Waterborne emulsified EVA memory-type foamed plastic and preparation method of product thereof

A water-based, memory-based technology, applied in the field of hydrophilic EVA foam and its product preparation, can solve the problems of non-hydrophilicity, poor oxidation resistance and hydrolysis resistance, and pungent smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

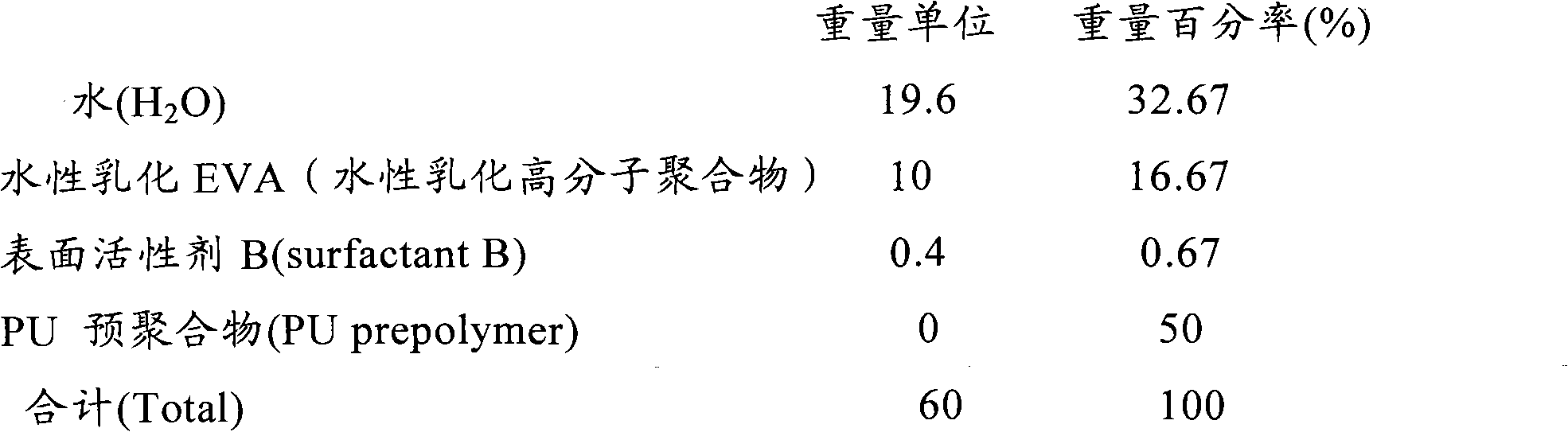

Embodiment 1

[0021]

[0022]

[0023] Wherein, surfactant B can be Pluronic 61, 62, 64 or 101 (German BASF company product); Or LK443, DC-198, DC504 (U.S. AIR PRODUCTS company product); Or LH525, LK260 (Germany TH.Goldschmidt company product) )Wait.

[0024]

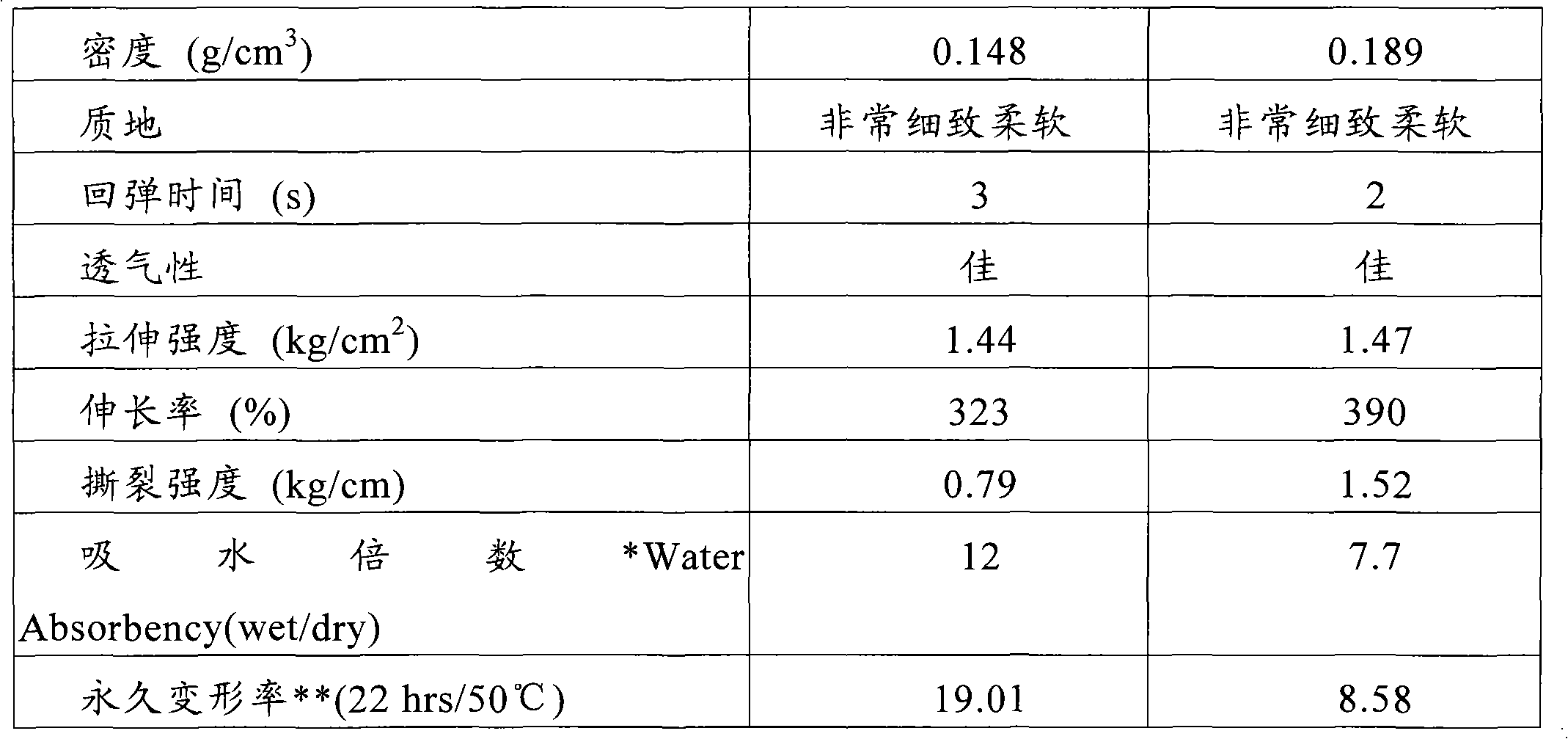

[0025] The foam has strong tensile and tear resistance, rebound time of 1-5 seconds, hygroscopicity and heat absorption, applicable products: pillows, medical mattresses, office chair cushions, bedding mattresses or shoe materials, etc. Products; however, shoe materials, cushions, and mattresses are the main applicable objects. Its physical data are as follows:

[0026]

[0027] *Water absorption multiple: weight after water absorption / weight before water absorption

[0028] **Permanent set: according to ASTM D395, method B, tested under 50% compression

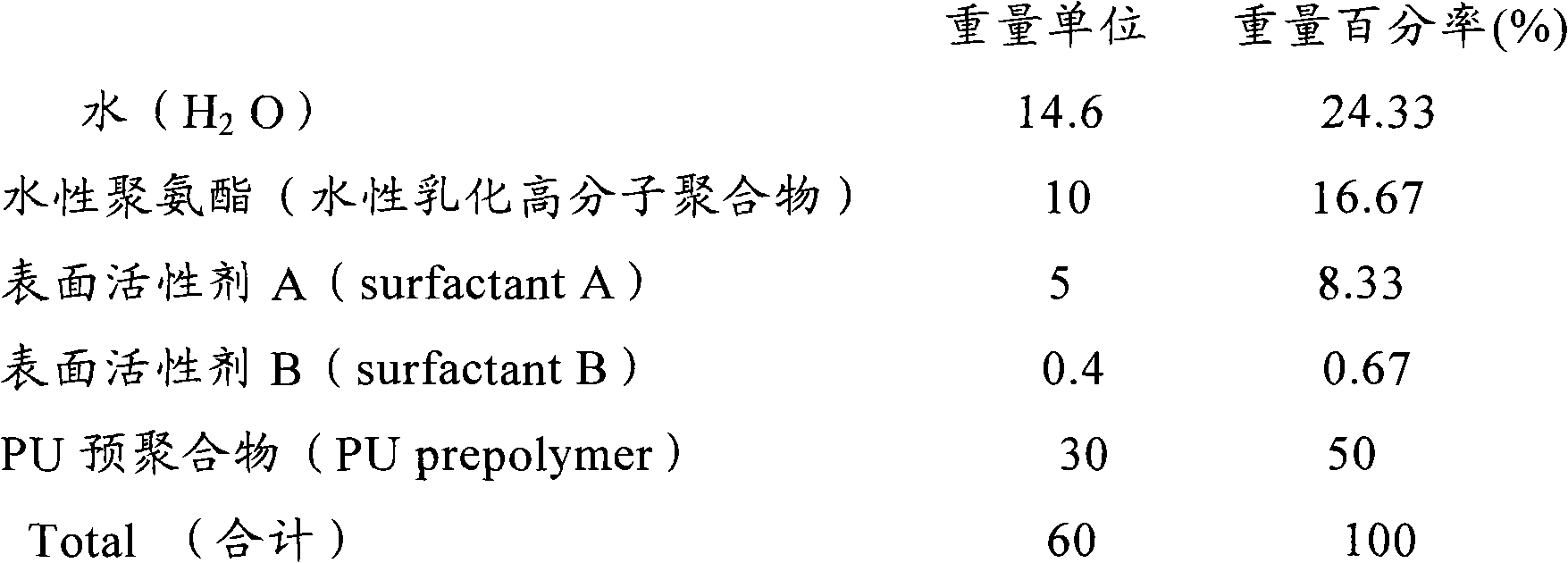

Embodiment 2

[0030]

[0031]

[0032] Wherein, surfactant A can be Brig 93 (ICI America company) or Emulgale 1000NI (Henktel company) etc.

[0033]

[0034] This foam is softer than Example 1, with a rebound time of 1-5 seconds, and has hygroscopicity and heat absorption; applicable products: pillows, medical mattresses, office chair cushions, bedding mattresses or shoe materials; but pillows , cushions and mattresses are the main applicable objects. Its physical data are as follows:

[0035]

Embodiment 3

[0037]

[0038]

[0039] Among them, the molecular weight of polyether polyol A is between 60-1800, preferably 50-400, and the content of ether group (-EO-) is 18-99.9%, but preferably 50-85%. For: PEG (Polyoxyethylene glycol) 200, PEG 600 or mixed ethylene glycol (Ethylene glycol), diethylene glycol (Diethylene glycol), propylene glycol (Propylene glycol) or glycerol (Glycerol), etc. Ammonia catalyst I (amine catalyst I) can be Dabco 33LV, Dabco DMEA (U.S. AIR PRODUCTS company product), and ammonia catalyst II (amine catalyst II) can be: Dabco BL-11, Dabco BL-19, Dabco BL-22 (U.S. AIR PRODUCTS company product); ZF-20, ZR-70, DMP (American HUNTSMAN company product)

[0040]

[0041] This foam is softer than Example 2, but has a small defect of shrinking in size. The rebound time can be adjusted between 1 and 10 seconds. Applicable products: pillows, medical mattresses, office chair cushions, bedding mattresses or shoe materials, etc., but pillows, cushions, and mattre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com