Mop-cleaning squeezer

A mop cleaning and dewatering machine technology, applied in the field of cleaning machines, can solve the problems of increasing production cost, economic loss, trouble in production, etc., and achieve the effects of reducing production cost, improving utilization rate and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

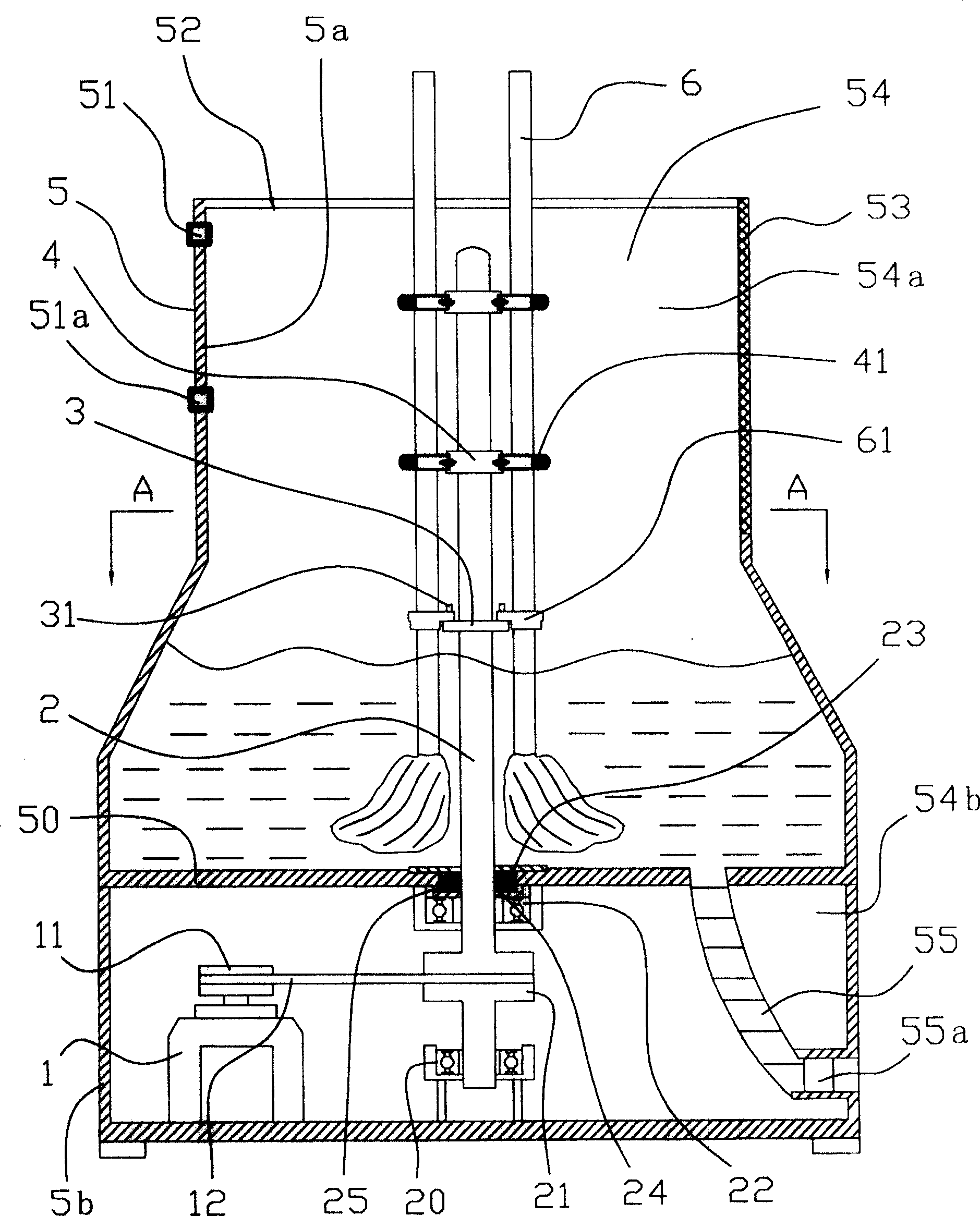

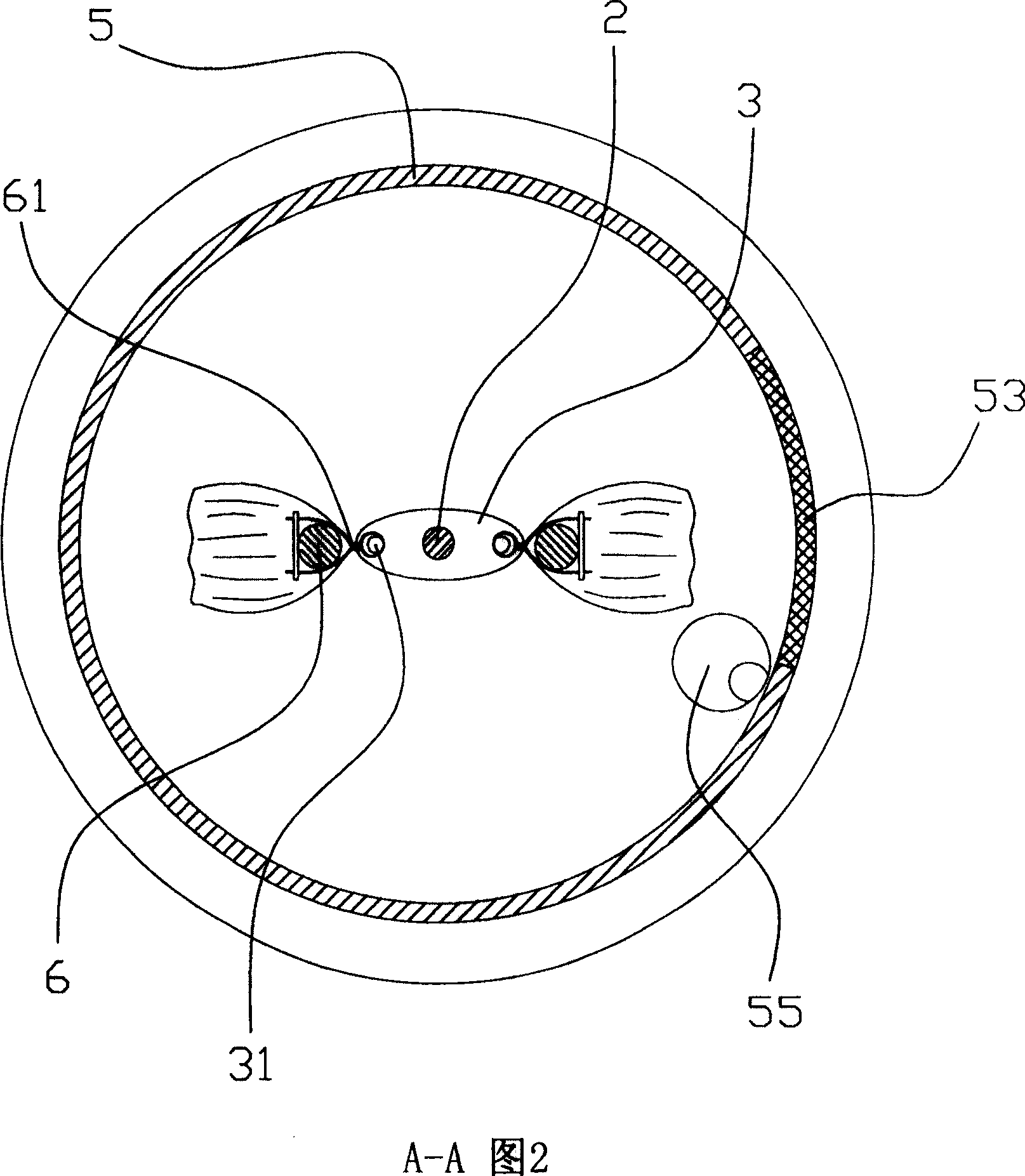

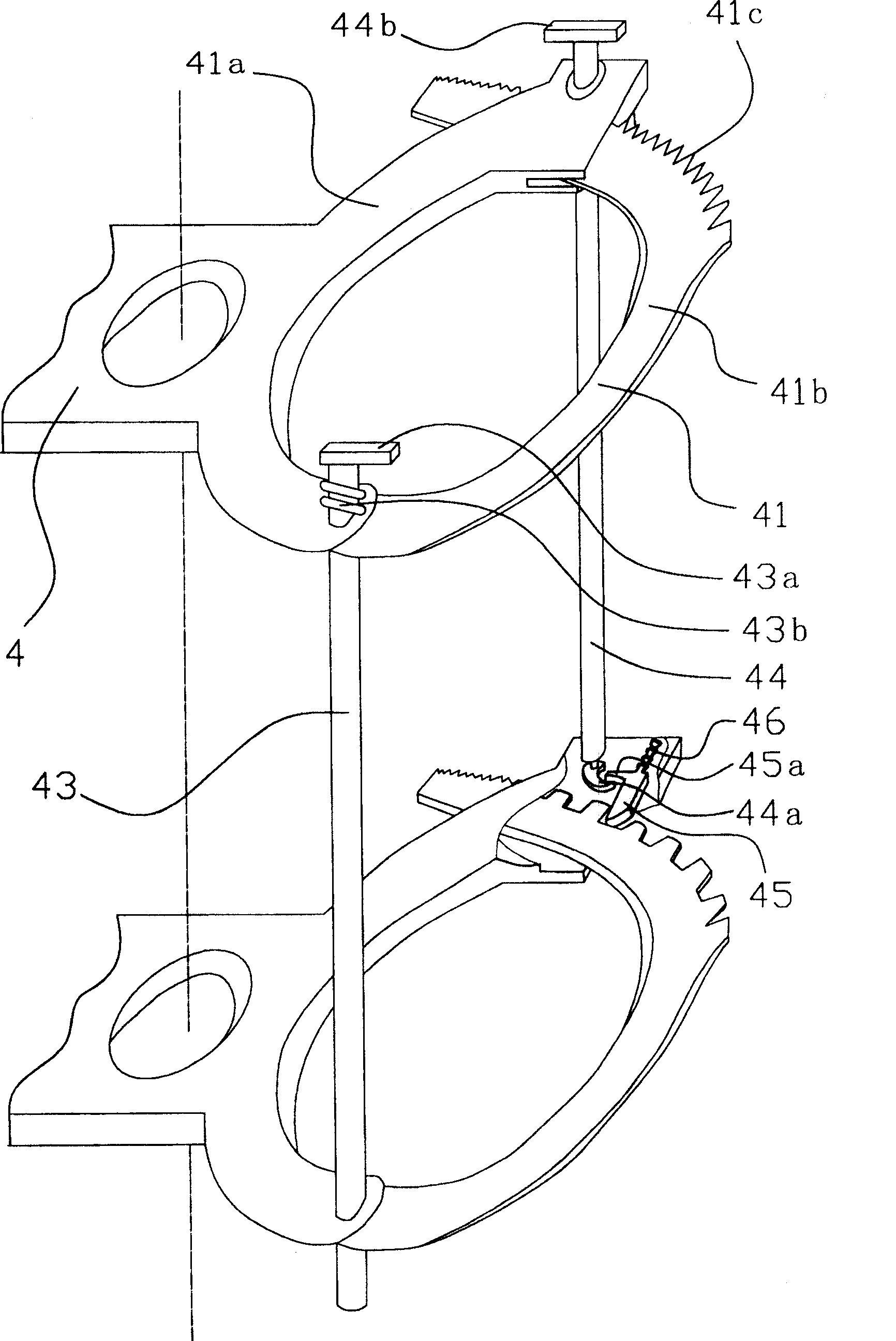

[0020] Such as figure 1 As shown in Figure 7, the mop cleaning and dehydrating machine includes a barrel body 5, a rotating shaft 2 for fixing the mop 6, and a motor 1. Hole 55, and the upper end of barrel body 5 has the opening 52 that can make mop 6 bars extend outside barrel body 5, see figure 1 As shown, the barrel body 5 is divided into an upper part 5a and a lower part 5b. The rotating shaft 2 is vertically rotatably placed in the middle of the upper inner cavity 54a of the barrel body 5, and its lower end penetrates the lower inner cavity 54b. It is linked together with the motor 1 placed in the lower inner chamber 54b through a transmission device, and a fixing device for the mop 6 is provided on the rotating shaft 2 located in the upper inner chamber 54a. The fixing device of the mop 6 is a bracket 3 and a clamping frame 4, the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com