Method for preparing regeneration pellet fuel of urban household garbage

A technology of municipal solid waste and granular fuel, applied in the direction of biofuel, fuel, solid fuel, etc., can solve the problems of high treatment cost, high processing cost, large deviation of fuel calorific value, etc., and achieve clean water with low energy consumption and dehydration The effect of high efficiency and balanced calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

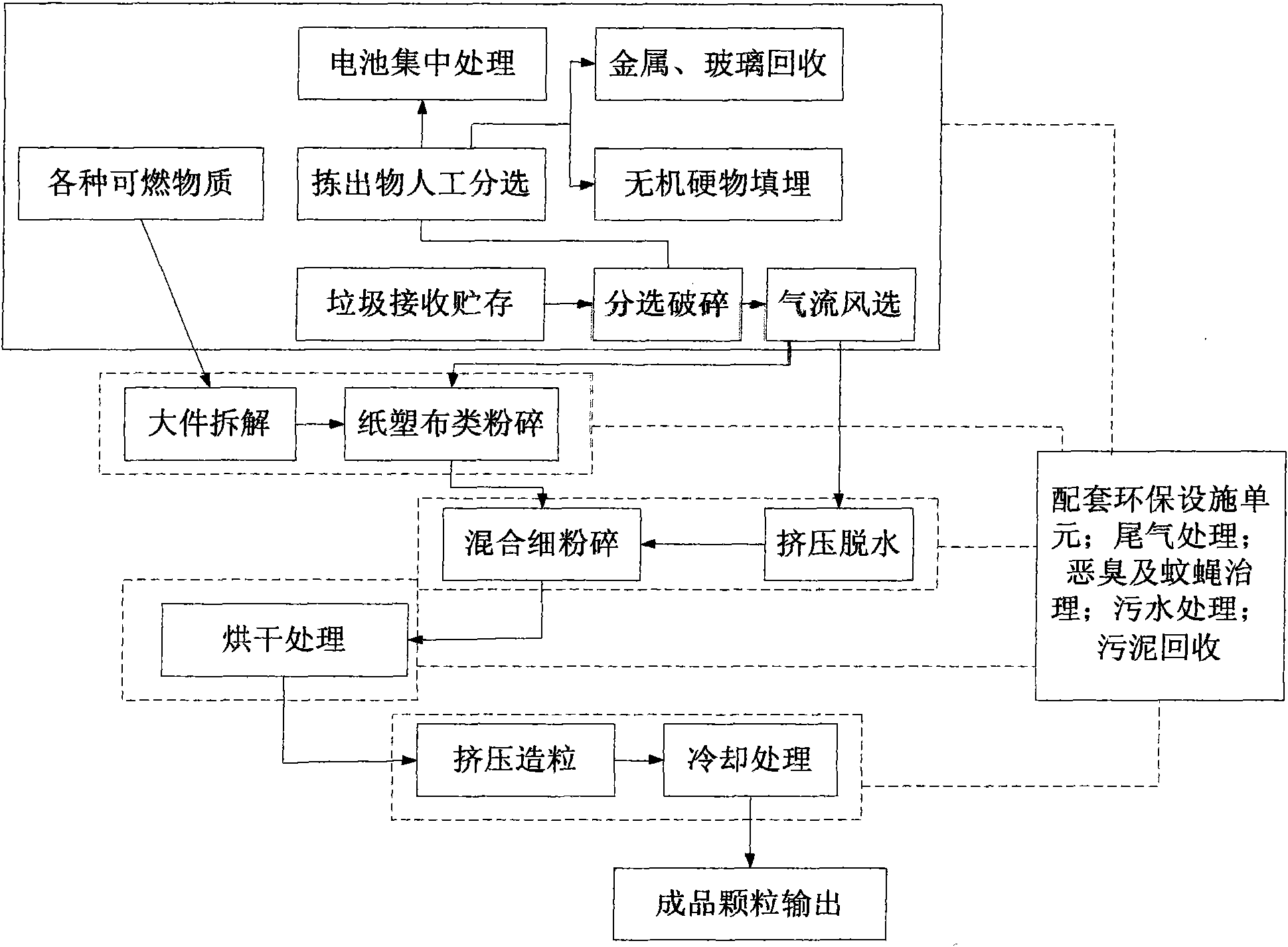

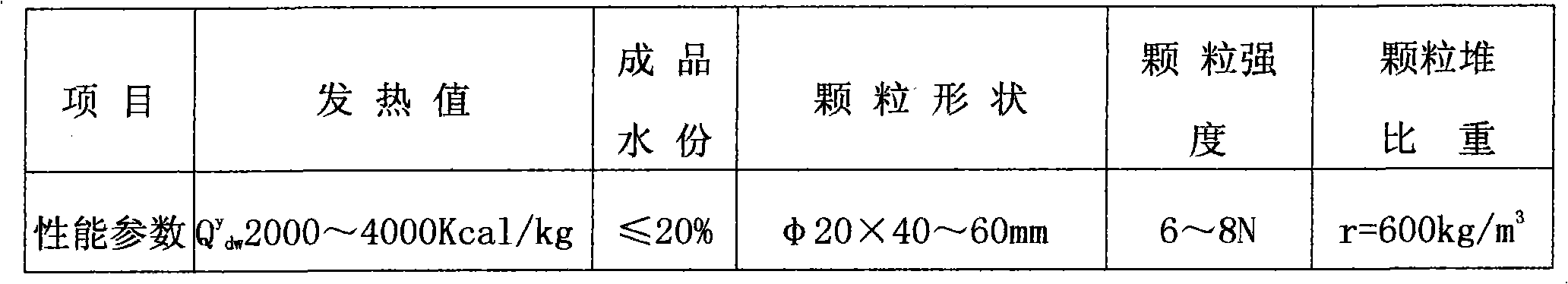

[0053] Embodiment 1, this embodiment is a preparation process of municipal solid waste regenerated particle fuel, such as figure 1 As shown in the figure, a method for preparing a pellet fuel regenerated from municipal solid waste is characterized in that: the production is carried out by adopting the following steps:

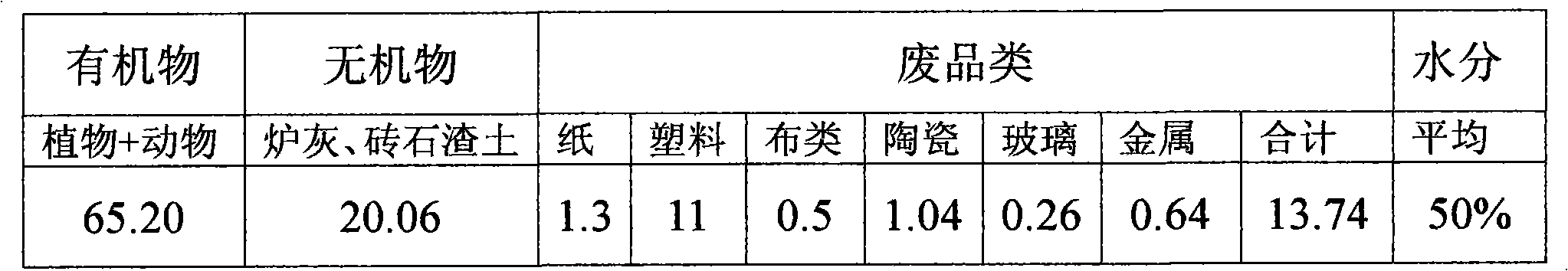

[0054] Step 1: Comprehensive treatment of municipal solid waste, automatic sorting, crushing, dehydration and recycling of the municipal solid waste, direct recycling of the usable materials in the municipal solid waste, safe landfill of harmful flame retardants, and fresh plants. Crushing and dehydration by cone-disc extrusion together with food waste, the organic degradable components with water content below 40% are recovered, and paper and plastic materials with low water content are pulverized;

[0055] This step is divided into two sub-steps, the first sub-step is automatic sorting and crushing: the urban domestic waste is effectively sorted and crushed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com