Air expansion self-floating sludge dewatering treatment process

A technology for sludge dehydration and treatment process, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. Water is difficult to separate and other problems, to improve the dehydration efficiency, speed up the dehydration efficiency, and avoid the effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

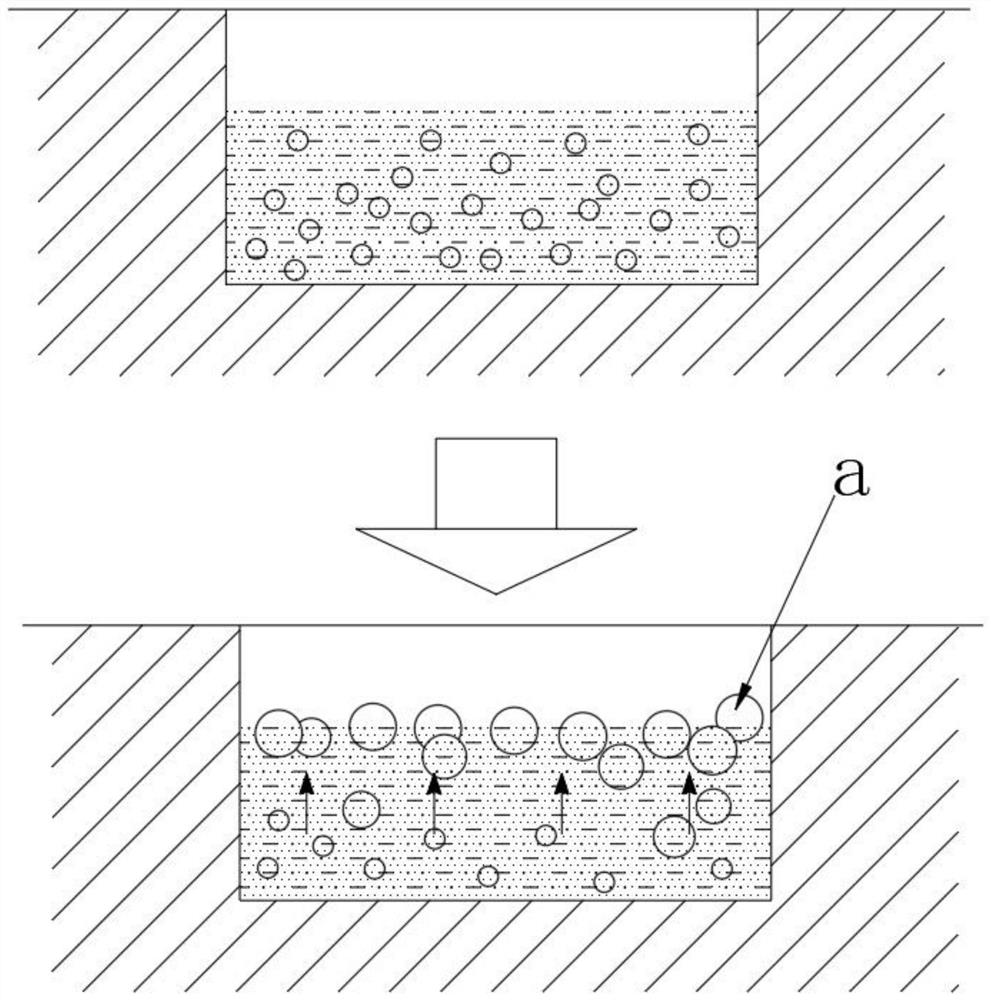

[0050] see figure 1 , an air-expanding self-floating sludge dewatering process, comprising the following steps:

[0051] S1. First, the sludge is left to settle, and the obviously layered sewage on the surface is discharged to obtain the sludge in a thick state;

[0052] S2, then evenly lay the inflatable floating ball at the bottom of the sewage dewatering tank, and then pass the sludge in a thick state into the dehydrating tank;

[0053] S3. The air-expanded floating ball gradually absorbs the water in the thick sludge, and then the gas overflows from the inside to make it expand in volume;

[0054] S4. Heat the inner wall of the dehydration tank, so that the temperature of the air-expanding float rises significantly, and the gas inside is heated and expands, making its volume further increase, so that the air-expanding float gradually floats from the bottom up until it floats on the thick sludge s surface;

[0055] S5. Pick up the obviously larger air-inflated float floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com