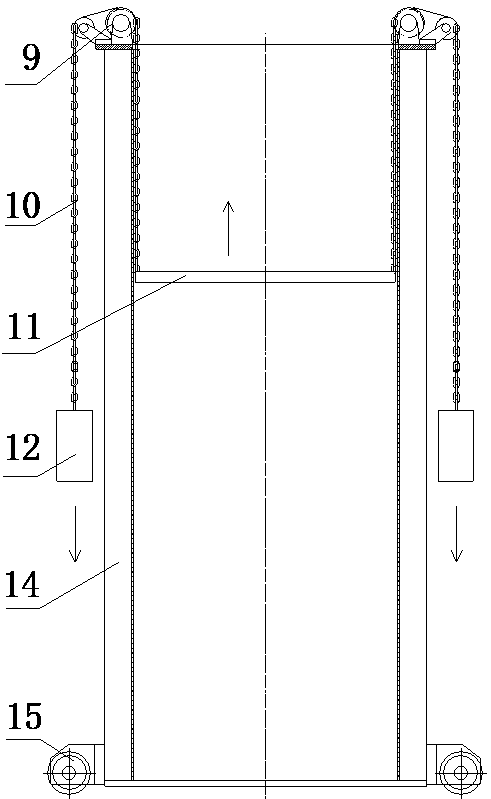

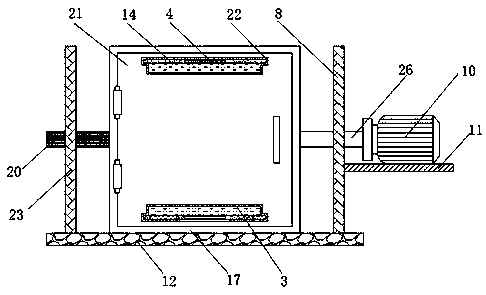

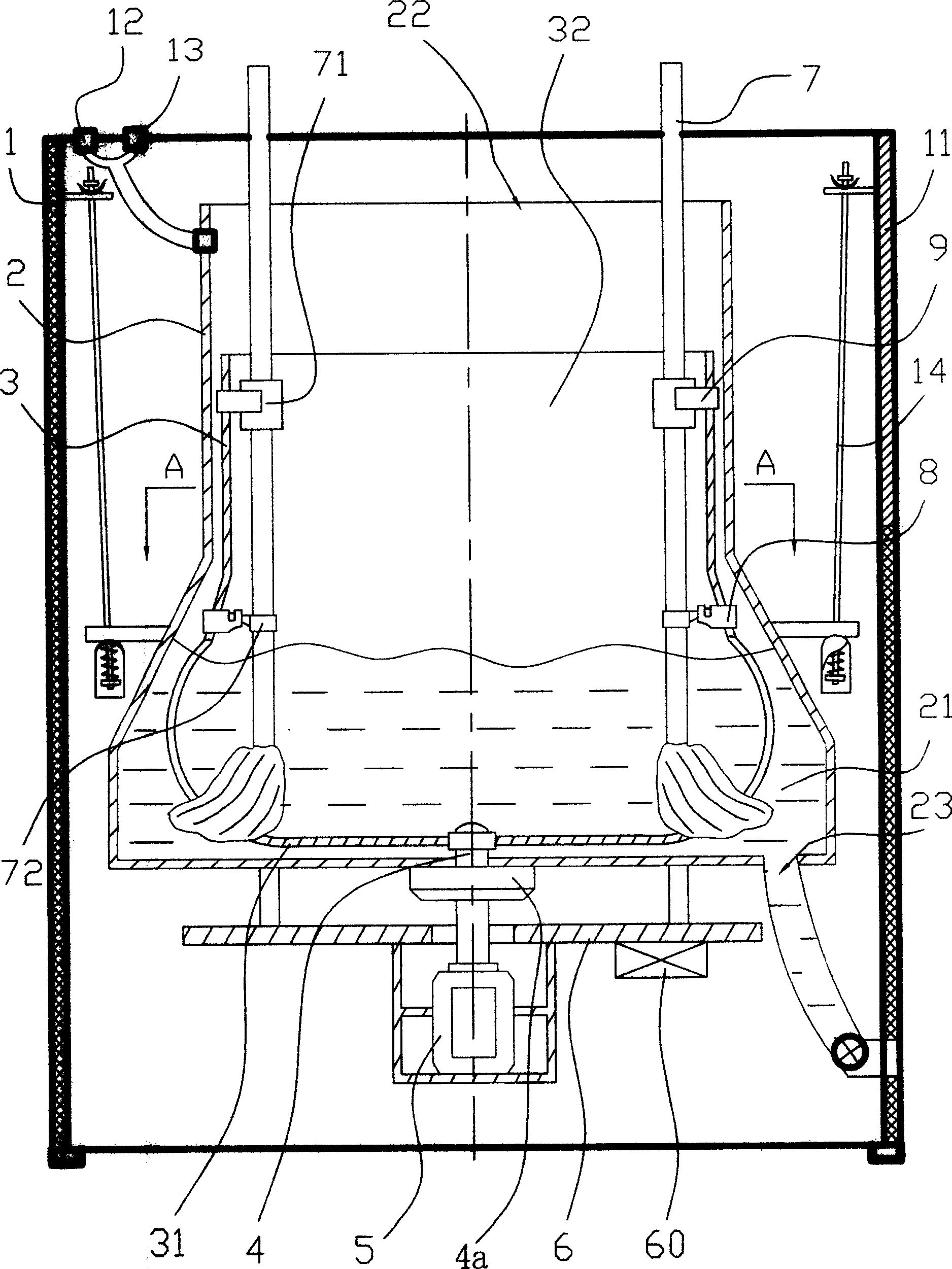

Suspension-type loose fiber dryer

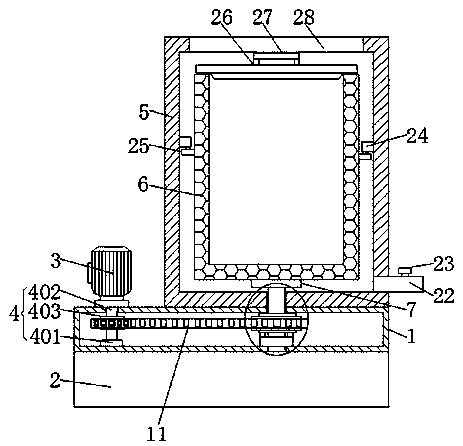

InactiveCN101762143AReduce mechanical vibrationAchieve dehydration effectDrying solid materials without heatDrying machines with non-progressive movementsFiberEngineering

The invention discloses a suspension-type loose fiber dryer which comprises a stander, a motor bracket arranged inside the stander, a motor positioned on the motor bracket, and an internal cage which is arranged above the motor and is connected with a motor shaft in a transmission way, wherein the internal cage is provided with a water outlet hole, a shell is fixedly arranged outside the internal cage, and the shell is provided with a machine cove and a pneumatic component used for opening the cover; the motor bracket is hung on the side wall of the stander by a suspension spring, and is connected with a downward stretched spring connected with the bottom of the stander; a shock absorber is connected between the motor bracket and the bottom of the stander; a water baffling ring is at the position where the bottom inside the shell and the motor; and the shell is communicated with a drainage pipe. In the period of high speed dehydration, the suspension-type loose fiber dryer has low mechanical shock and fault rate, safe and reliable running, high production efficiency, can automatically time and brake, and selects different rotating speeds according to the need.

Owner:鹤山精湛染整设备厂有限公司

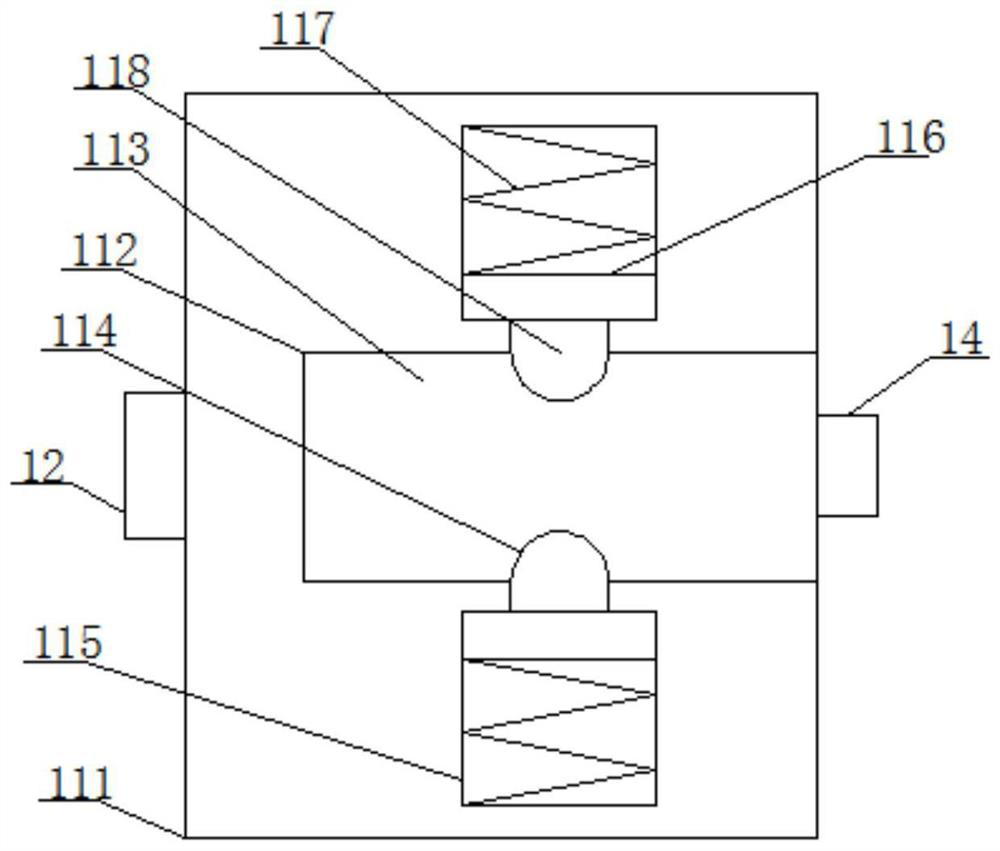

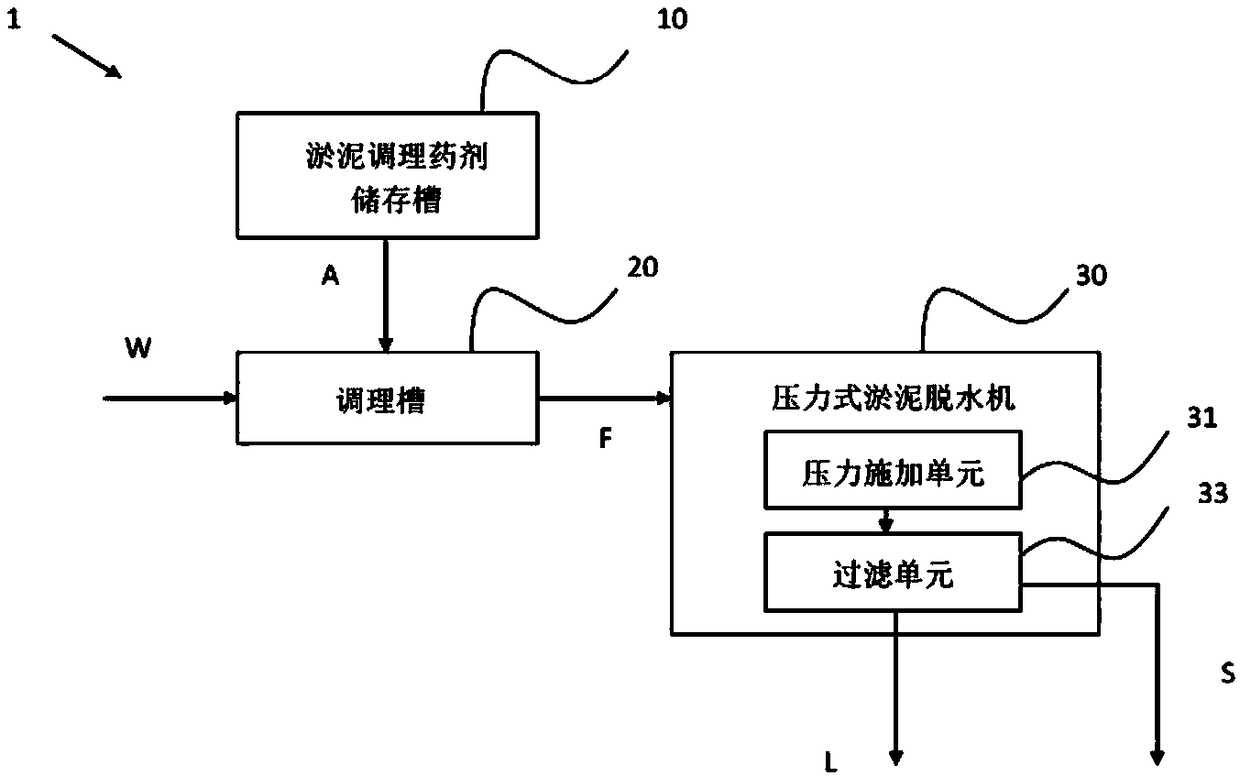

Composite conditioner for sludge dewatering and using method thereof

ActiveCN105541081AAchieve dehydration effectHigh calorific valueSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPolyacrylamideBiomass

The invention relates to a composite conditioner for sludge dewatering and a using method thereof, and belongs to the field of sludge treatment in environmental protection. The composite conditioner is composed of an agent A and an agent B, wherein according to the agent B, biomass raw materials replace polyacrylamide raw materials in the prior art, the defects that a conditioner composed of polyacrylamide raw materials is poor in degradation performance, toxic and instable in flocculent body structure are overcome, and the composite conditioner is efficient, harmless and stable.

Owner:ZHEJIANG ZHENGJIE ENVIRONMENTAL SCI & TECH CO LTD

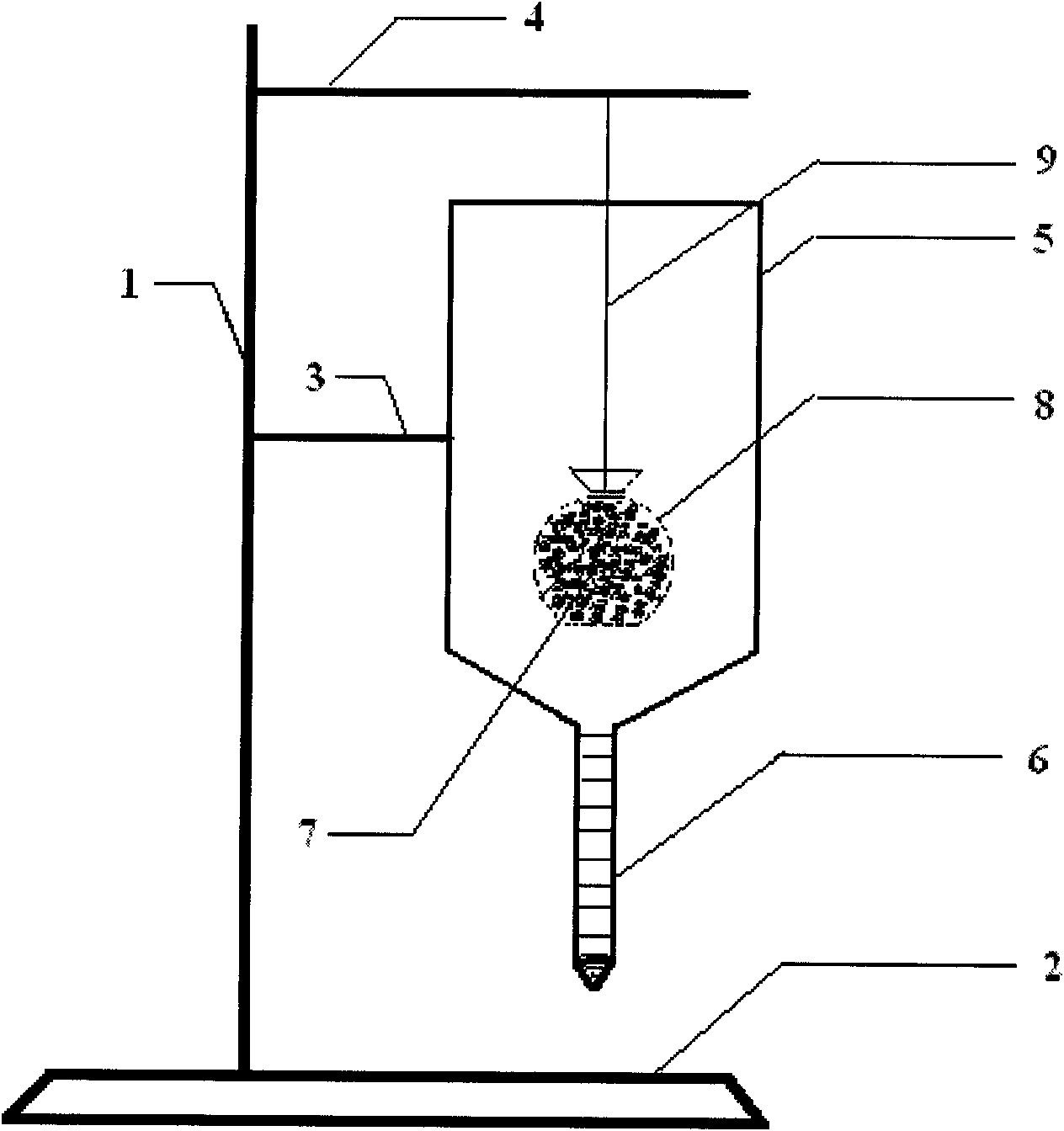

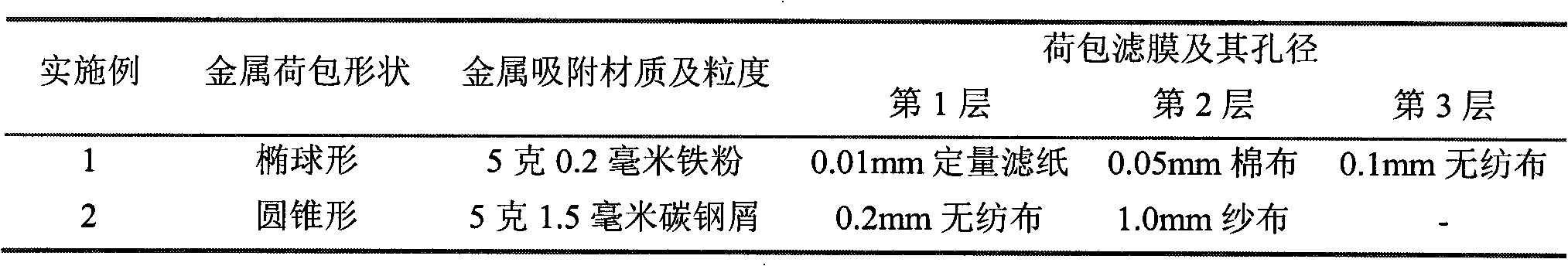

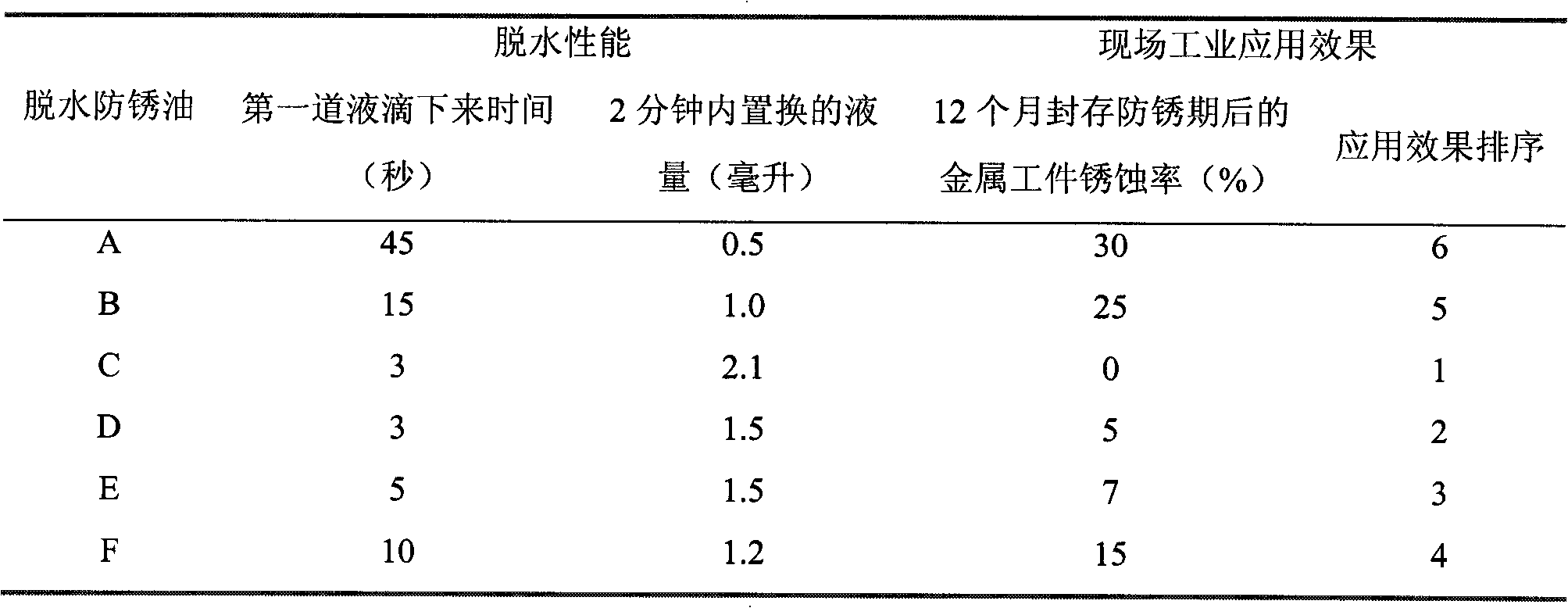

Method for testing use performance of dewatering rust preventive oil

ActiveCN102759580AThe replacement effect is achievedAchieve dehydration effectComponent separationOil canDiffusion

The invention relates to a method for testing the use performance of dewatering rust preventive oil, and mainly solves the problems existing in the prior art that the rust preventive performance or the dewatering performance only can be independently evaluated, the actual effect achieved by the dewatering rust preventive oil during the use in a water-containing environment cannot be rapidly tested, and the dewatering performance, the rust preventive performance and the oil membrane state of the dewatering rust preventive oil cannot be described at the same time. The method wells solves the problems through adopting the steps as follows: a) metal adsorbing material is wrapped in at least one filter membrane to obtain a metal pouch, and the dewatering performance of the dewatering rust preventive oil to be tested is evaluated through testing the actual dewatering time and the dewatering amount of the metal pouch already absorbing water; b) the rust preventive performance of the dewatering rust preventive oil is evaluated according to the situation of corroded blots on the filter membrane of the pouch and the measurement of the areas of the corroded blots; and c) the oil membrane condition of the dewatering rust preventive oil is evaluated according to the diffusion diameter of a residual oil membrane on the metal pouch on the filter paper. The method can be used in formulation research and product quality inspection of the dewatering rust preventive oil.

Owner:CHINA PETROLEUM & CHEM CORP

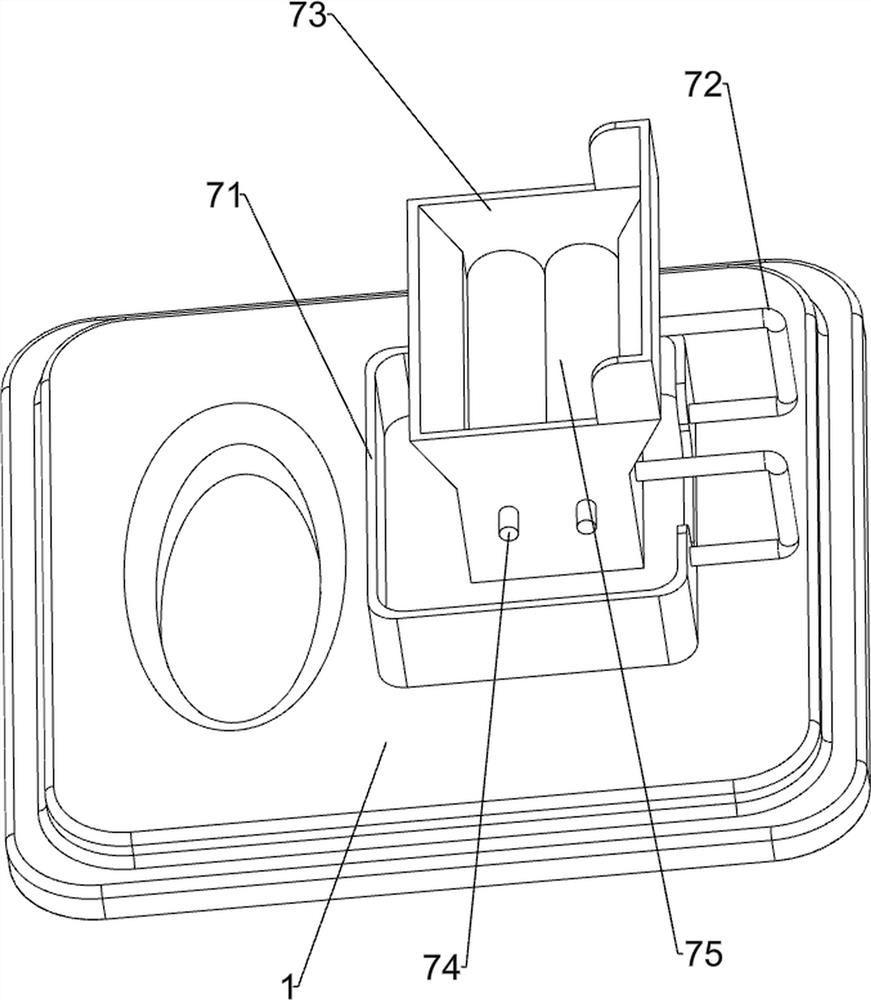

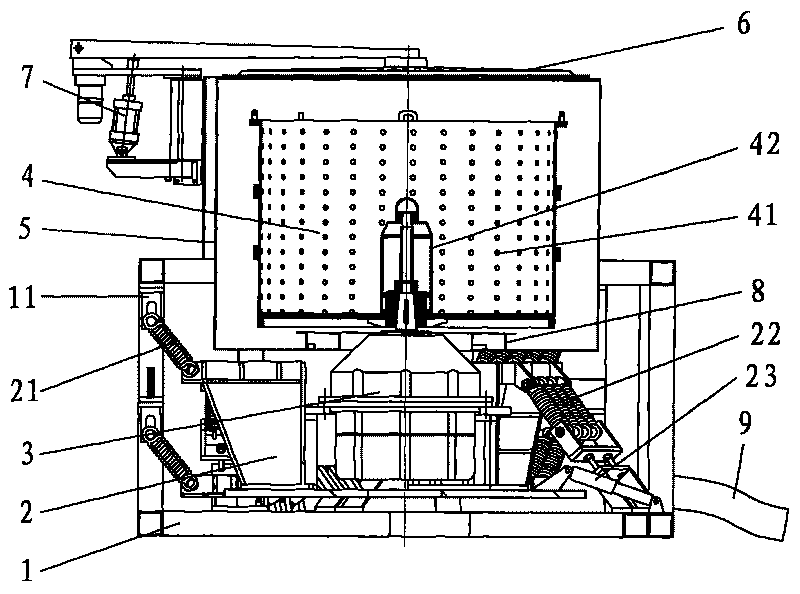

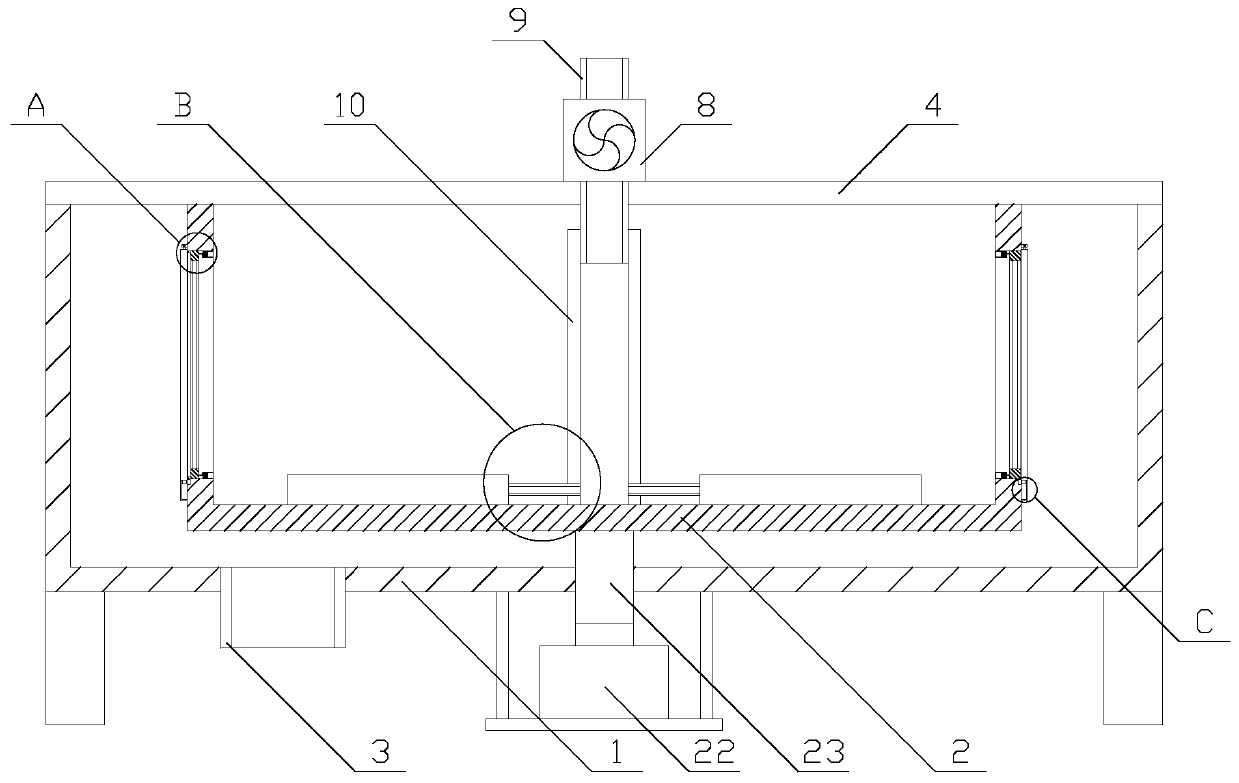

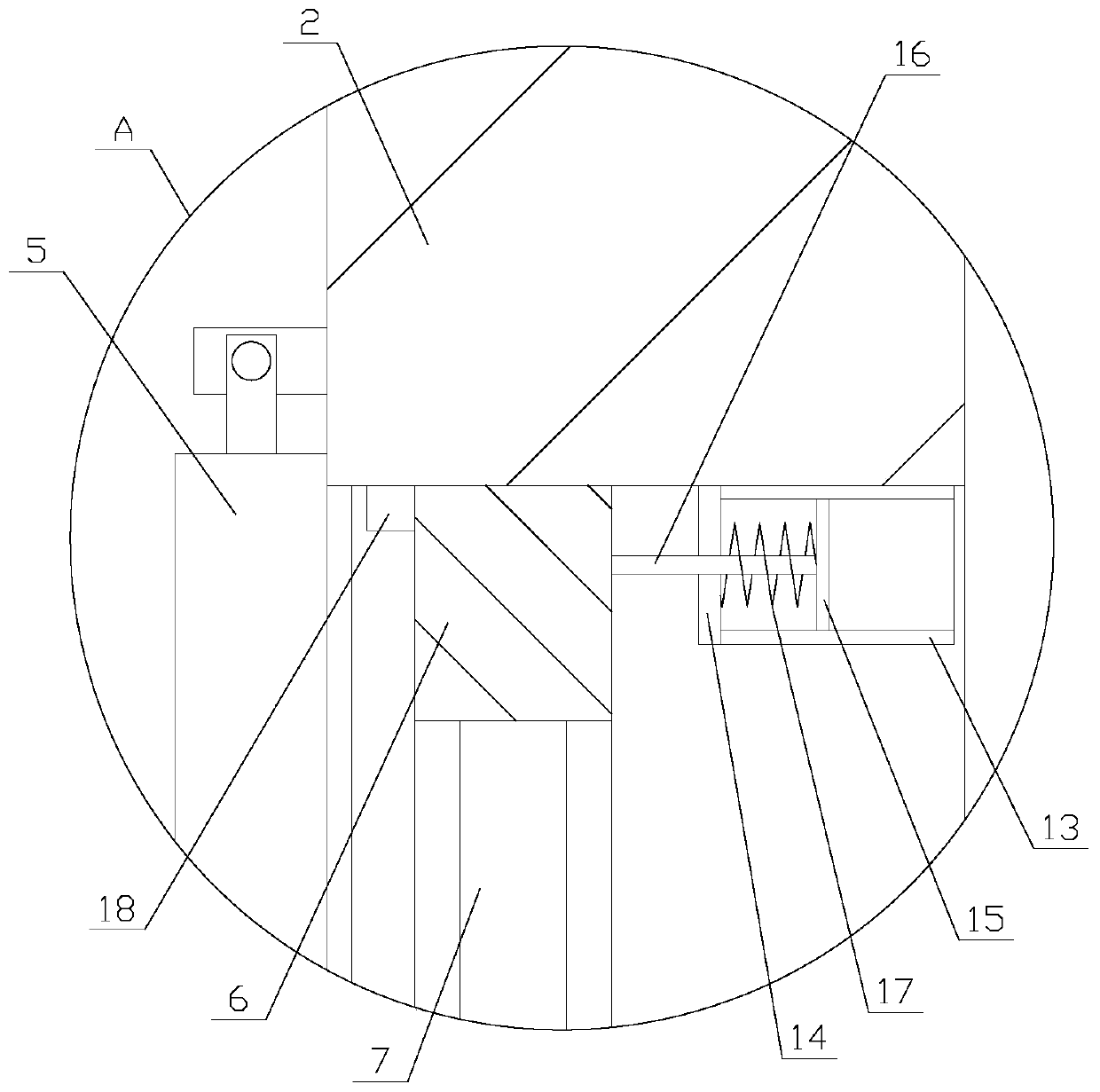

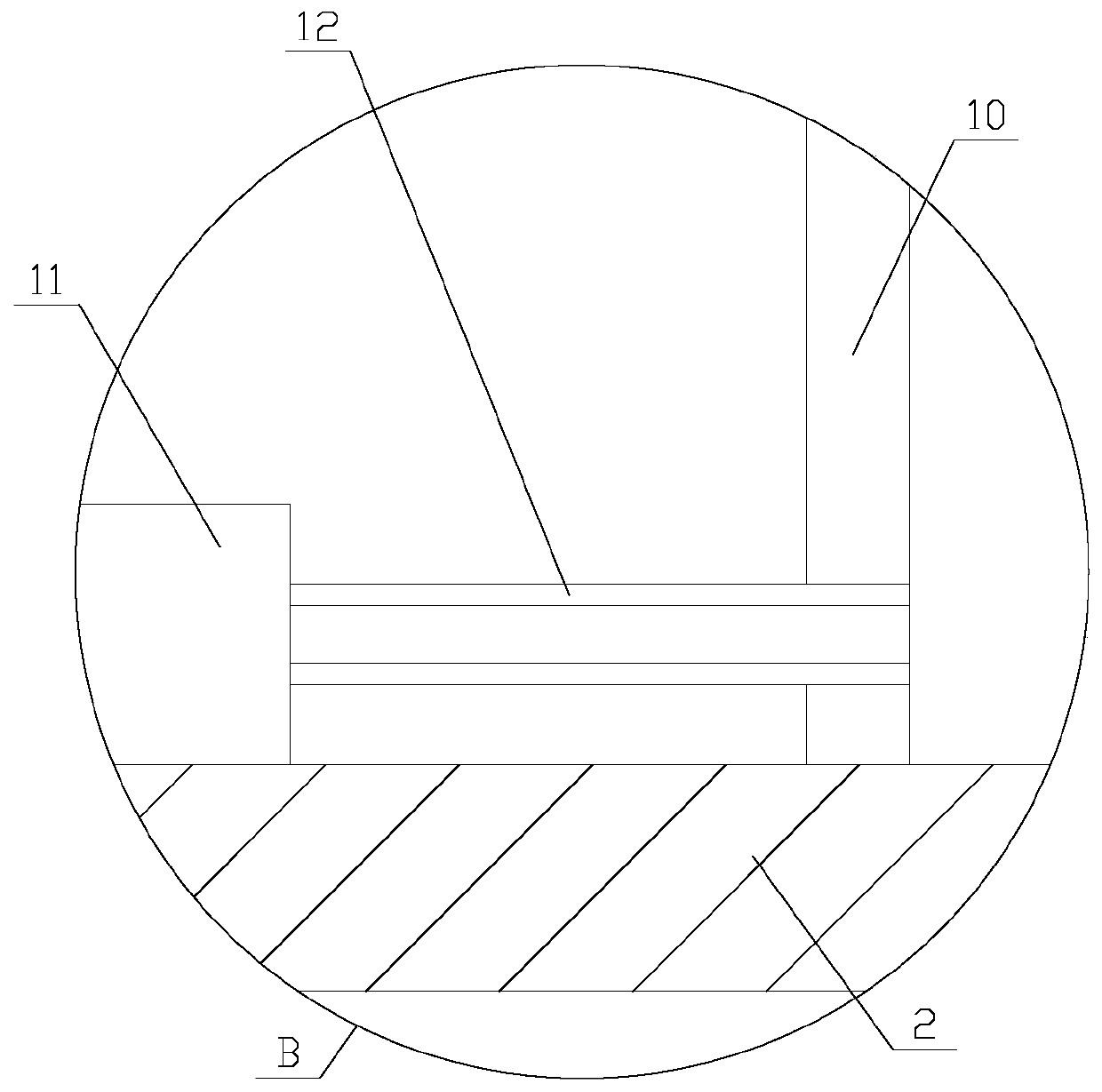

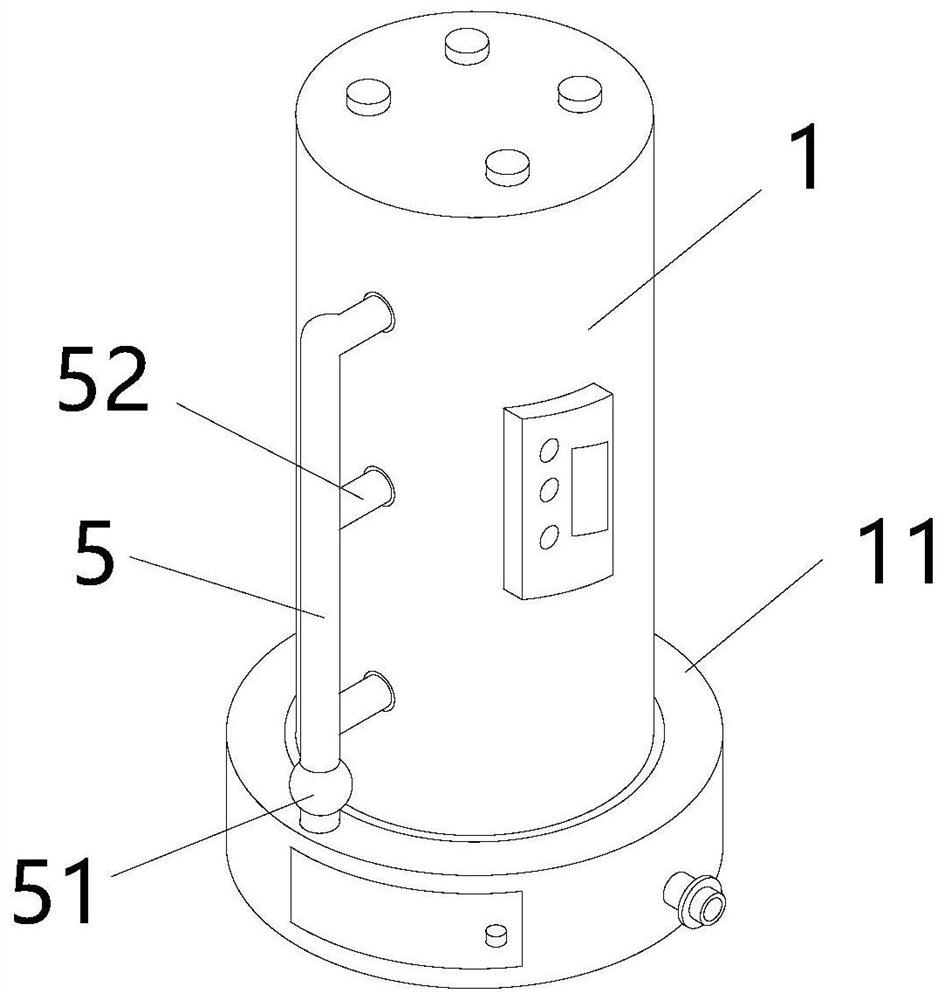

Centrifugal dewatering apparatus having high safety factor and used for chemical industry

InactiveCN110369161AImprove securityImprove dehydration efficiencyCentrifugesChemical industryDrive motor

The invention relates to a centrifugal dewatering apparatus having the high safety factor and used for the chemical industry. The centrifugal dewatering apparatus comprises a main body, a protective cover and a dewatering cylinder, the dewatering cylinder is arranged in the main body, the protective cover is arranged at the top of the main body, the main body is internally provided with a drivingmechanism and an auxiliary mechanism, the driving mechanism is in transmission connection to the bottom end of the dewatering cylinder, the auxiliary mechanism is arranged at the top end of the dewatering cylinder, and the auxiliary mechanism comprises a pressing cover, a connecting shaft, a bearing, a pressing disc and a pushing assembly; and the driving structure comprises a driving assembly andat least three clutch assemblies, and the driving assembly comprises a drive motor, a transmission shaft, a drive friction disc, a driven friction disc and a fixing ring. By means of the centrifugaldewatering apparatus having the high safety factor and used for the chemical industry, the driving mechanism is used for achieving the function of driving the dewatering cylinder to rotate, the dewatering effect is achieved, and the dewatering efficiency is achieved through the auxiliary mechanism.

Owner:广州贤智科技有限公司

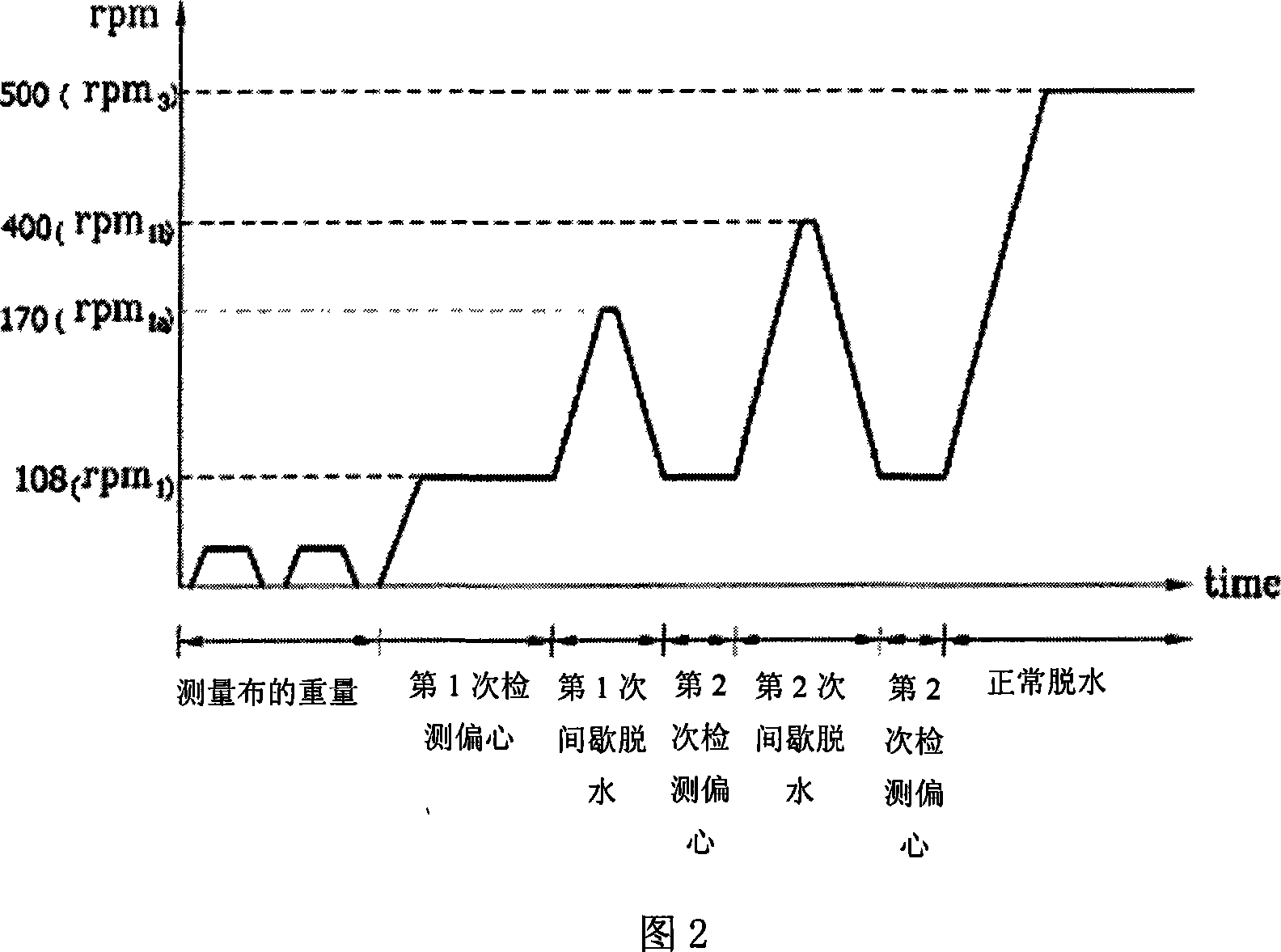

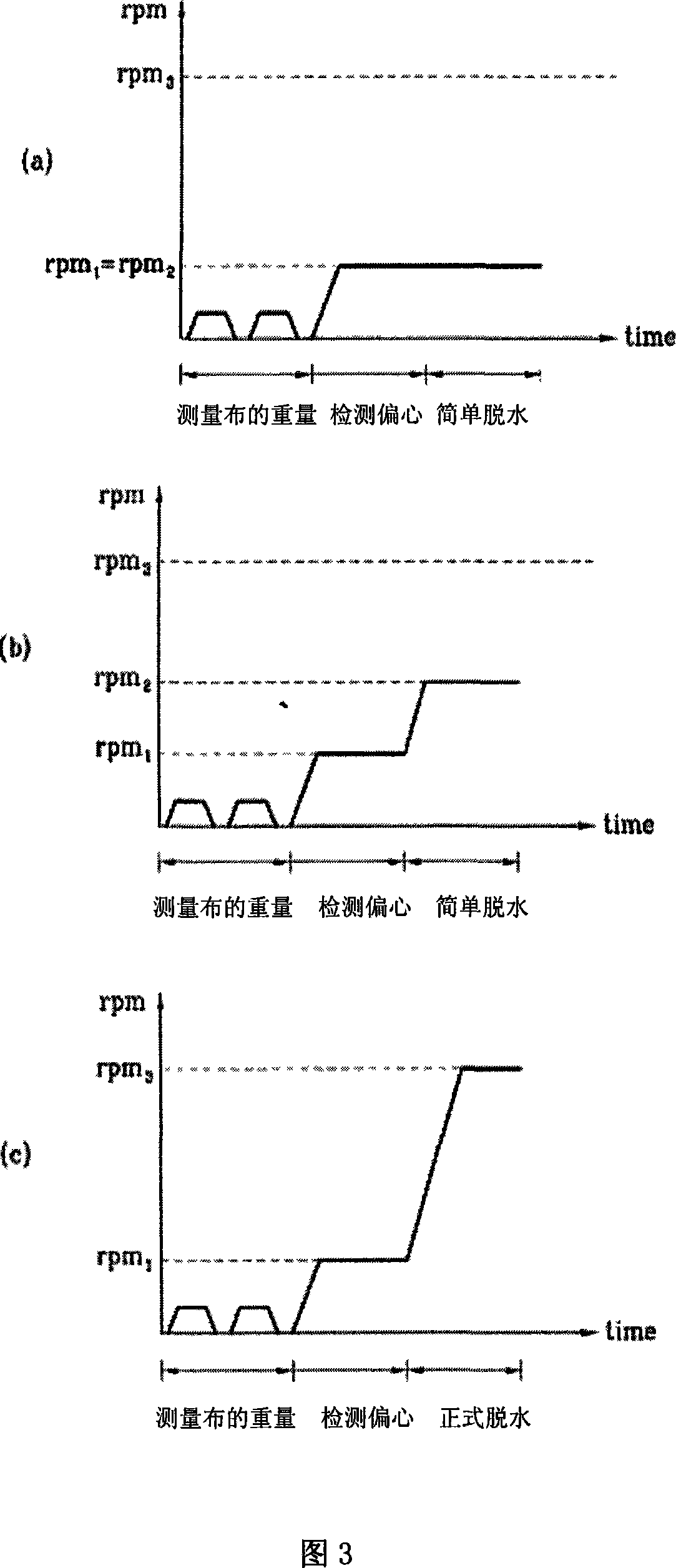

Control method for business washing machine

InactiveCN101187125AAchieve dehydration effectShorten washing timeOther washing machinesControl devices for washing apparatusPulp and paper industry

Owner:NANJING LG PANDA APPLIANCES

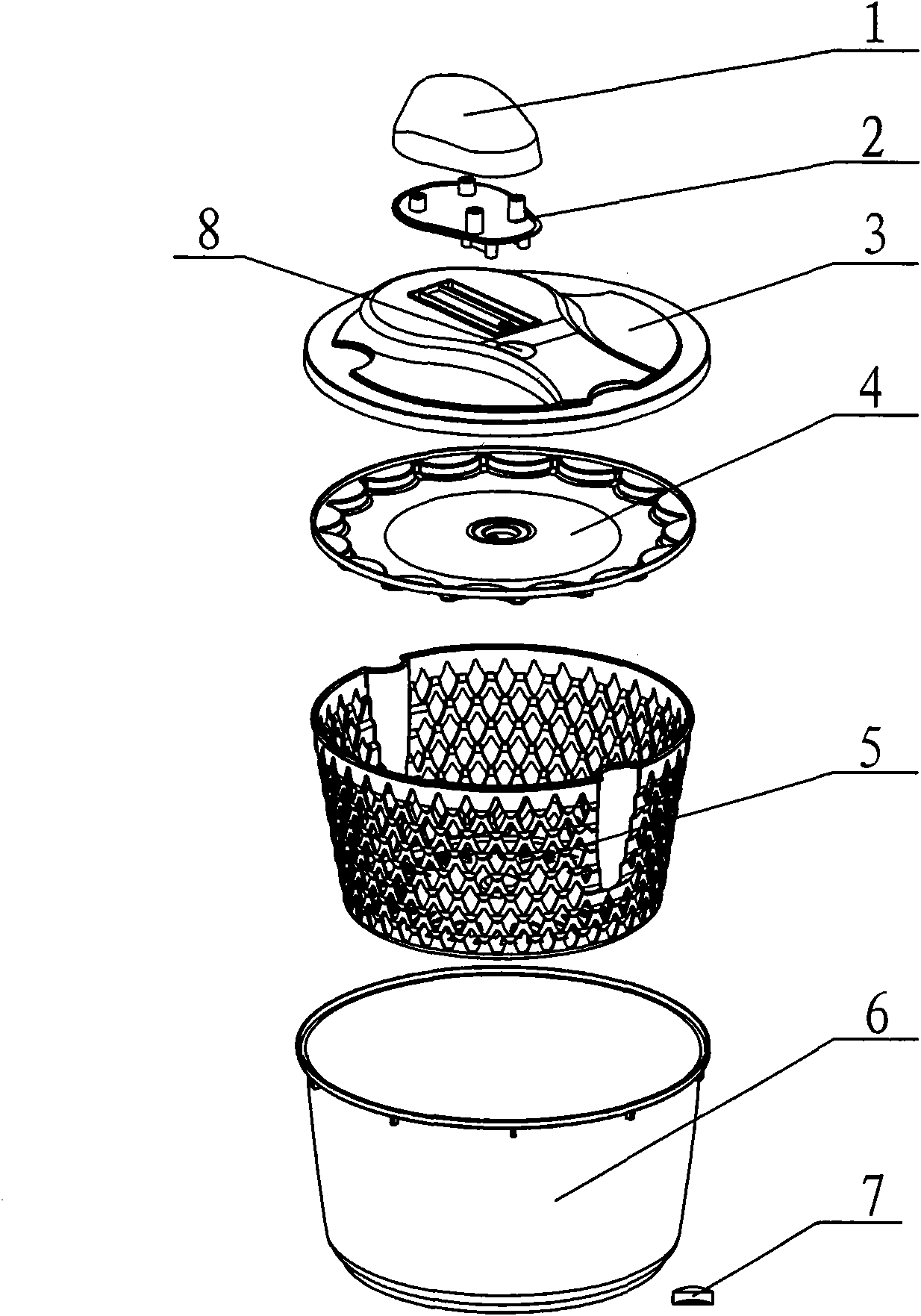

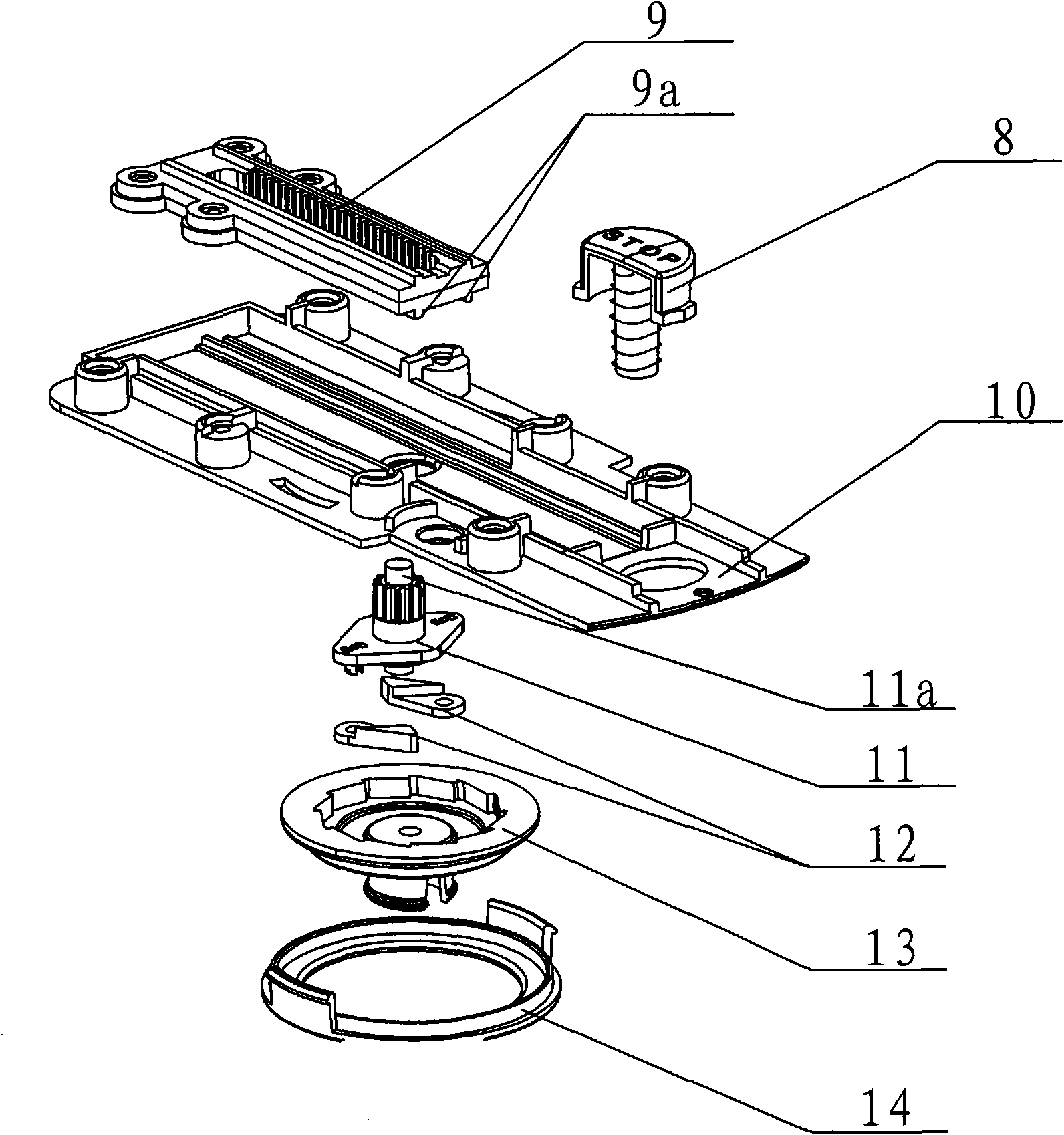

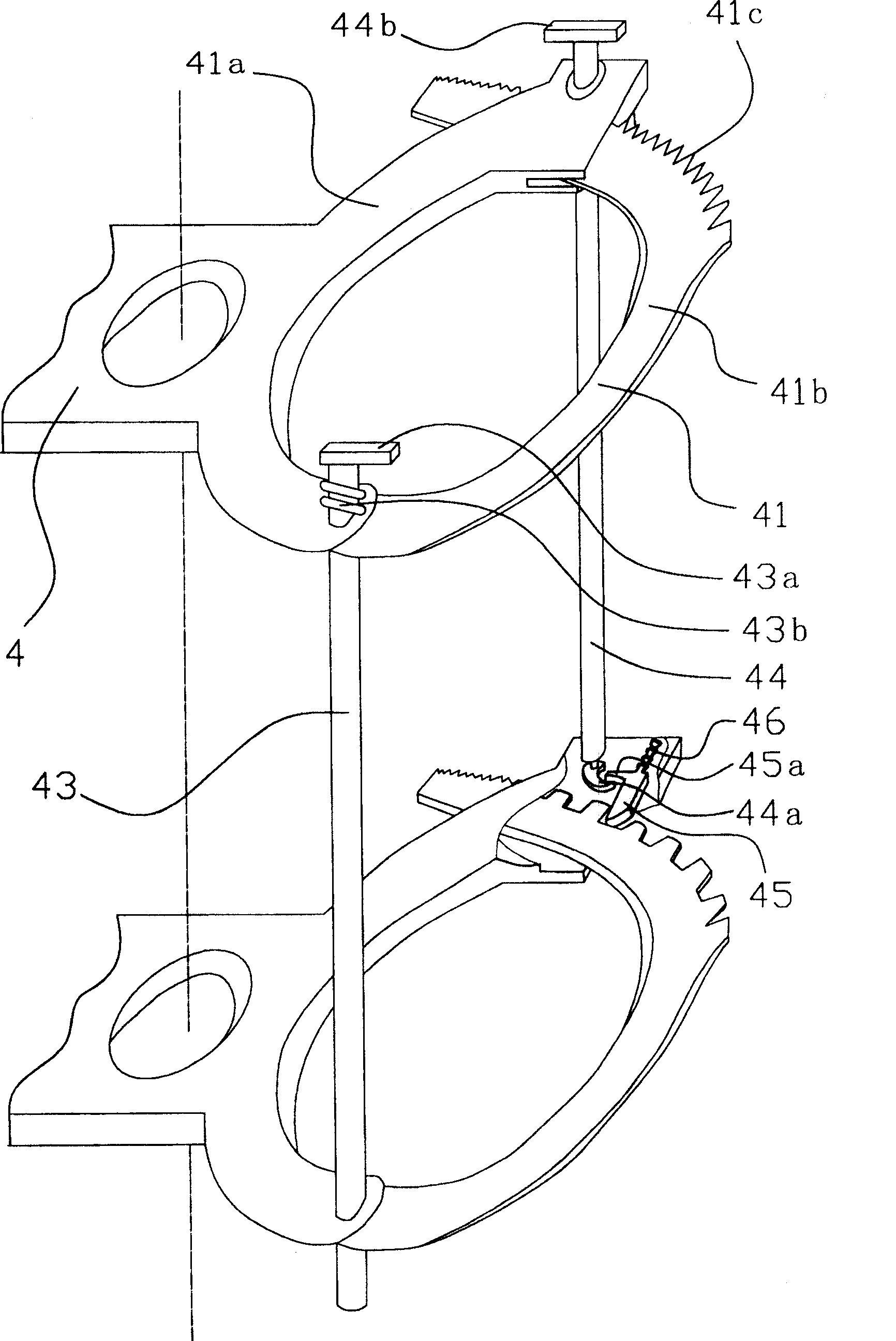

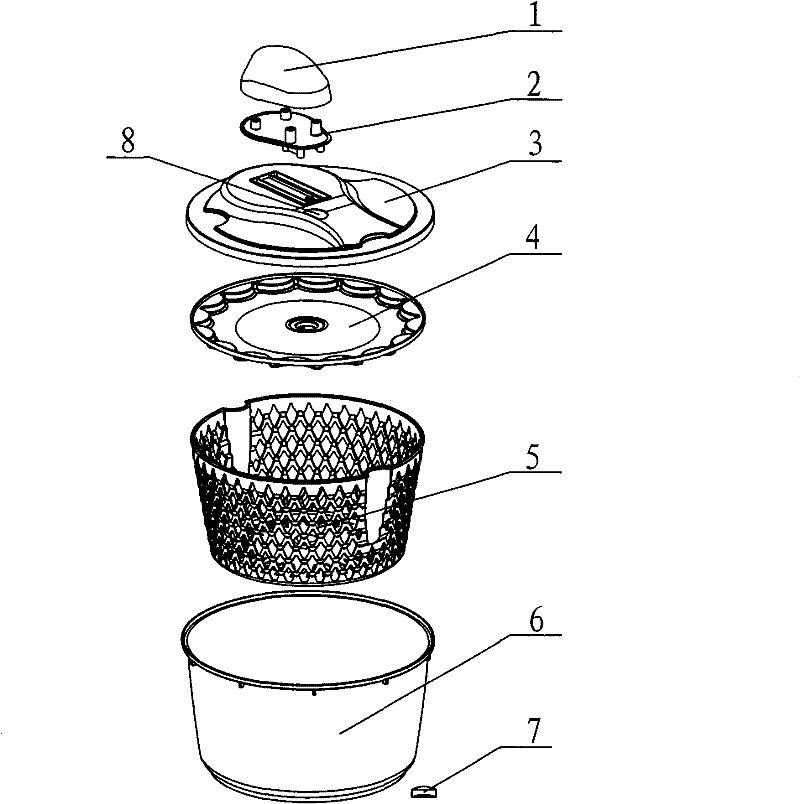

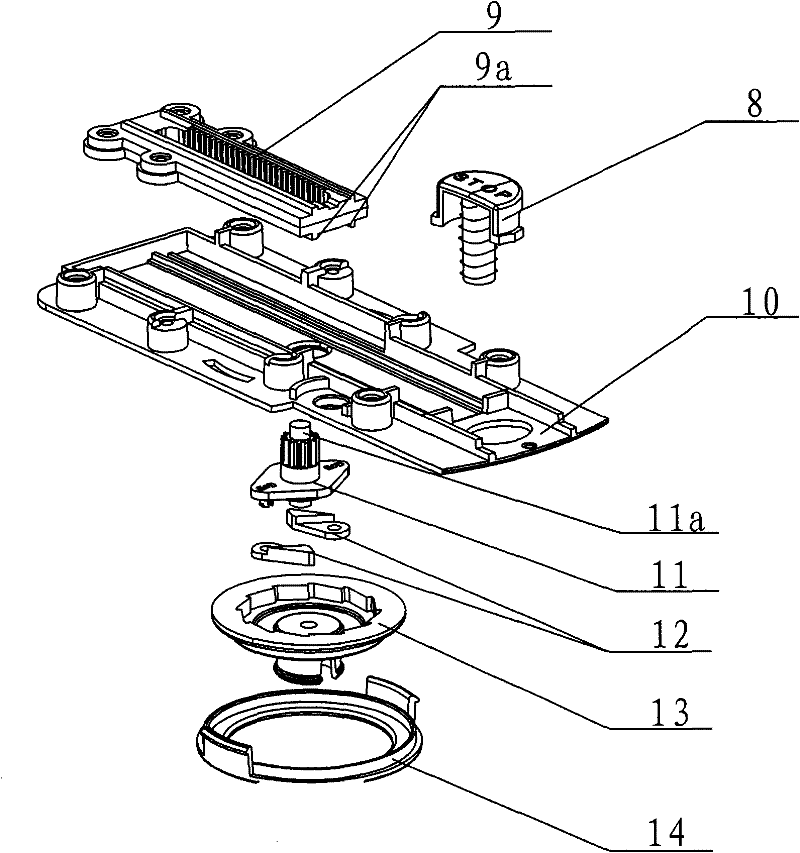

Dehydrator

ActiveCN101586903AReasonable designCompact structureDrying solid materials without heatEngineeringFan blade

A dehydrator belongs to the dehydration apparatus technical field, comprising a planer head cover, a basket and a barrel, characterized in that the planer head cover comprises a planer head cover body provided with a notch on surface, a press-hand body at upper portion of the planer head cover and a fan blade at lower portion of the planer head cover. The lower surface of the planer head cover is connected with a fix plate fixedly which matches a rack on surface. The rack is at lower portion of the notch of the planer head cover and is provided with toothrow meshed with gears which are linked to a rotor via actively set gear rocker. The rotor is locked with the fix plate via set rotor cover. The dehydrator is rational in design, compact in structure and completes dehydration only by pushing the press-hand lightly. Dehydration can be stopped at any time via a brake button in work process. The apparatus is low in manufacturing cost, simple in operation and easy to control and convent to carry.

Owner:SHUANGMA PLASTIC MFG INC

Full-automatic vegetable washing equipment applied to food pairings

PendingCN109198688AIncrease feeding rateHas a centrifugal effectFood treatmentDrive shaftEngineering

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD +1

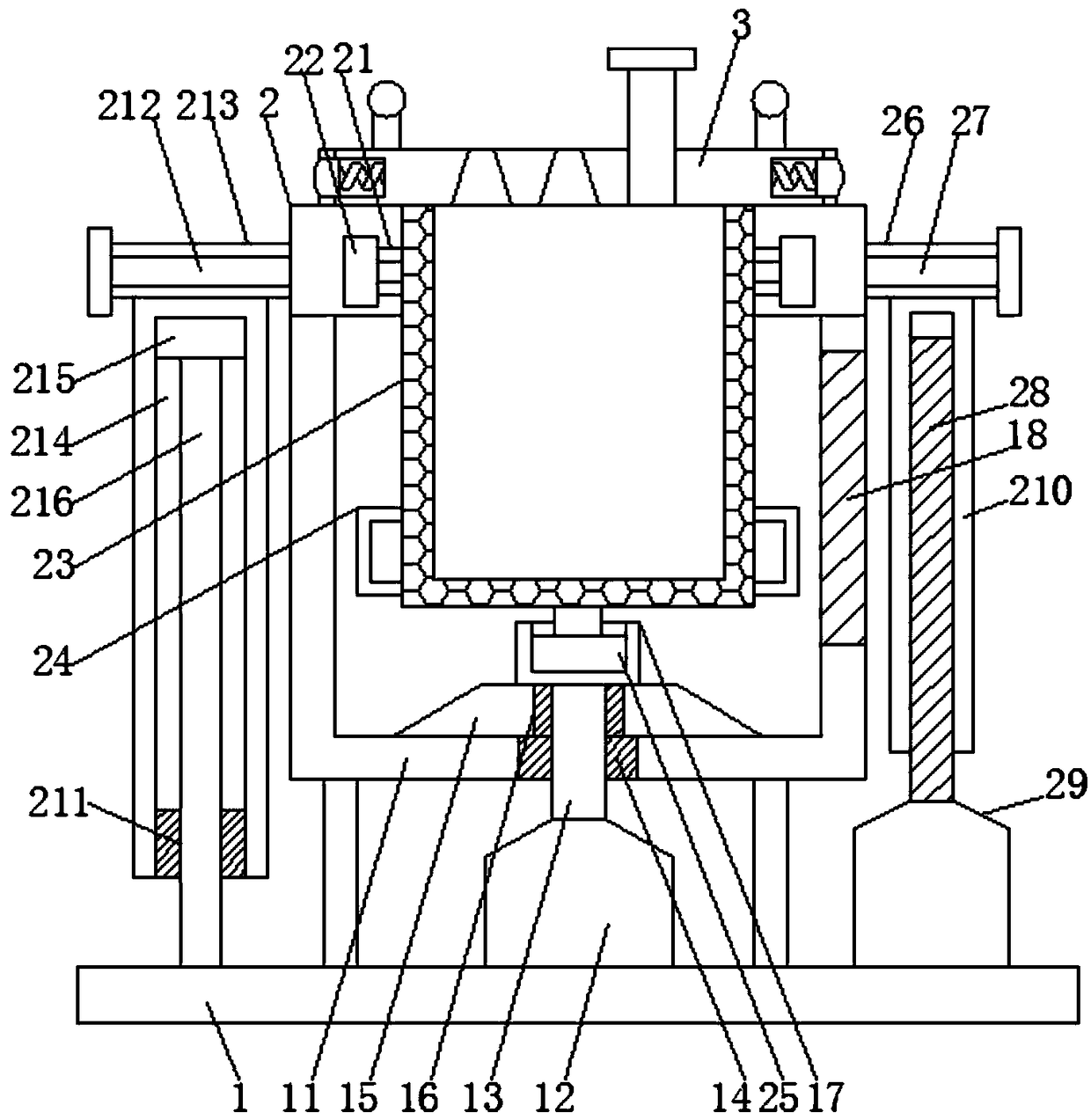

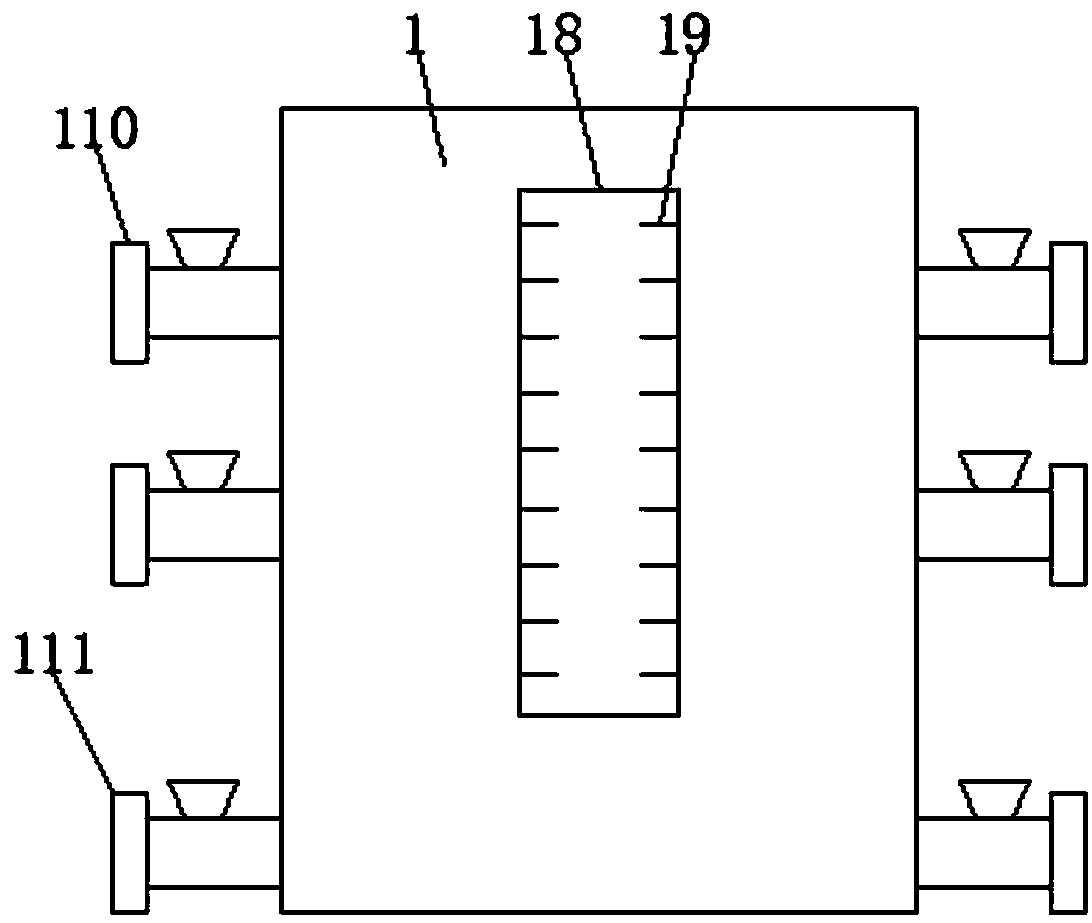

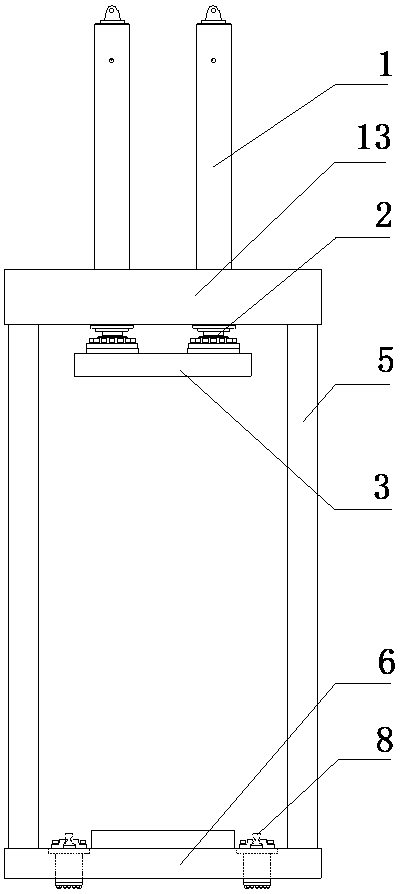

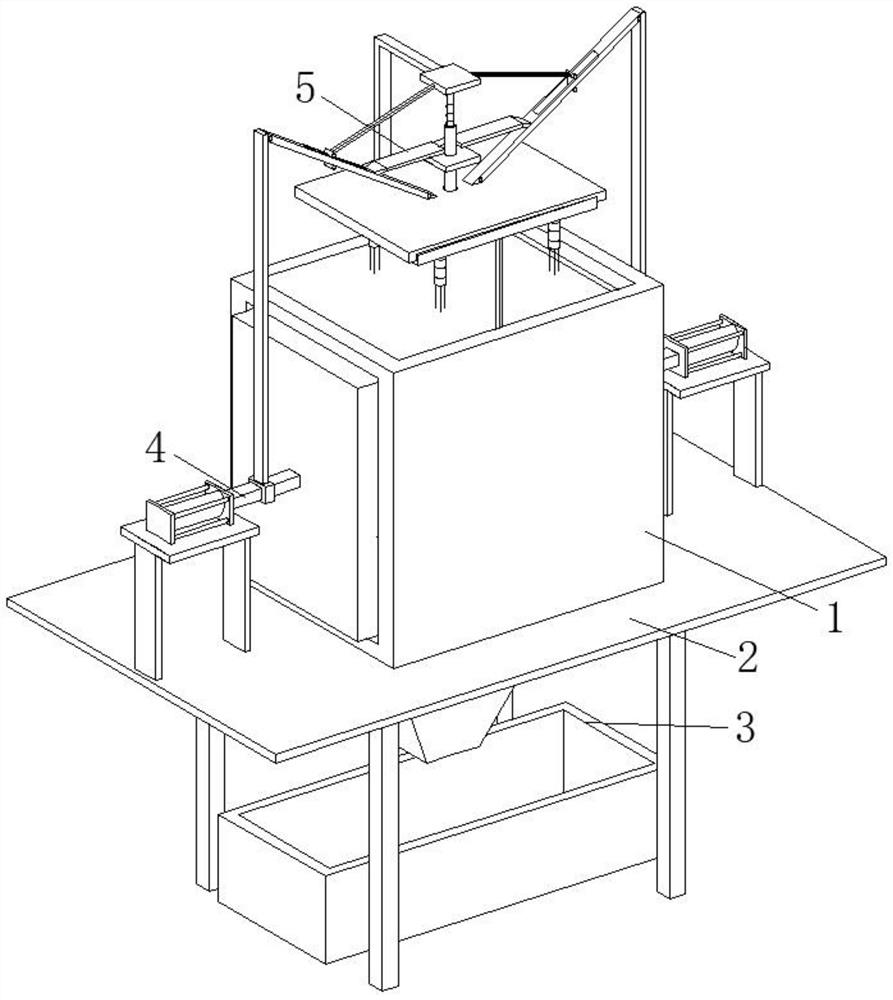

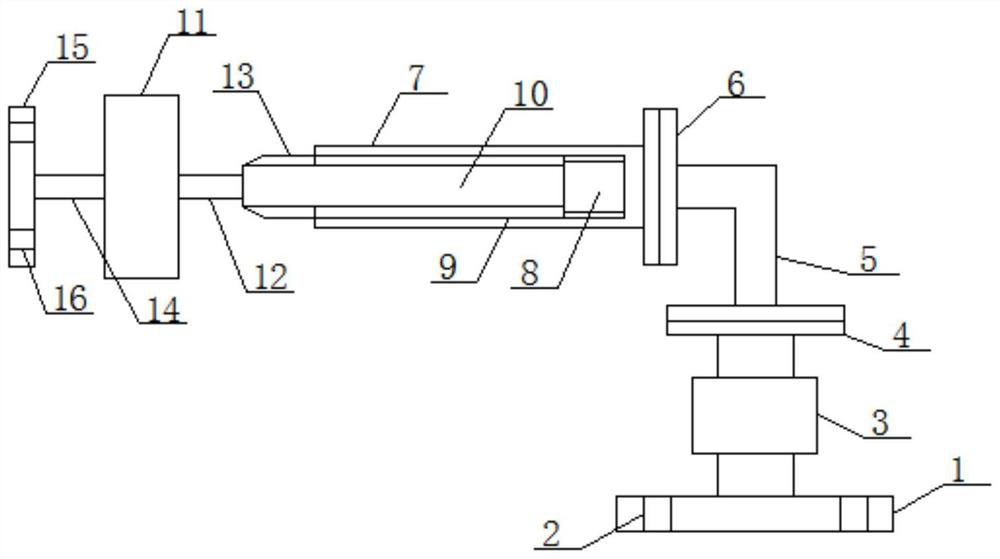

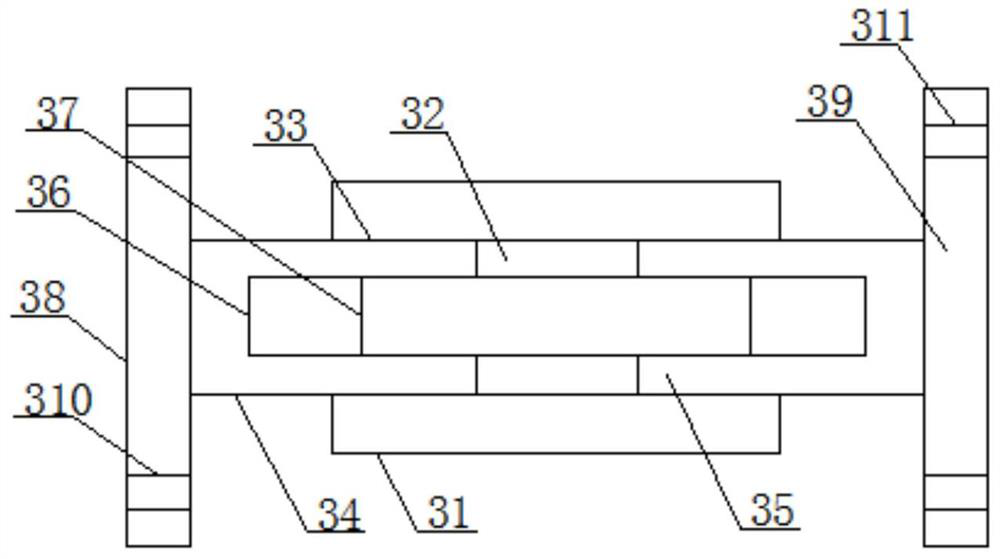

Sludge filter pressing device of deep sludge filter-pressing dehydration system

PendingCN111087157AImprove filtration efficiencySmall footprintSludge treatmentMachine pressProcess engineering

The invention discloses a sludge filter pressing device of a deep sludge filter-pressing dehydration system, and belongs to a sludge filter-pressing dehydration device. The sludge filter press comprises a filter pressing barrel and a press machine, wherein the filter pressing barrel is arranged below the filter pressing platform of the press machine, the press machine applies filtering pressure tosludge in the filter pressing barrel, and comprises a filter pressing oil cylinder, a filter pressing oil cylinder piston, a filter pressing platform, a filter pressing support column, a filter pressing bottom seat, a filter barrel guide rail and a filter pressing top seat, the filter pressing support column is connected between the filter pressing top seat and the filter pressing bottom seat, the filter pressing oil cylinder is connected to the filter pressing top seat, the filter pressing oil cylinder piston of the filter pressing oil cylinder penetrates through the filter pressing top seat, the filter pressing platform is connected to the end of the filter pressing oil cylinder piston, the filter barrel guide rail is arranged on the filter pressing bottom seat, and the filter pressingbarrel operates on the filter barrel guide rail. According to the invention, no chemical additive needs to be added in the dewatering filter pressing work of the sludge filter pressing device, the cost is effectively reduced, the operation is stable and reliable, the equipment automation degree is high, and operators do not need to operate on site.

Owner:XUZHOU KUANGYUAN UNDERFLOW PUMP IND CO LTD

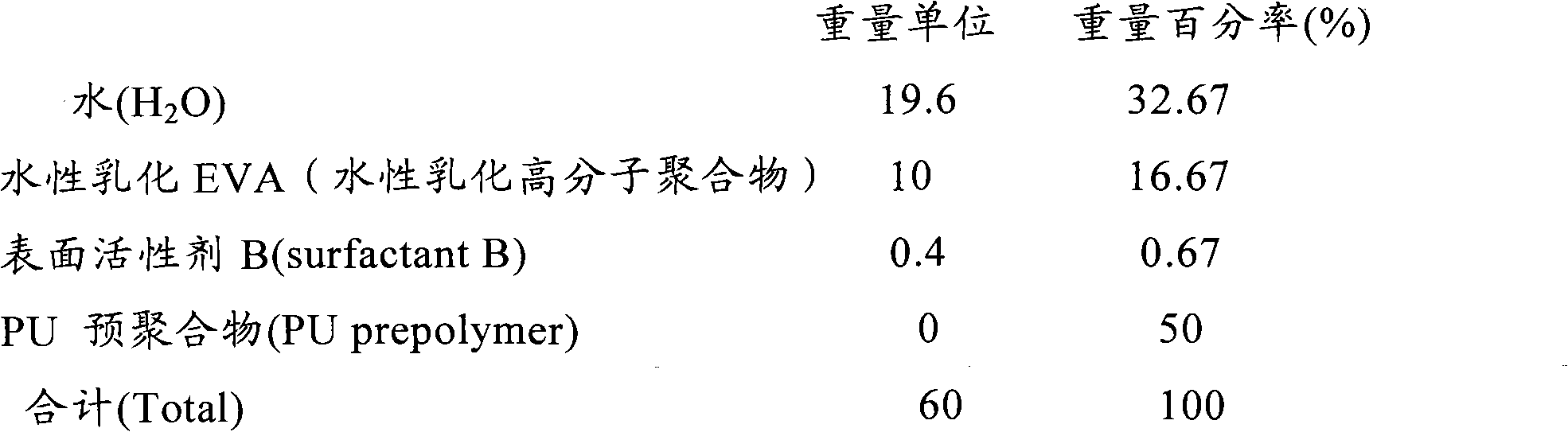

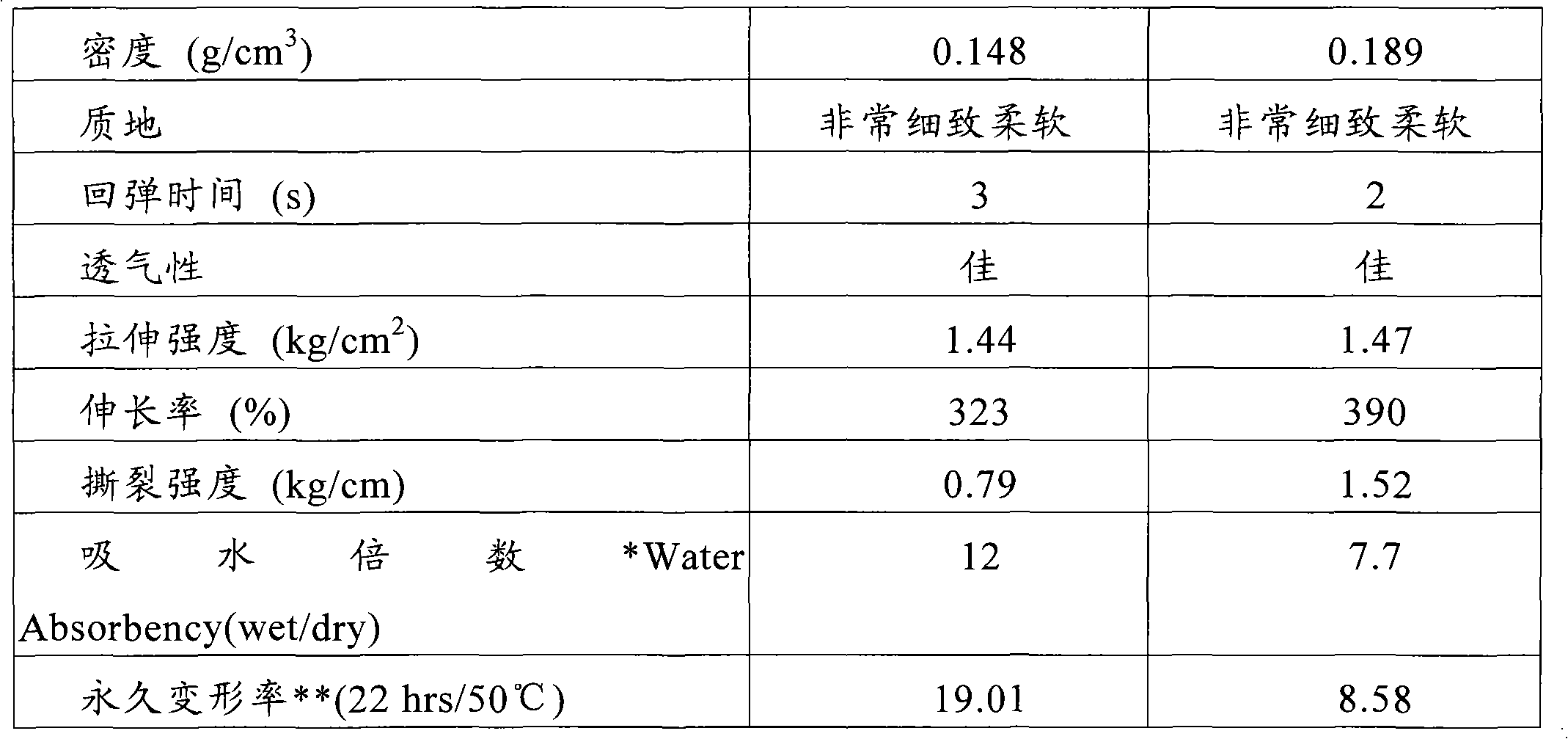

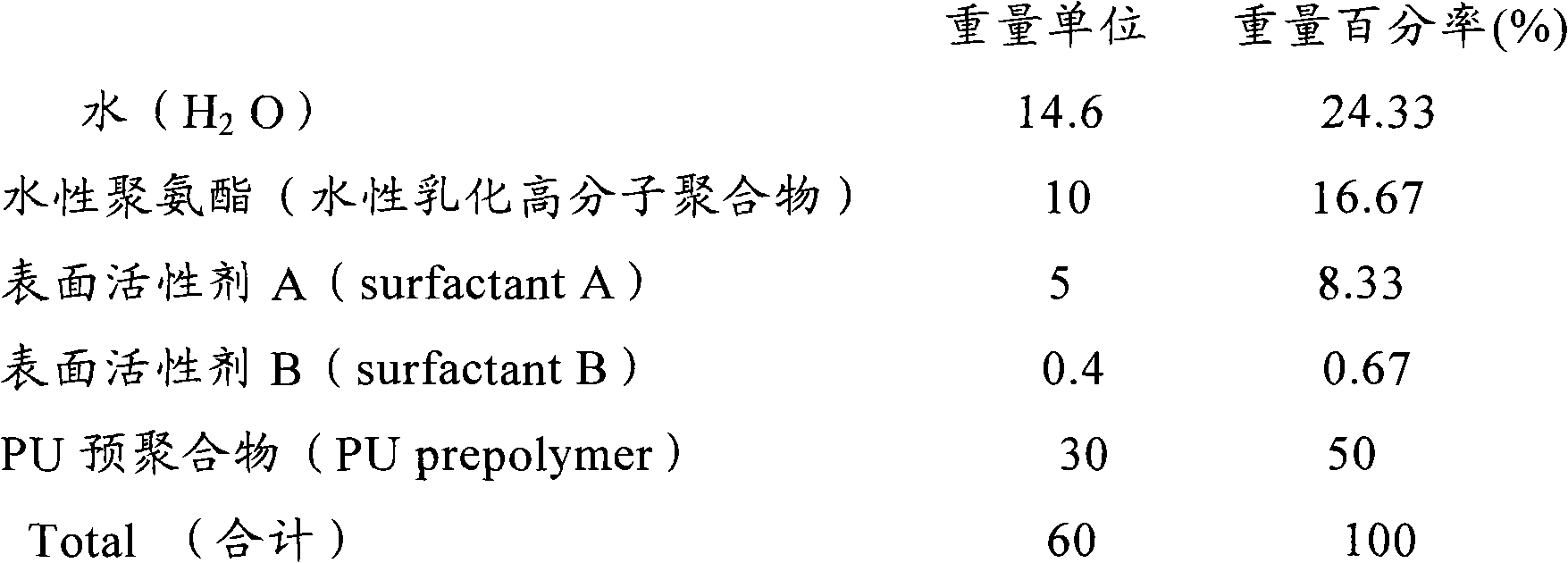

Waterborne emulsified EVA memory-type foamed plastic and preparation method of product thereof

The invention discloses a waterborne emulsified EVA memory-type foamed plastic and a preparation method of a product thereof; the foamed plastic comprises the following main composition components: 38-58% of hydrophilic PU prepolymer, 8-22% of waterborne emulsified EVA, and 8-20% of polyether polyol, wherein the PU prepolymer comprises 40-70% of polyether polyol and 30-60% of isocyanate, the polyether polyol has a molecular weight of 60-1800, and at least has more than 40 mol% of ether groups (-EO-), and the ether group (-EO-) content is 18-99.9%. The PU foamed plastic of the invention has a special hydrophilic high-molecular structure, not only has good shock absorption and average pressure relief, but also has hygroscopicity, heat absorptivity, and low temperature resistance, realizes drying and cooling effect when contacting human body, does not harden below a temperature of 10 DEG C, and improves the comfort level for contacting between the foamed plastic and human body, and the application scope.

Owner:ISOTECH PRODS

Drying machine for pesticide production

InactiveCN108716820AEasy maintenanceStable jobDrying solid materials without heatDrying machines with non-progressive movementsAgricultural engineeringRaw material

The invention discloses a drying machine for pesticide production. The drying machine for pesticide production comprises a base body, wherein a first support rod is fixedly connected to the left sideof the upper surface of the base body; a first bearing is fixedly embedded to the middle of the first support rod; a second support rod is fixedly connected to the right side of the upper surface of the base body; a second bearing is fixedly embedded to the middle of the second support rod; a support plate is fixedly connected to the right side surface of the second support rod; a motor is fixedlyconnected to the upper surface of the support plate; a drying machine body is fixedly connected to the middle of the upper surface of the base body; a door is fixedly hinged to the front surface of the drying machine body through a hinge; plate pulling ports are formed in the upper part and the lower part of the front surface of the door; and a first cavity is arranged in the drying machine body.According to the drying machine for pesticide production, the drying machine can be conveniently repaired and maintained, the working stability of the drying machine is realized, the drying machine is prevented from shaking during working, and pesticide raw materials can be dewatered.

Owner:WUXI JIABAO PESTICIDE & PHARMA

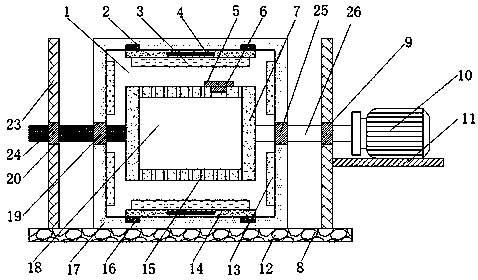

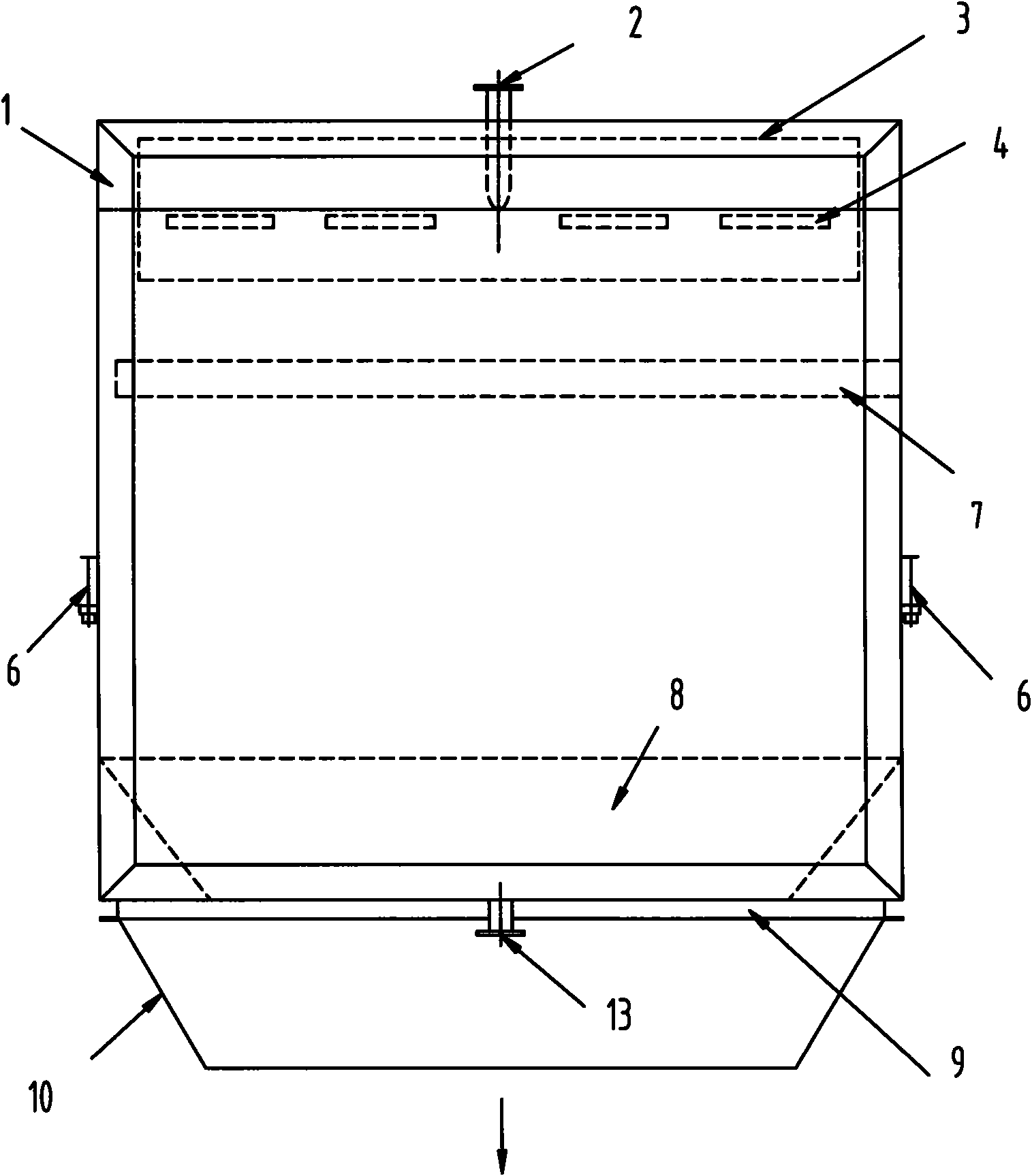

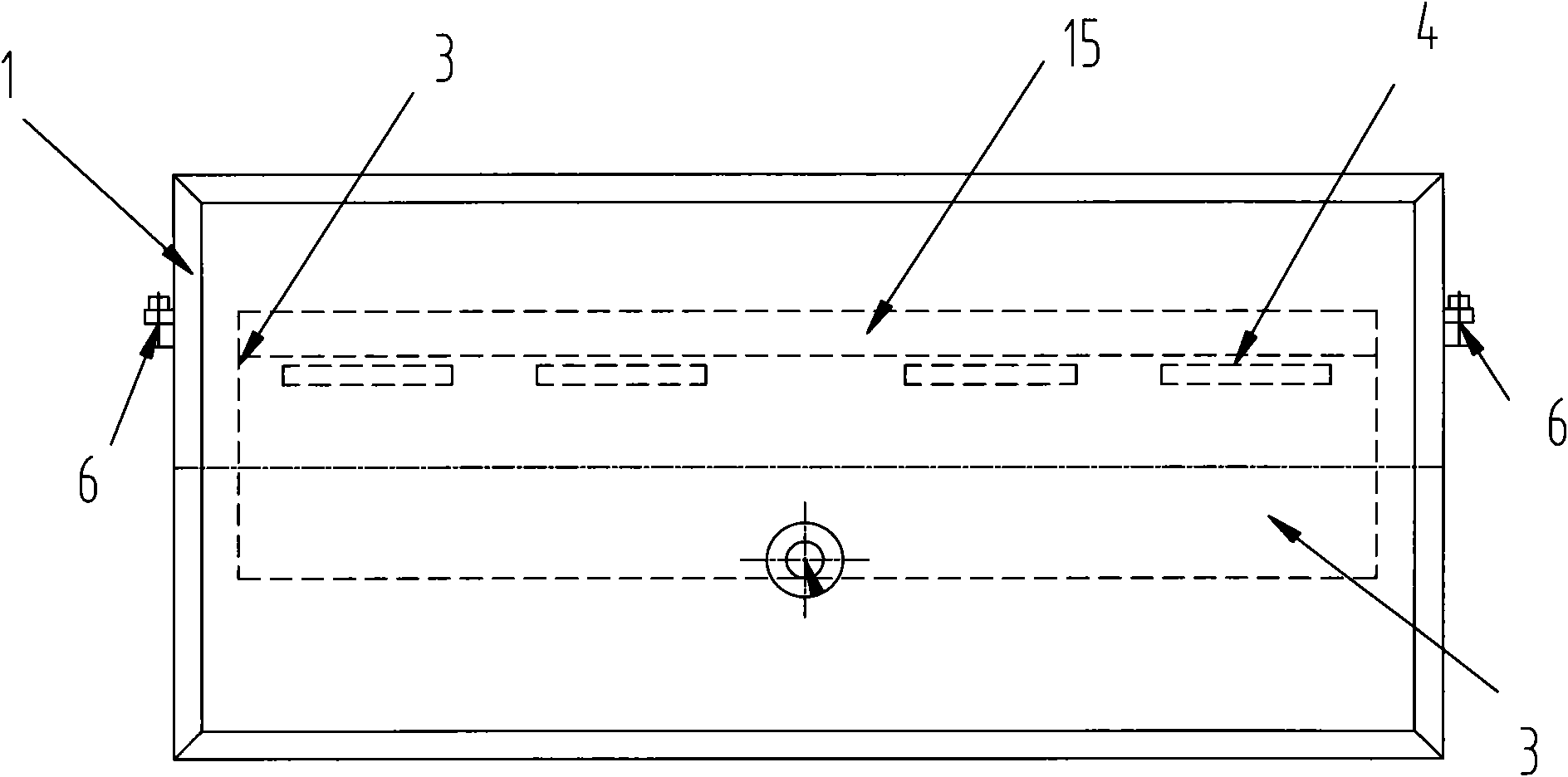

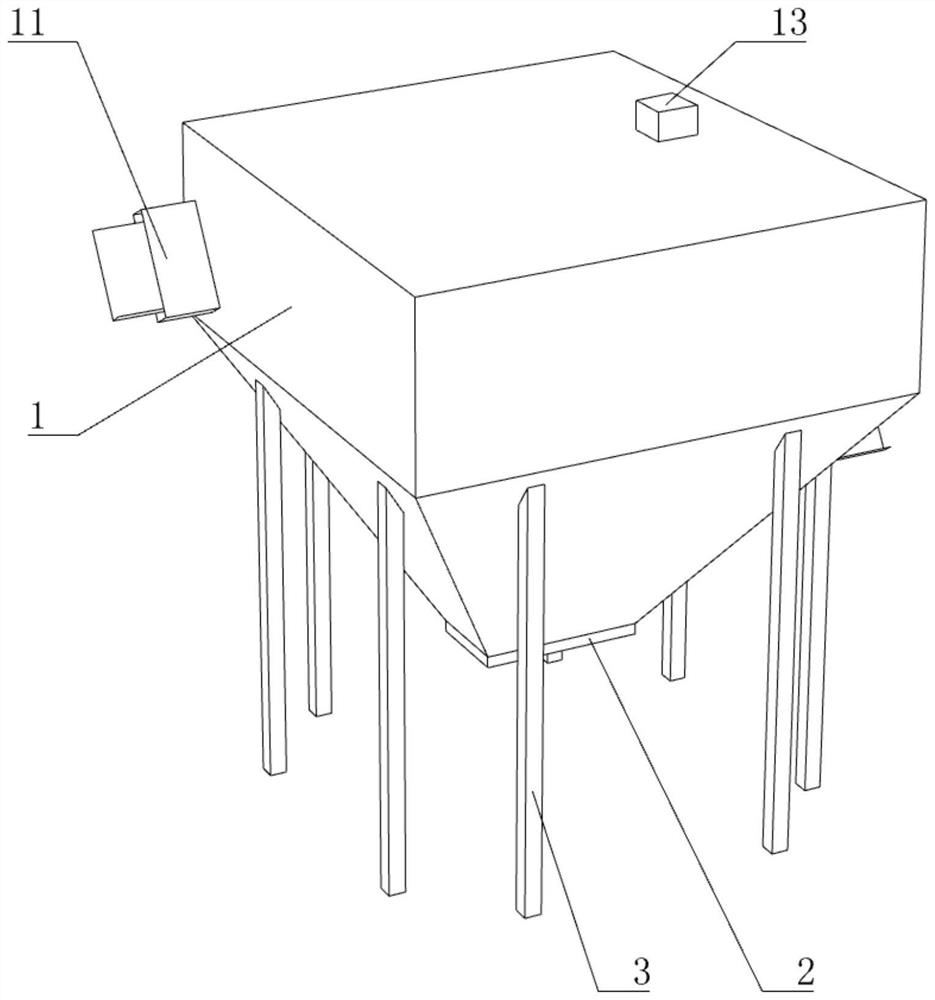

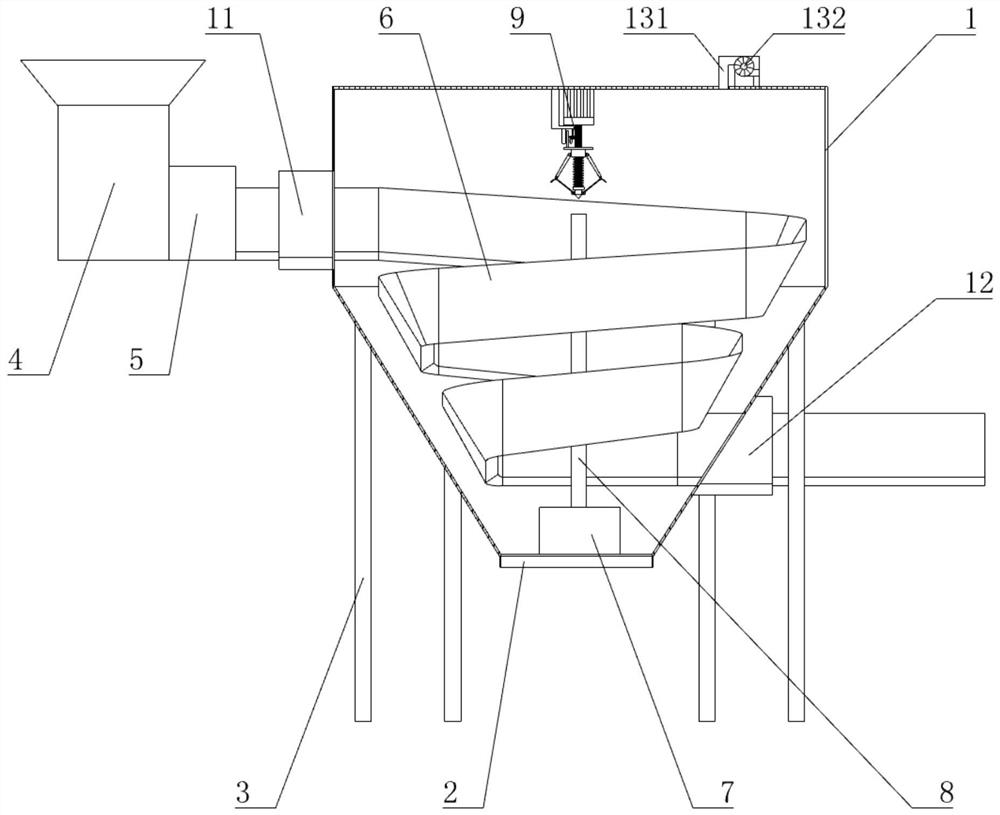

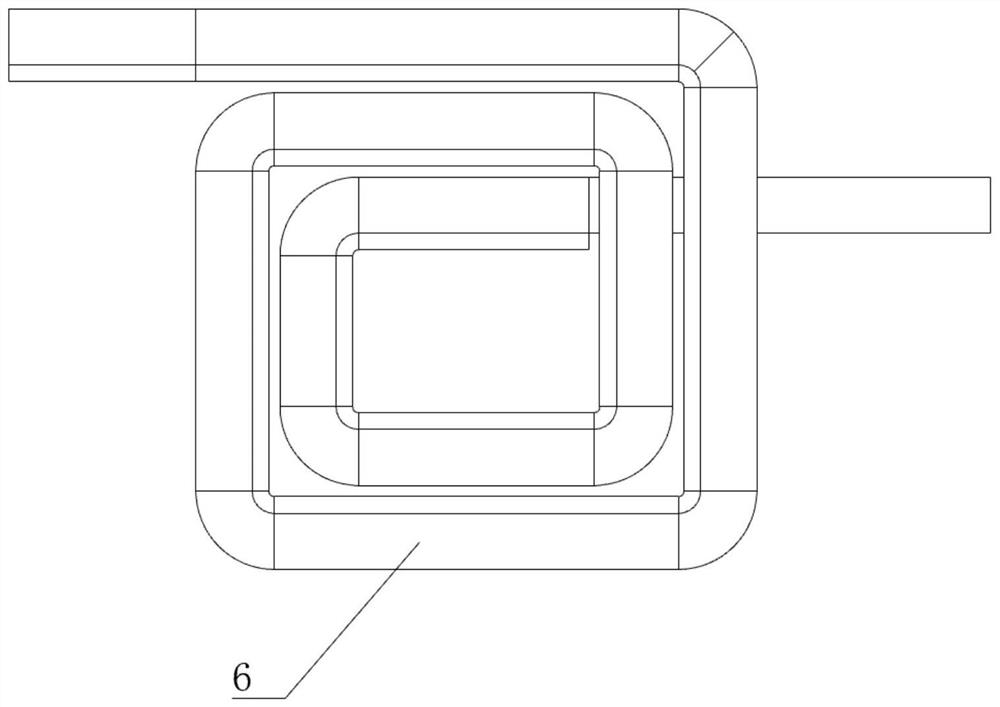

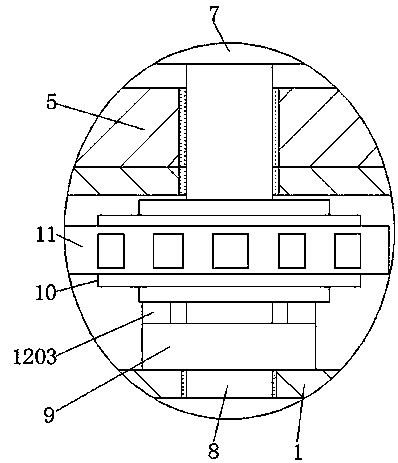

Gravity type sludge dehydration device

ActiveCN101613172AAchieve dehydration effectImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningDraining tubeSludge

The invention discloses a gravity type sludge dehydration device, which comprises a shell, wherein the upside of the shell is provided with a water inlet pipe while the downside is provided with a drain pipe and a mud pipe, a dehydration device is connected with the inside of the shell from top to bottom and divides the cavity of the shell into a water purifying area and a mixing area, a mixing distribution cylinder having a round cross section and communicated with the water inlet pipe, a first water eliminator, a second water eliminator are arranged from top to bottom in the mixing area, and the mud pipe is communicated with the lower end of the mixing area; a water collection bailer is arranged in the water purifying area, and the drain pipe is communicated with the lower end of the water collection bailer; and the water inlet pipe is communicated with the mixing distribution cylinder, the mixing distribution cylinder is provided with water distribution holes, and the first water eliminator and the second water eliminator are arranged below the mixing distribution cylinder at intervals, tilt downwards and are opposite to the dehydration device. The gravity type sludge dehydration device is free from being driven by power devices, and the dehydration process depends on the gravity flow of water and the osmosis of filter cloth to release the water in the sludge. Besides, the dehydration efficiency of the sludge is high, the liquid holdup of filter cakes is between 80 and 85 percent, and the sludge recovery percent is over 90 percent.

Owner:江苏八达科技股份有限公司

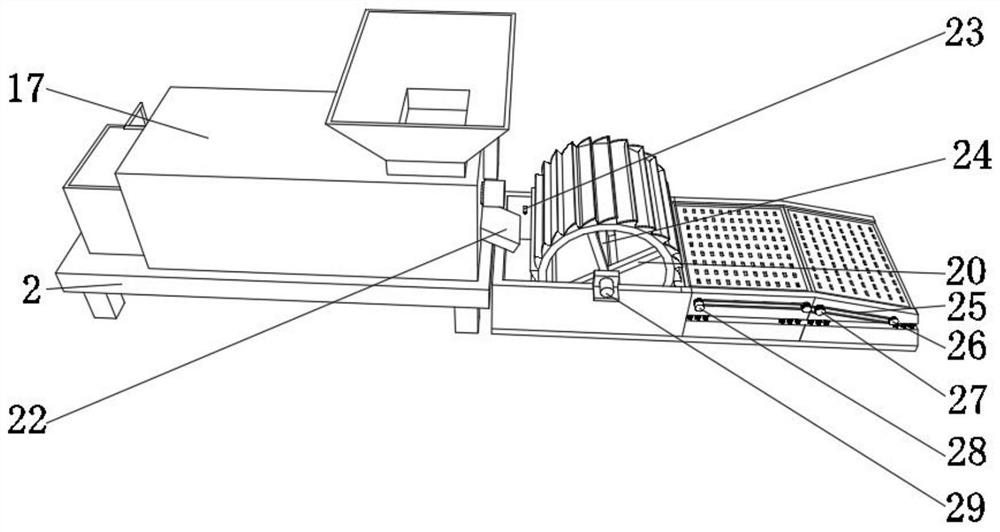

Concrete recovery sand-stone separation device for constructional engineering

PendingCN112317123AAchieve dehydration effectImprove filtering effectMechanical material recoveryWet separationArchitectural engineeringElectric machinery

The invention discloses a concrete recovery sand-stone separation device for constructional engineering, and relates to the technical field of gravel separation. In order to solve the problem of finesand water removal, the device specifically comprises a base and a sedimentation tank, a box body is fixed to the top of the base through bolts, a water tank is fixed to the outer wall of one side ofthe box body through bolts, a feeding hopper is fixed to the top of the box body through threads, a stone outlet and a sand outlet are fixed to the outer wall of one side of the box body through threads, and a controller is fixed to the outer wall of one side of the box body through bolts; and an alarm is fixed to the outer wall of the top of the controller through bolts, a separation mechanism isarranged in the box body, a flushing mechanism is arranged on the inner wall of the top of the box body, and a discharging pipe is fixed to the outer wall of one side of the box body through threads.A second motor is started, so that the output end of the second motor drives a connecting rod to rotate, a rotary drum and a filtering frame can be driven to rotate through a fixing rod, mud enters the filtering frame through rotation of the rotary drum, and the mud is dewatered due to gravity.

Owner:魏雪

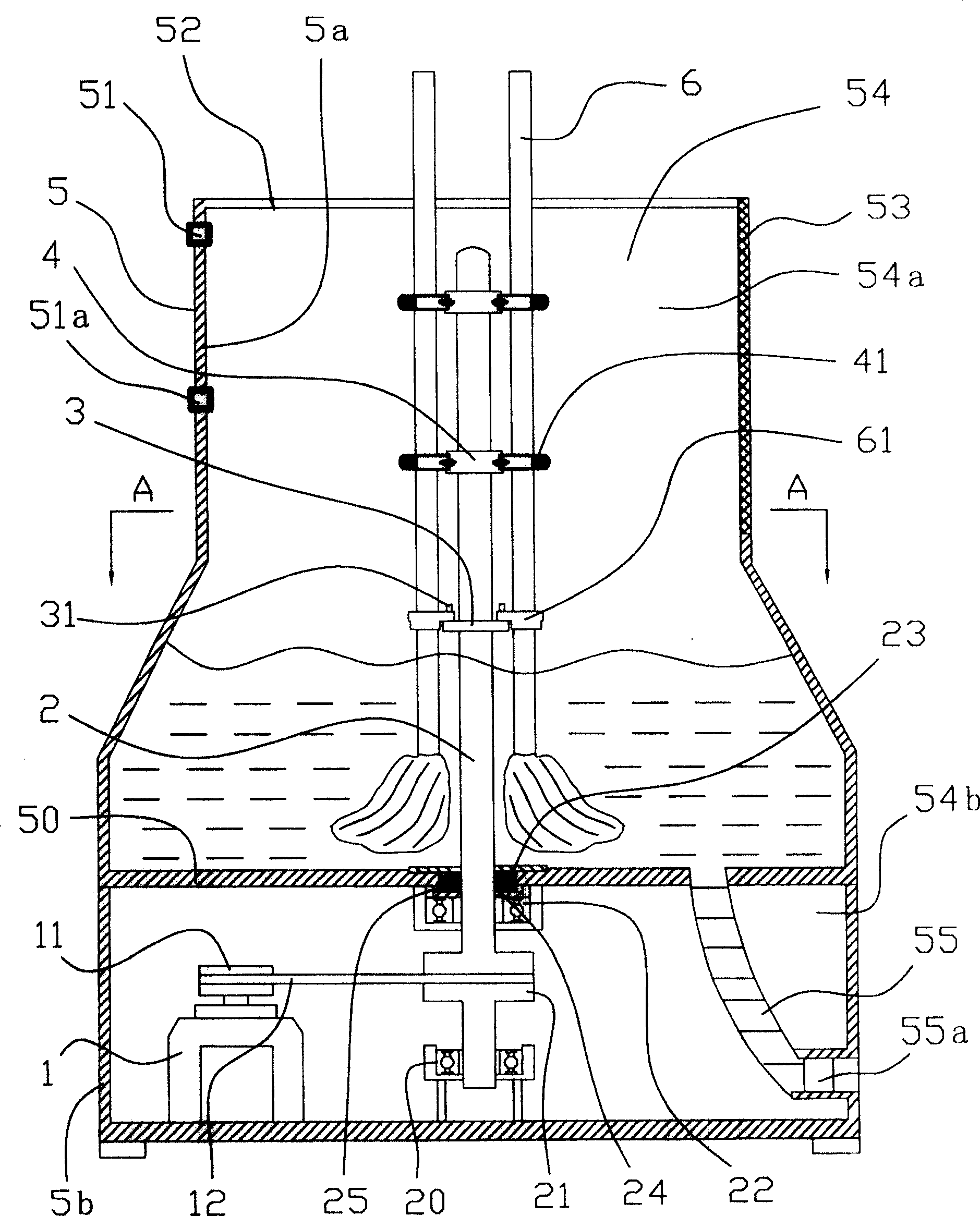

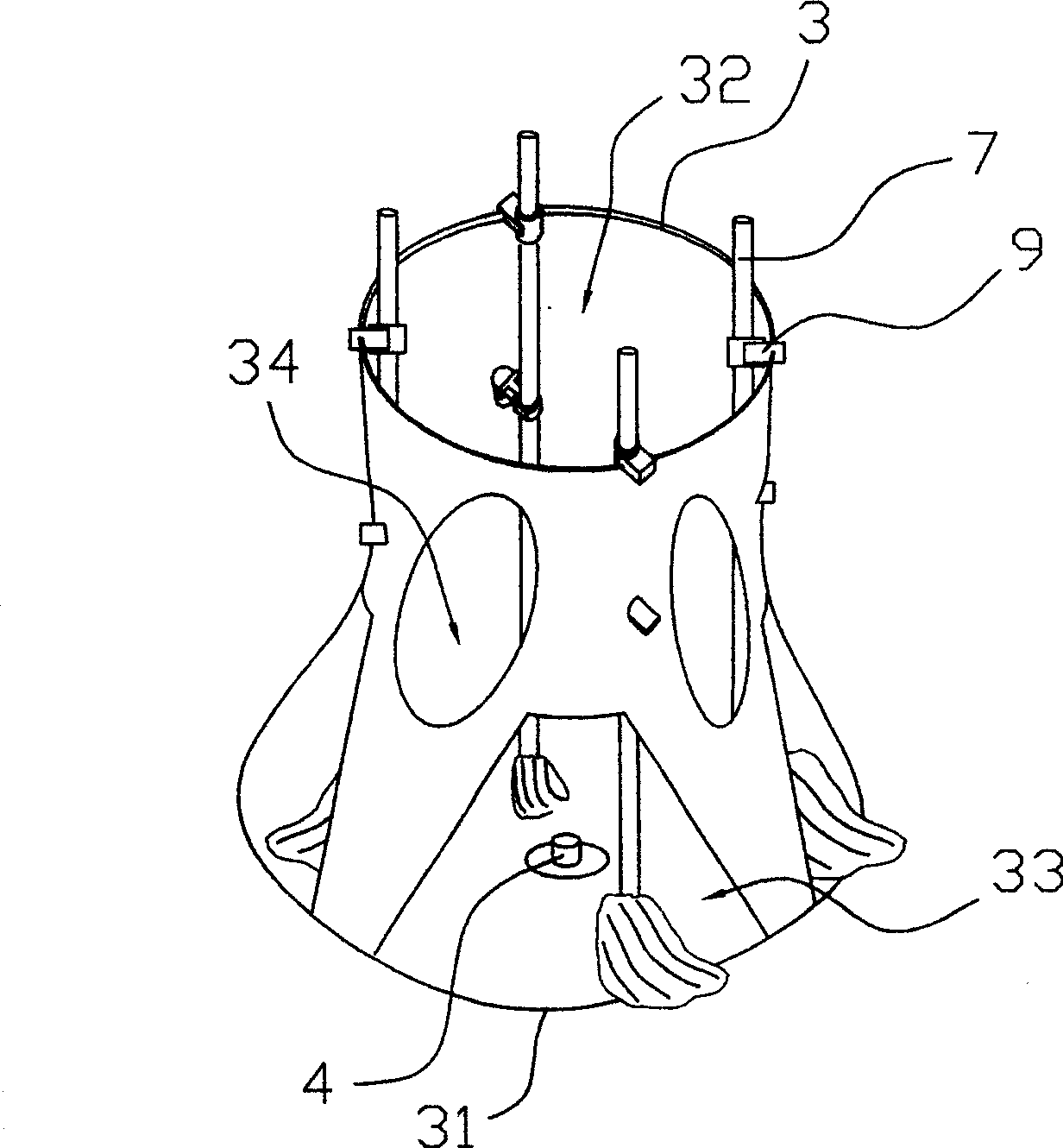

Mop-cleaning squeezer

The invention relates to a mop cleaner, which comprises barrel (5), rotation axle (2) fixing the mop (6), and motor (1). Wherein, the invention is characterized in that; the barrel (5) via baffle plate (50) separates the chamber of barrel (54) into upper chamber (54a) and lower chamber (54b); the rotation axle (2) is vertically rotationally arranged in the middle of upper chamber, while its lower end is through the baffle plate (50) to enter into lower chamber, to connect the motor via transmitter; the rotation (2) at the upper chamber has fixer of mop. The invention can reduce the cost, and simplify the structure. And it can wash several mops via support and clamping support, to save water and electricity.

Owner:王会才

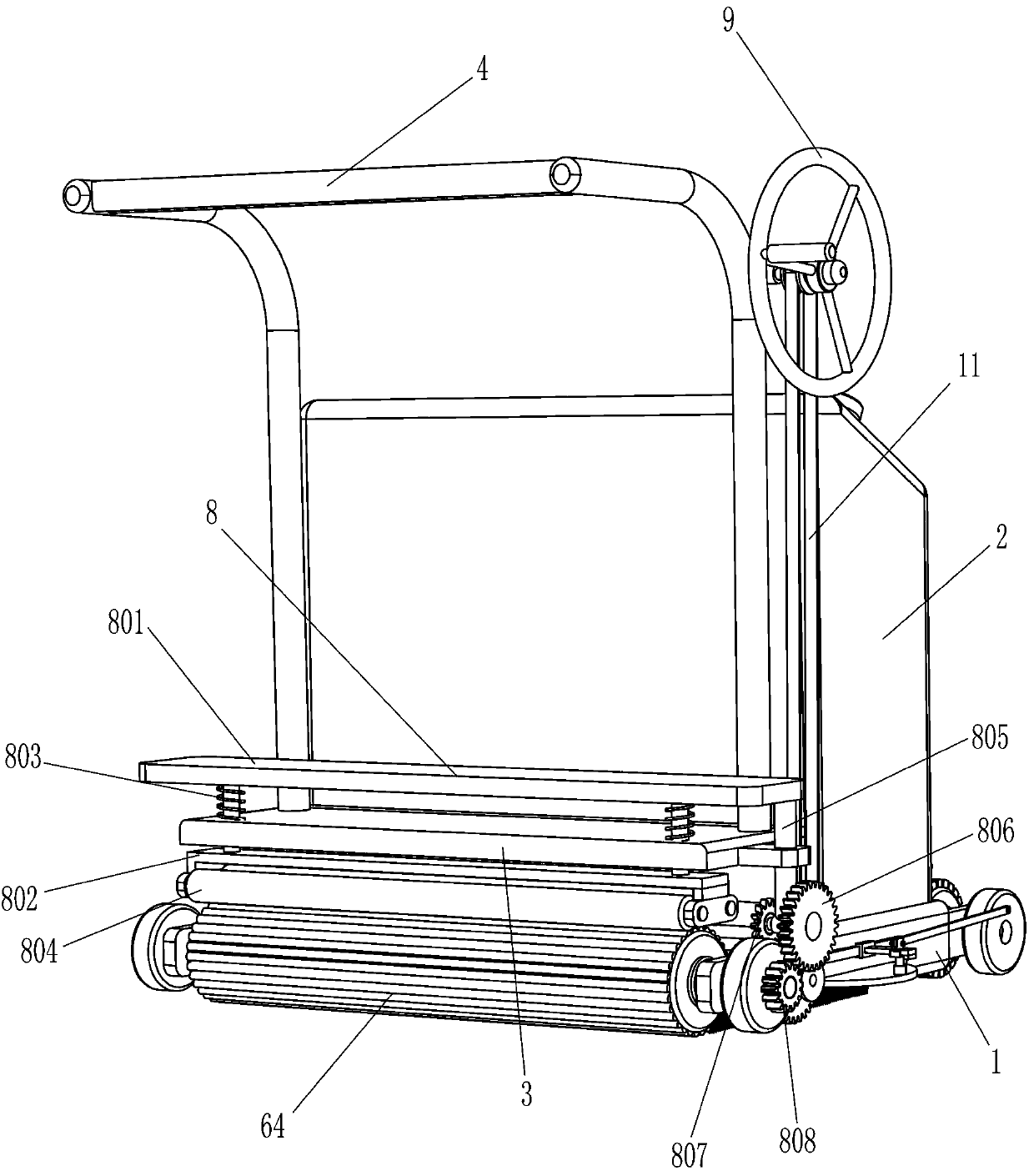

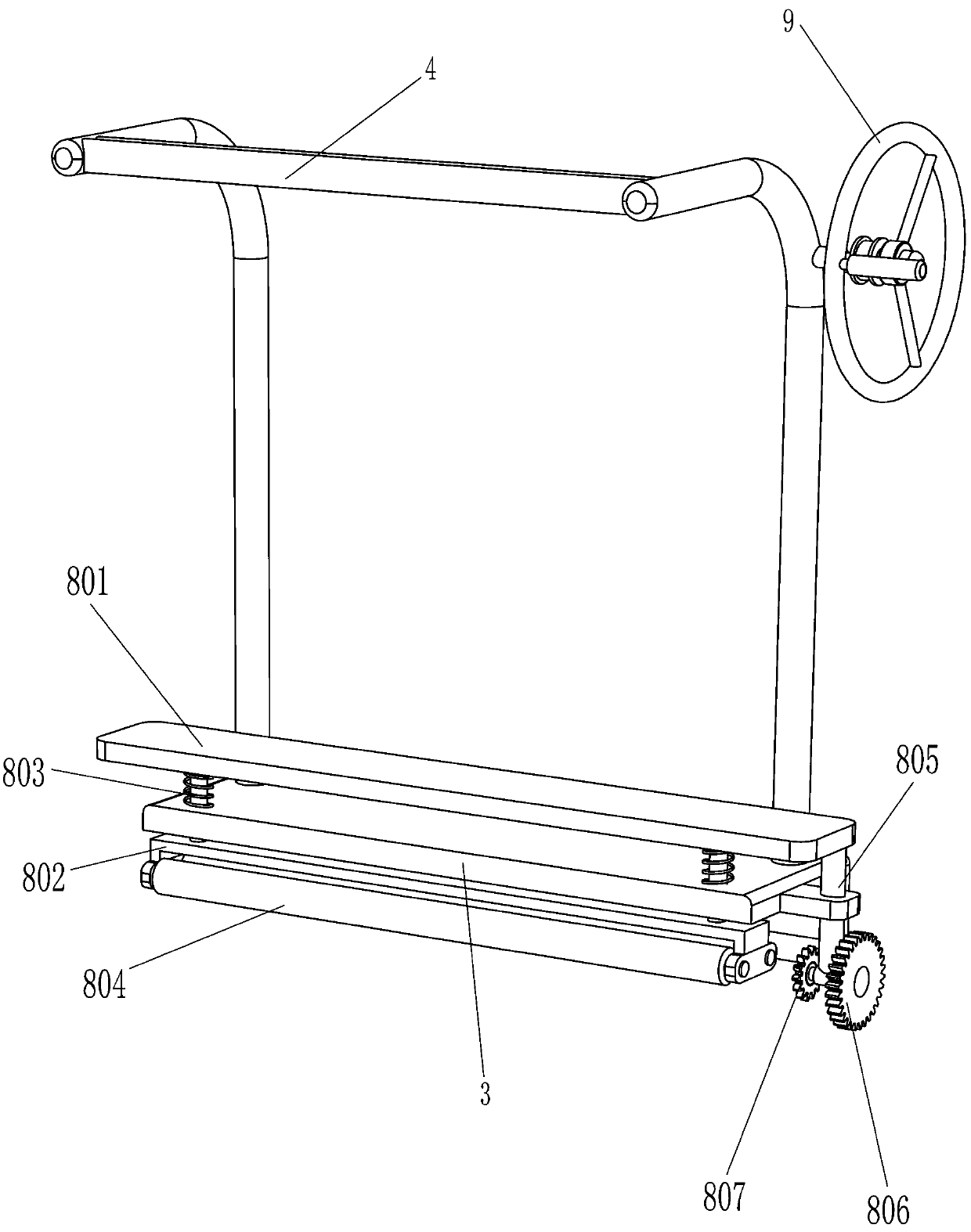

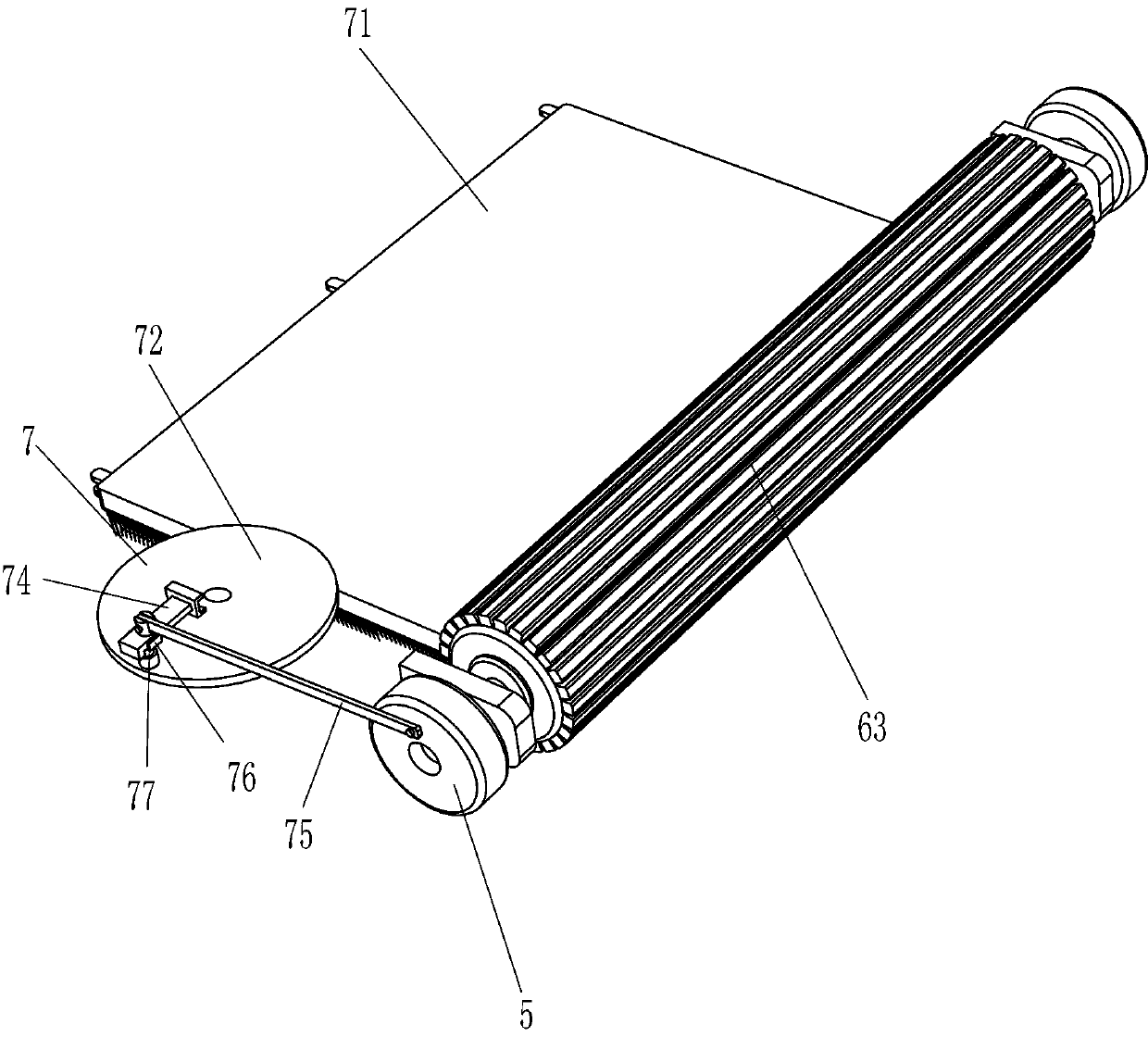

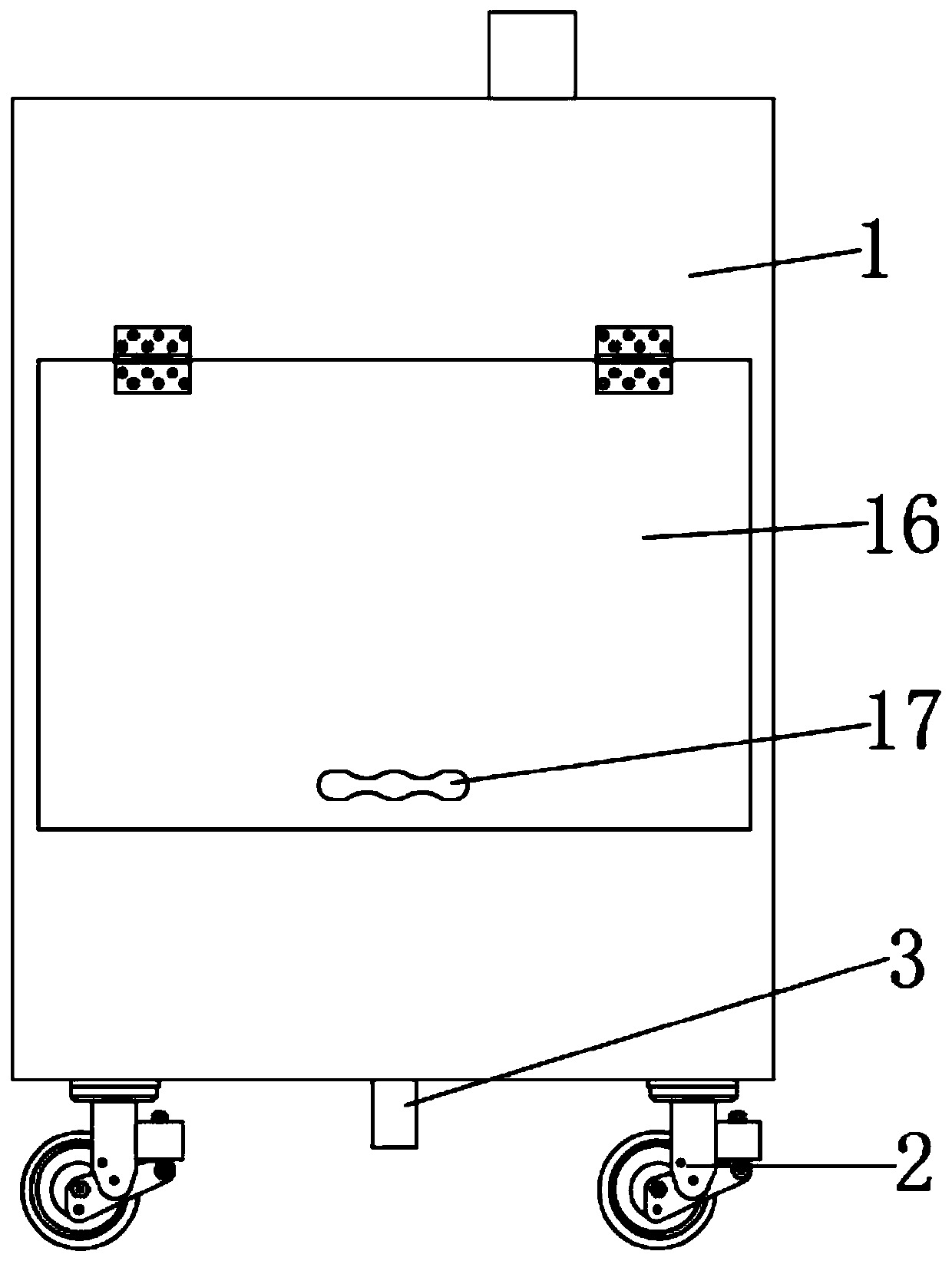

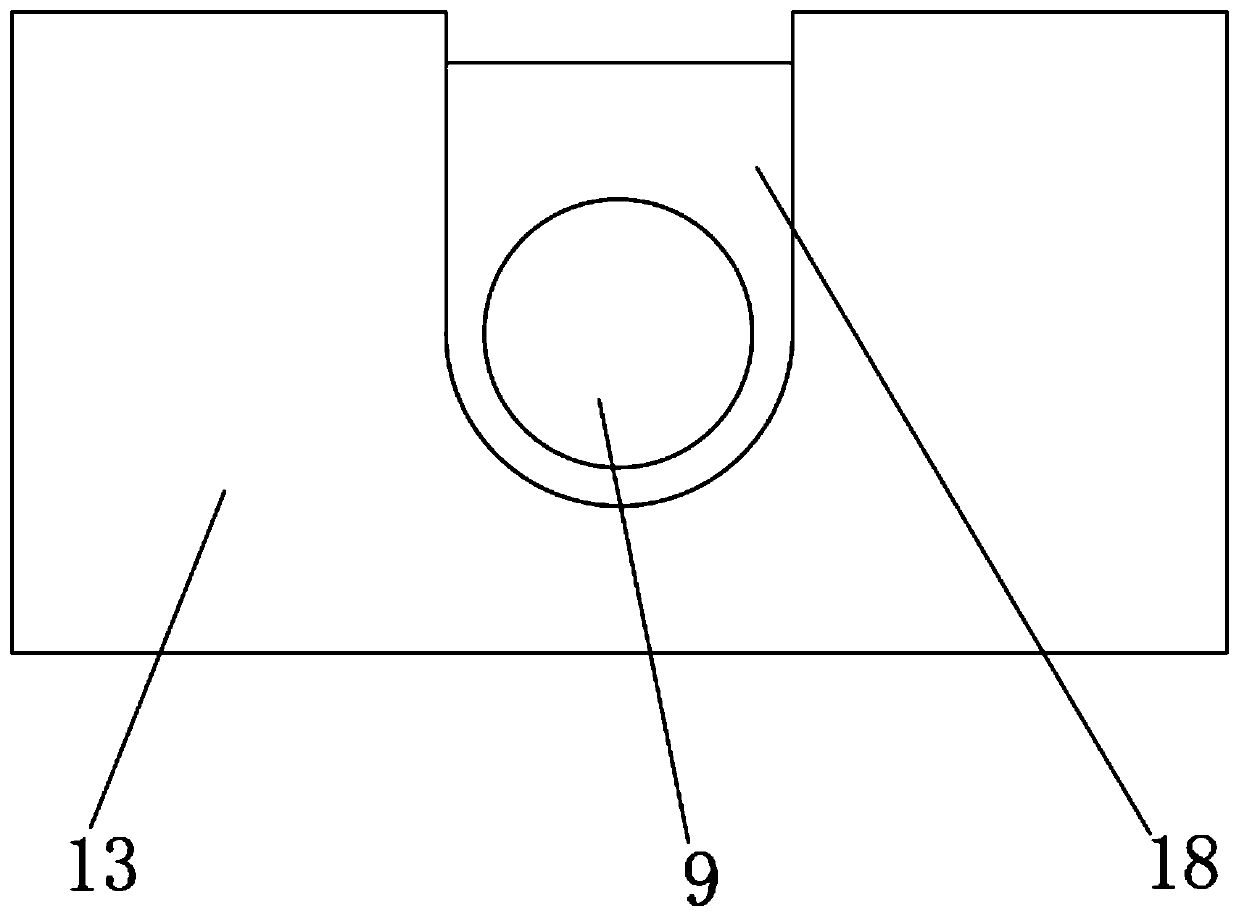

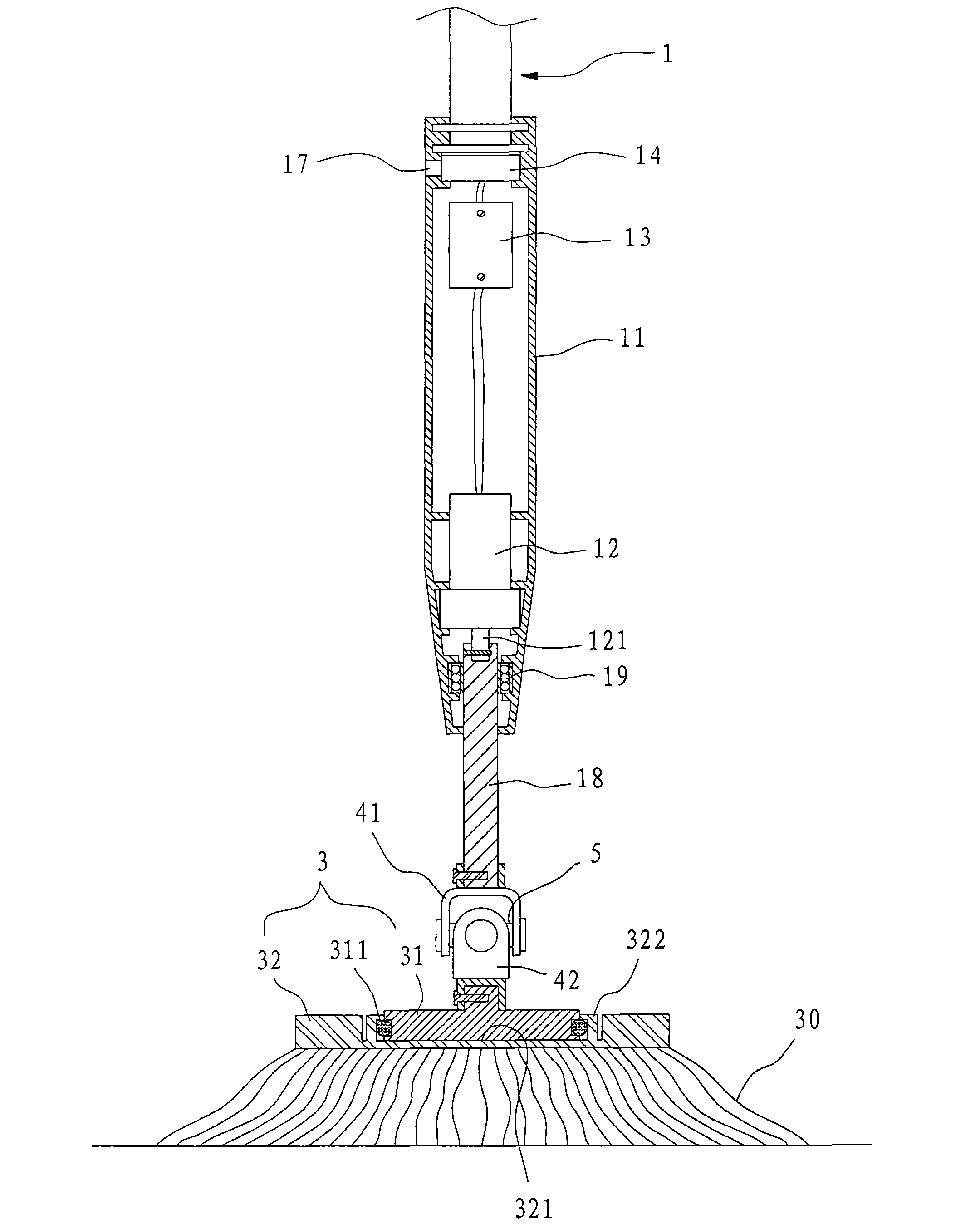

Medical ground disinfectant wiping vehicle

ActiveCN111529731ADisinfect evenlyAchieve dehydration effectLavatory sanitoryChemicalsProcess engineeringIdler-wheel

The invention relates to the technical field of medical care sanitation, in particular to a medical ground disinfectant wiping vehicle. The invention aims to solve the technical problem of providing the medical ground disinfectant wiping vehicle which can evenly disinfect the ground and save disinfectants and has an obvious disinfection effect. In order to solve the above technical problems, the invention provides the medical ground disinfectant wiping vehicle. The medical ground disinfectant wiping vehicle comprises a base, a handle, idler wheels, a smearing component and a wiping component,wherein two sides of the top of the base are independently provided with a liquid storage box and a bracket; one side, which is near the liquid storage box, on the top of the bracket is provided withthe handle; four corners of the base are independently provided with the idler wheel; the smearing component is installed between two sides of the base and is used for smearing the disinfectant to theground; and the wiping component is installed on the bottom of the base and is used for wiping the ground. Through the medical ground disinfectant wiping vehicle disclosed by the invention, through the smearing component and the wiping component, an effect that the ground is evenly disinfected, the disinfectant is saved and a disinfection effect is obvious can be realized.

Owner:姜凤举

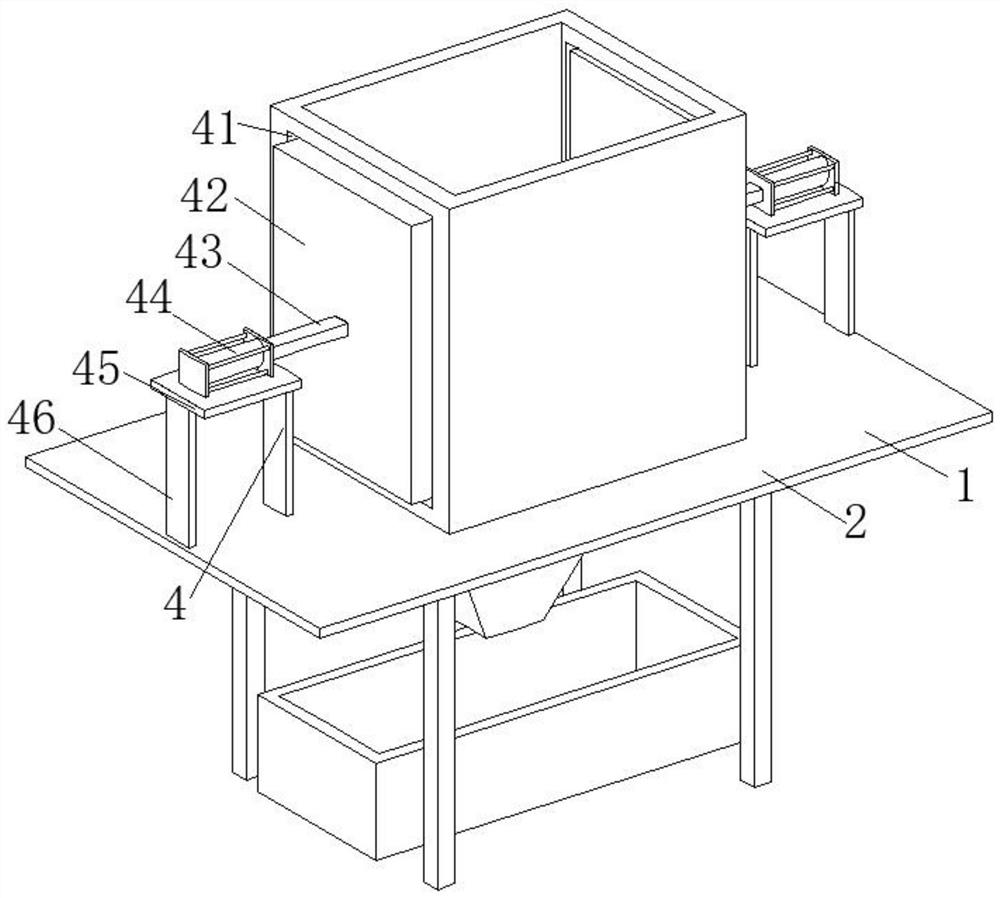

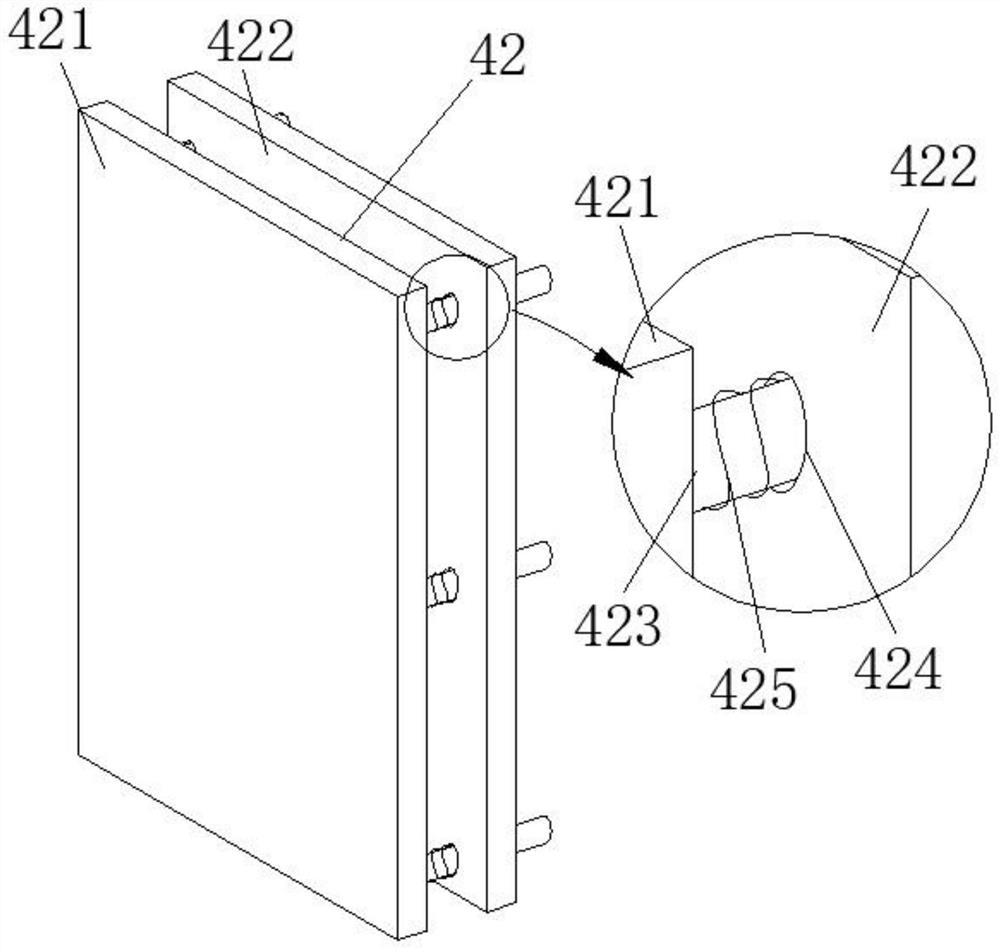

Sludge dewatering device and using method thereof

InactiveCN112661377AReasonable dehydration structure designEasy to operateSludge treatmentProcess engineeringWorkbench

The invention relates to a sludge dewatering device and a using method thereof. The sludge dewatering device comprises a sludge dewatering box, a workbench and a storage box, the sludge dewatering box is arranged on the workbench, the storage box is arranged under a drain pipe of the sludge dewatering box, and side extrusion mechanisms are arranged on the sludge dewatering box and the workbench; according to the sludge dewatering device, an extrusion dewatering mode is adopted for dewatering, the dewatering mode can be suitable for dewatering a large amount of sludge, the effect of efficient dewatering can be achieved in the dewatering process, the arrangement and dewatering structure of the dewatering device is reasonable in design, operation is easy, and in the dewatering process, dewatering can be conducted through cooperation of multiple steps, the dewatering effect is achieved, the dewatering time in the sludge dewatering process can be greatly saved, saves the cost investment in the dewatering process can be saved, and the market requirements can be better met.

Owner:HANGZHOU YUEQI ENVIRONMENTAL PROTECTION TECH CO LTD

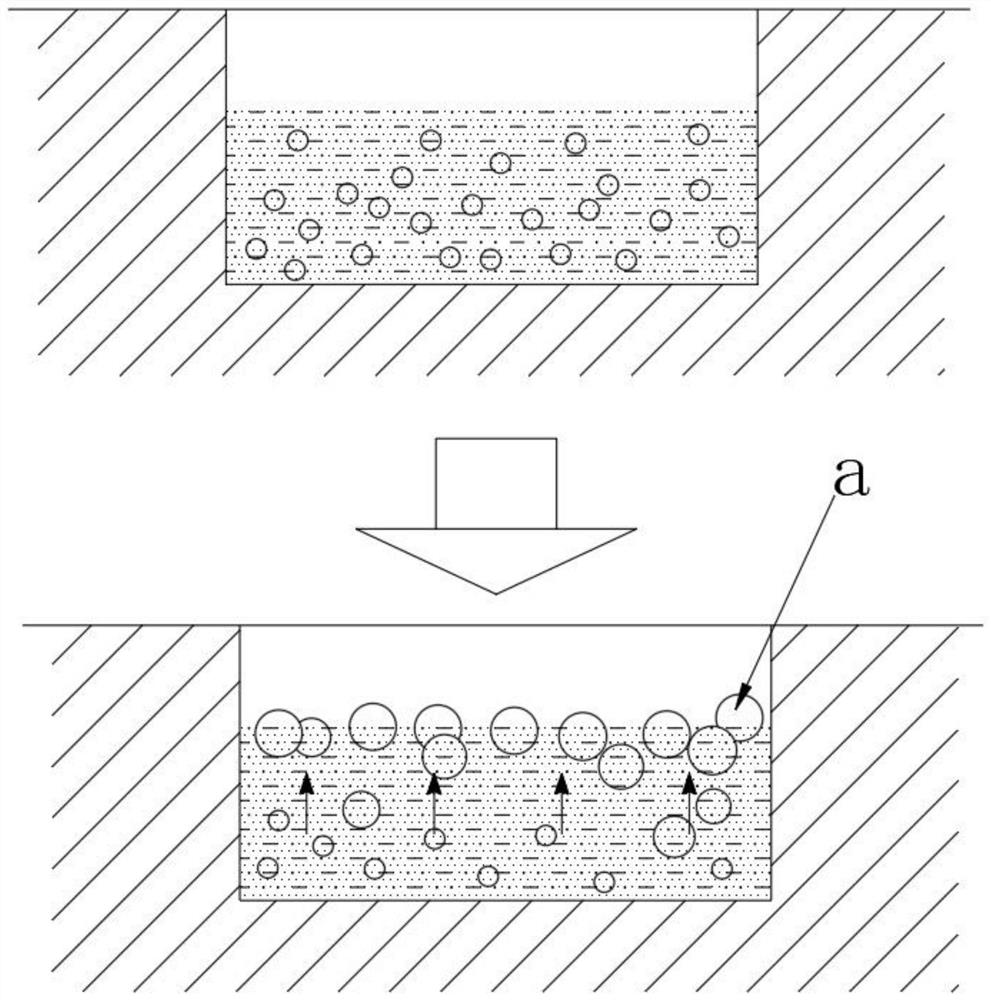

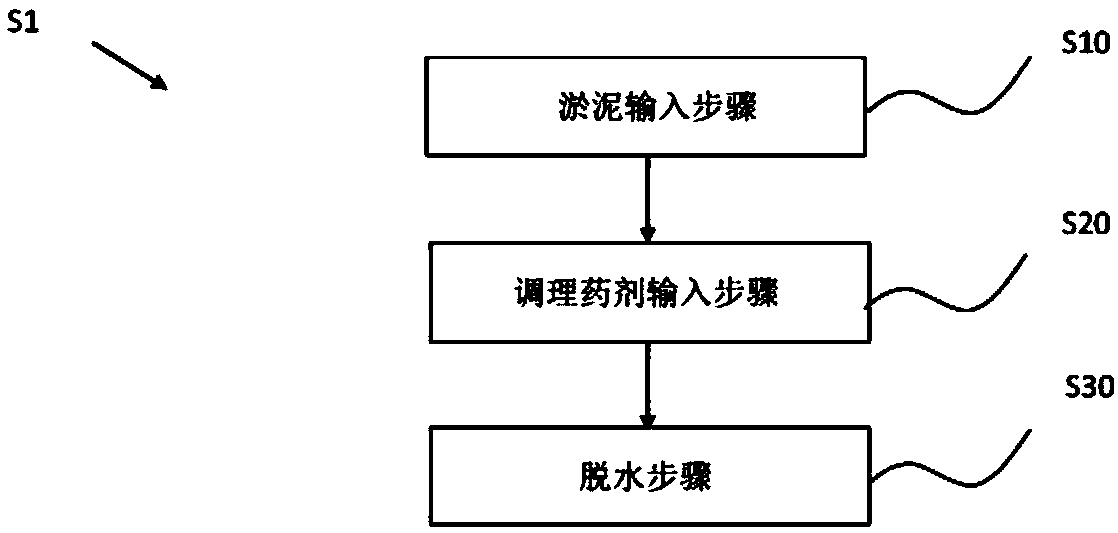

Air expansion self-floating sludge dewatering treatment process

InactiveCN112374719AImprove dehydration efficiencyAvoid burstingSludge treatment by de-watering/drying/thickeningCarbon dioxideSludge dewatering

The invention discloses an air-expansion self-floating sludge dewatering treatment process, belongs to the field of sludge treatment, and particularly relates to an air expansion self-floating sludgedewatering treatment process which comprises the following steps: adding an air expansion floating ball in the dewatering process, so that water absorbed by the air expansion floating ball can be in direct contact with sludge, thereby adsorbing moisture in the sludge and transporting the sludge into the air expansion floating ball, the air production inner core in the air expansion floating ball reacts with water, carbon dioxide air overflows, and along with increase of the water absorption capacity, the amount of the overflowing air is increased as well, so that the expansion degree of the expansion air layer is gradually increased, namely the overall volume of the air expansion floating ball is gradually increased, and the air expansion floating ball floats upwards in sludge; on one hand, the process is a process of absorbing moisture in the sludge, and is also process of consuming moisture, and thus the sludge dewatering efficiency is obviously improved; on the other hand, when theair expansion floating ball floats up to the surface of the sludge, a worker can recover and replace the air expansion floating ball in time, that is, the recovery difficulty is low, and the overall dehydration efficiency of the sludge is further improved.

Owner:徐强

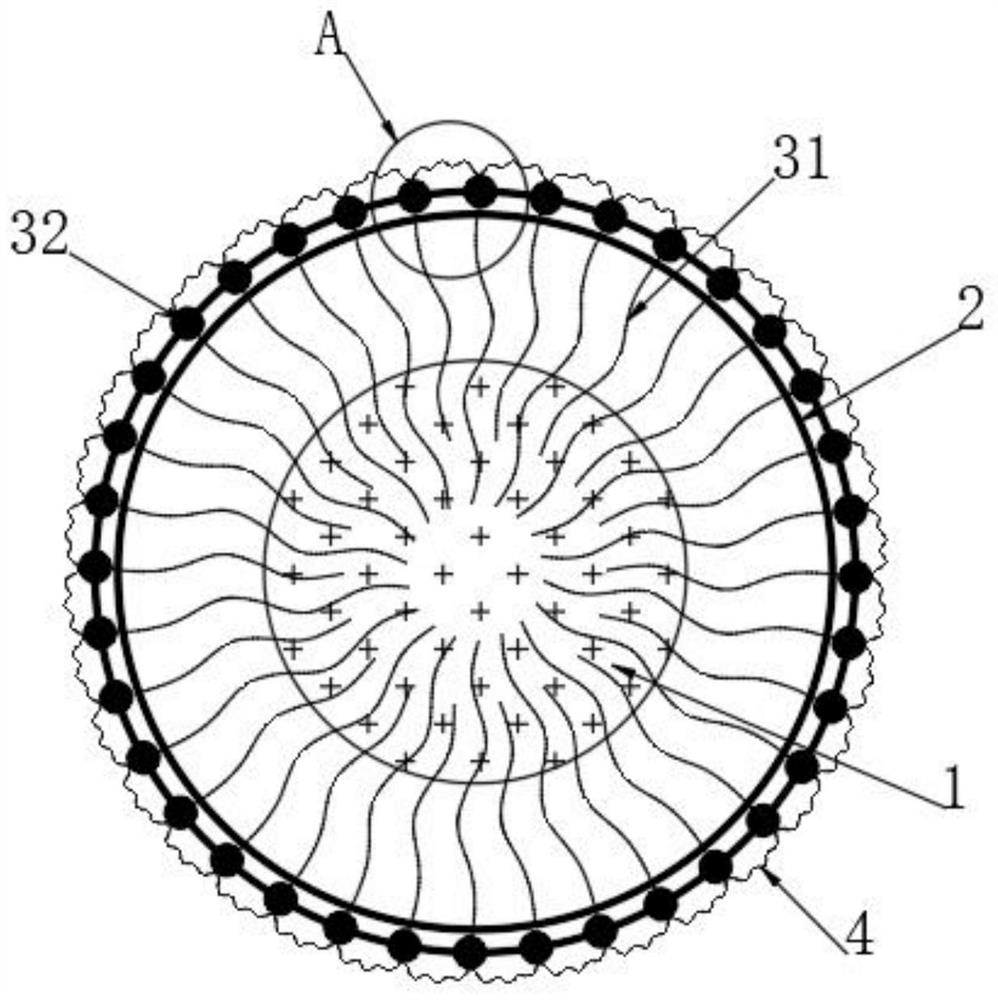

Pickling sludge dewatering device

ActiveCN112759224AImprove uniformityReduce occupancySludge treatmentWaste water treatment from metallurgical processWaveguideMechanical engineering

The invention discloses a pickling sludge dewatering device, and the device comprises a dewatering chamber; a main body of the dewatering chamber is in an inverted pyramid frustum shape, a spiral conveying belt matched with the inner wall of the dewatering chamber is arranged in an inner cavity of the dewatering chamber from top to bottom, a magnetron is arranged in the center of the bottom of the inner cavity of the dewatering chamber, a vertical waveguide tube is connected to the upper portion of the magnetron, a microwave stirrer fixed to the top of an inner cavity of the dewatering chamber is arranged over the output end of the waveguide tube, the input end and the output end of the conveying belt penetrate through a feeding port and a discharging port of the dewatering chamber respectively, and the bearing face of the conveying belt is obliquely arranged and faces the waveguide tube and the microwave stirrer. The pickling sludge is dewatered in a microwave heating mode, the sludge plate absorbs microwave energy, so the temperature is continuously increased;meanwhile, water in the sludge plate is evaporated, the dewatering effect is achieved, and environmental pollution and land occupation are reduced.

Owner:江苏亿洲再生资源科技有限公司

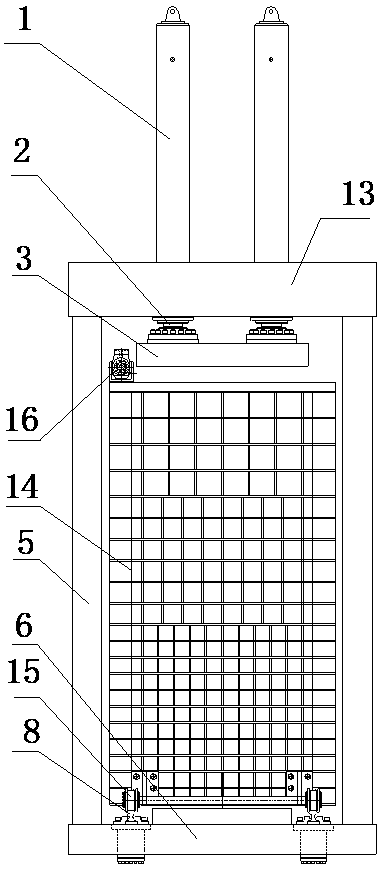

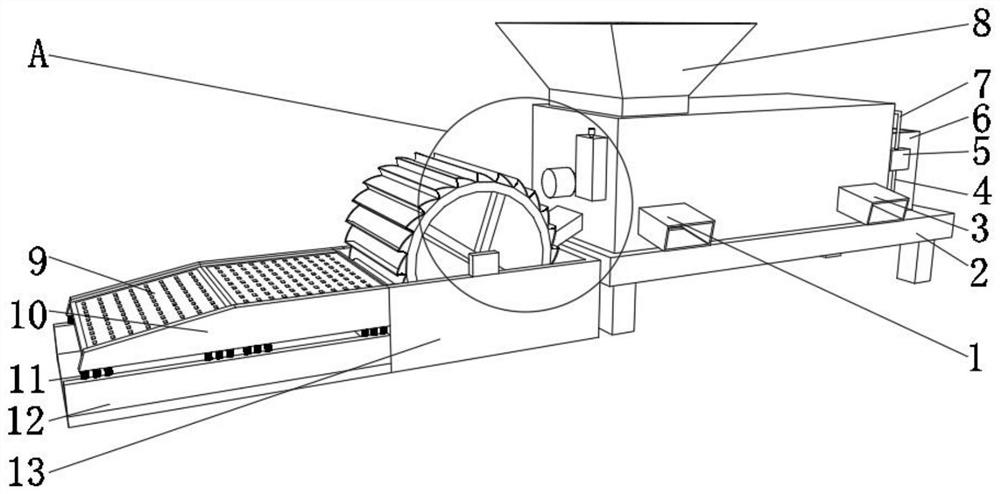

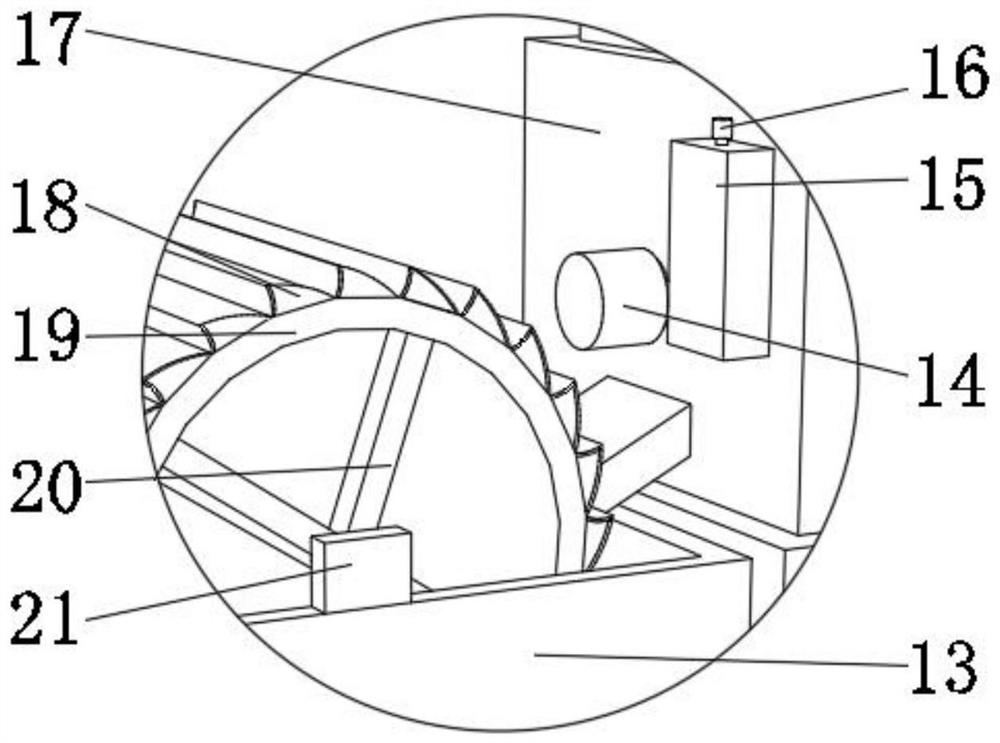

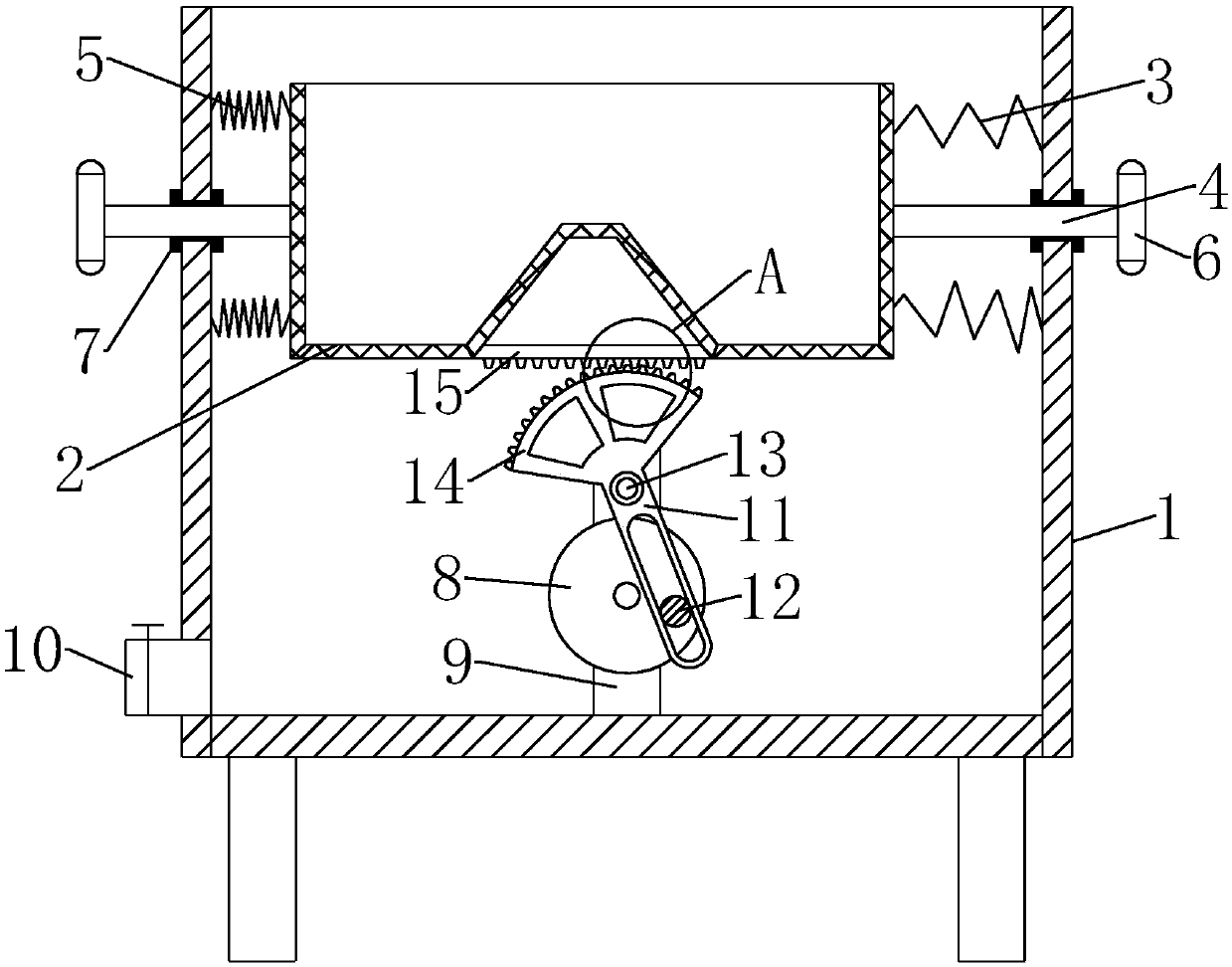

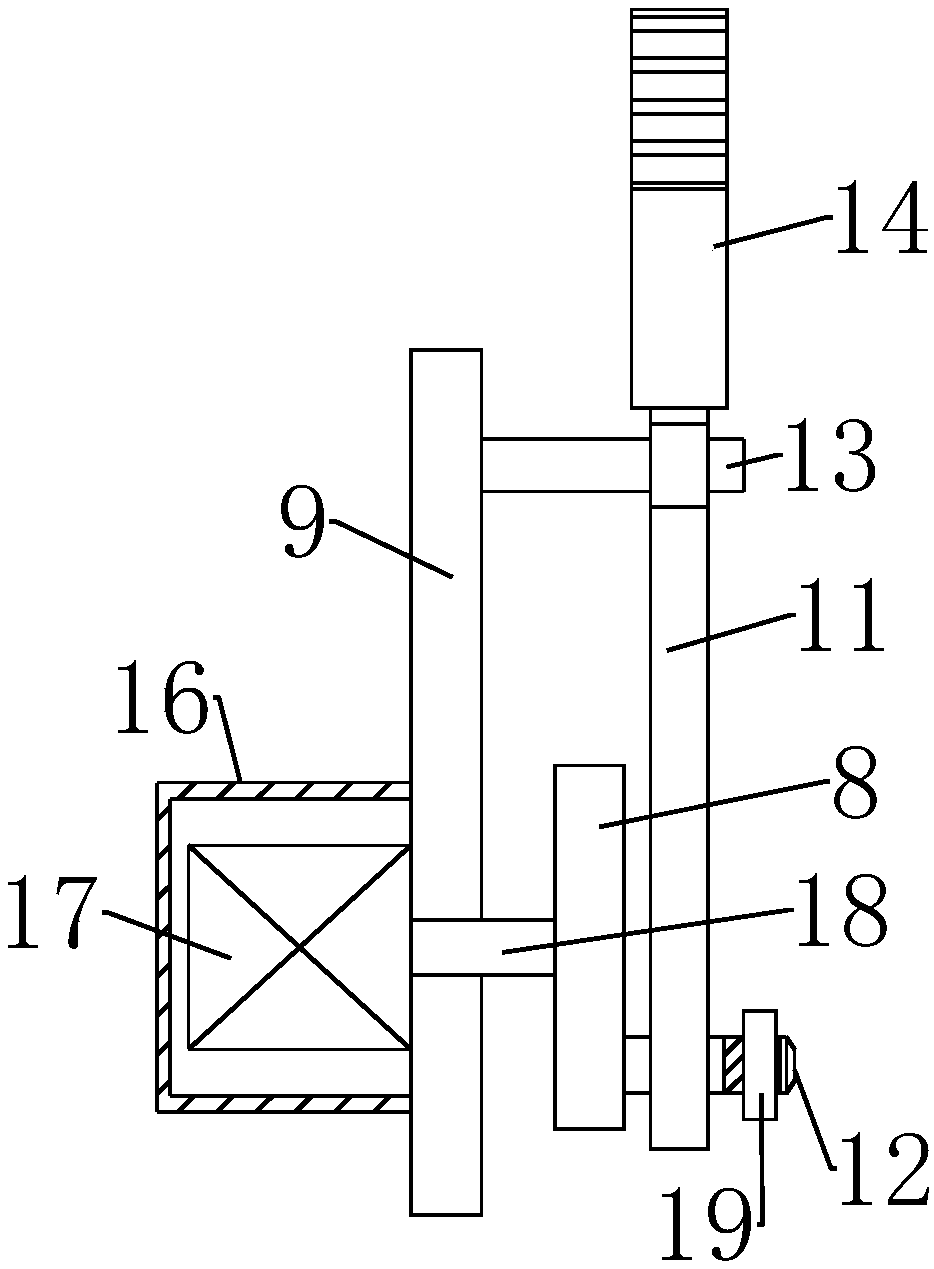

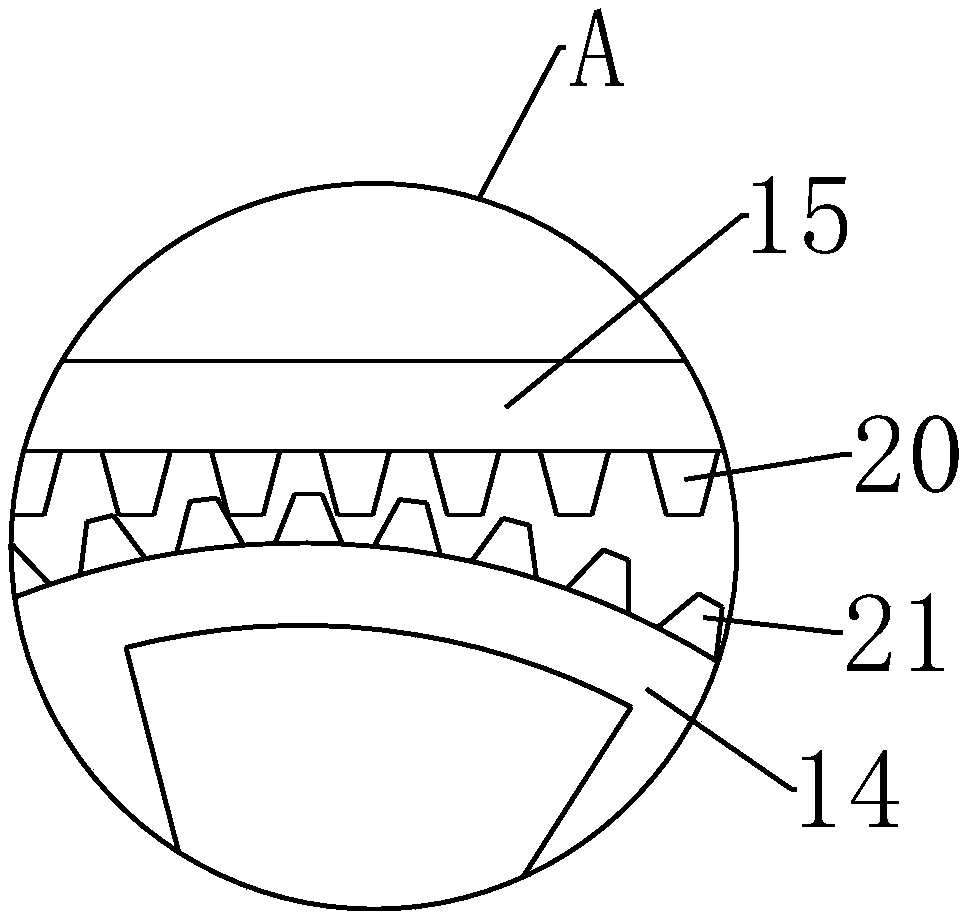

Swing-type tea dewatering device

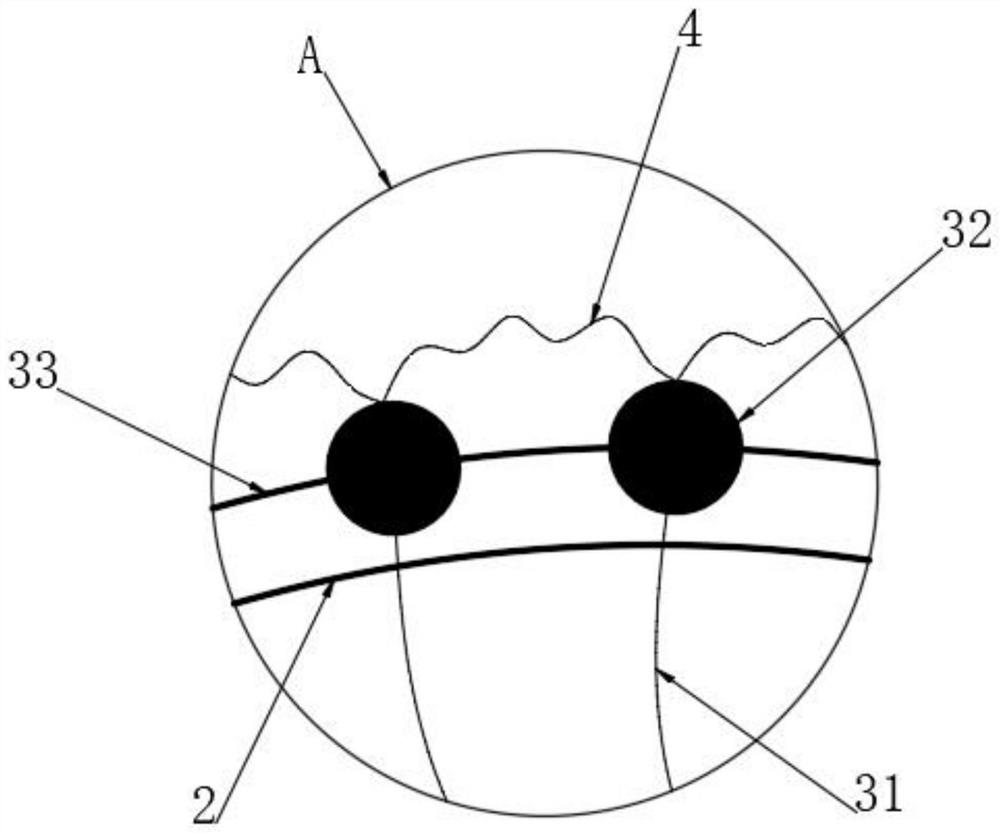

PendingCN107691682AEasy resetAchieve dehydration effectPre-extraction tea treatmentEngineeringBULK ACTIVE INGREDIENT

The invention discloses a swing-type tea dewatering device which comprises an outer box, a dewatering box and a swing mechanism, wherein the dewatering box is arranged in an inner cavity on the upperpart of the outer box through an elastic connecting rack; a toothed plate is fixedly erected at the bottom of the dewatering box; a plurality of teeth A are uniformly distributed on the surface at thebottom of the toothed plate; the swing mechanism comprises a rotating disc, a swing loop bar, a guide post and an arc fluted disc; the guide post is fixedly arranged on the outer end face of the rotating disc; the lower part of the swing loop bar is arranged on an outer circumference of the guide post in a sliding manner by virtue of a guide sliding cavity; the upper part of the swing loop bar isrotationally arranged on a rotating rod in a bearing connecting manner; the arc fluted disc is fixedly arranged on the top of the swing loop bar; and a plurality of teeth B meshed with the teeth A are uniformly distributed and fixedly arranged on the outer peripheral surface of the arc fluted disc. The swing-type tea dewatering device disclosed by the invention is simple in structure, convenientto use and excellent in dewatering effect, loss of active ingredients in fresh leaves is not lost, the tea quality is ensured, and the device is suitable for popularization and application.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

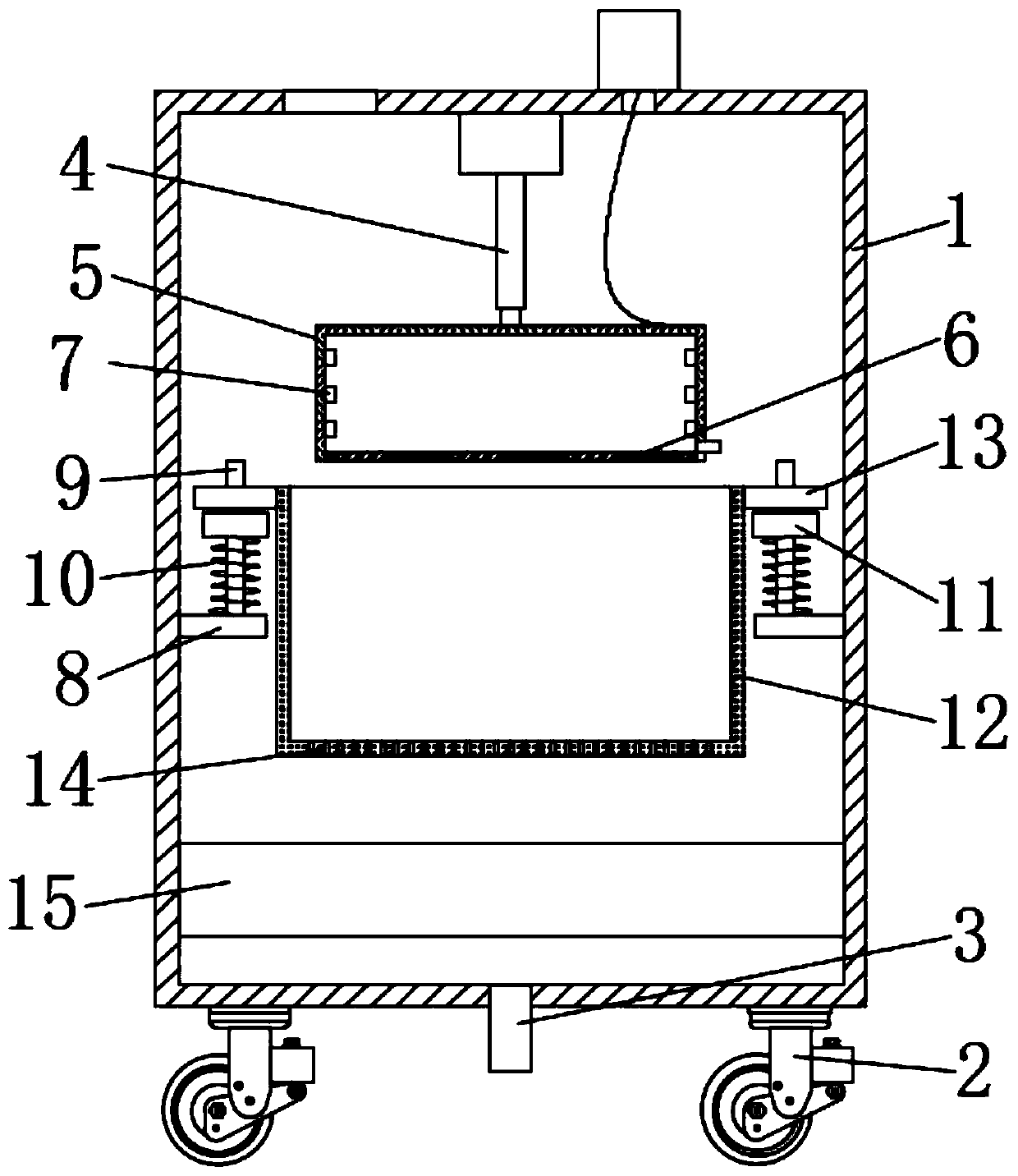

Dehydration device for food processing

InactiveCN111536764AImprove efficiencyAvoid working environment pollutionDrying solid materials without heatTreatment involving filtrationActivated carbonProcess engineering

The invention provides a dehydration device for food processing, and relates to the technical field of food processing. The dehydration device for food processing comprises a dehydration box, a plurality of universal casters and a drainage pipe, wherein the plurality of universal casters are fixed to the bottom of the dehydration box; the drainage pipe is arranged at the center of the bottom of the dehydration box; a hydraulic rod is fixedly connected to the center of the inner top wall of the dehydration box; a heating box is fixedly connected to the bottom of the hydraulic rod; and a plurality of heating blocks are fixedly connected to the two side walls inside the heating box. Heat of hot water in the heating box is transferred to food in a material box through a heat conducting plate so as to heat and soften an outer shell of the food, so that cracks are easily formed in the outer shell of the food through extrusion, water extruded out of the interior of the food passes through theouter shell easily, and the dehydration efficiency is improved; and extruded waste water is purified through a filter screen and an activated carbon layer so that the waste water discharged from thedehydration box cannot attract mosquitoes and flies, and therefore pollution to working environment is avoided.

Owner:CHAOHU MEADVILLE FOOD CO LTD

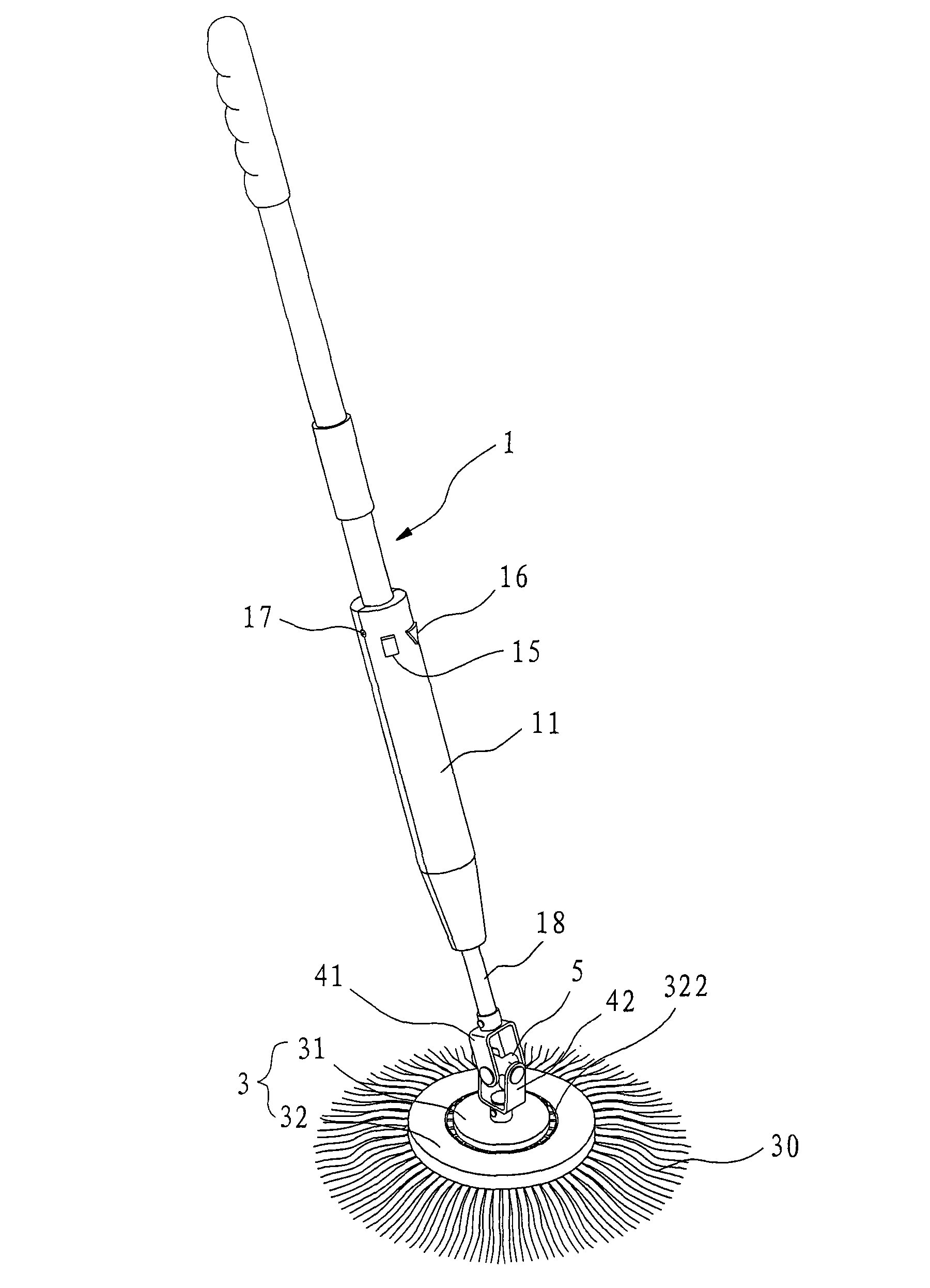

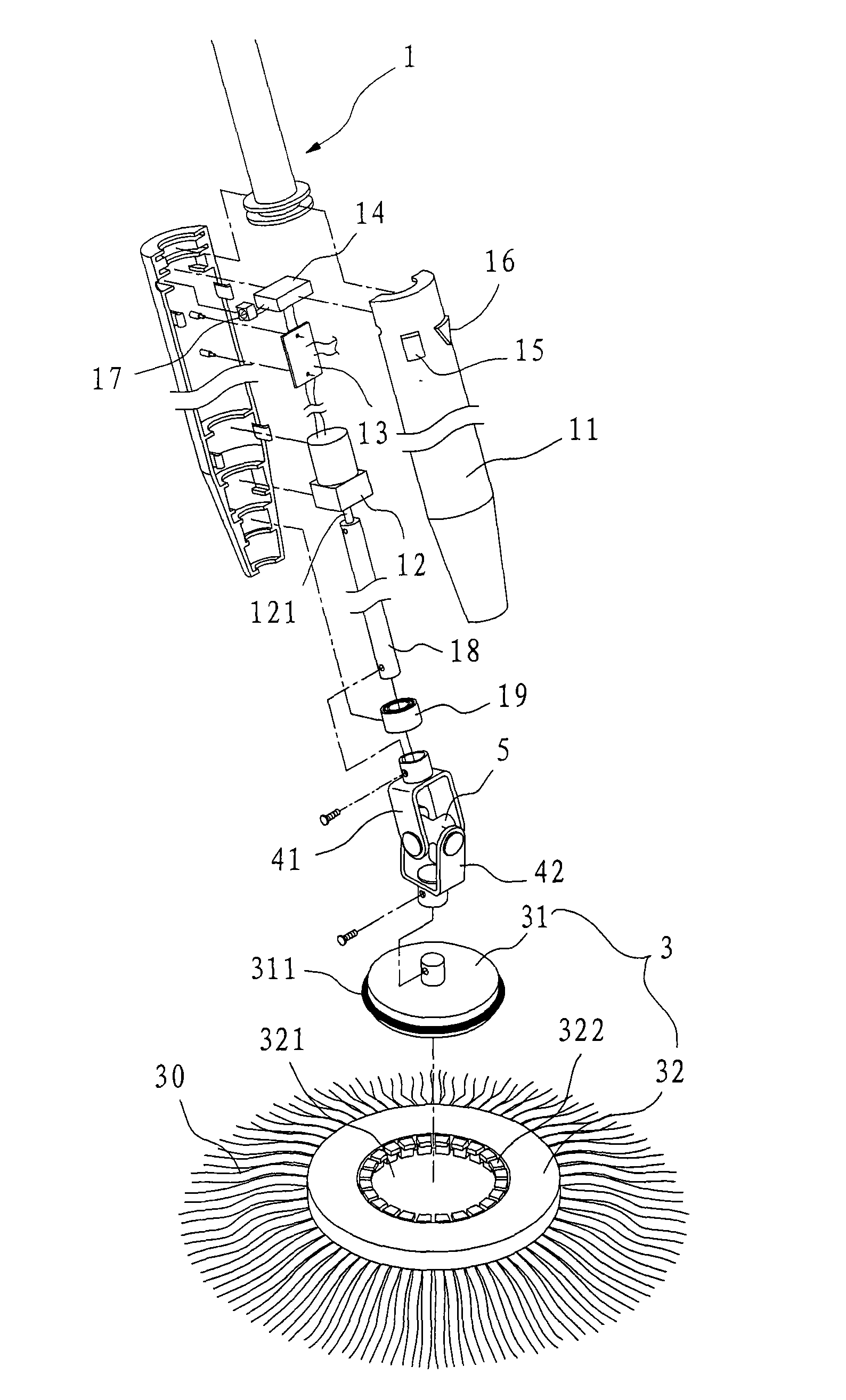

Mop and mop dehydration structure

InactiveCN101961233AAchieve the effect of automatic moppingAchieve dehydration effectCarpet cleanersFloor cleanersEngineeringControl circuit

The invention discloses a mop which is provided with a motor and a control circuit, wherein the control circuit is connected with the motor, the rotary shaft of the motor is also provided with a shaft lever, and the bottom end of the shaft lever is connected with a disk seat. The motor rotates to rotate the disk seat, and the effect of automatically mopping the floor can be realized by simple operation. The invention also discloses a mop dehydration structure comprising the mop.

Owner:曾玉叶 +1

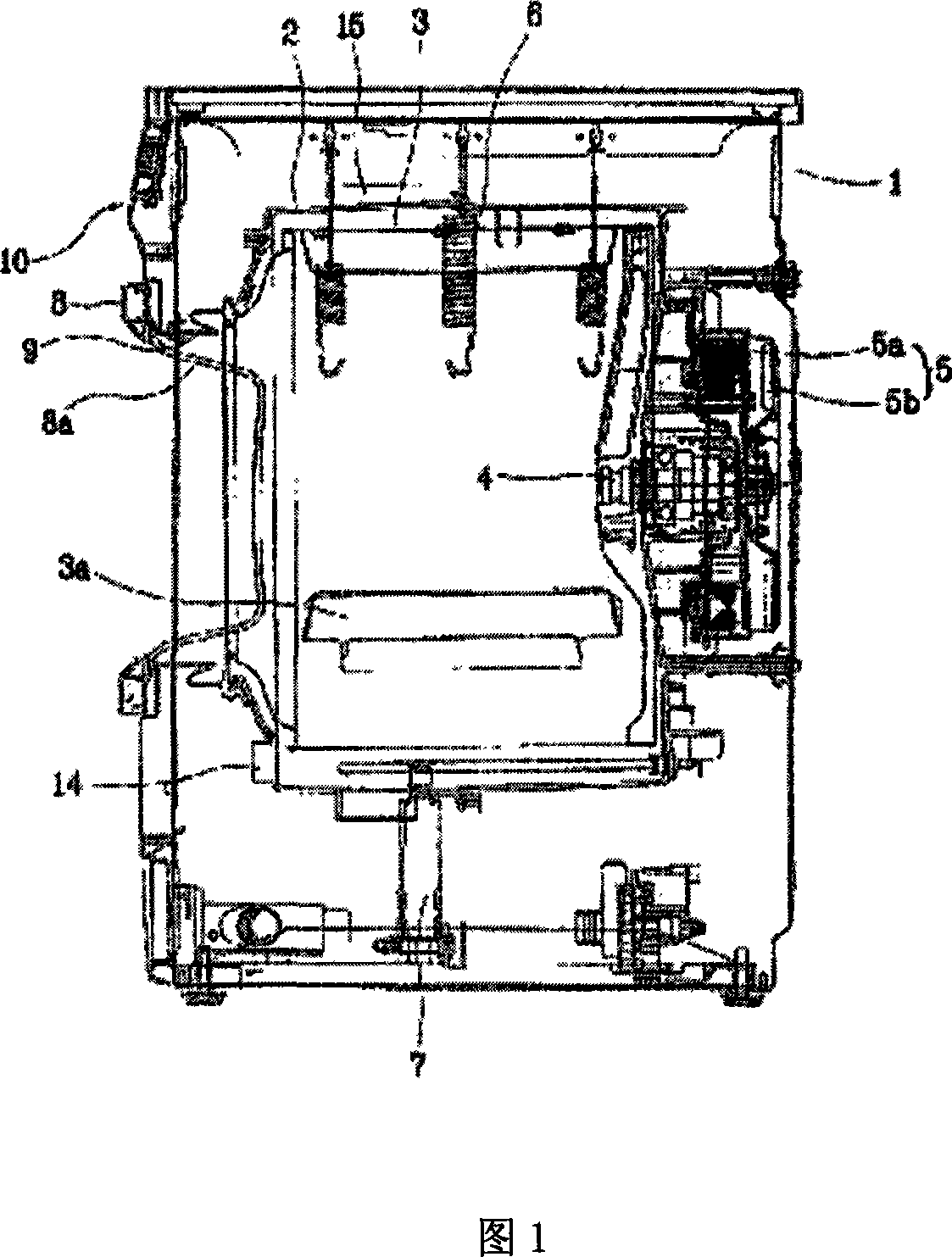

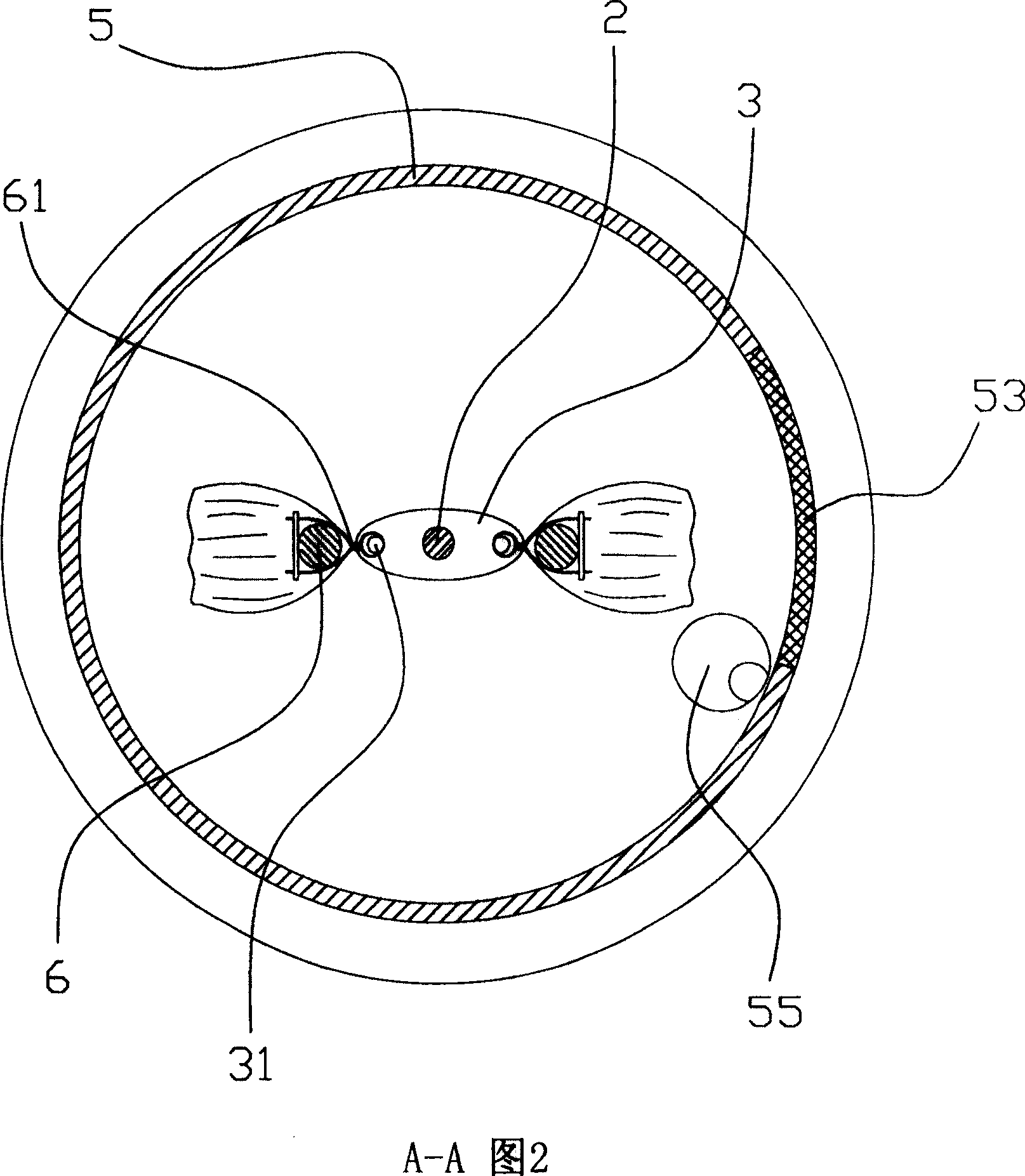

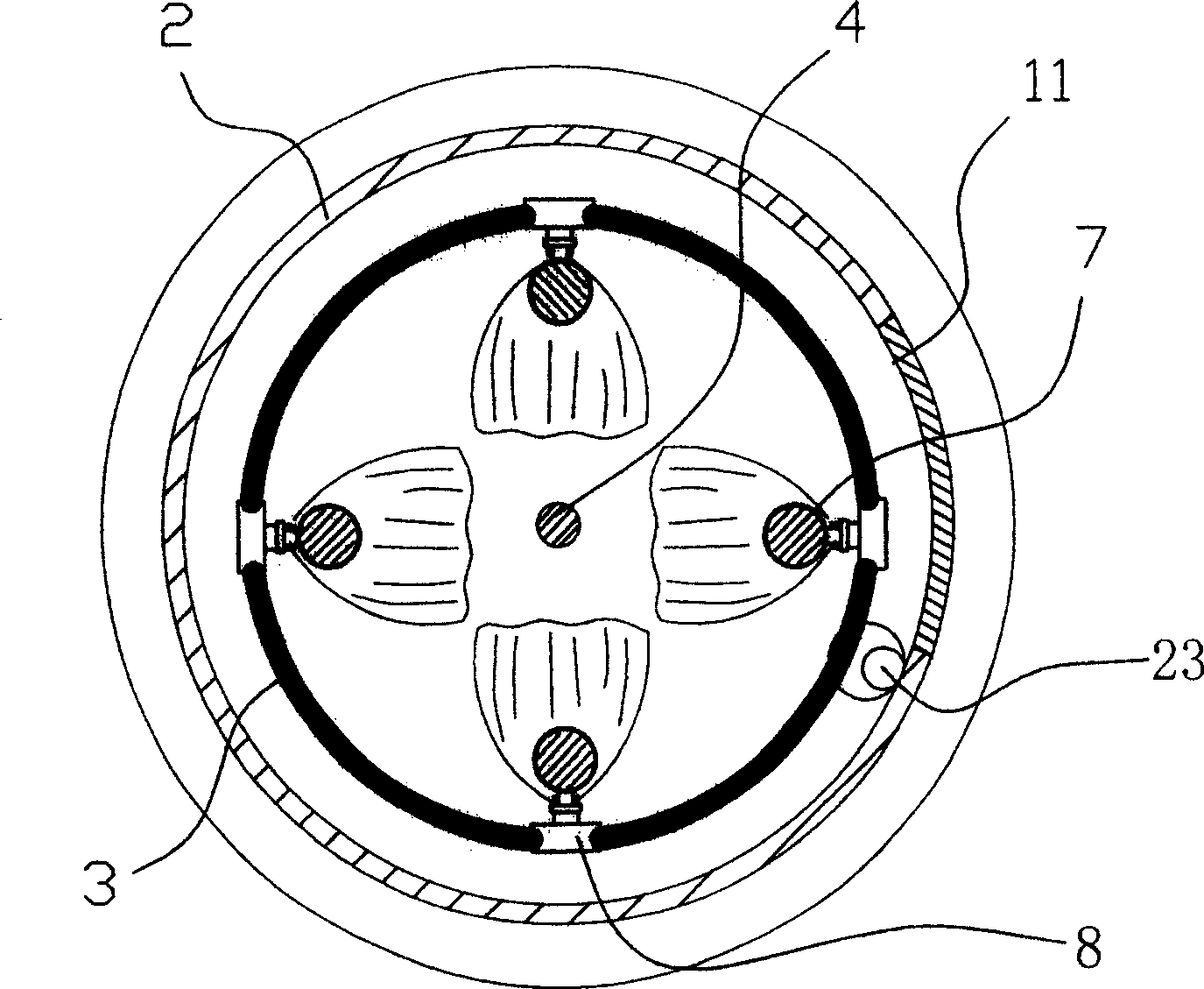

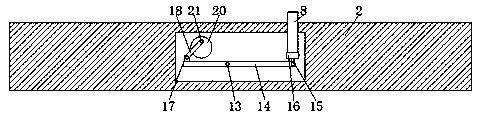

Apparatus for washing and squeezing mop

InactiveCN100469301CEasy maintenanceCooperate with each other firmlyCarpet cleanersFloor cleanersElectric motorInternal cavity

A mop washing and dewatering machine has a water containing drum with top opening and a stirrer in it, a rotary annular washing frame in said water drum and with an internal cavity communicated with the internal cavity of water drum and several mop holders on its inner surface, and an electric motor linked with the bottom of said annular washing frame via drive unit.

Owner:王会才

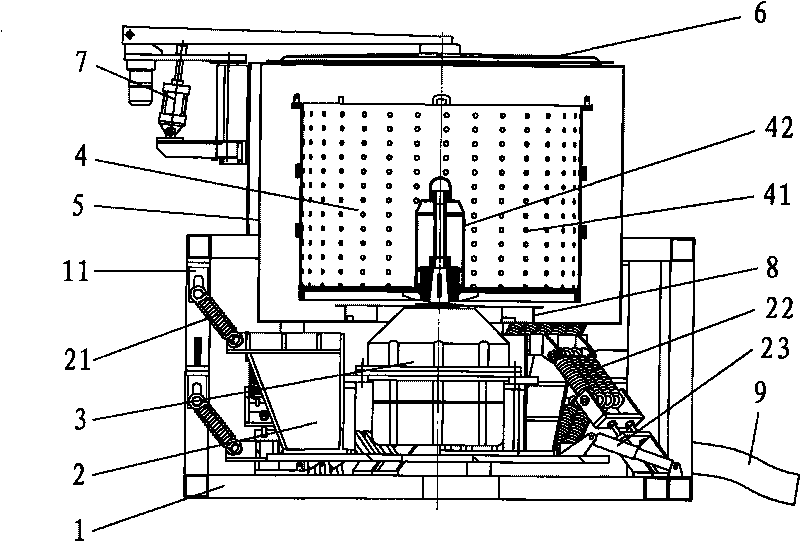

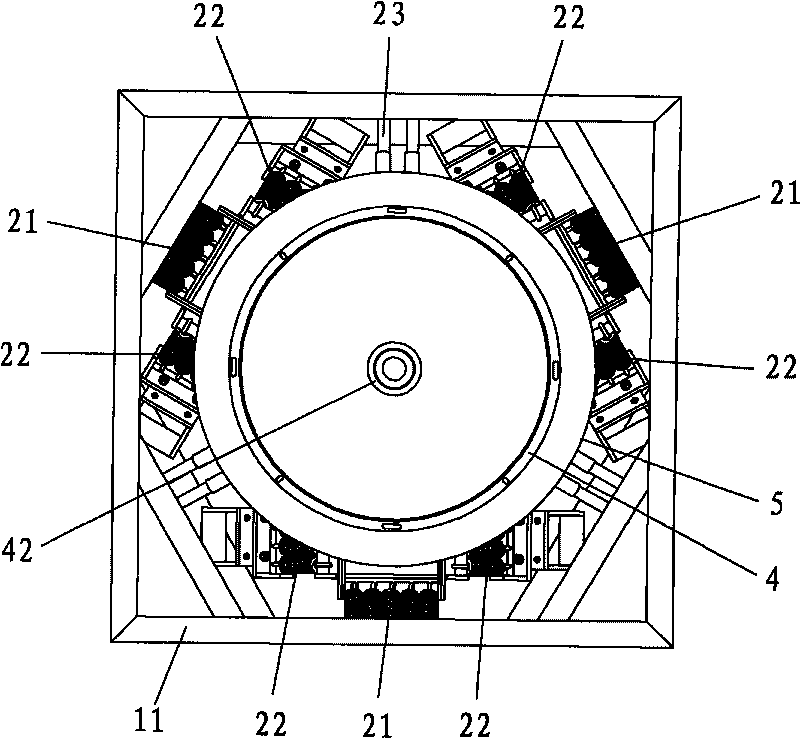

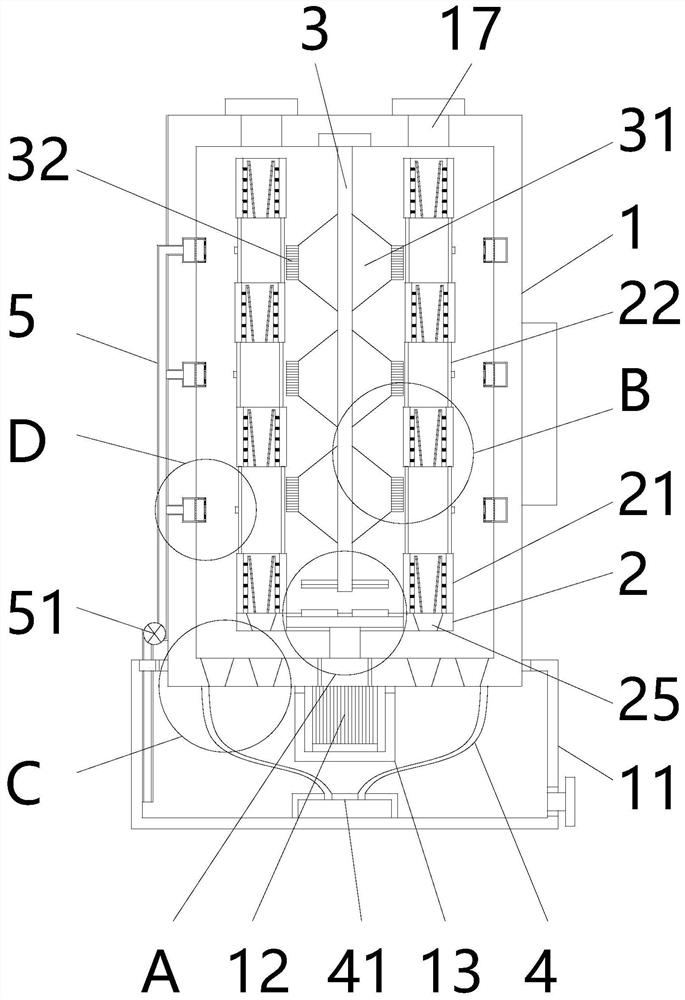

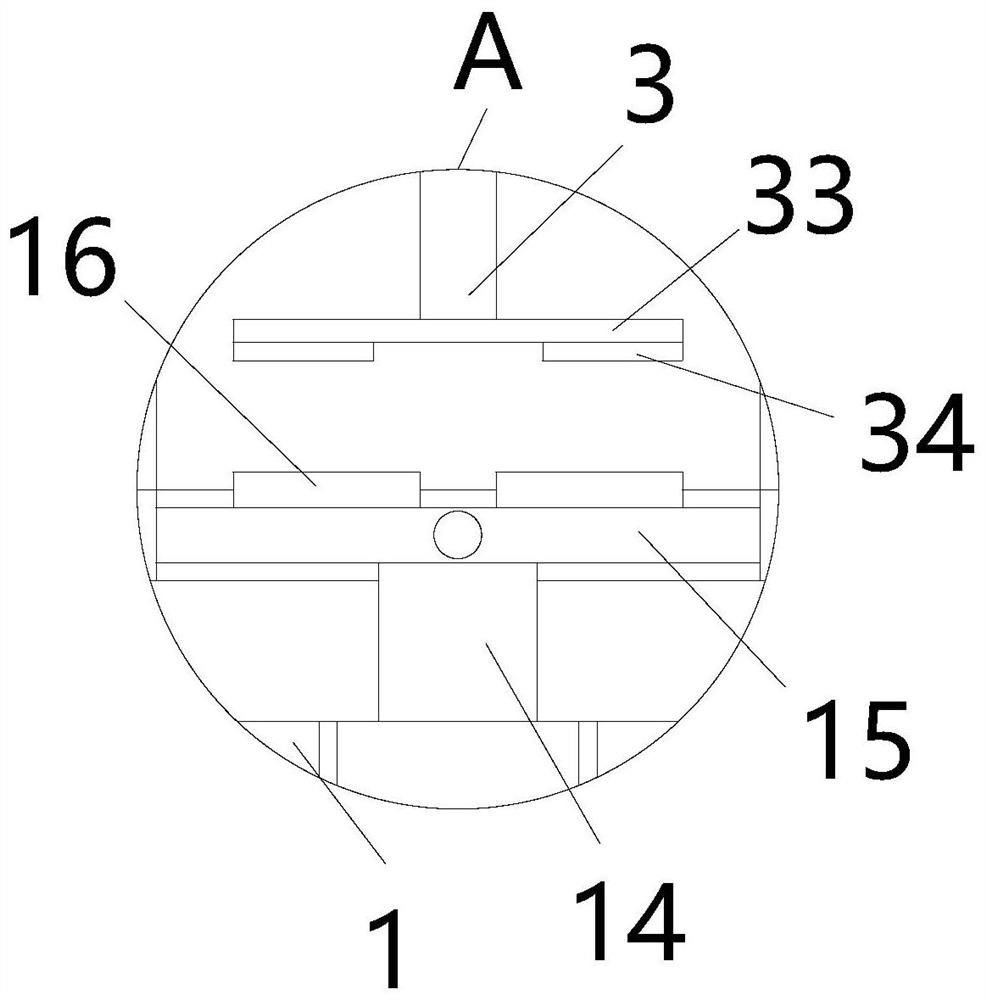

Efficient centrifugal dewatering equipment for industry

InactiveCN110844969AAchieve dehydration effectImprove dehydration efficiencyWater/sewage treatment by centrifugal separationTreatment involving filtrationThermodynamicsStructural engineering

The invention relates to efficient centrifugal dewatering equipment for the industry. The efficient centrifugal dewatering equipment comprises a main body, a dewatering cylinder, a drain pipe and a sealing cover, wherein the drain pipe is arranged at the bottom of the main body; the sealing cover covers the top of the main body and is sealed with the top of the main body; the dewatering cylinder is arranged in the main body and is coaxially arranged with the main body; the top end of the dewatering cylinder is in sliding and sealed connection with the sealing cover; a driving device is arranged at the bottom of the main body and is in transmission connection with the dewatering cylinder; an auxiliary mechanism and at least two dehydration mechanisms are arranged in the main body; the dehydration mechanisms are evenly distributed at the periphery of the dewatering cylinder in the circumferential direction with the axis of the dewatering cylinder as the center; and the auxiliary mechanism is arranged in the dewatering cylinder. The efficient centrifugal dewatering equipment for the industry achieves dehydration effect through the dehydration mechanisms, and is improved in dehydrationefficiency through the auxiliary mechanism.

Owner:GUANGZHOU LINDIAN TECH CO LTD

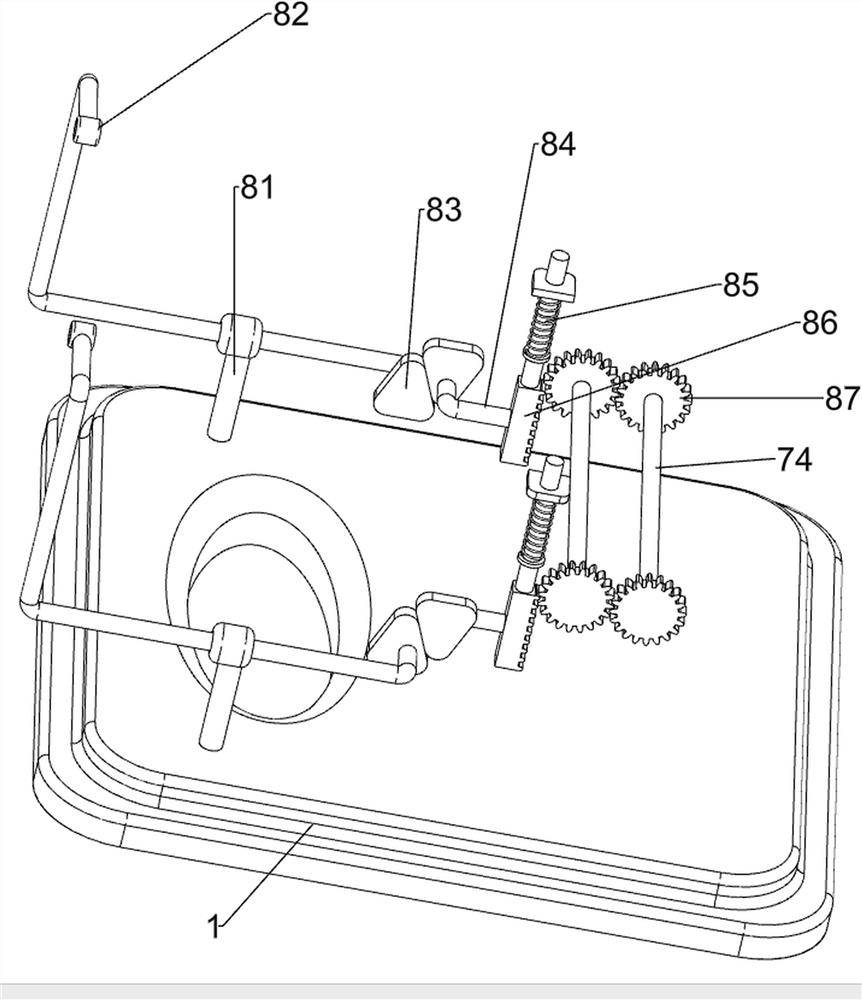

Dehydrator

ActiveCN101586903BReasonable designCompact structureDrying solid materials without heatKitchen equipmentFan bladeRocker arm

A dehydrator belongs to the dehydration apparatus technical field, comprising a planer head cover, a basket and a barrel, characterized in that the planer head cover comprises a planer head cover bodyprovided with a notch on surface, a press-hand body at upper portion of the planer head cover and a fan blade at lower portion of the planer head cover. The lower surface of the planer head cover isconnected with a fix plate fixedly which matches a rack on surface. The rack is at lower portion of the notch of the planer head cover and is provided with toothrow meshed with gears which are linkedto a rotor via actively set gear rocker. The rotor is locked with the fix plate via set rotor cover. The dehydrator is rational in design, compact in structure and completes dehydration only by pushing the press-hand lightly. Dehydration can be stopped at any time via a brake button in work process. The apparatus is low in manufacturing cost, simple in operation and easy to control and convent tocarry.

Owner:SHUANGMA PLASTIC MFG INC

Water removal device for feather production

InactiveCN109539705AAchieve dehydration effectImprove integrityDrying solid materials without heatDrying chambers/containersEngineeringRotating disc

The invention discloses a water removal device for feather production. The water removal device comprises a gearbox, a transmission box is fixedly connected to the bottom of the gearbox, and a first motor is fixedly connected to the left side of the top of the gearbox. The gear box, the transmission box, the first motor, a gear structure, a third bearing, a second movable column, a second gear, ashell, a leakage cylinder, a first fixing block, a first movable column, a first bearing, a first gear, a chain, a sliding structure, a sliding block, a sliding chute, a third fixing block, a first fixing column, a first transmission rod, a second fixing column, a second bearing, a second fixing block, a second transmission rod, a second motor, a rotating disc and a third fixing column are used ina matched mode, so that the problems that drying water removal or heating water removal is adopted in more occasions as an existing way of water removal, so that feathers are damaged and the efficiency is low are solved. The water removal device for feather production has the advantages of being complete and high in efficiency and is convenient for users to use and better in practicability.

Owner:张永伍

Vehicle-mounted umbrella storage device

ActiveCN111964363AAchieve dehydration effectAchieve scrub cleaning effectGeneral water supply conservationDrying solid materials without heatIn vehicleStructural engineering

The invention relates to the technical field of vehicle-mounted equipment, and discloses a vehicle-mounted umbrella storage device. The vehicle-mounted umbrella storage device comprises a water-spinning barrel, a water tank and a servo motor, wherein a rotating column is fixedly arranged at the output end of the servo motor; a cross-shaped rotating rod is fixedly arranged on the top of the rotating column; rotating rings are fixedly arranged on the outer wall of the rotating rod; and combinations of rotating rings and limiting sleeves being assembled one above the other at intervals are arranged on the tops of the rotating rings. The vehicle-mounted umbrella storage device is simple in structure. Through work of a power source, not only the dehydration effect of a long-rod umbrella is achieved, but also the repeated washing-cleaning effect is achieved for the outer wall of the long-rod umbrella, a water body spun from an umbrella is filtered, and then the outer wall of the long-rod umbrella is washed, so that the effect of washing in a matching way is achieved. Moreover, the spun rain water is utilized fully and reused, the long-rod umbrella can be dehydrated easily and rapidly after passengers get on vehicles, the rainwater on the long-rod umbrella is prevented from falling in a bus, and the problem of wet and slip ground in the vehicles is solved.

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

One-way rotary extruding device for textile fabric dewatering device

InactiveCN111649560AAvoid damageRealize extrusion dehydrationDrying solid materials without heatDrying machines with non-progressive movementsStructural engineeringCentrifugal force

The invention discloses a one-way rotary extruding device for a textile fabric dewatering device. The one-way rotary extruding device comprises a main mounting plate. The one-way rotary extruding device is used in cooperation with a centrifugal dewatering device for the textile fabric dewatering device, high-speed rotation can be generated on a textile fabric to form centrifugal force, so that centrifugal dewatering is achieved, and a threaded extendable structure can be controlled according to the rotating direction to achieve extruding dewatering of the internal textile fabric, so that the dewatering effect in two aspects is achieved; the device is provided with a rotary longitudinal height adjusting mechanism with a reverse thread structure to be capable of achieving the longitudinal height adjusting effect, so that the device can be more conveniently connected with the centrifugal dewatering device for the textile fabric dewatering device; and in addition, the device is provided with an annular array spiral spring abutting type maximum-rotating-strength control mechanism to avoid the phenomenon that the thread structure is damaged due to too large rotation resistance.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

Organic sludge conditioning agent and method for using agent to dewater sludge

PendingCN108751667AIncrease in sizeReduce volumeSludge treatment by de-watering/drying/thickeningInorganic saltsSediment

The invention discloses an organic sludge conditioning agent. The organic sludge conditioning agent is prepared from, by weight, 20-35% of alkane-series amine salt compound, 2-8% of polyamine-type polymer and 55-70% of ferric-series inorganic salt. When the organic sludge conditioning agent is mixed with sludge to form floc sludge, the situation that dewatering filter cloth is clogged when the clustering viscosity of the glue-feather sludge is too large is avoided; besides, when the glue-feather sludge generated after conditioning is squeezed under pressure, influences on moisture releasing due to deformation and structural damage cannot be caused, and thus the dewatering effect is achieved; meanwhile, a large amount of extra deposit cannot be generated, so that the situation that the sizeof finally to-be-removed sludge is increased due to deposit derived from the agent during dewatering cannot occur; therefore, the size of the sludge can be greatly reduced, and the removing cost is lowered at the same time.

Owner:苏州崇越工程有限公司

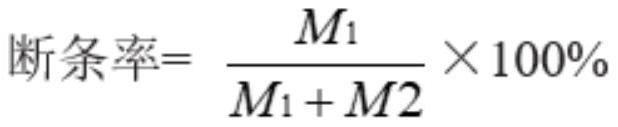

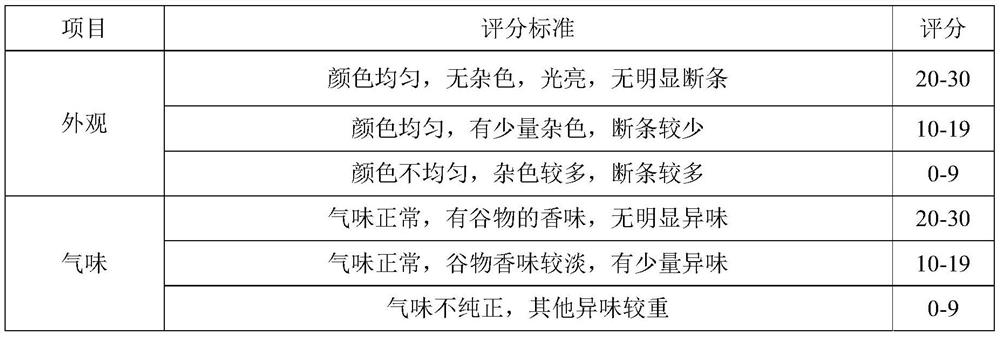

Processing method of fresh wet rice noodles

ActiveCN111838530AEnsure safetyEasy to eatClimate change adaptationFood ingredientsBiotechnologyFood additive

The invention discloses a processing method of fresh wet rice noodles, and belongs to the technical field of food processing. The preparation method comprises the following steps: cleaning early indica rice, removing impurities, soaking, grinding into thick liquid, uniformly mixing the thick liquid with corn starch in proportion, balancing moisture, and carrying out vacuum precuring, flash evaporation dehydration, extrusion molding, cold soaking, packaging, sterilization and the like to obtain the convenient instant fresh wet rice noodle product with smooth mouthfeel. Compared with the traditional dry rice noodles, the fresh wet rice noodles processed by the method disclosed by the invention do not need to be cooked, are ready to eat after being soaked in boiled water for 3-5 minutes, andare good in mouth feel. Compared with damp-heat treatment, vacuum pre-curing is easy to operate, short in consumed time, uniform in curing and high in curing degree, and the dehydration effect is achieved while the materials are further cured through the flash evaporation dehydration process. No food additive is added, starch is completely cured through vacuum precuring and flash dehydration, andthe quality of the fresh wet rice noodles is remarkably improved.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com