Concrete recovery sand-stone separation device for constructional engineering

A technology for sand and gravel separation and construction engineering, which is applied in the field of sand and gravel separation, and can solve problems such as dehydration of fine sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

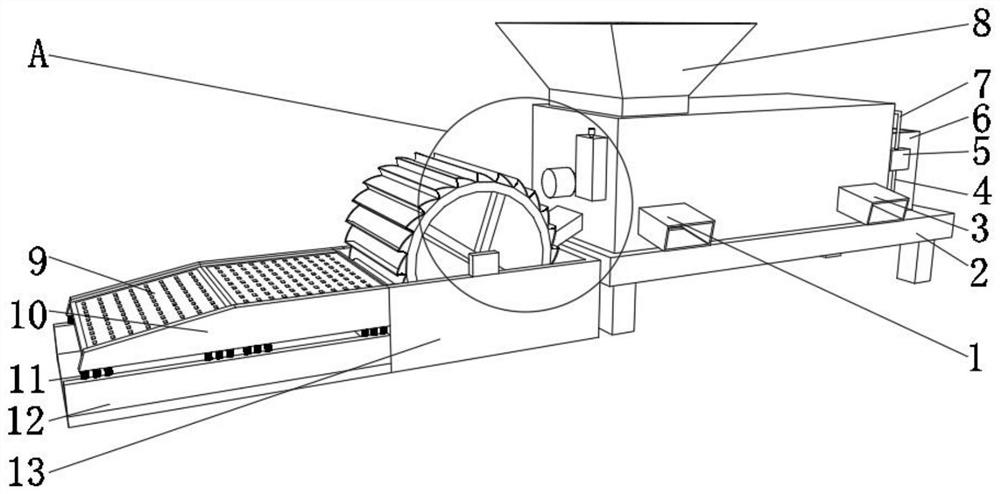

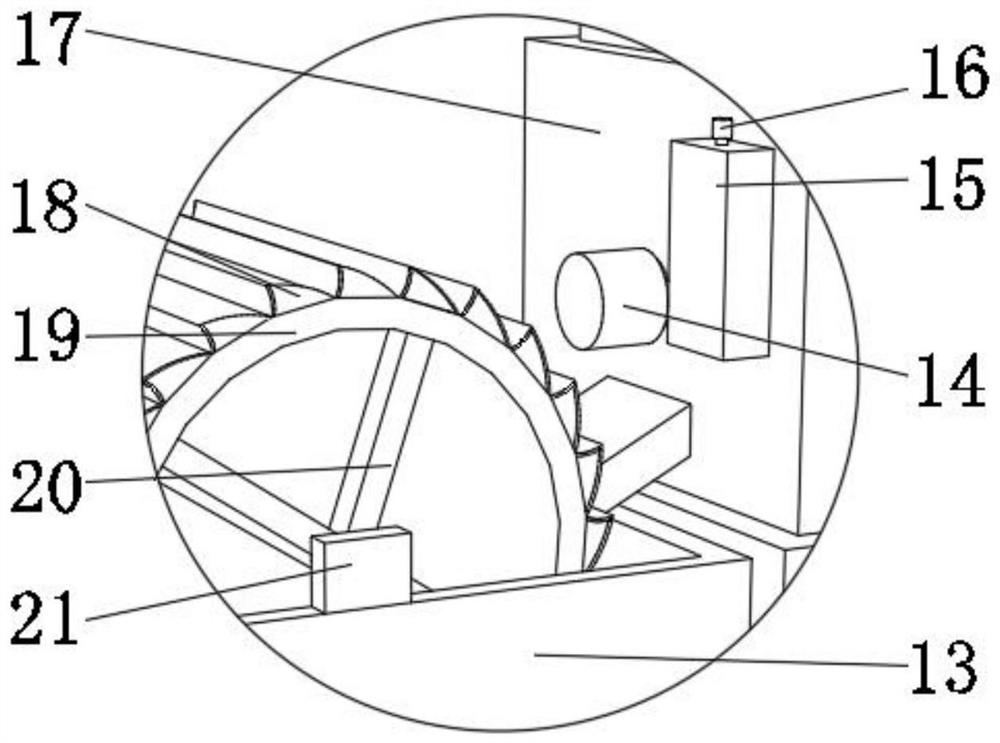

[0032] A kind of concrete recycling sandstone separation device for construction engineering, such as Figure 1-5As shown, it includes a base 2 and a sedimentation tank 13. The top of the base 2 is fixed with a box body 17 by bolts, the outer wall of one side of the box body 17 is fixed with a water tank 6 by bolts, and the top of the box body 17 is screwed. Bucket 8, one side outer wall of box body 17 is fixed with stone outlet 3 and sand outlet 1 by thread, one side outer wall of box body 17 is fixed with controller 15 by bolt, and the top outer wall of controller 15 is fixed with alarm 16 by bolt , the inside of the box 17 is provided with a separation mechanism, the top inner wall of the box 17 is provided with a flushing mechanism, one side of the outer wall of the box 17 is fixed with a discharge pipe 22, and one side of the inner wall of the sedimentation tank 13 is fixed with a liquid level sensor 23, and the liquid level sensor 23 is electrically connected with the al...

Embodiment 2

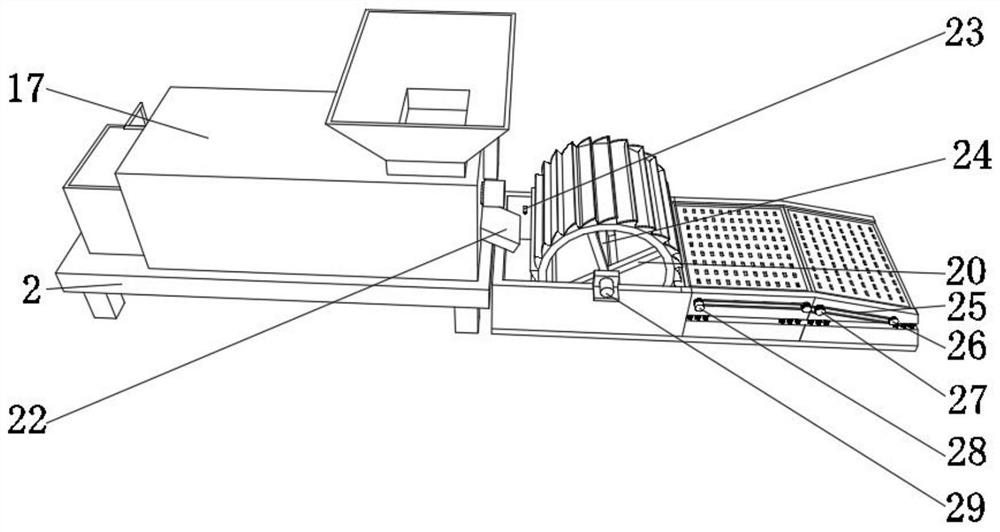

[0038] A kind of concrete recycling sandstone separation device for construction engineering, such as figure 1 , 3 , 4, and 5, in order to solve the problem of promoting the dehydration effect; this embodiment makes the following improvements on the basis of embodiment 1: comprising a sedimentation tank 13, one side of the outer wall of the sedimentation tank 13 is fixed with a fixed seat 12 by bolts , the top of the fixing seat 12 is fixed with more than three springs 11 by bolts, the top end of the springs 11 is fixed with two fixed plates-10 by bolts, and the outer wall of the opposite side of the two fixed plates-10 is fixed with two vibrating screens by bolts 9. The outer wall on one side of one of the fixing plates one 10 is fixed with two pulleys one 26 and two pulleys 27 through bearings, one of the outer walls on one side of the pulley one 26 is fixed with an electric motor 28 through a rotating shaft, and the inner walls of the three transmission belts 25 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com