Patents

Literature

75results about How to "To achieve the screening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

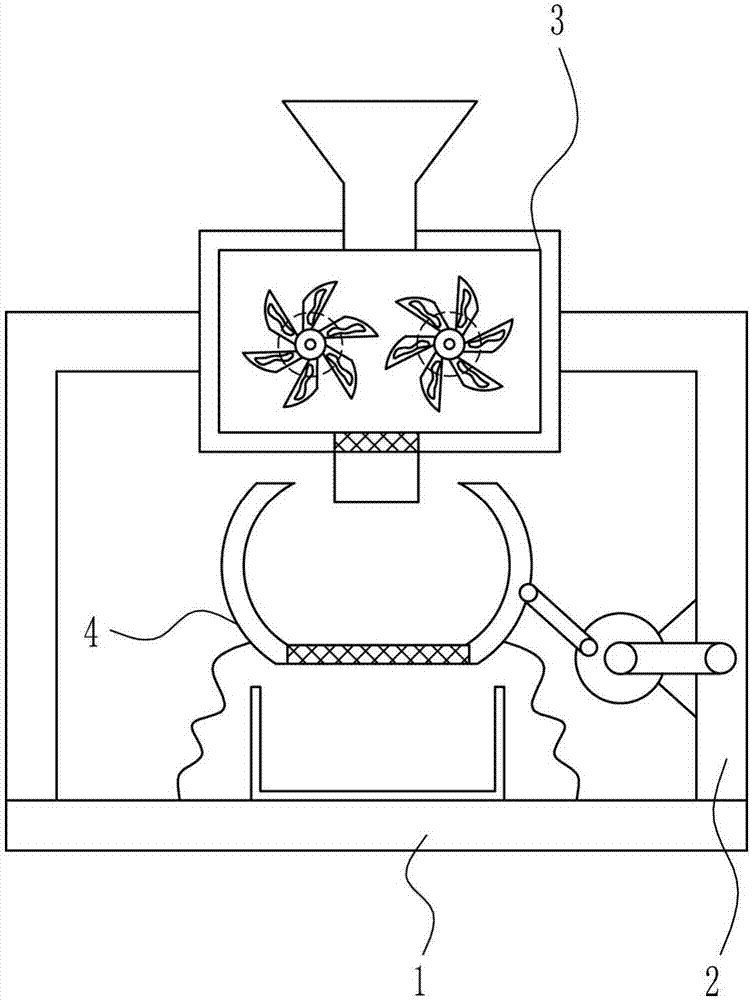

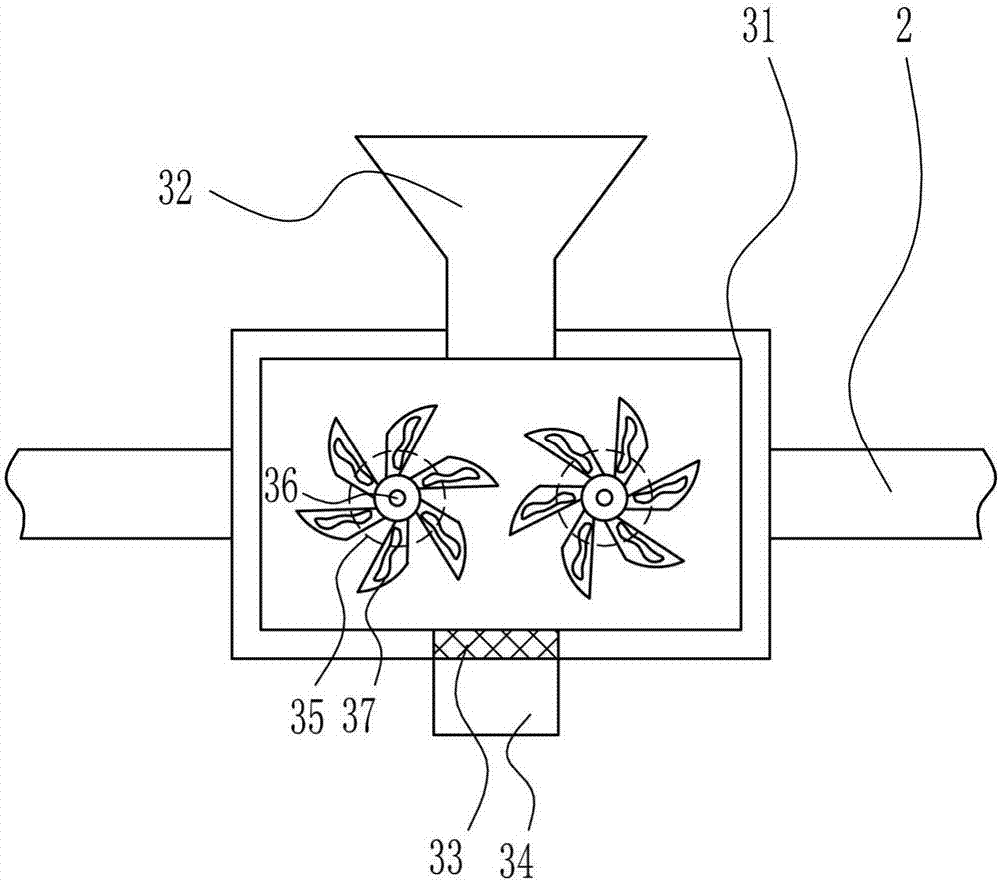

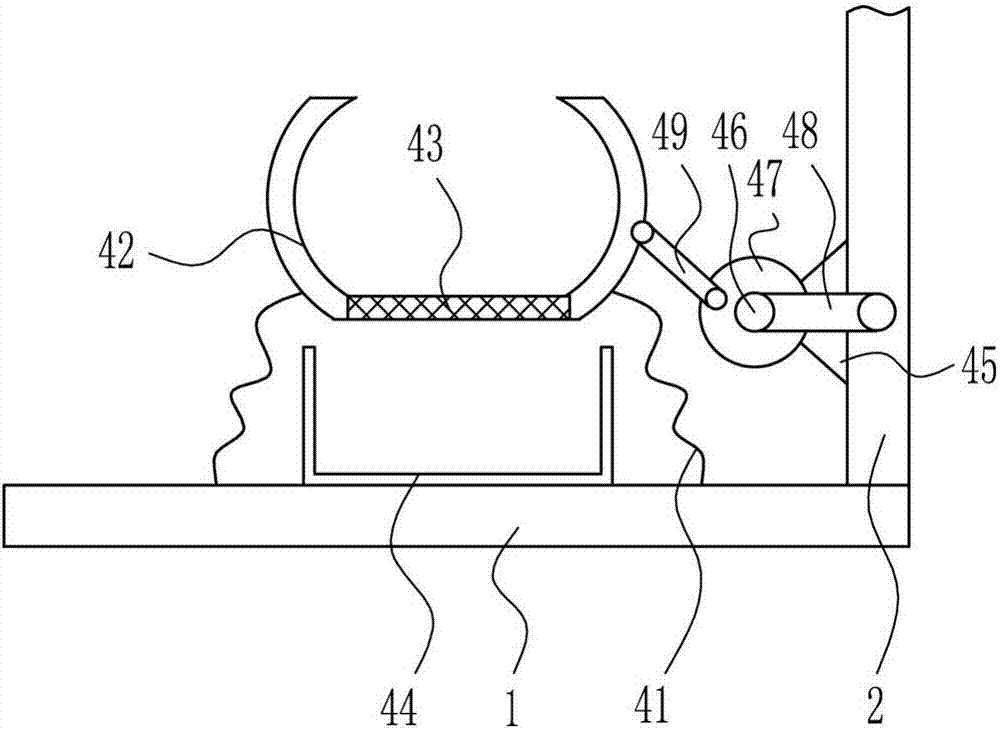

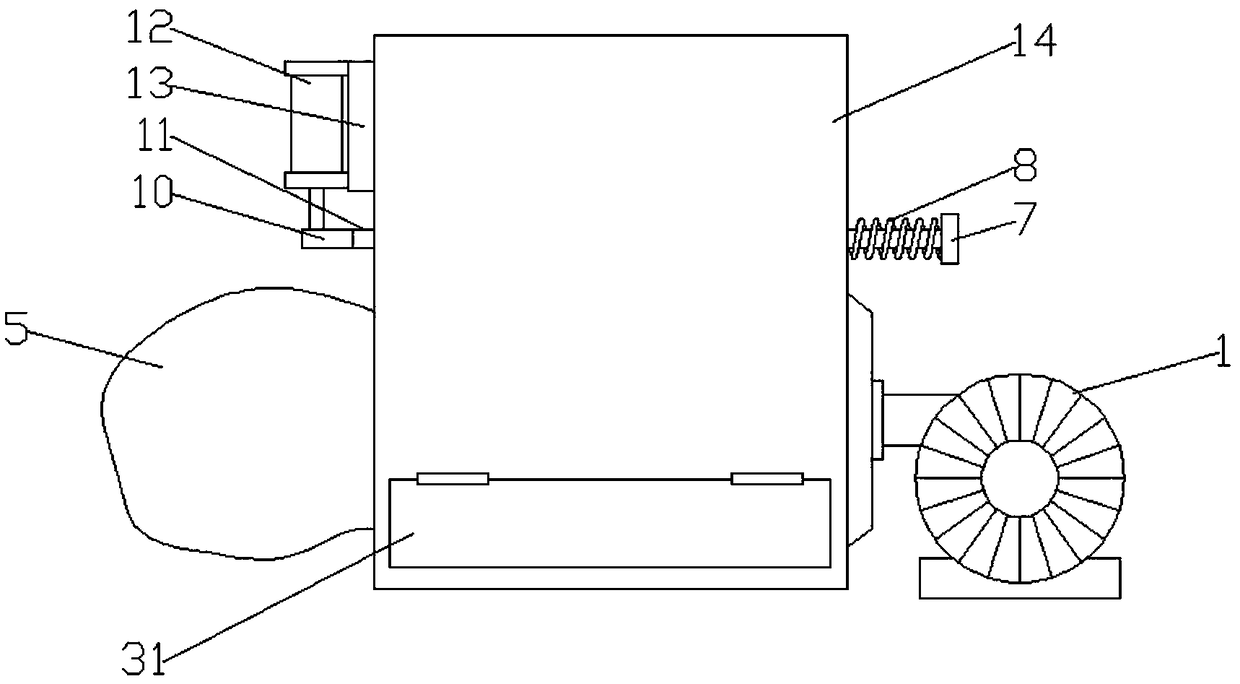

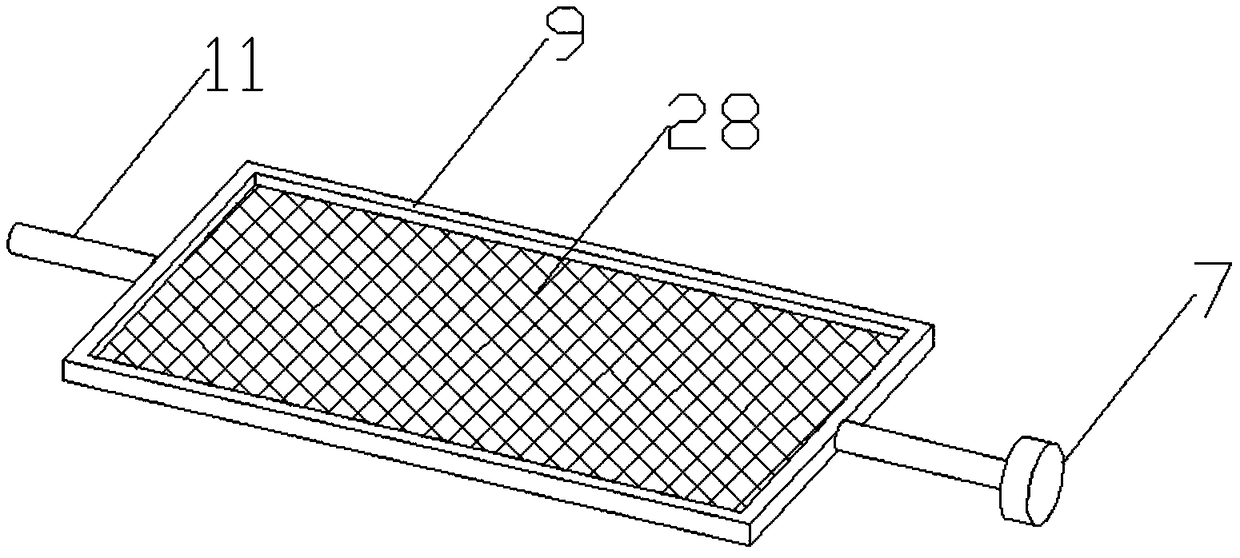

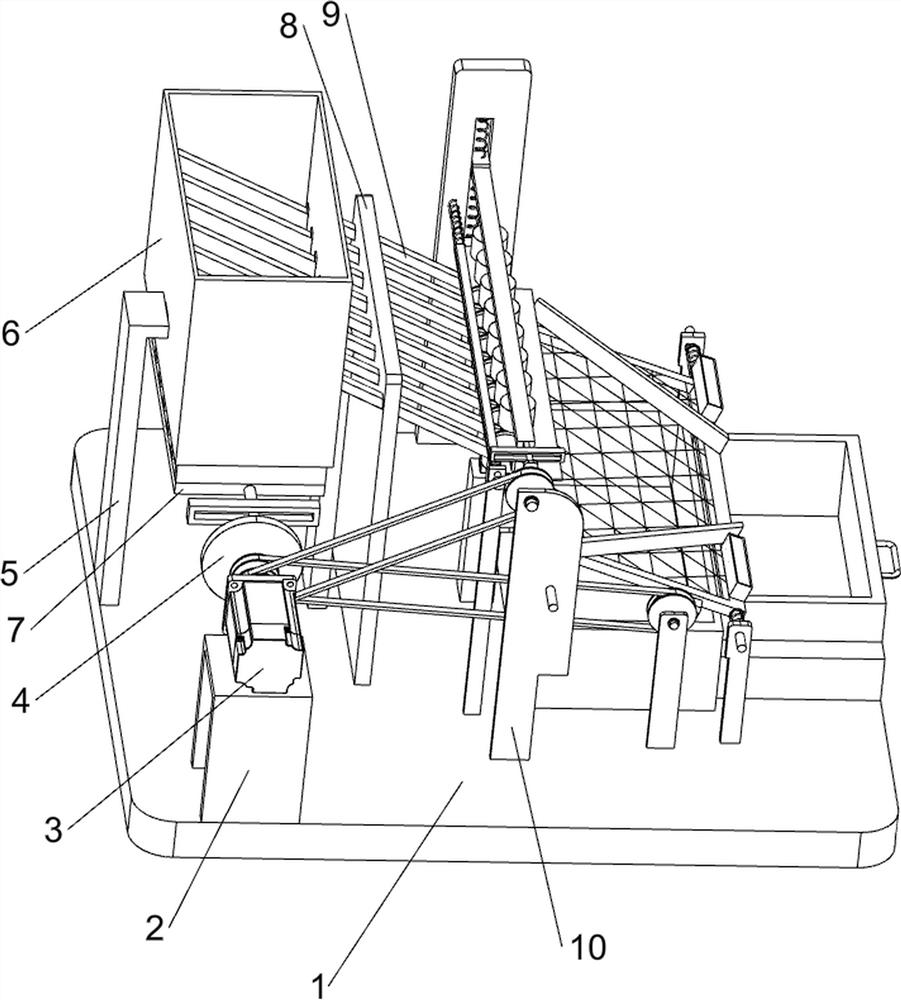

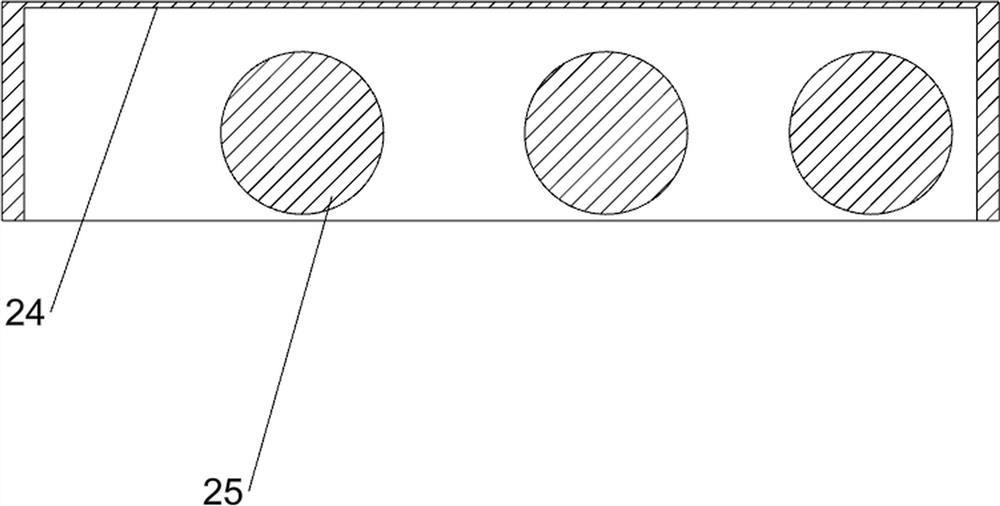

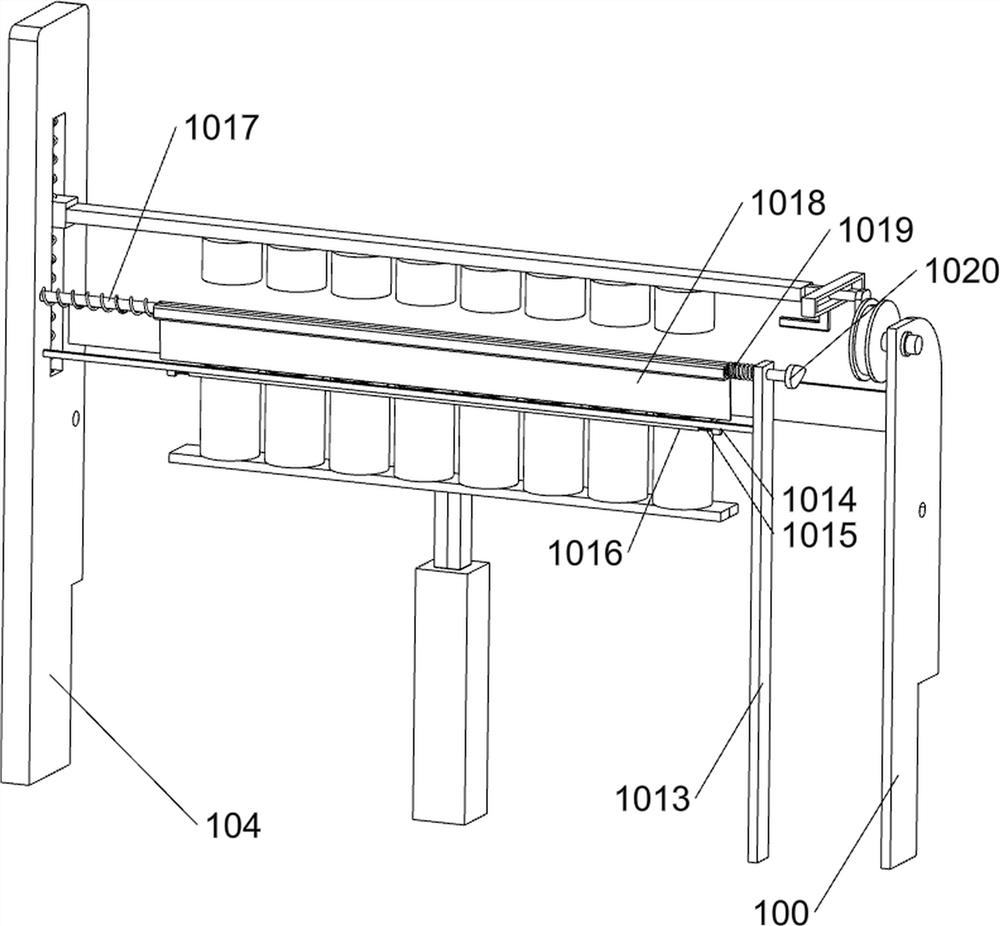

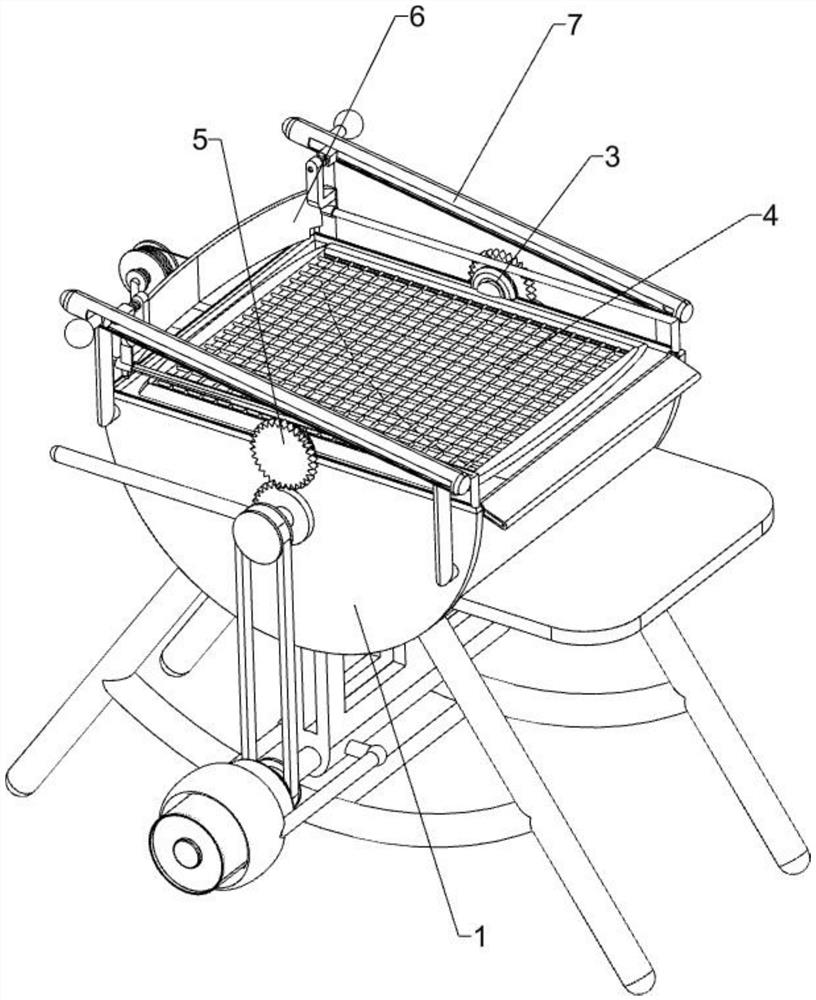

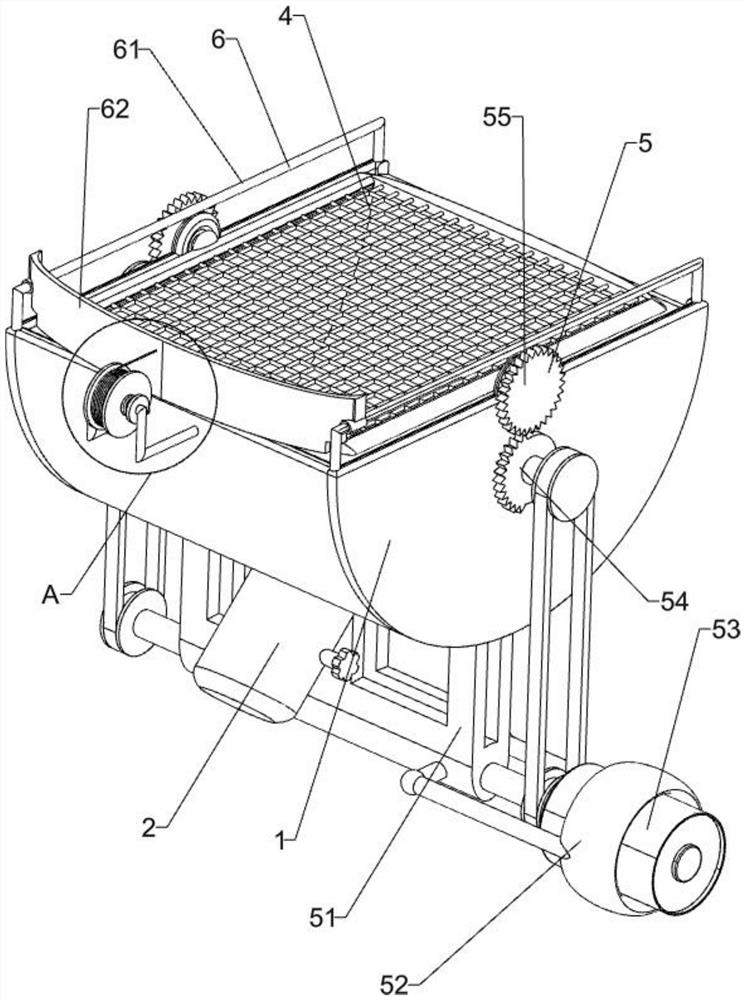

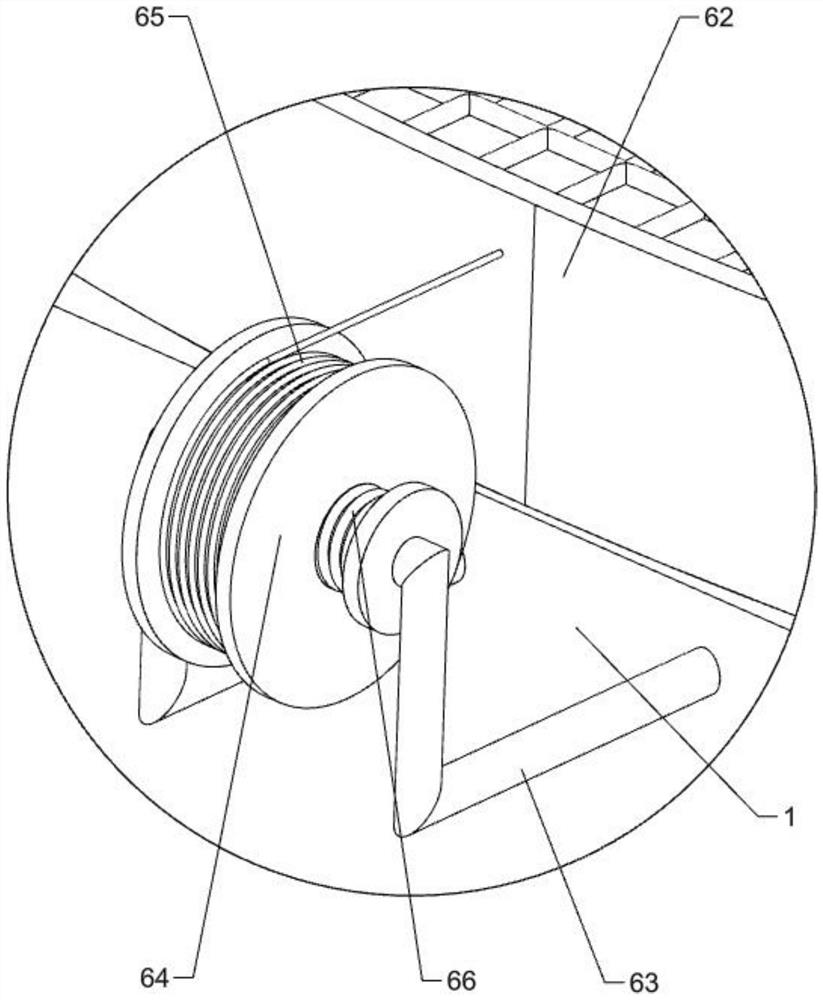

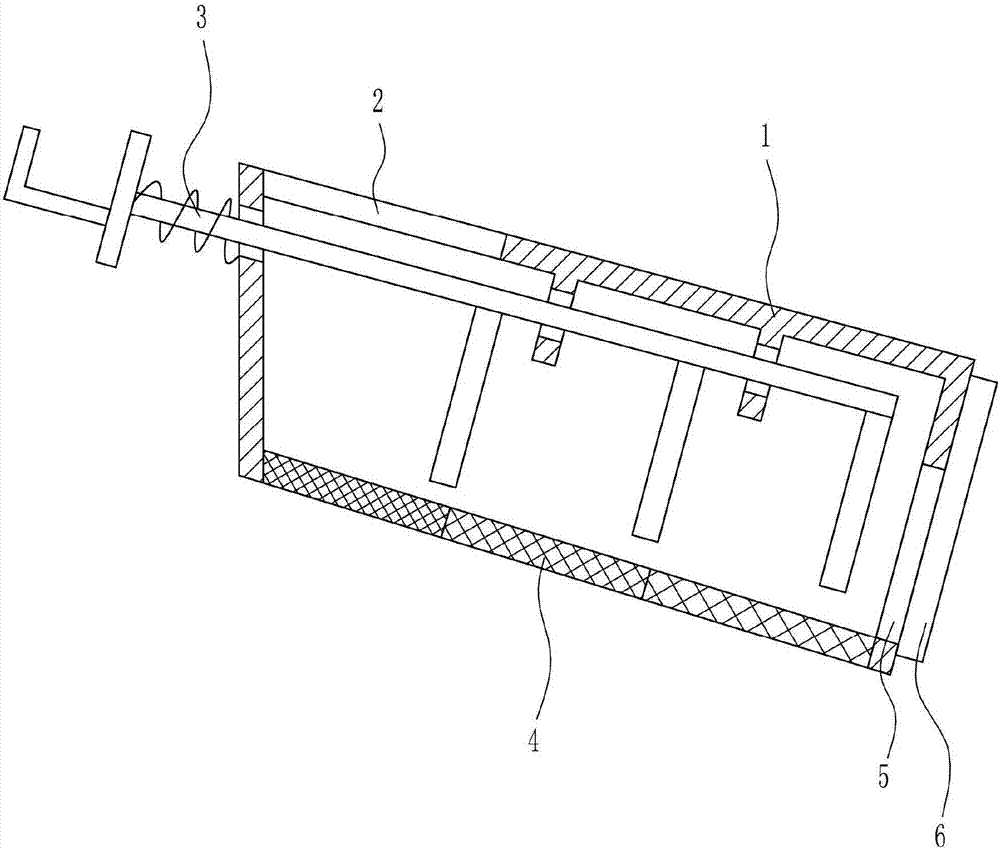

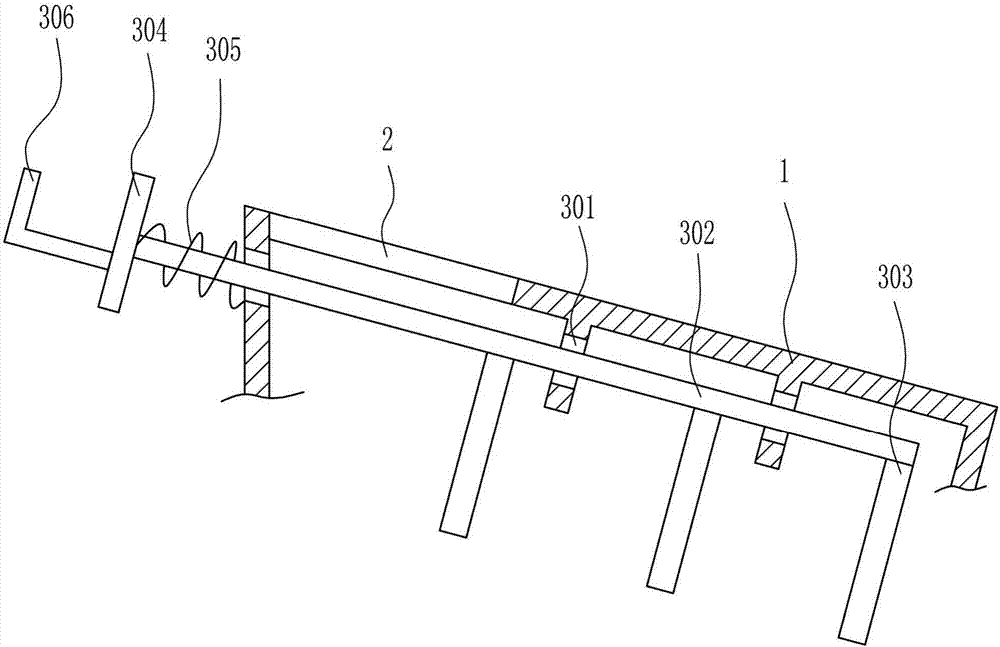

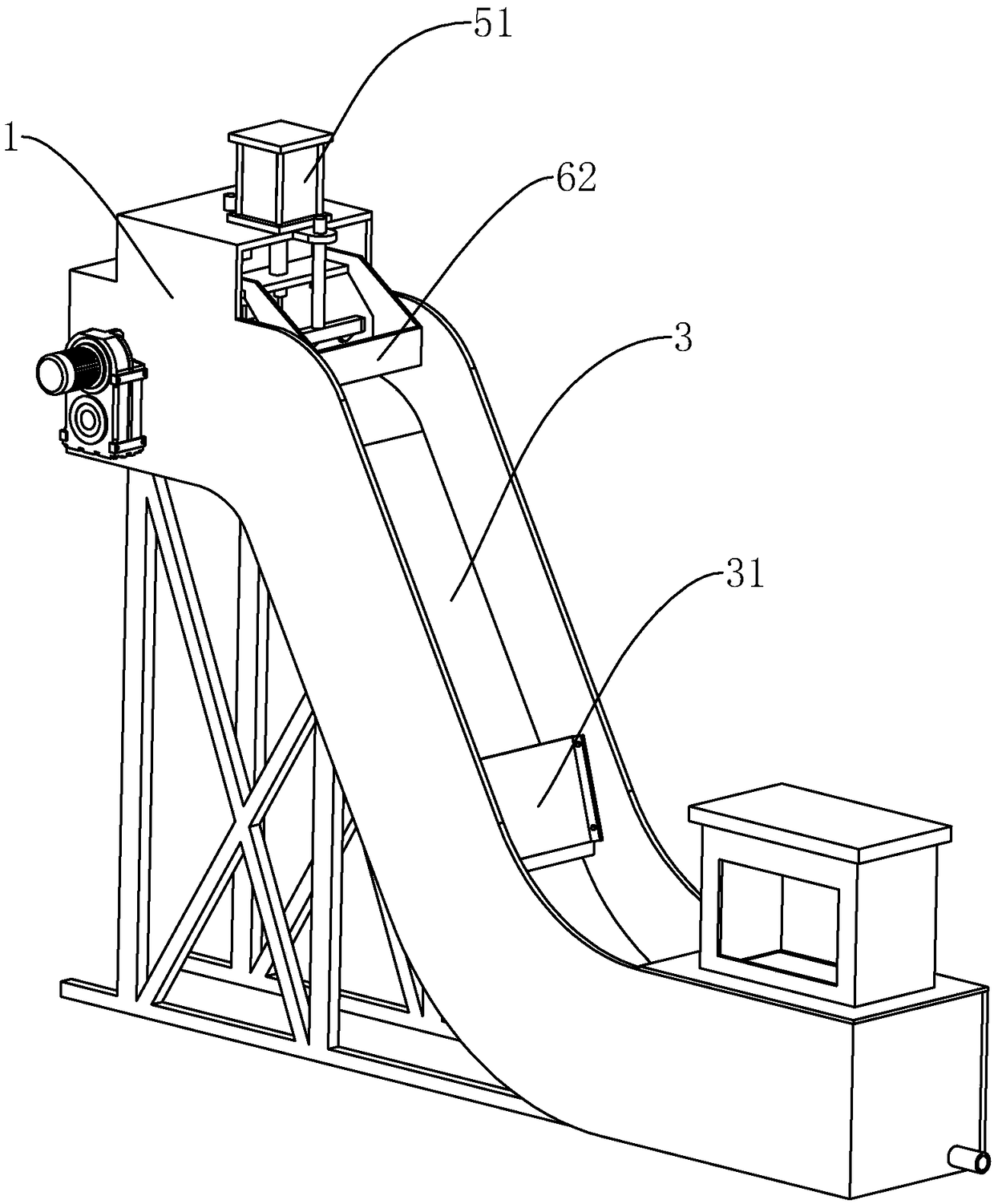

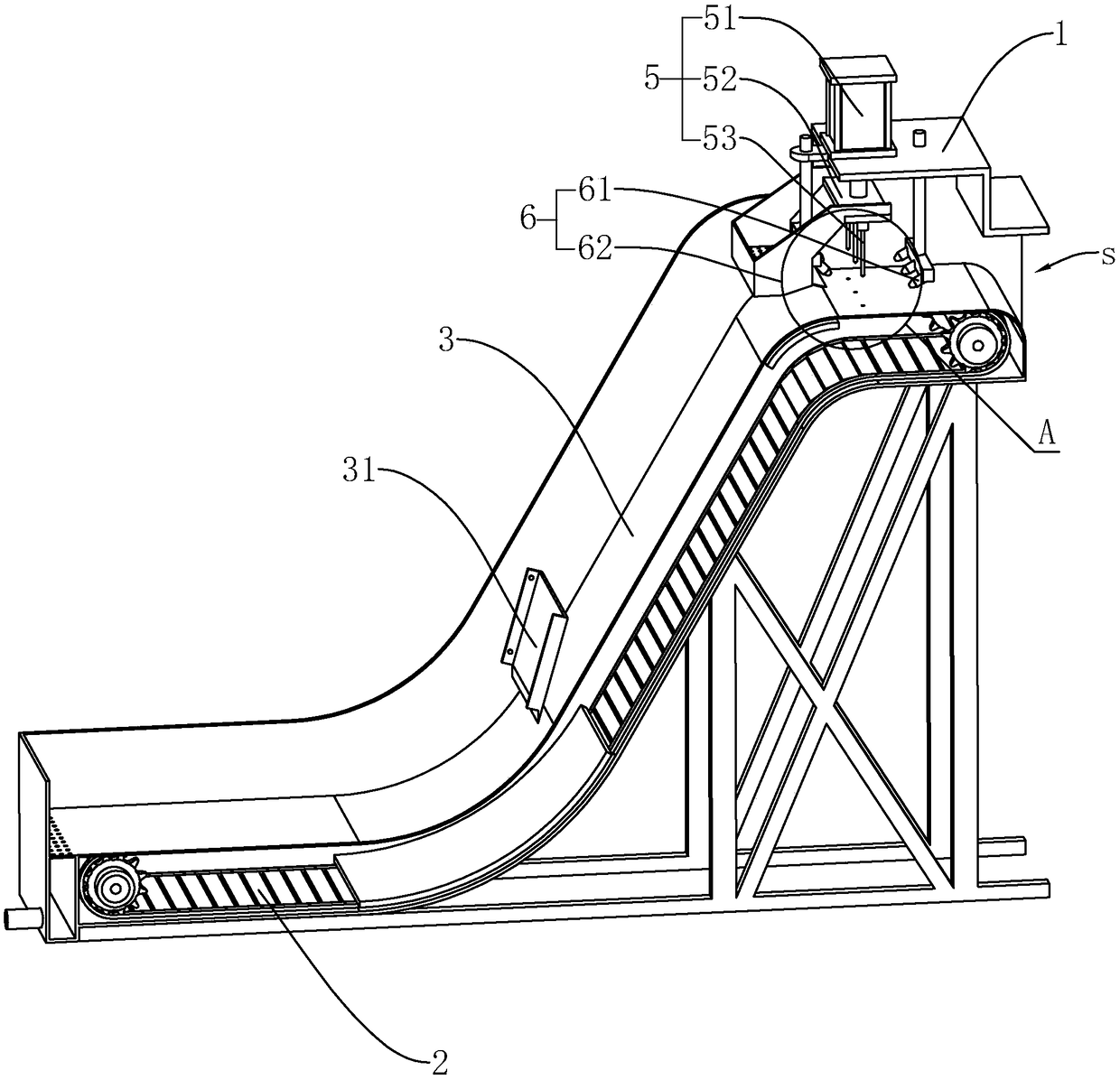

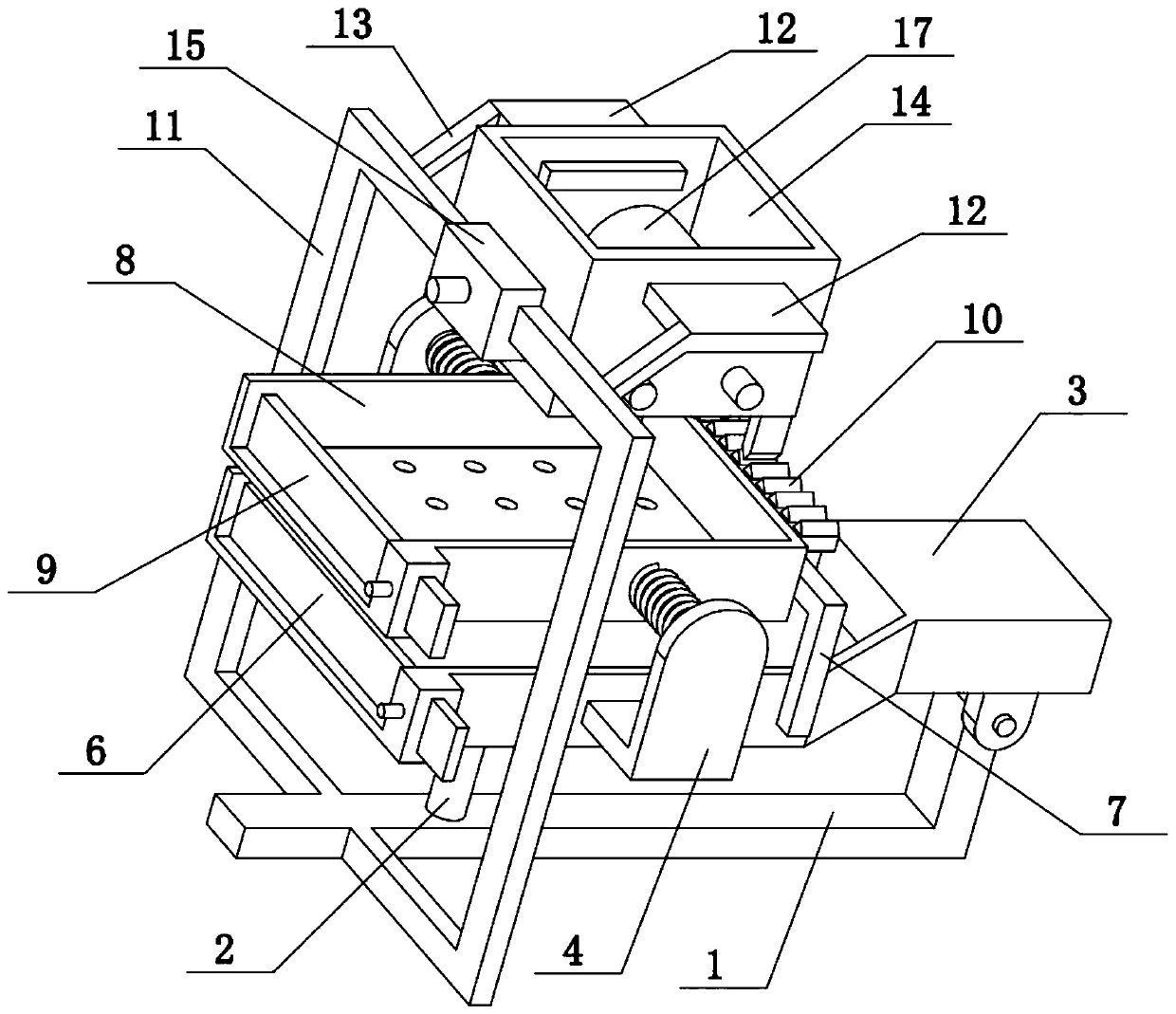

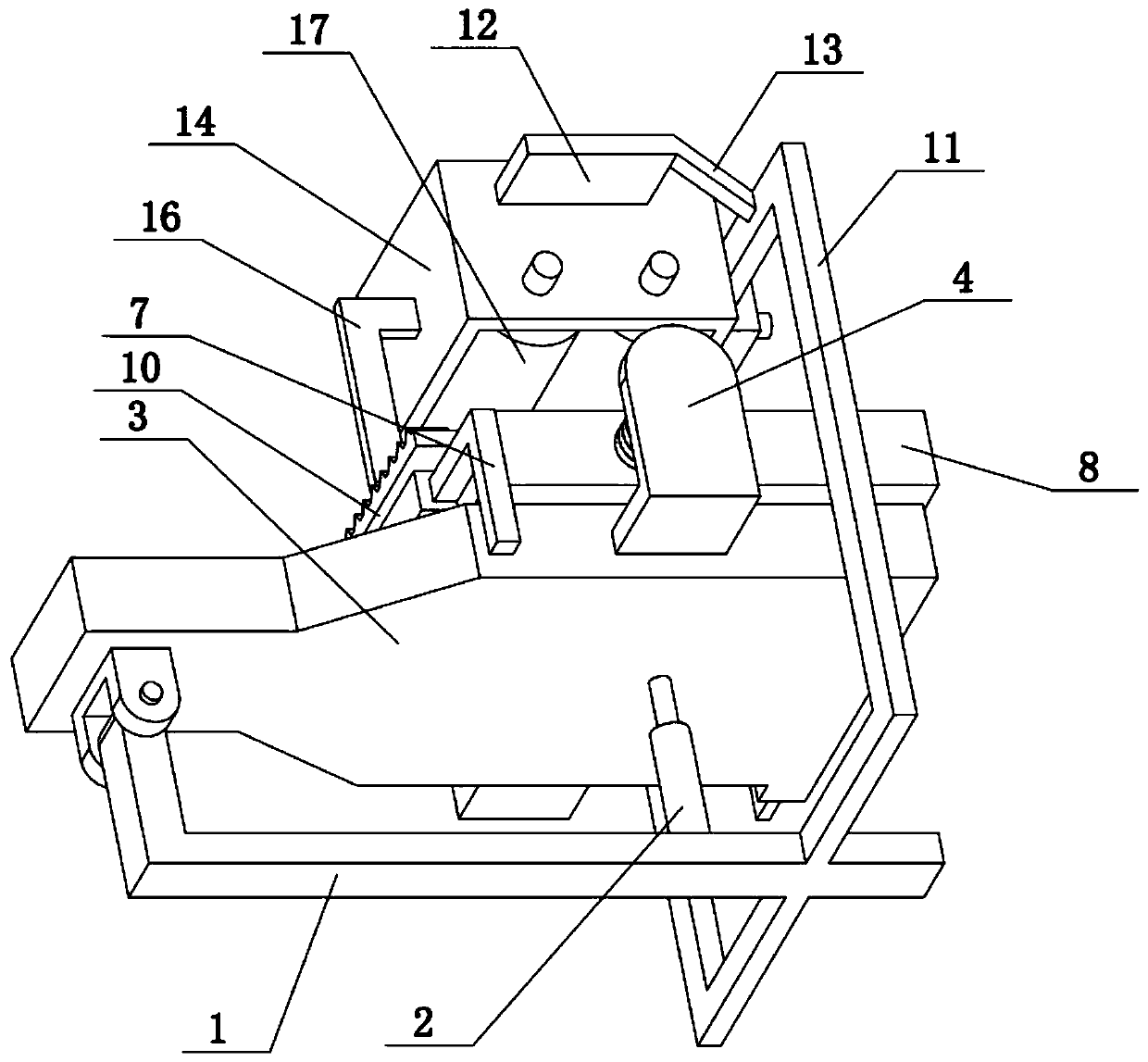

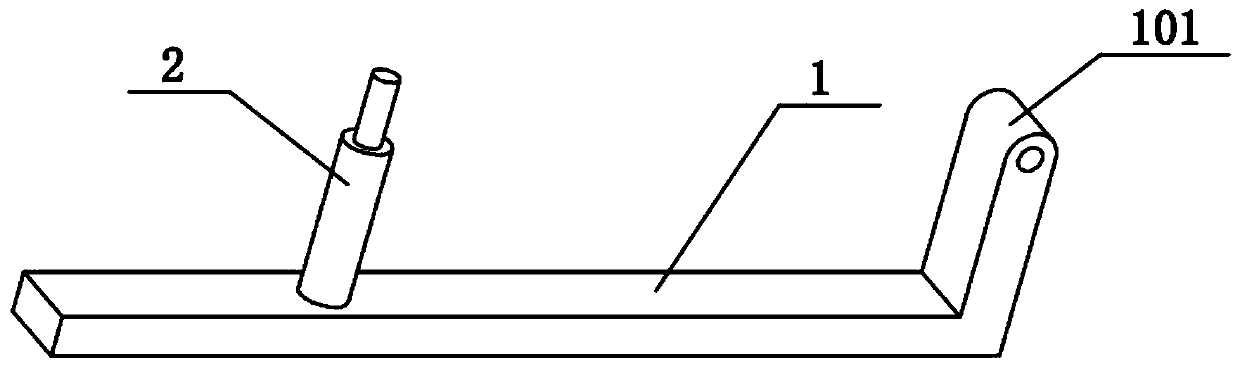

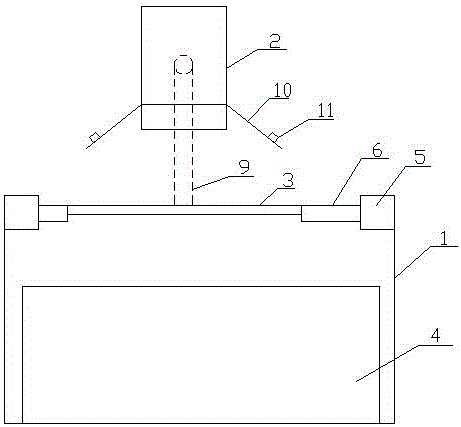

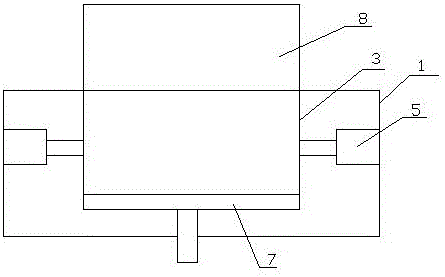

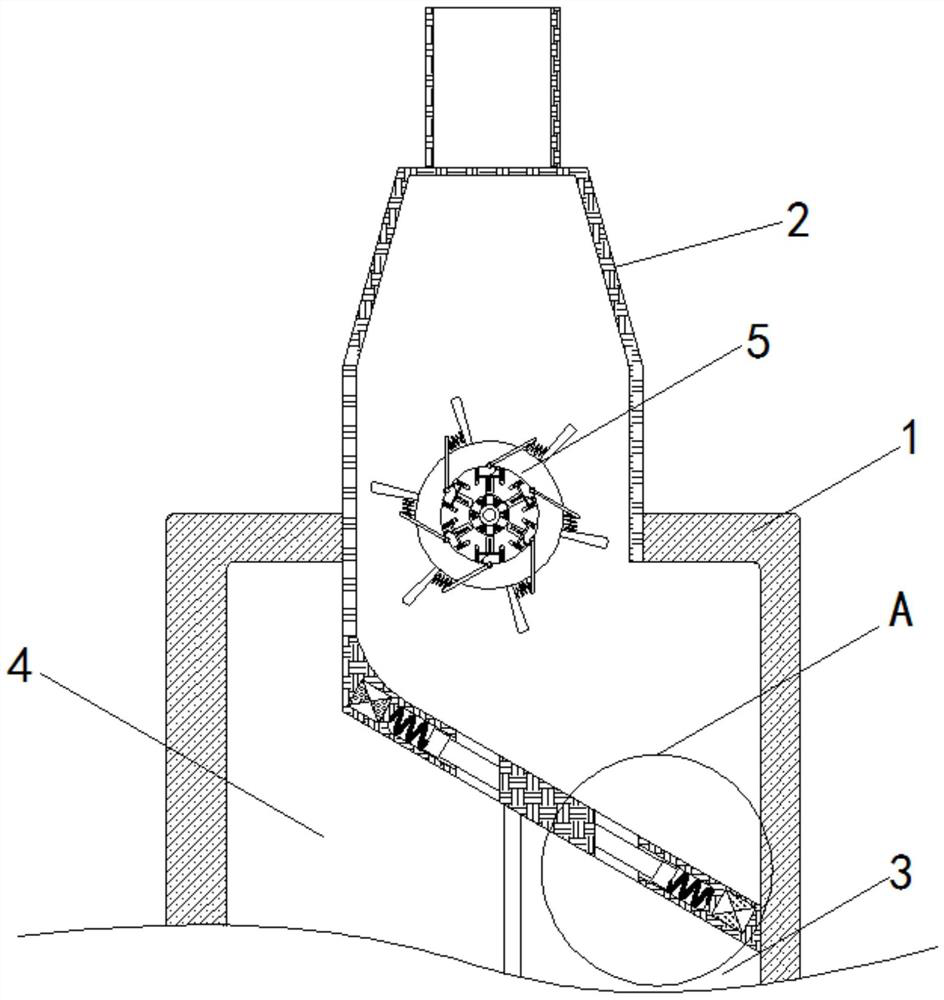

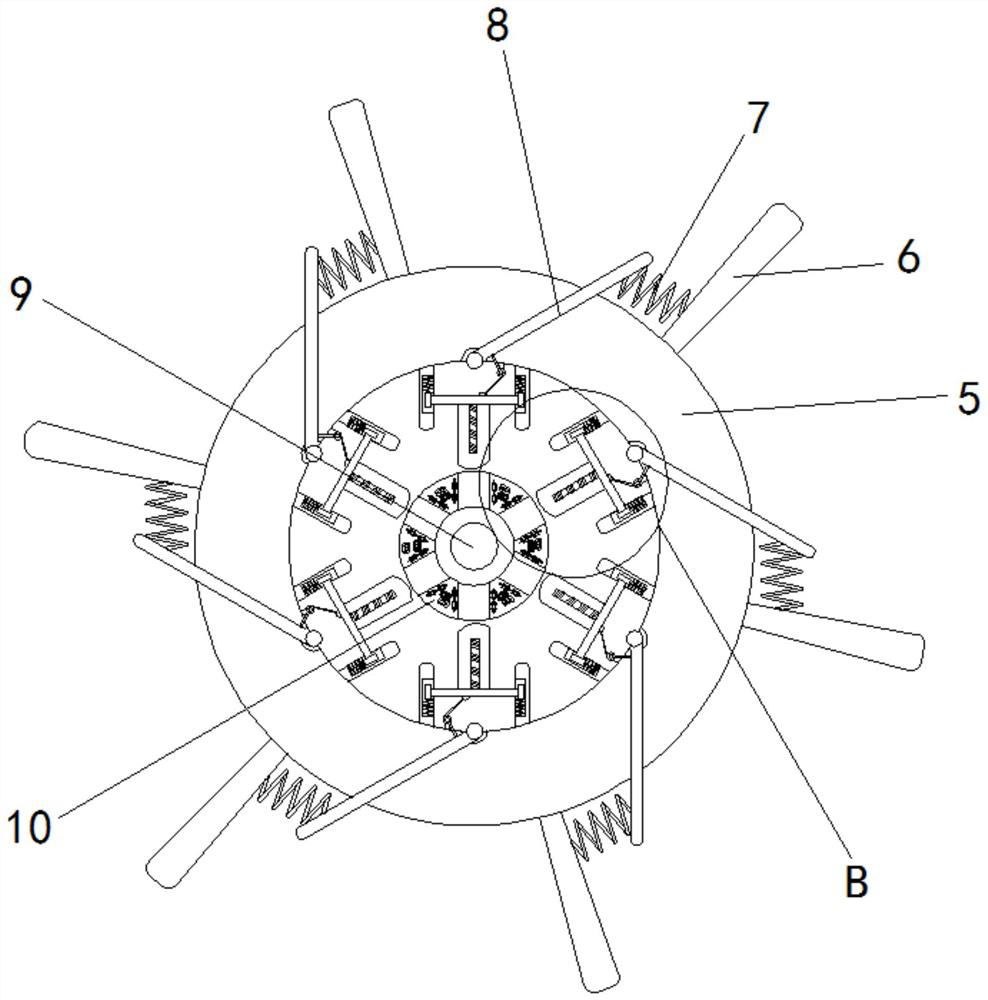

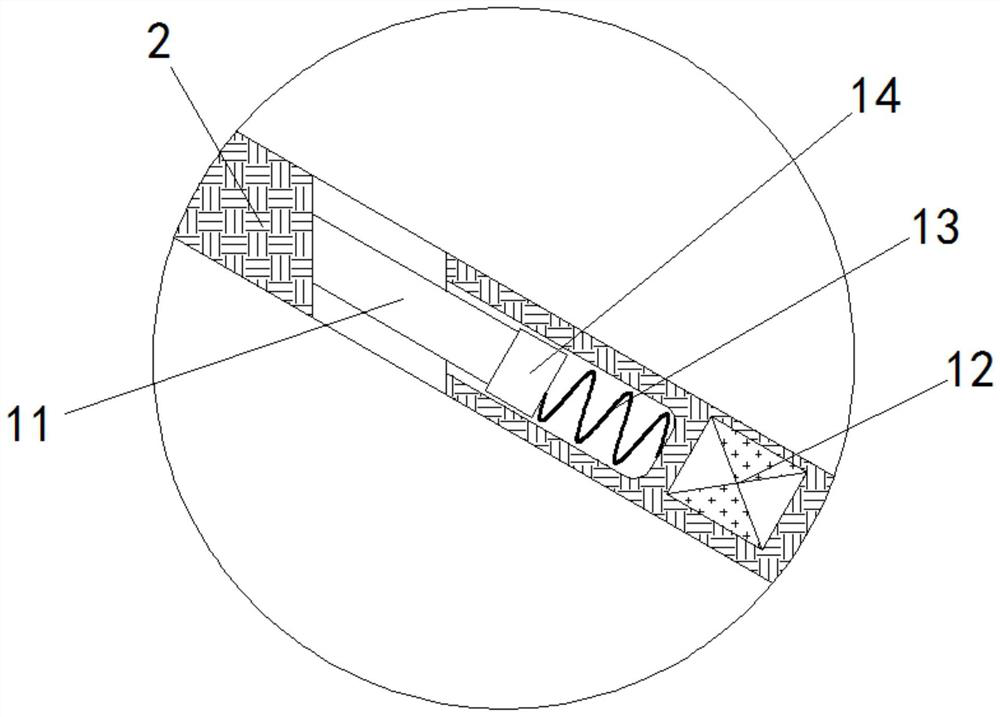

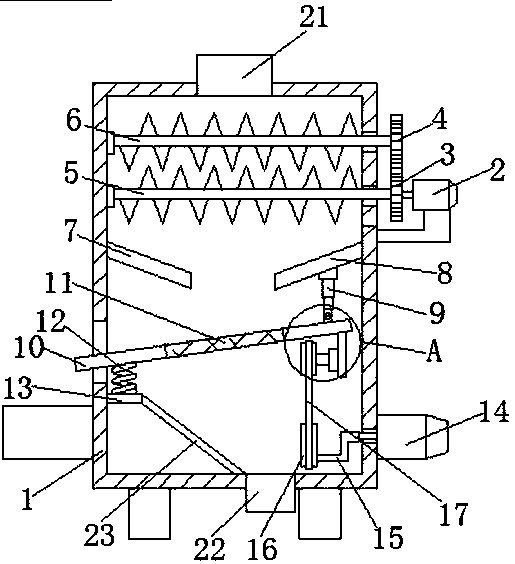

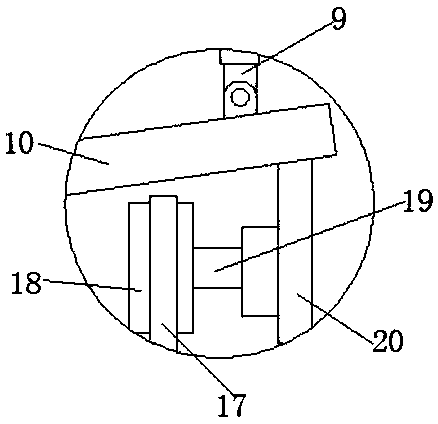

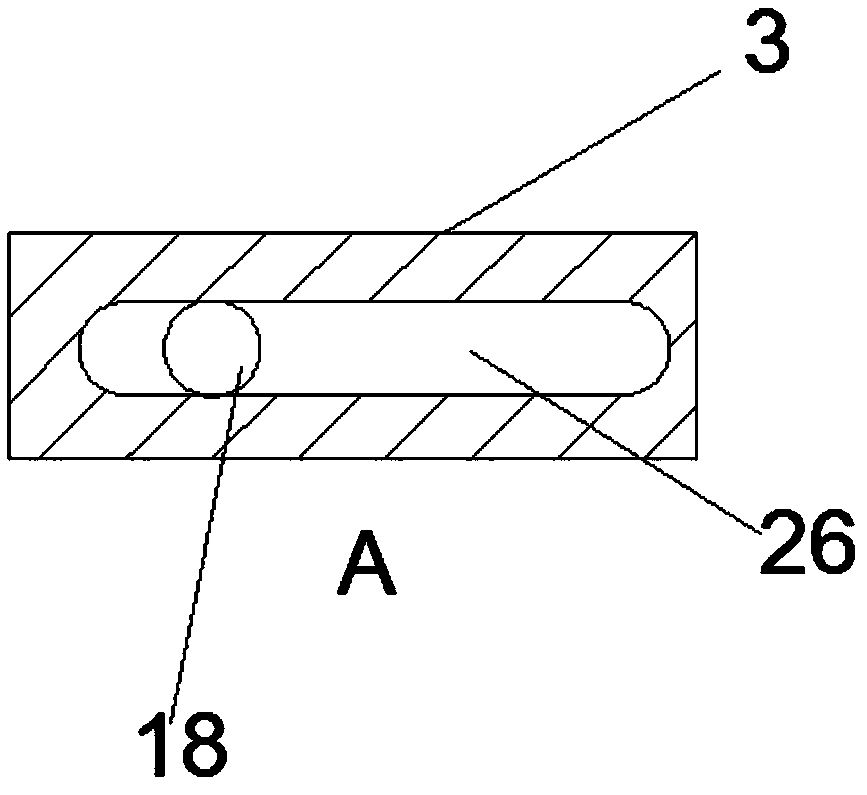

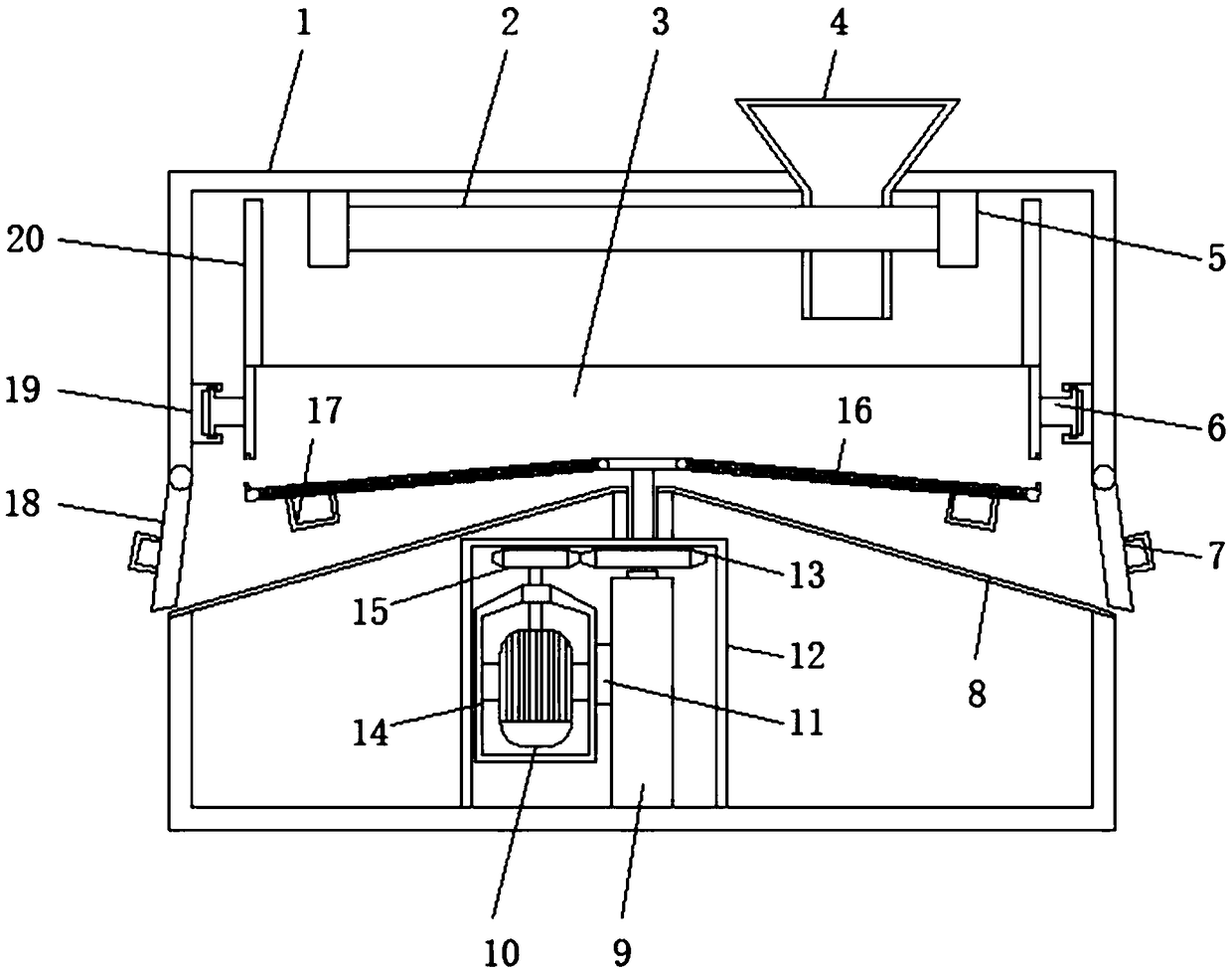

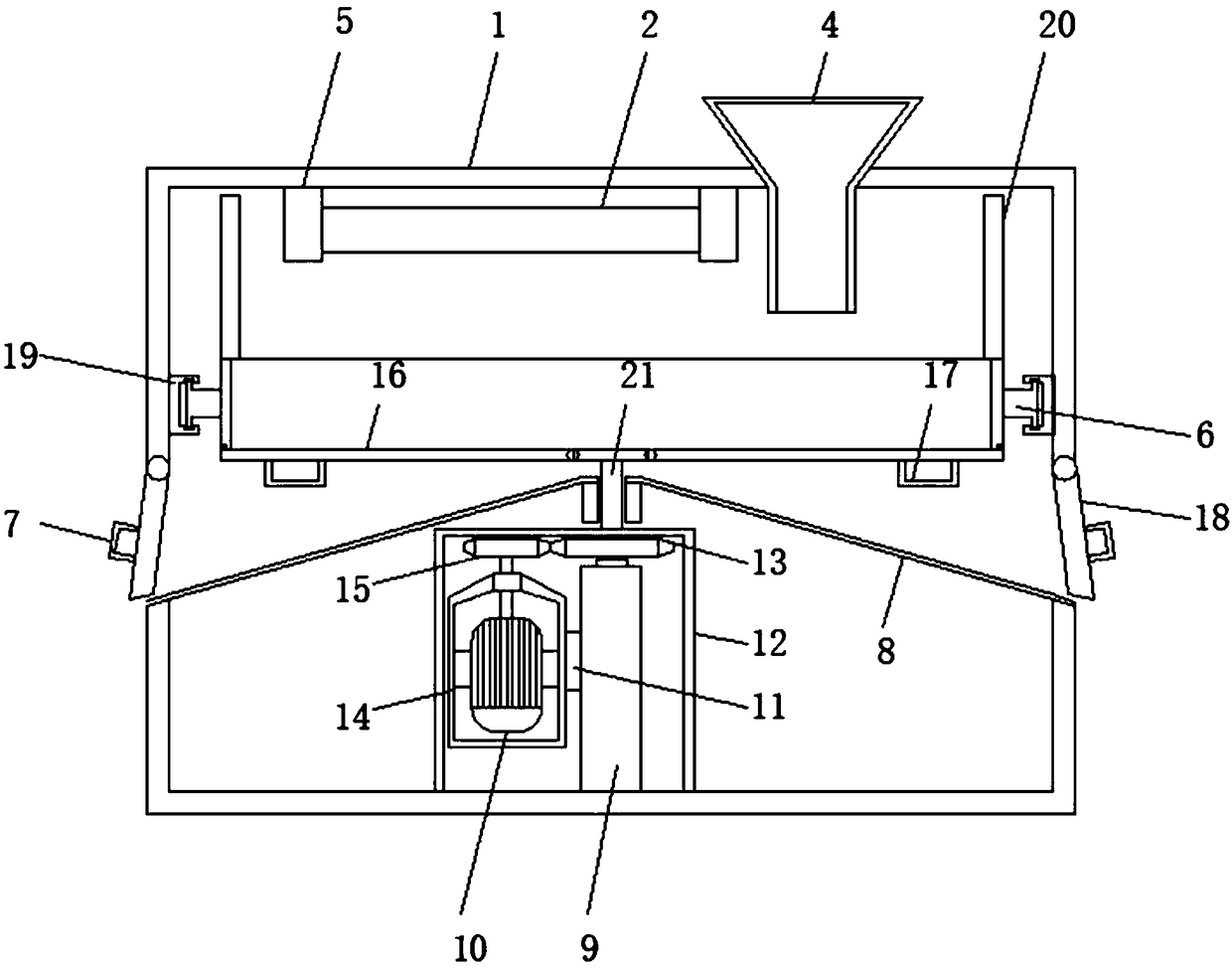

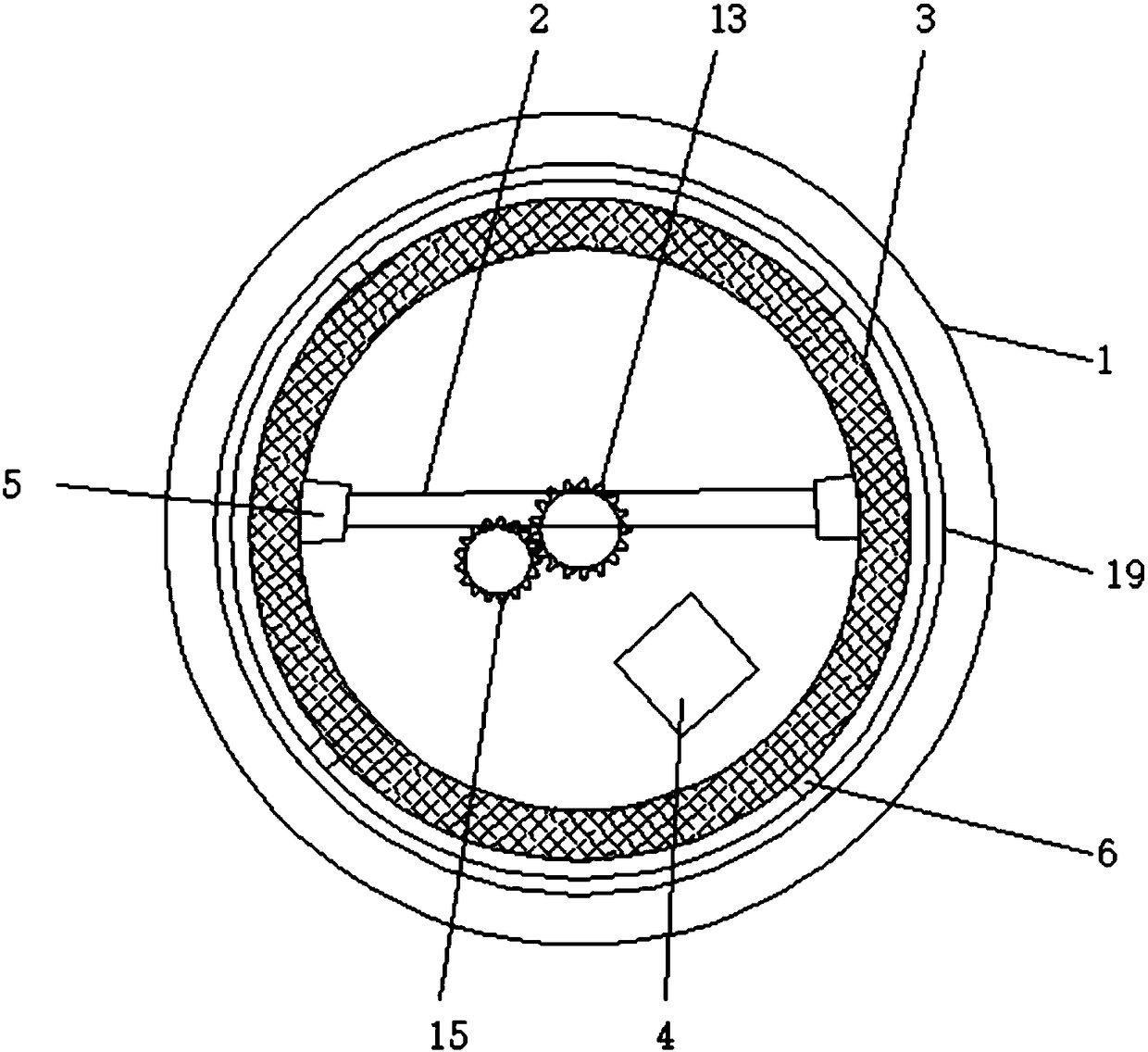

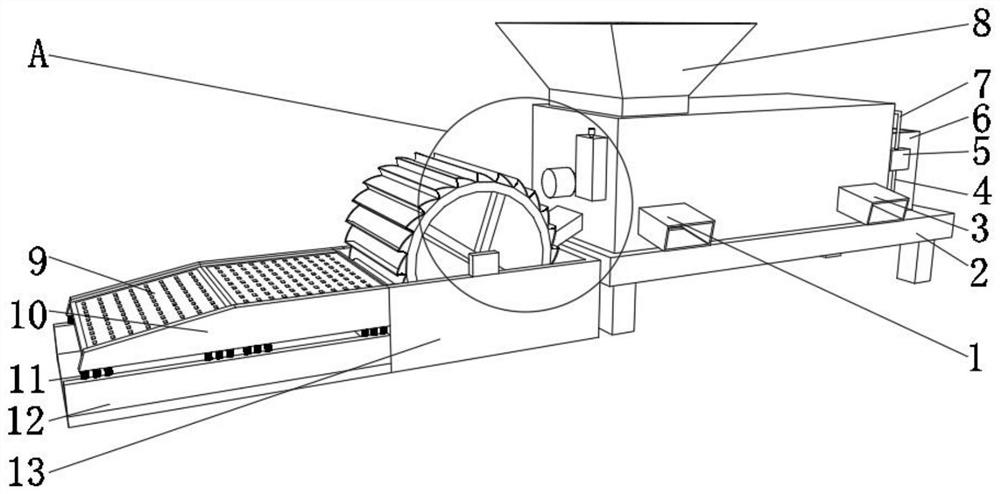

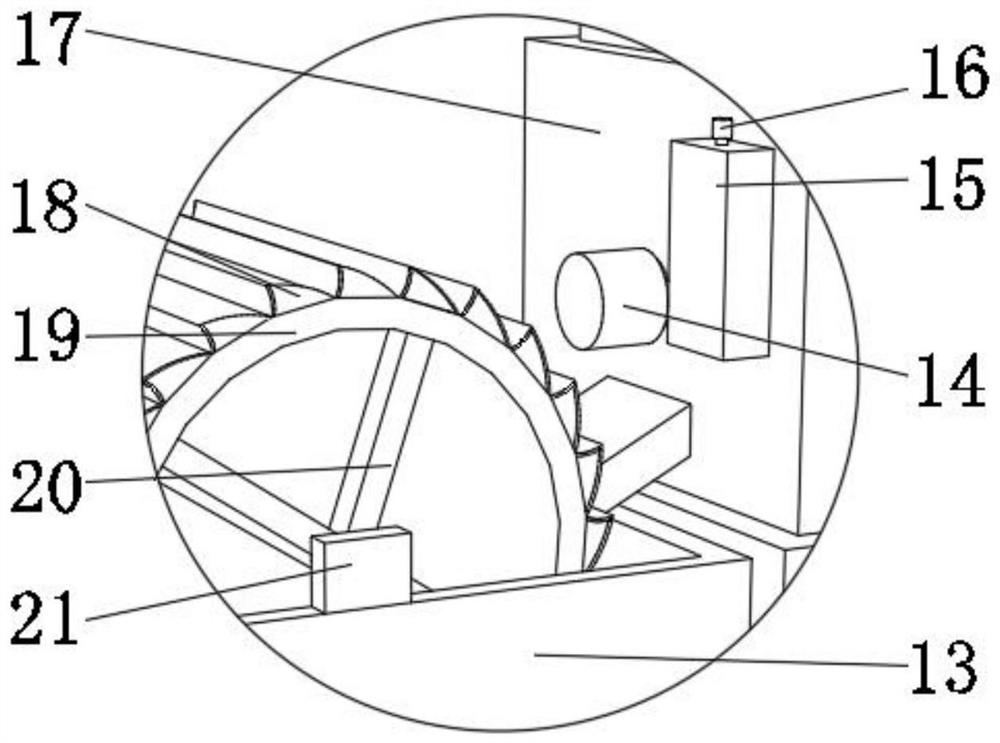

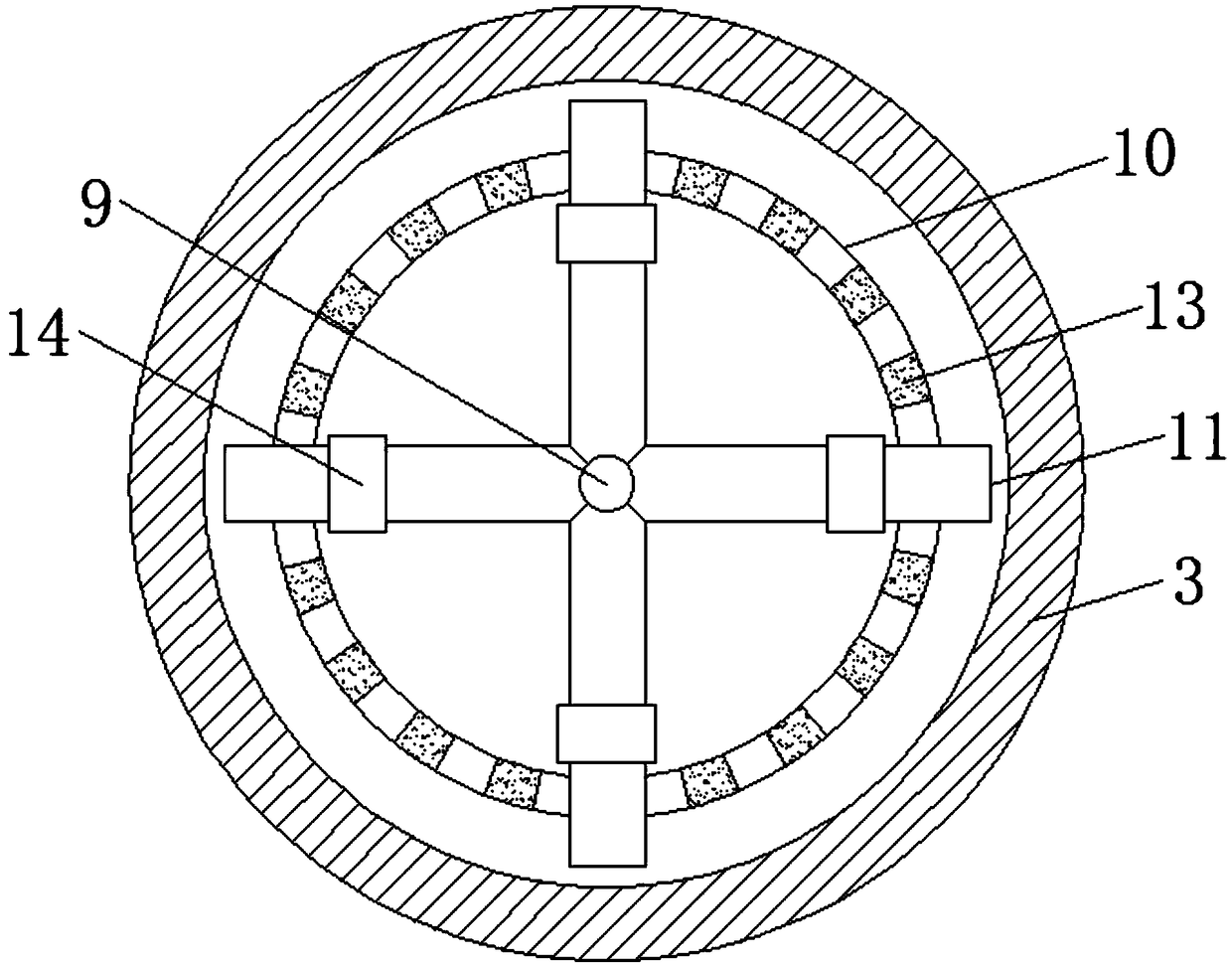

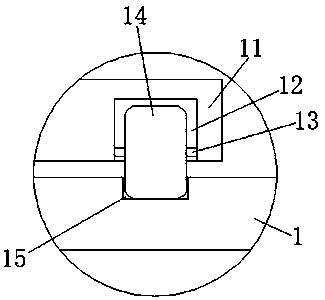

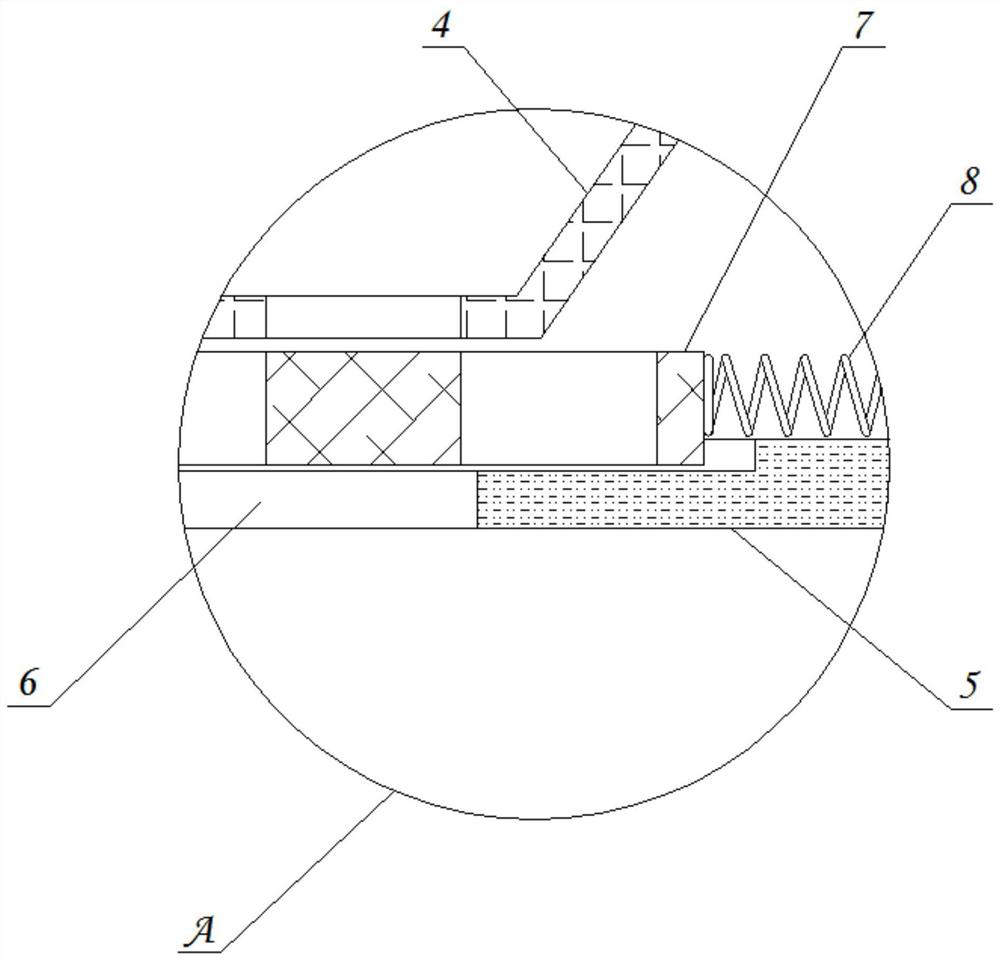

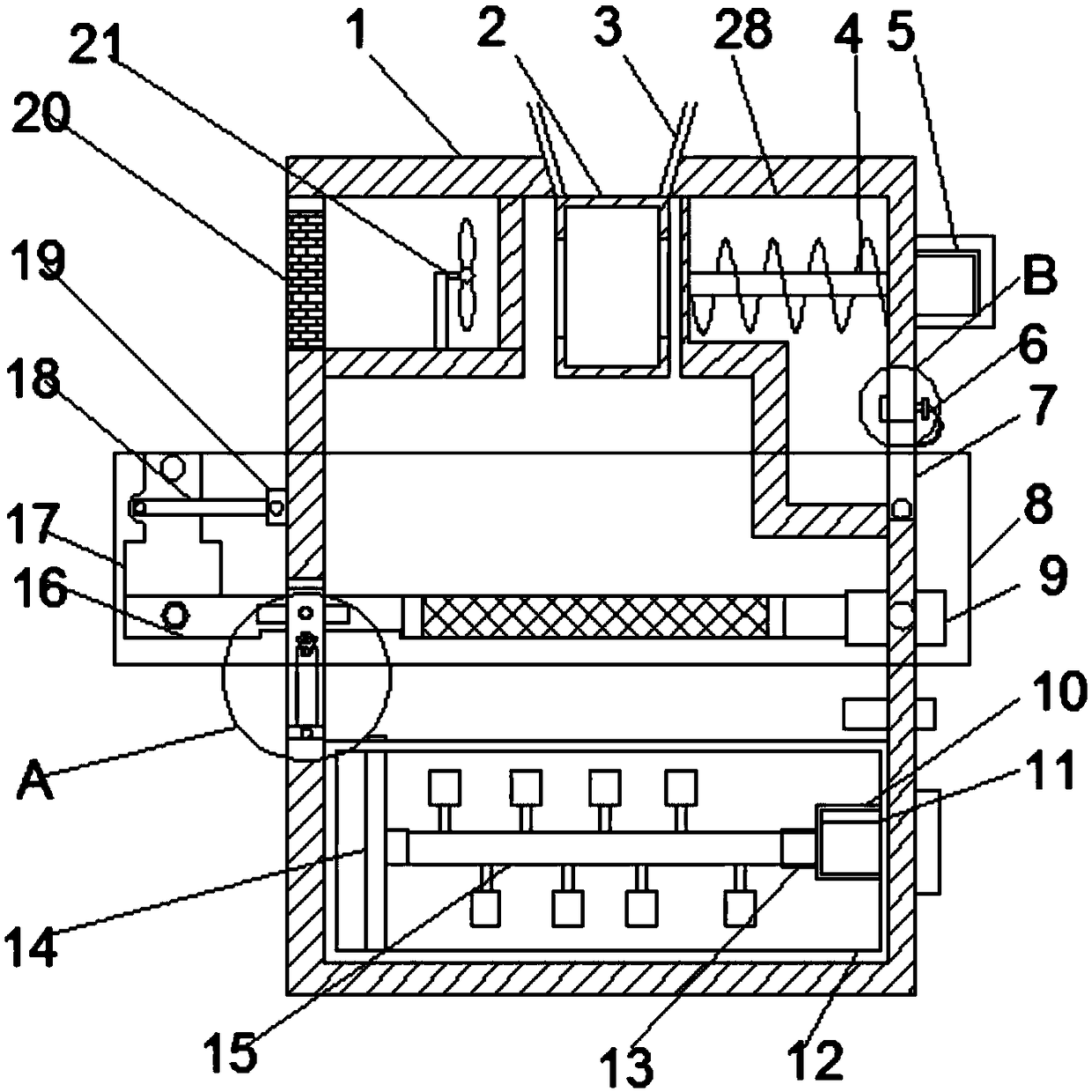

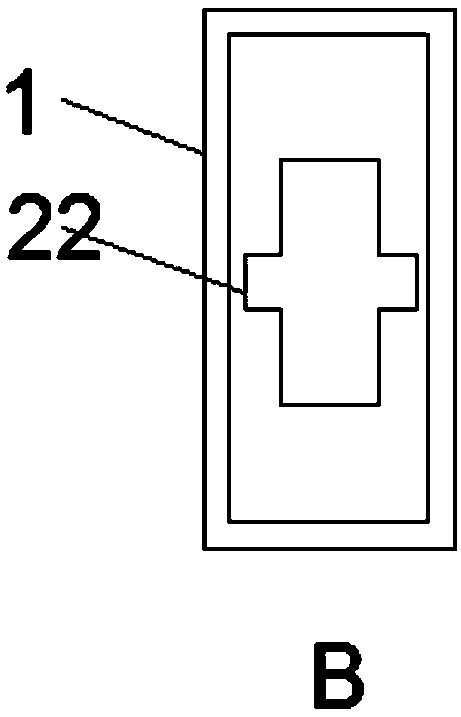

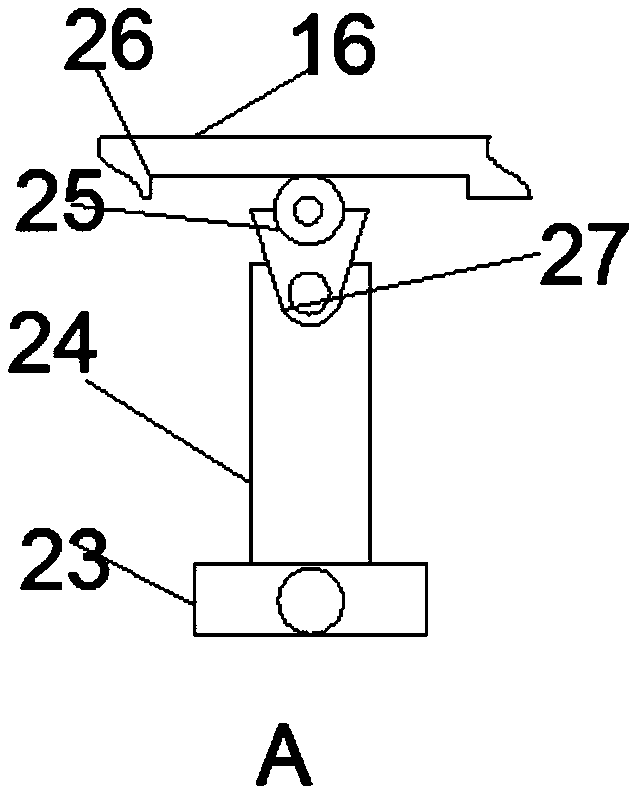

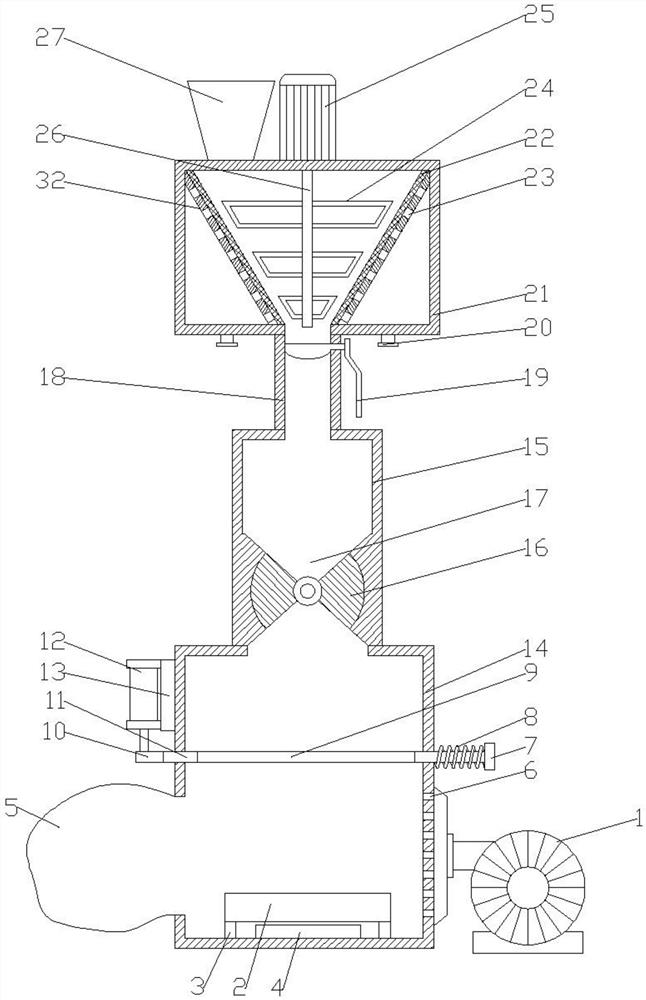

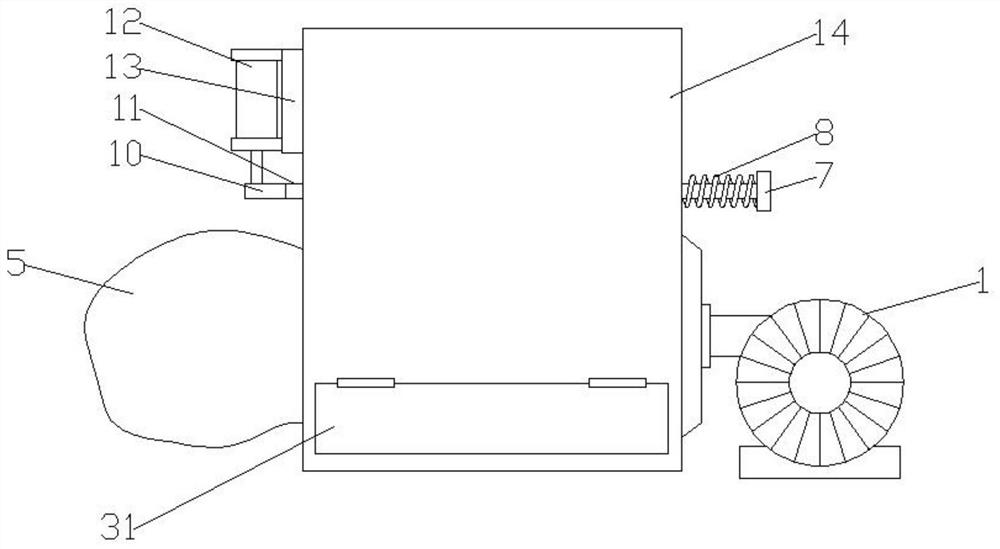

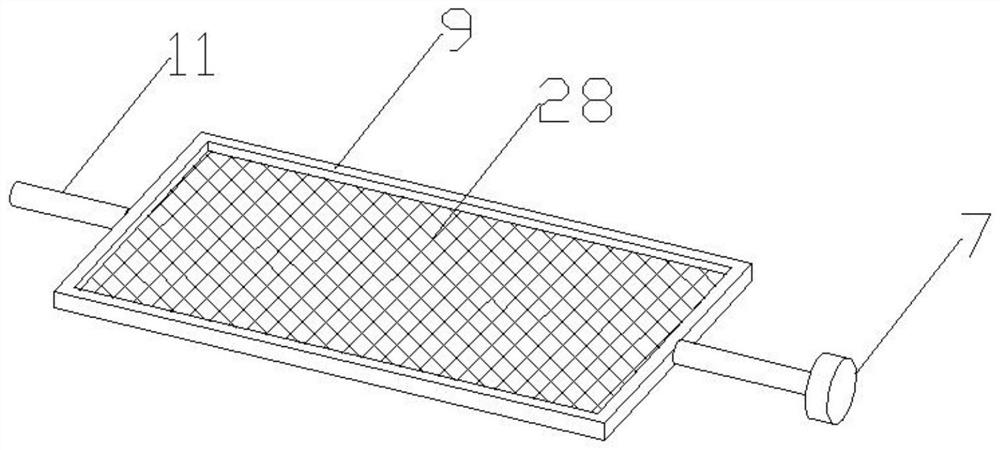

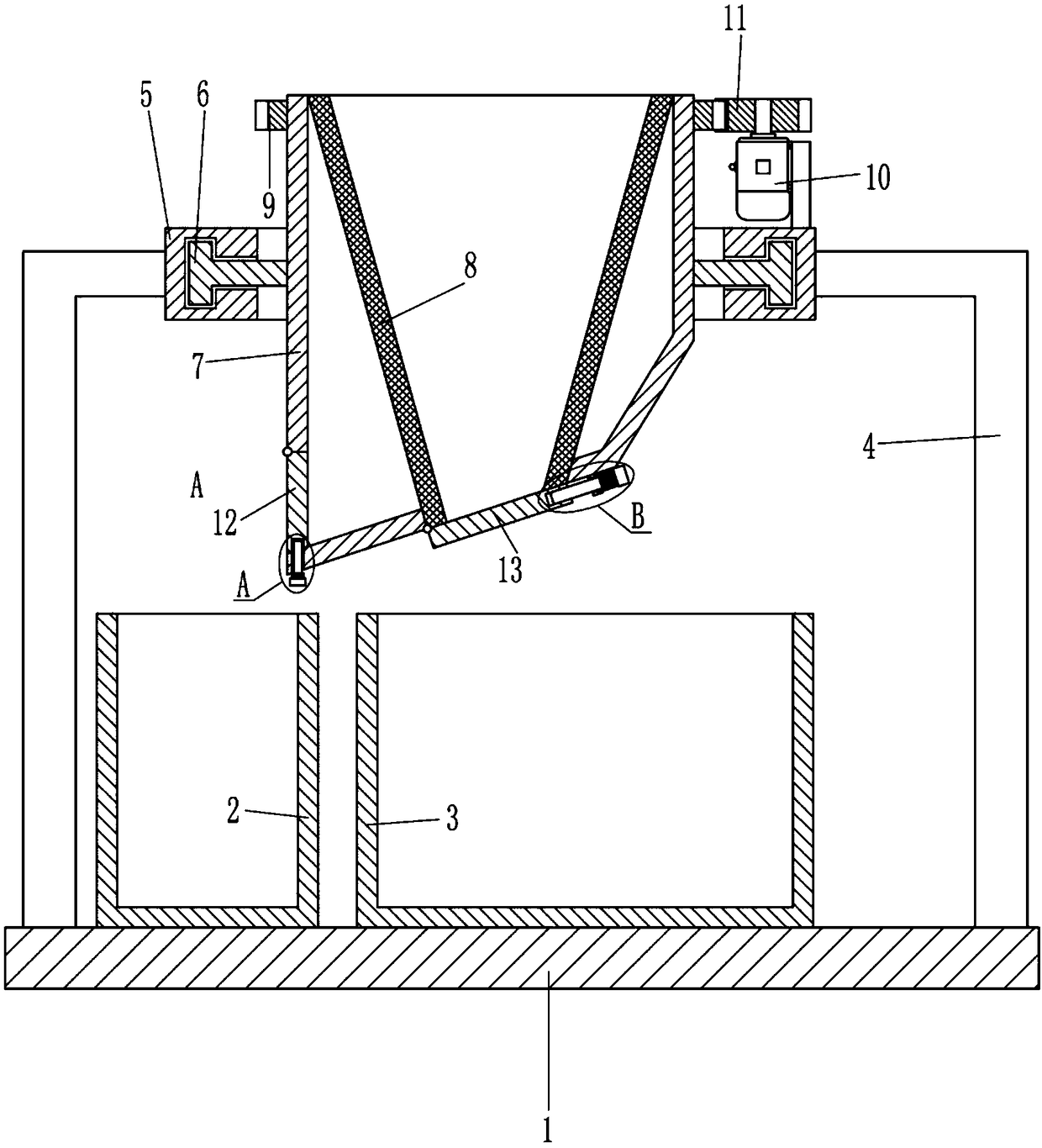

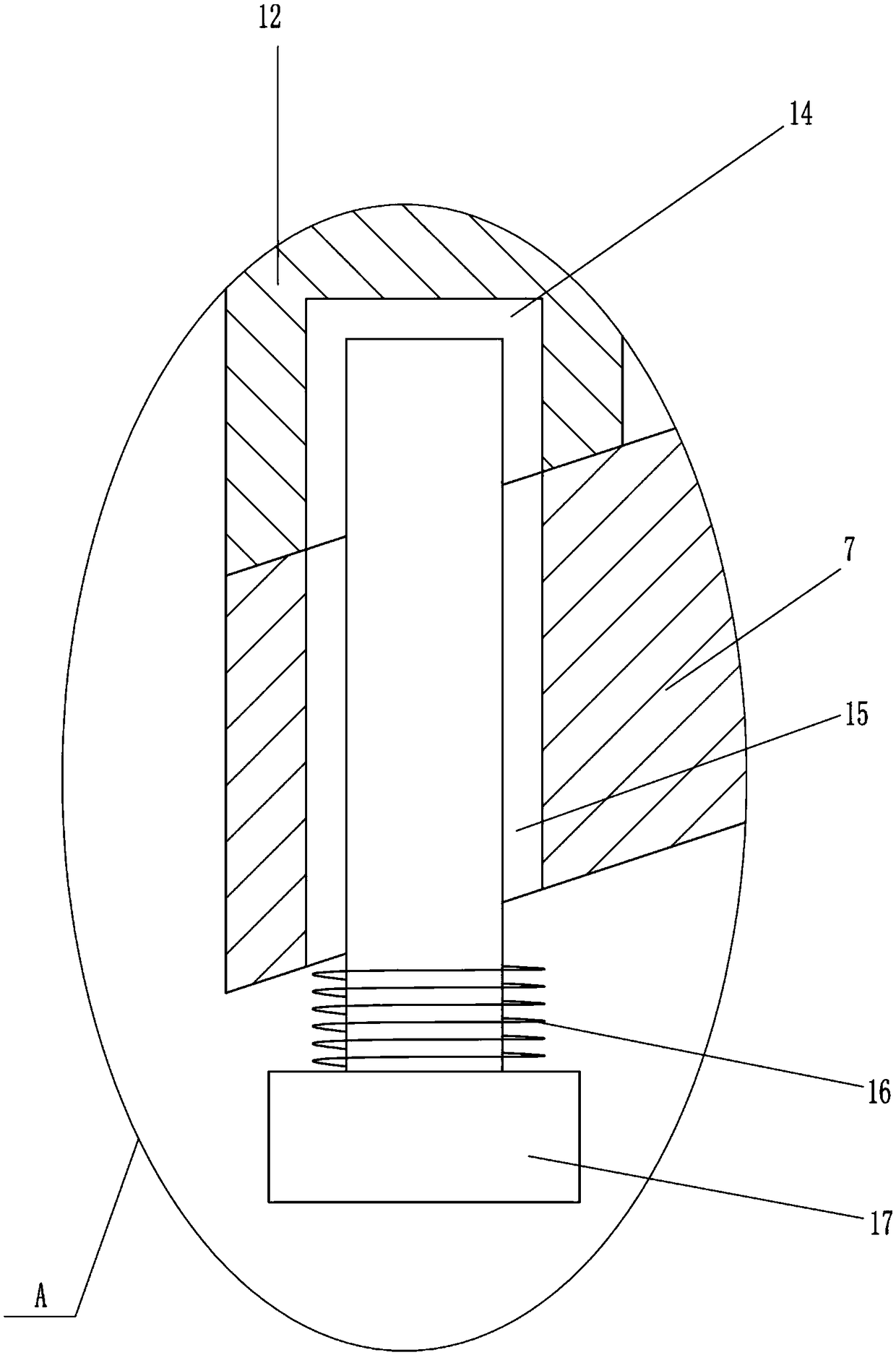

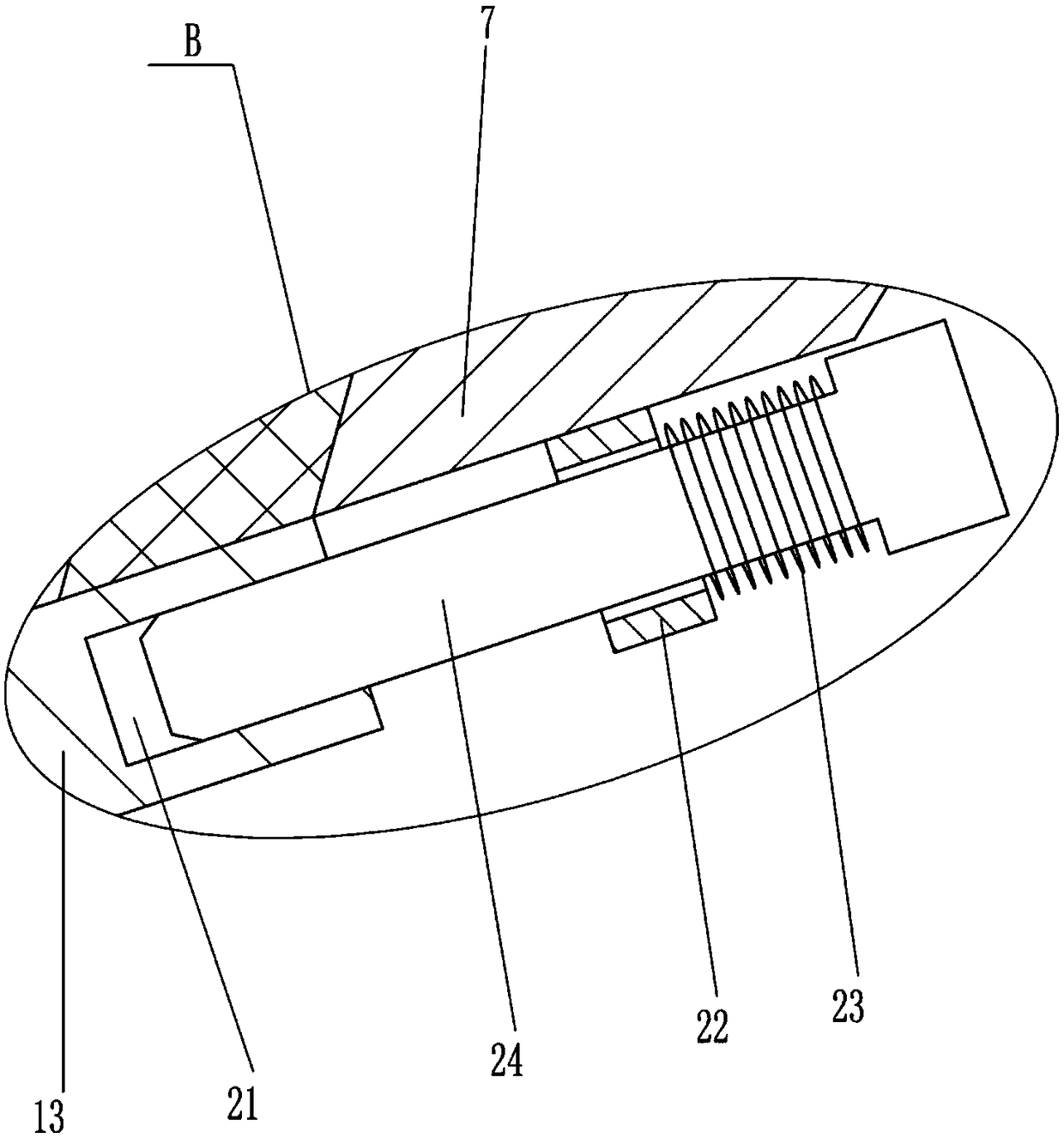

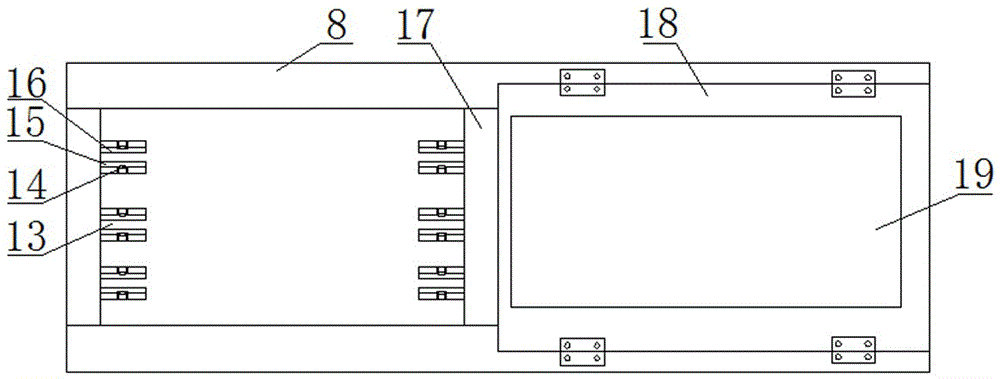

Crushing and screening equipment for automobile tire recycling

ActiveCN107009550AAvoid incomplete crushingTo achieve the screening effectSievingScreeningScreening effectTire recycling

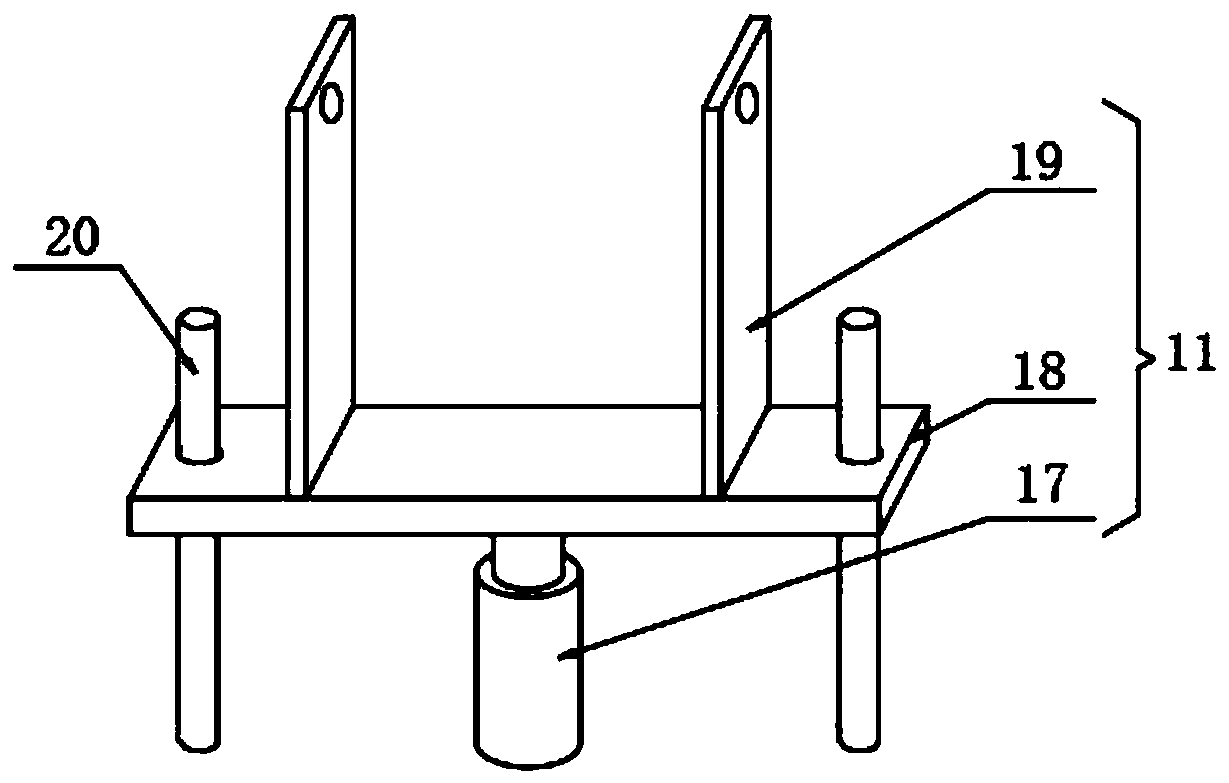

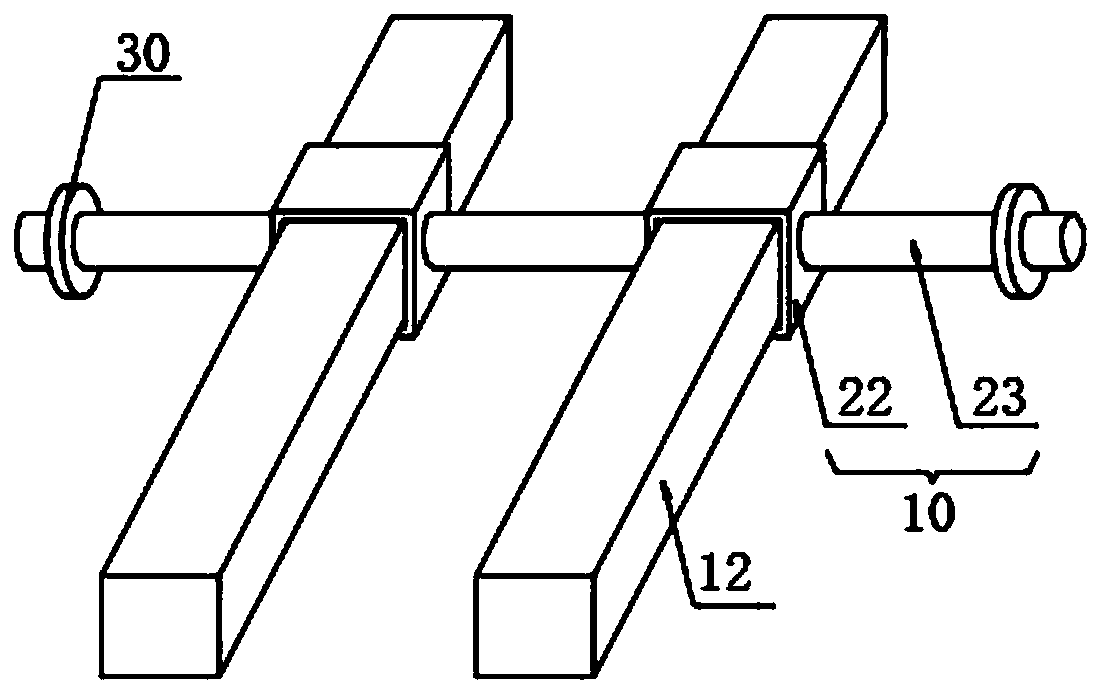

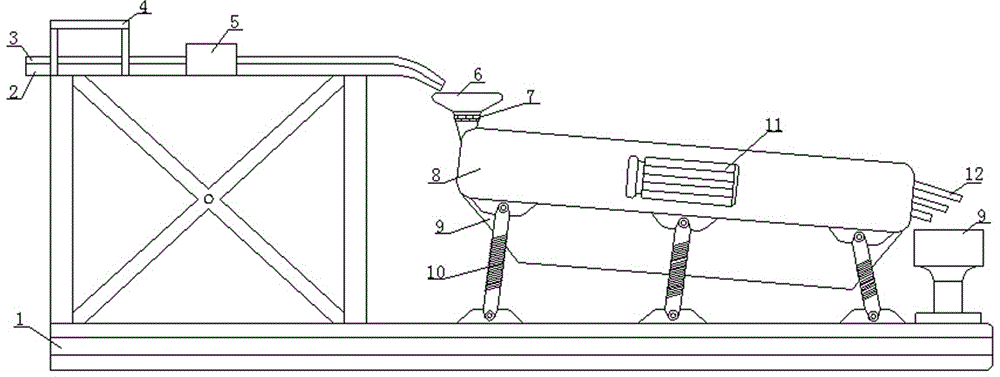

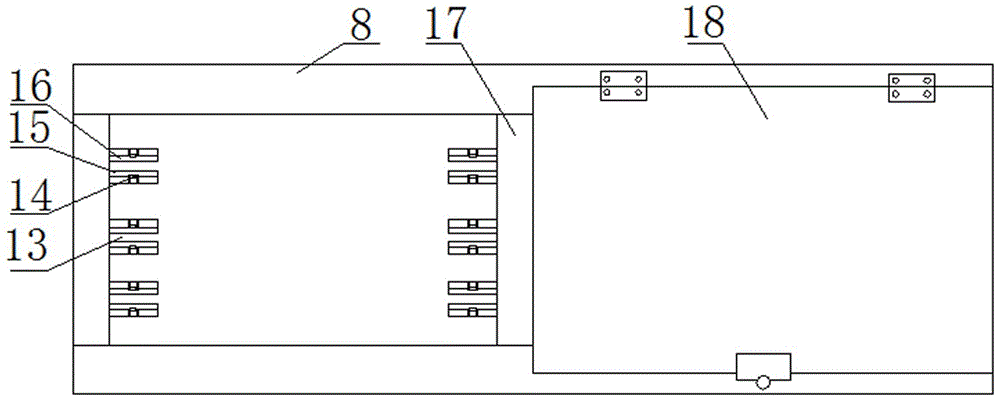

The invention relates to crushing and screening equipment, in particular to crushing and screening equipment for automobile tire recycling. The technical problem to be solved is to provide the crushing and screening equipment which is used for automobile tire recycling and convenient to screen and controllable in feeding rate. To solve the technical problem, the crushing and screening equipment for automobile tire recycling is provided. The crushing and screening equipment comprises a bottom plate, L-shaped supports, a crushing device, a screening device and the like. The L-shaped supports are symmetrically arranged on the top of the bottom plate in a left-right manner. The crushing device is arranged between the two L-shaped supports. The screening device is arranged below the crushing device. According to the crushing and screening equipment for automobile tire recycling, a first operating crank is rocked to drive a screening frame to swing left and right, the screening effect is achieved, the feeding amount is adjusted by rocking a second operating crank, and it is avoided that crushing is not thorough due to the too large feeding amount.

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

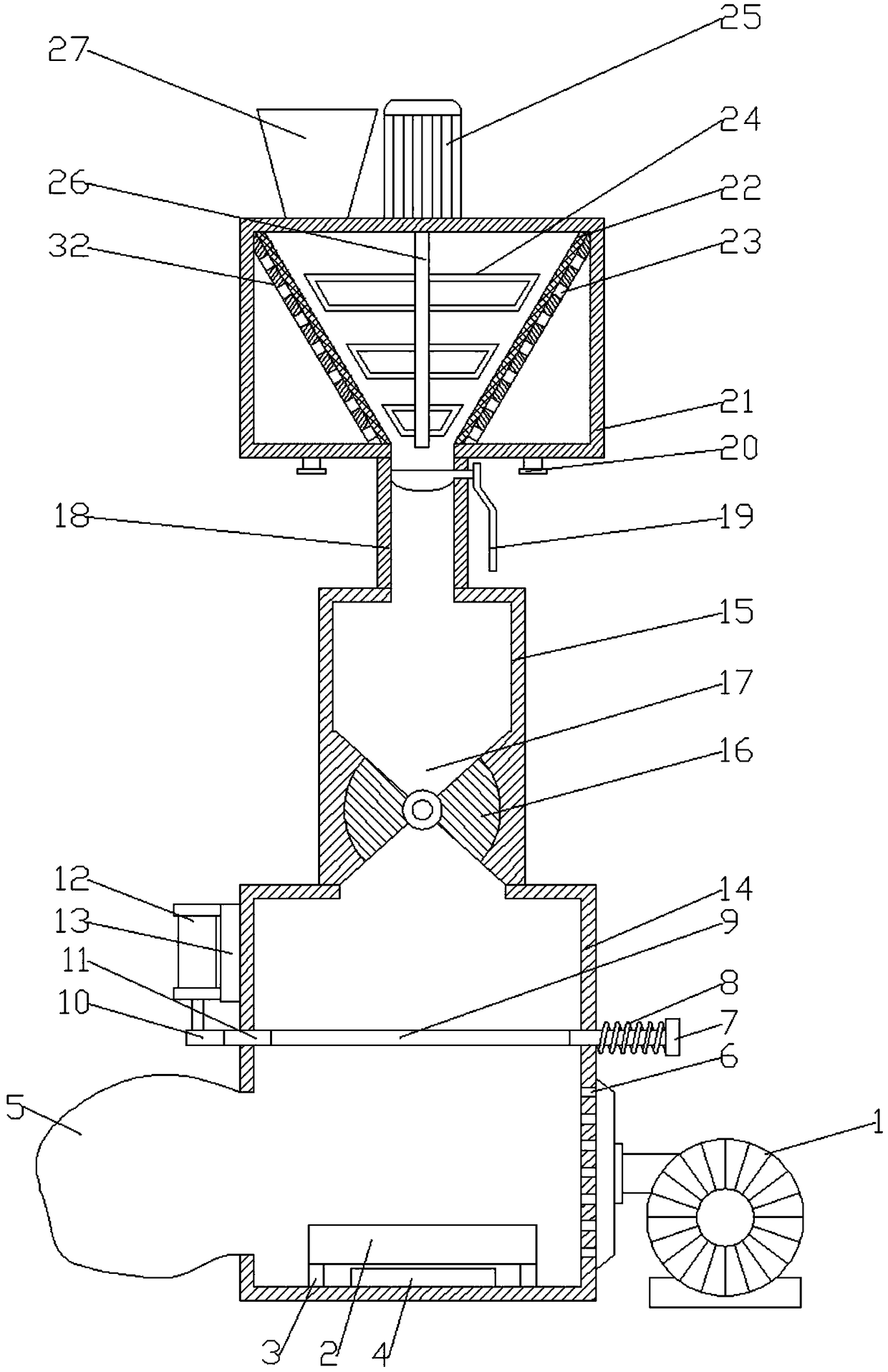

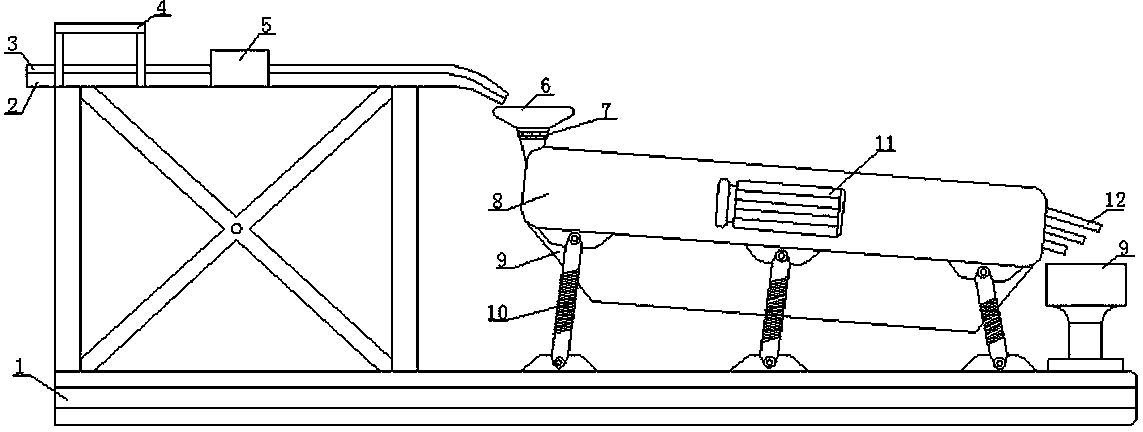

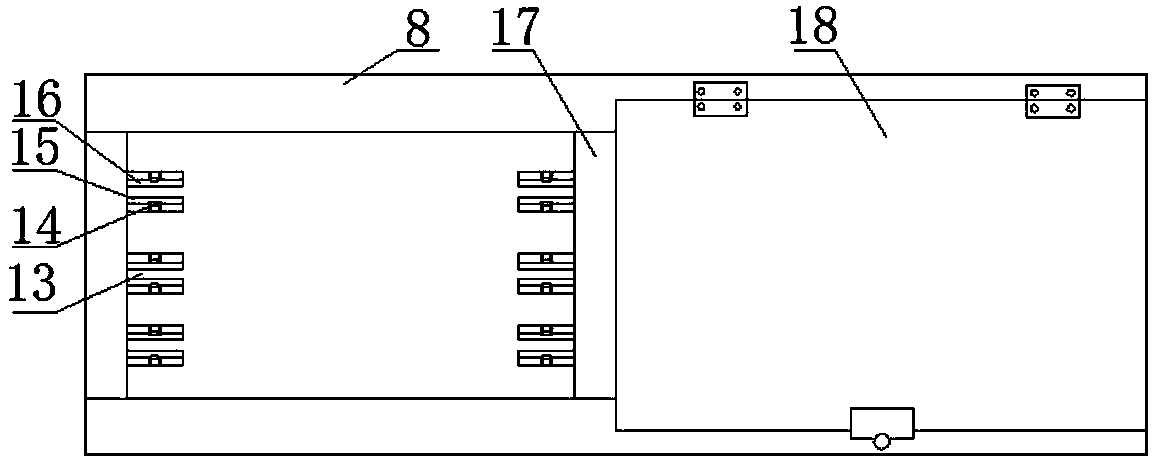

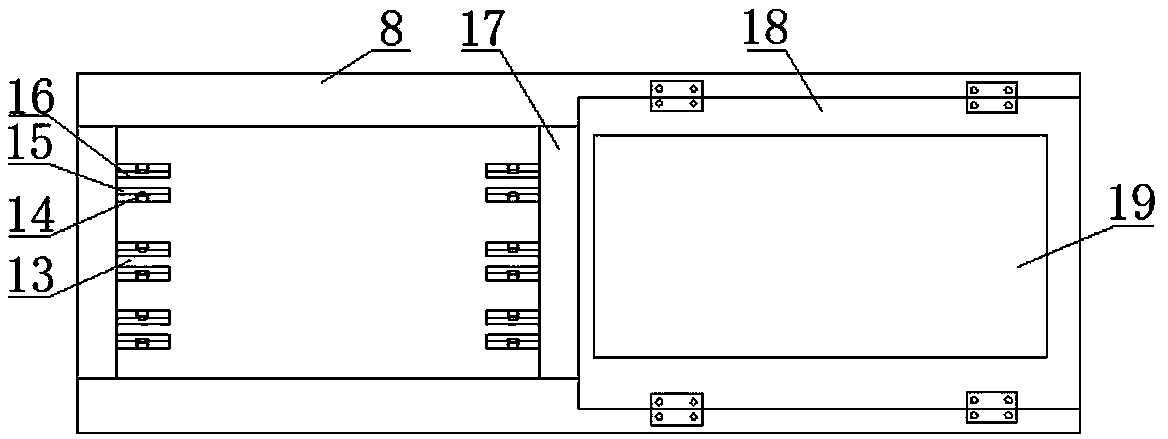

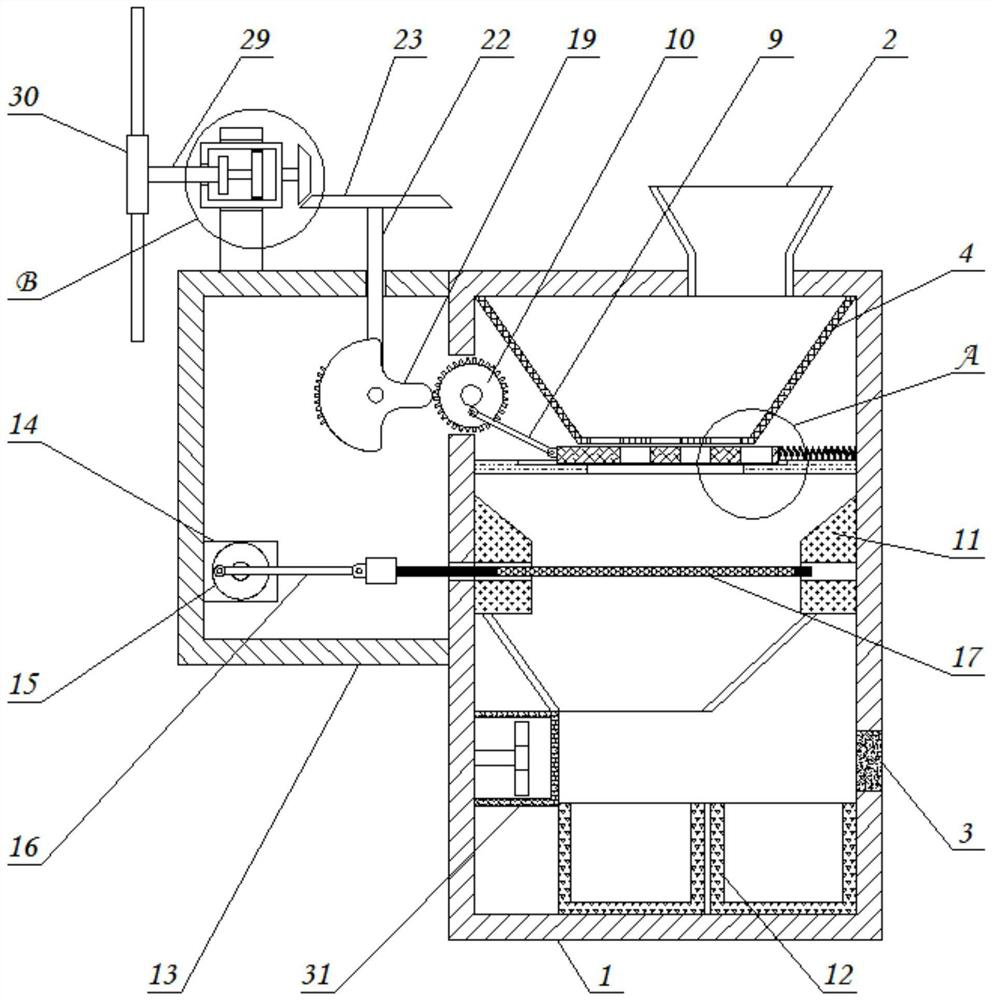

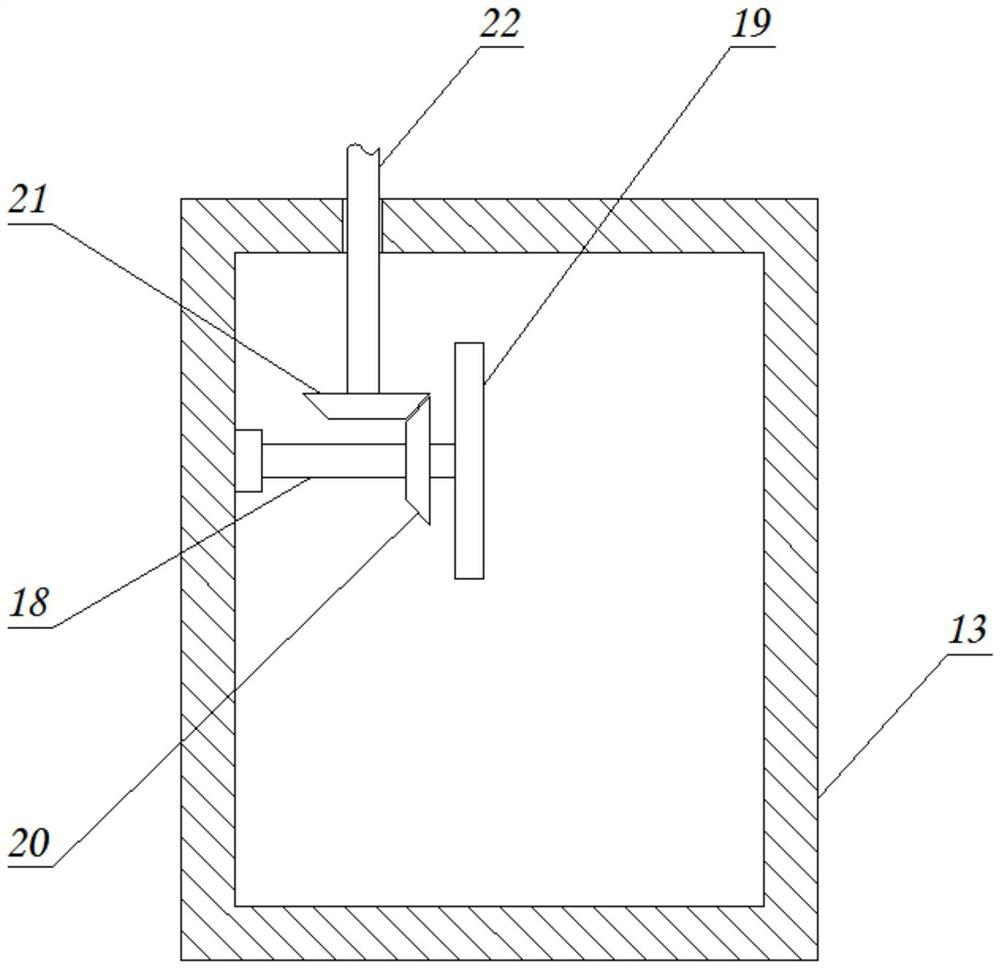

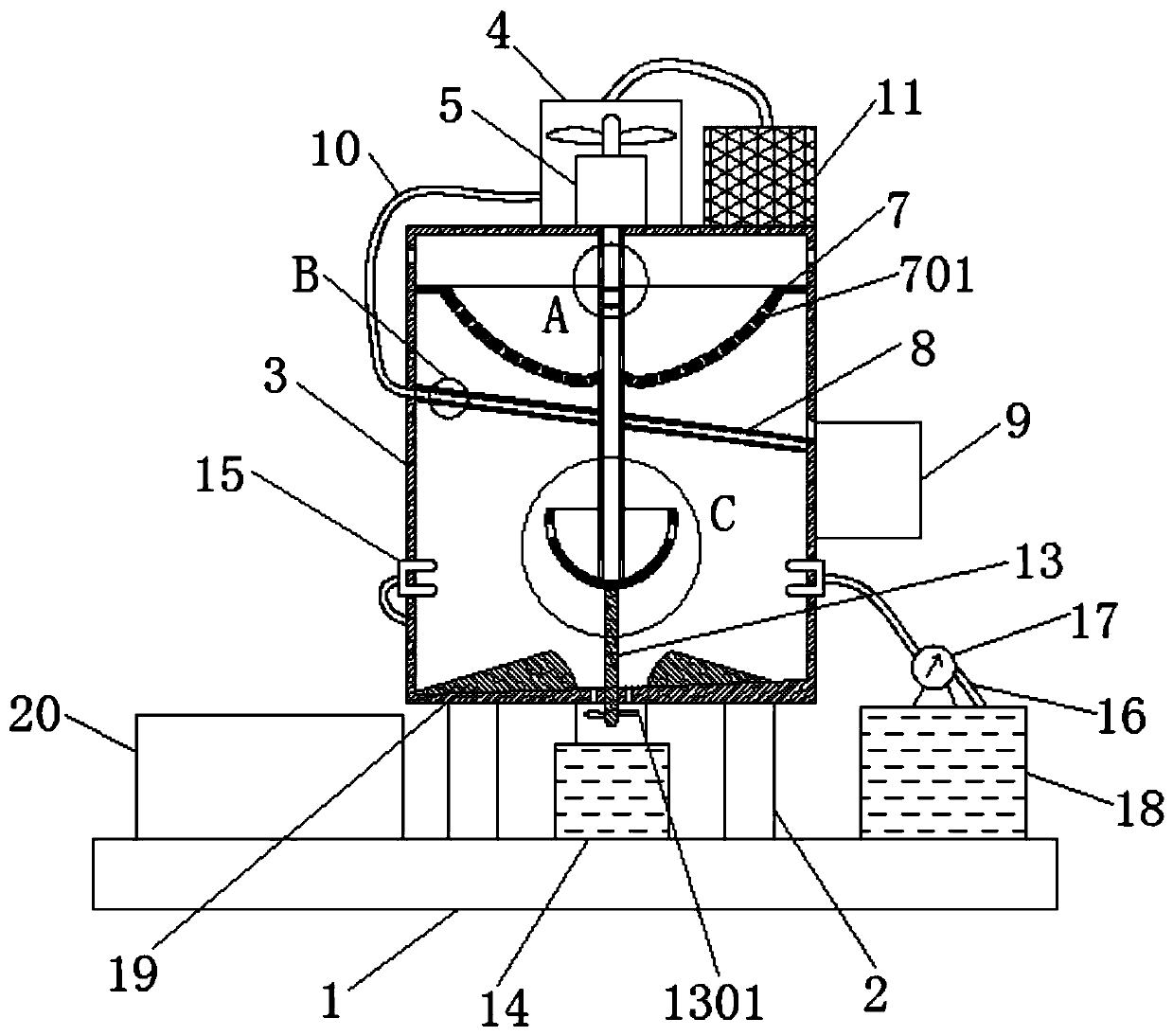

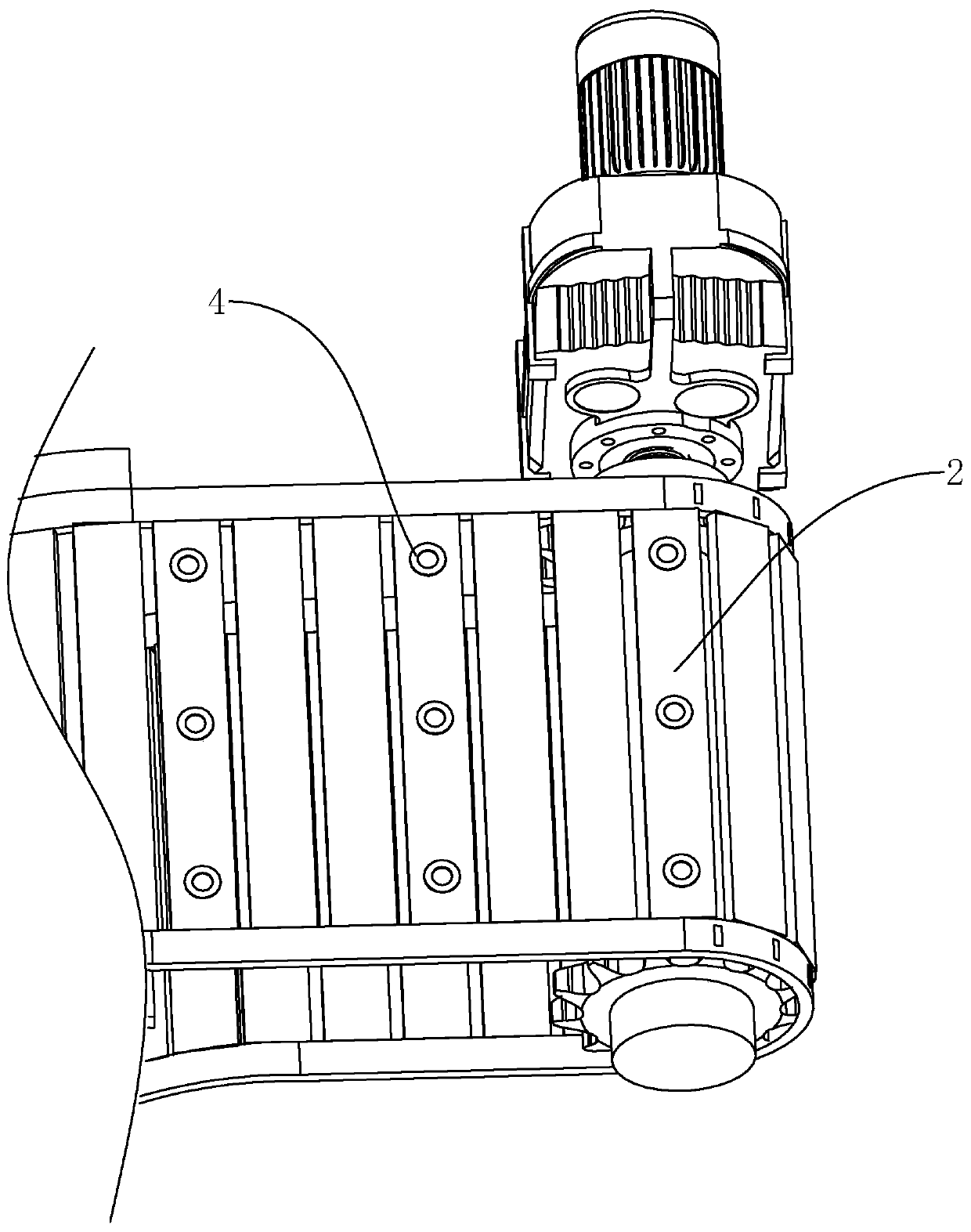

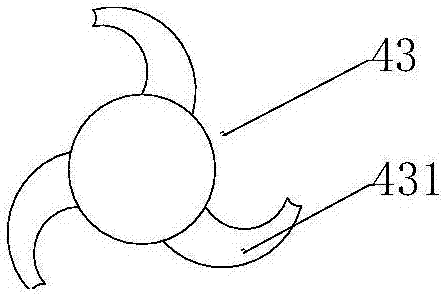

Sieving and drying device for metal powder

ActiveCN108889608ATo achieve the screening effectRealize quantitative screeningSievingTransportation and packagingScreening effectEngineering

The invention discloses a sieving and drying device for metal powder, include a hot air fan, sieve powder box, distribution box and dispersing box, An upper end of that dispersion box is provide witha motor 2 and a feeding port, A taper stirring drum is arrange in that dispersion box, the main shaft of the motor 2 is provided with a stirring shaft, the lower end of the conical stirring drum is provided with a blanking pipe, A low end of that blanking pipe is communicate with the distribution box, A control valve is arranged on the feeding pipe, A run wheel is arranged in the material distribution box, two grooves are symmetrically arranged on the runner, the upper end side of the sieve powder box is provided with a mounting seat, A motor 1 is arranged on the mounting seat, the main shaftof the motor is provided with an eccentric wheel, A screen net frame is arranged in the screen powder box, a screen net is arranged on the inner side of the screen net frame, a bracket is arranged onthe bottom of the screen powder box, and a recovery box is arranged on the upper end of the bracket. The device realizes the quantitative screening of the powder, ensures the screening effect and efficiency of the screen net, and the treated powder contains less impurities and the water content of the powder is low.

Owner:芜湖市晨睿建材有限公司

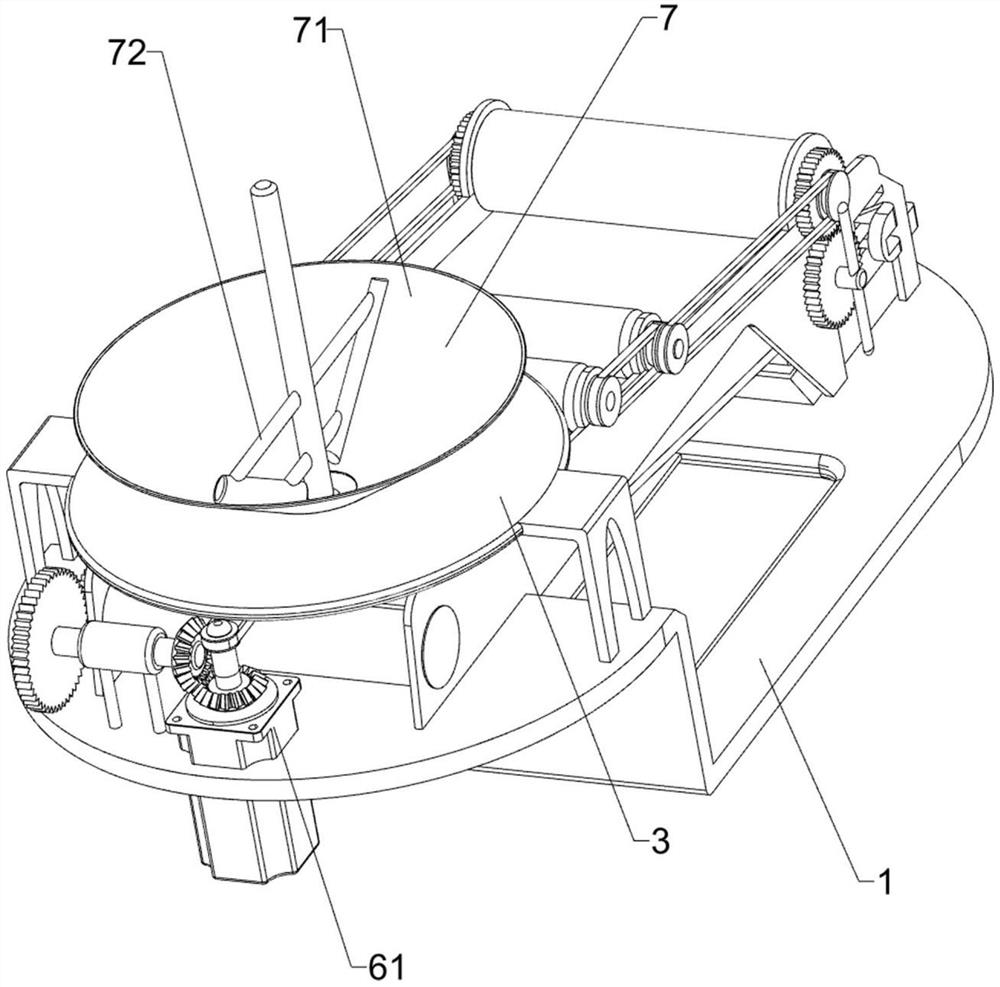

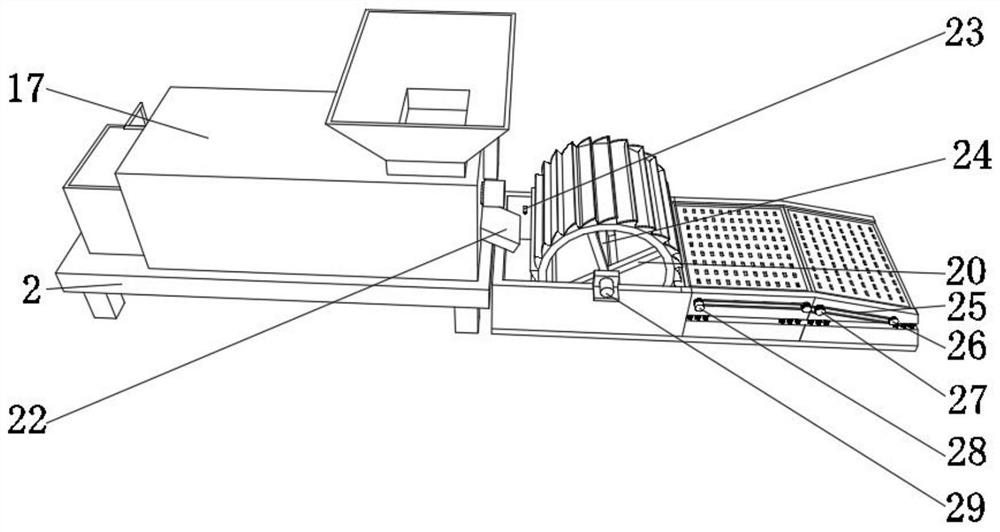

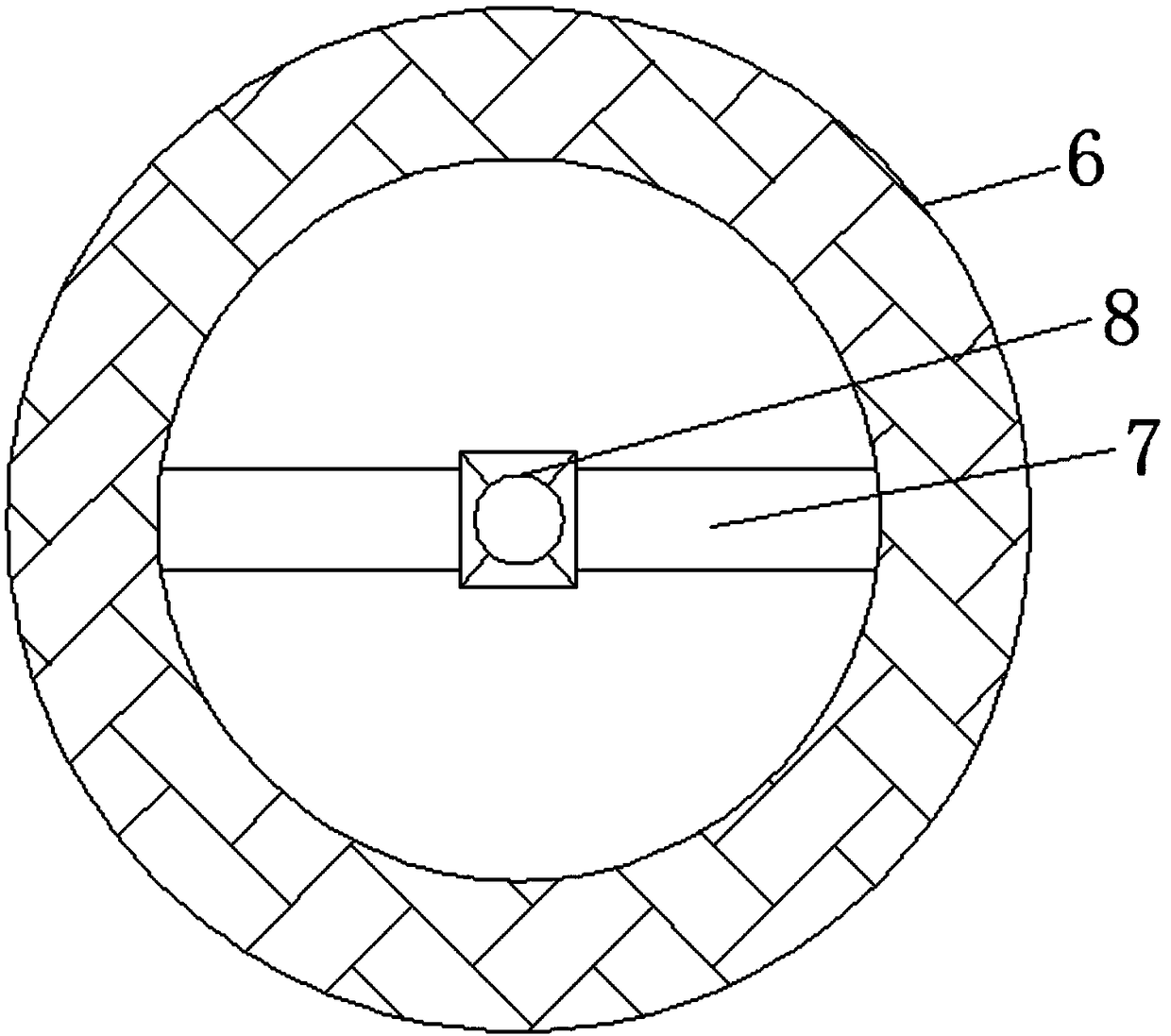

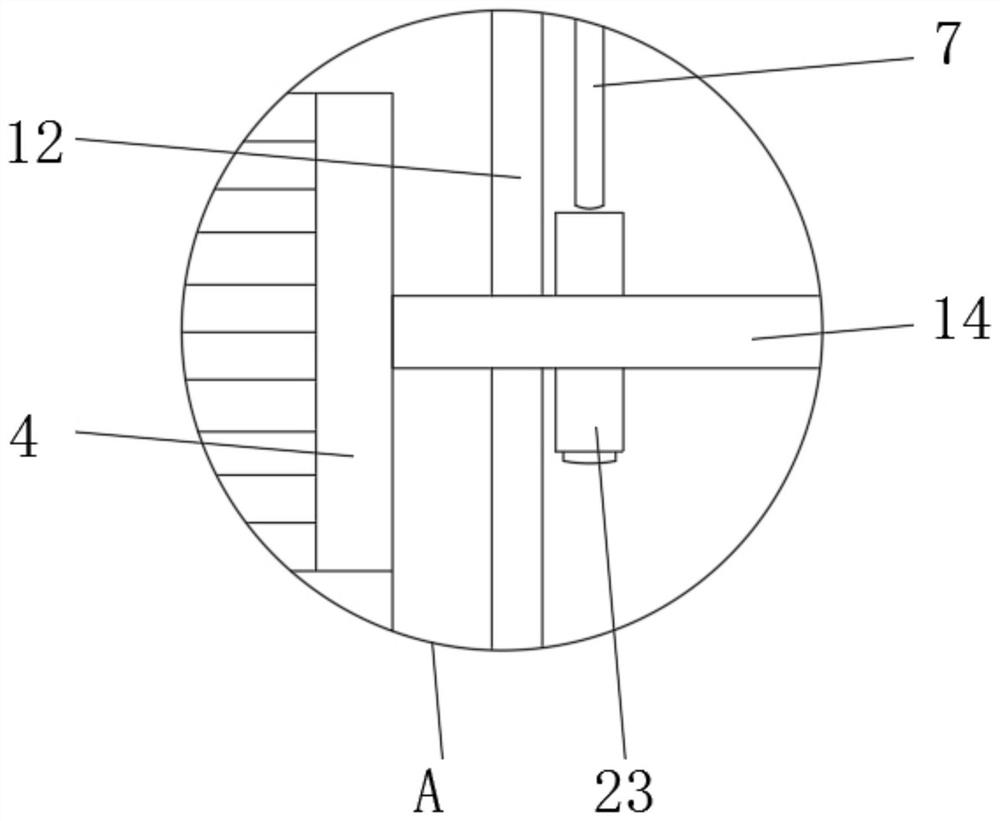

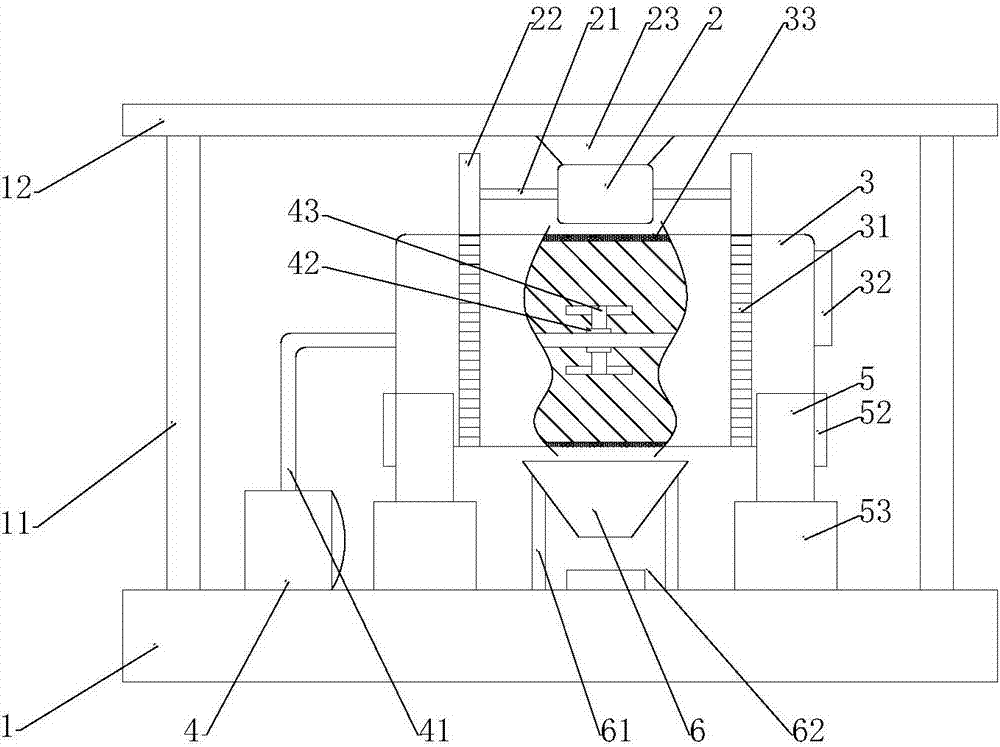

Agricultural apricot kernel shell breaking equipment

PendingCN112006292ATo achieve the screening effectImprove filtering effectSievingScreeningCircular discAgricultural engineering

The invention relates to shell breaking equipment, in particular to agricultural apricot kernel shell breaking equipment. The technical problem to be solved is to provide the agricultural apricot kernel shell breaking equipment capable of breaking shells of apricot kernels in batches and screening powder generated after the shells of the apricot kernels are broken. The agricultural apricot kernelshell breaking equipment comprises a bottom plate, a servo motor and a rotating disc; one side of the top of the bottom plate is fixedly connected with a supporting frame; the servo motor is mounted at the top of the support frame; and the rotating disc is connected to an output shaft of the servo motor. The effects that apricot kernels can be broken in batches, and powder generated after the apricot kernels are broken can be screened are achieved, under cooperation of a third rotating rod and a wedge-shaped block, a discharging frame can be driven to continuously move front and back, and under the action of a vibration box and a movable ball, the screening effect of the discharging frame is better.

Owner:温海辉

Clean production process of jasmine tea

The invention discloses a clean production process of jasmine tea. The process mainly comprises the steps of curing fresh flowers, scenting, cleaning, holding out of scented flowers, baking, conveying while vibrating, and packaging. The jasmine tea prepared by adopting the process is long-lasting in aroma, fresh, rich and mellow in taste and clear, and yellow and bright in color of soup. The fresh flowers are cured, scented and cleaned on an operation platform, so that the cleanness of the jasmine tea can be ensured and the grade of the jasmine tea can not be influenced.

Owner:四川省炒花甘露茗茶有限公司

Fry screening device for aquaculture

ActiveCN111869611ATo achieve the screening effectSave human effortClimate change adaptationPisciculture and aquariaEngineeringDrainage tubes

A fry screening device for aquaculture comprises a frame body, two bearing seats, a driving device and a pushing device, wherein the bottom of the frame body is connected with a drainage pipe; the twobearing seats are connected to the two sides of the top of the frame body respectively, and a screen is rotationally connected between the bearing seats on the two sides; the driving device is arranged between the frame body and the screen; and the pushing device is arranged on the frame body. Fry is screened through cooperative operation of the driving device, the pushing device and the screen,and therefore the effect of screening the fry is achieved; the pushing device is assisted to operate through a transmission device, the pushing device does not need to be manually operated to operate,and manpower is effectively saved; and when the fry screening device is operated, the screen can conduct comprehensive screening in the frame body, the screening effect is guaranteed, and the technical problems existing in above patents are effectively solved.

Owner:湖北大场科技有限公司

Gravel screening device for buildings

InactiveCN106955835AStir wellTo achieve the screening effectSievingScreeningSand filterAgricultural engineering

Owner:翁帆安

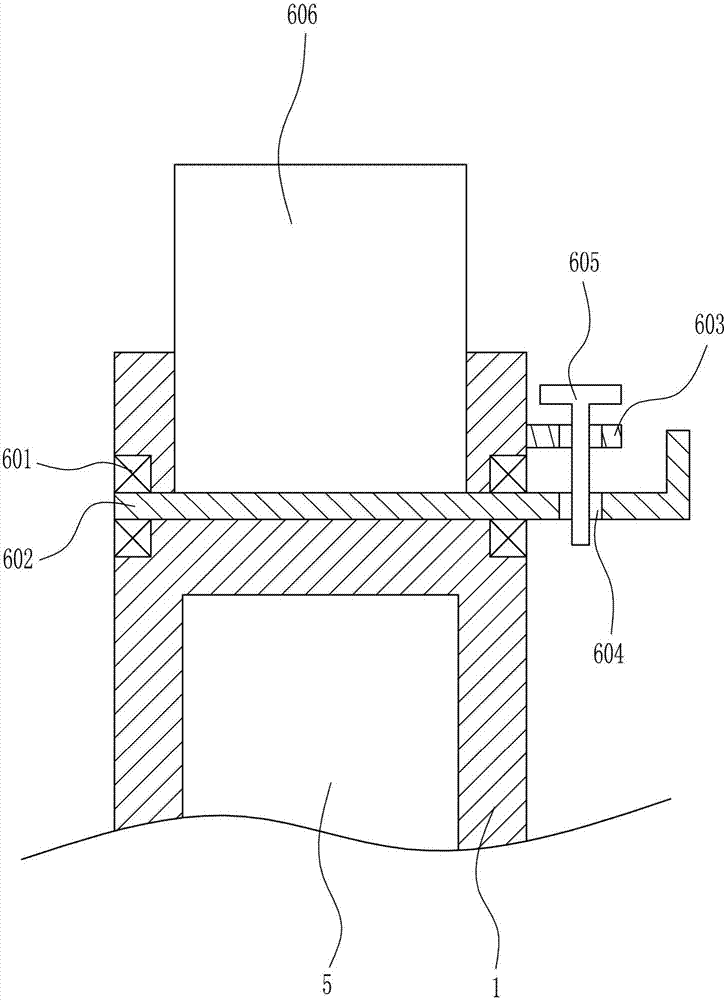

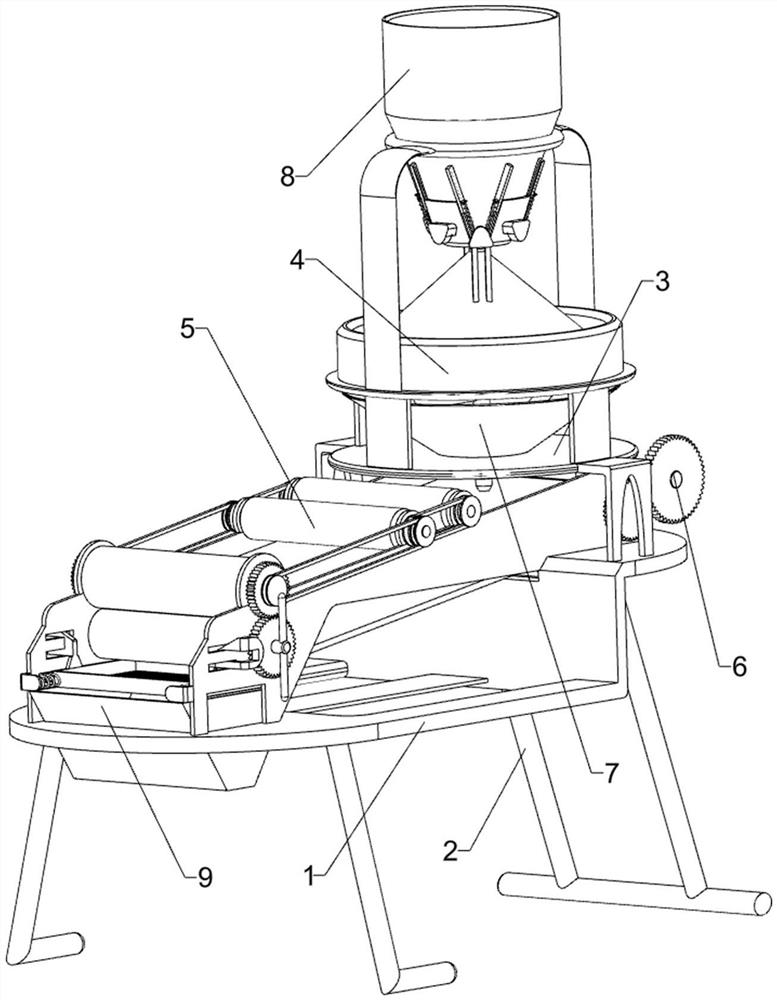

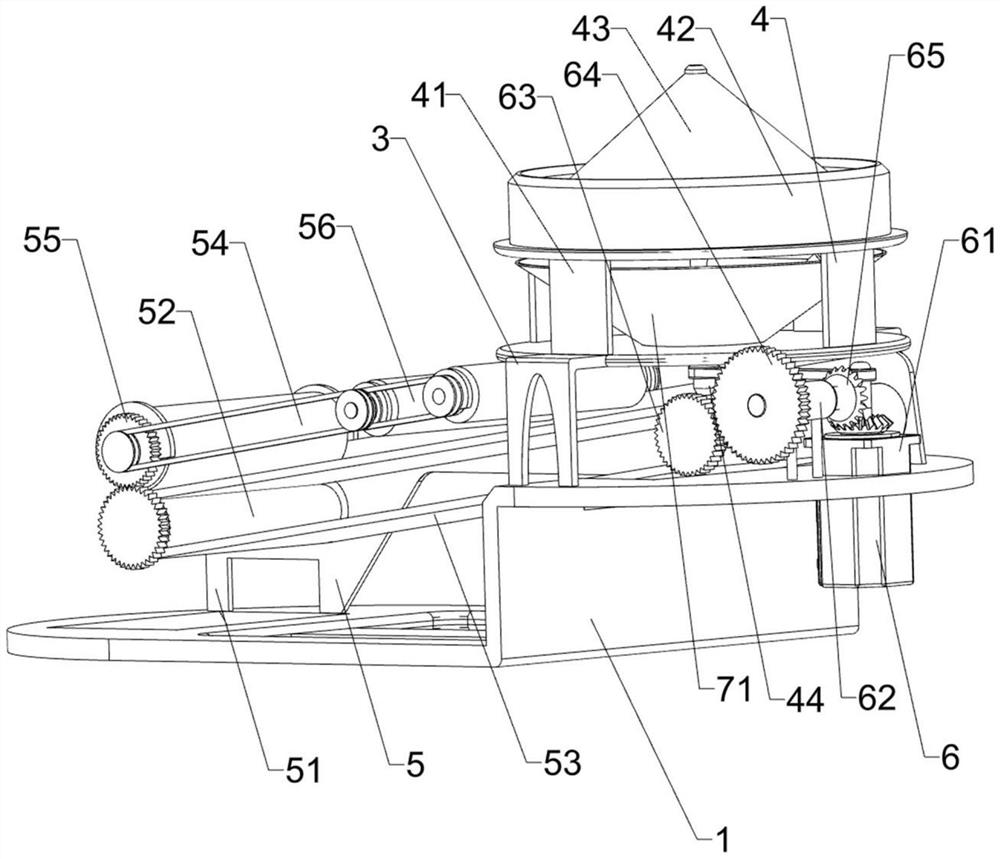

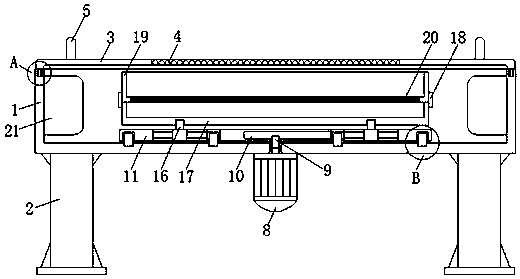

Raw material screening device for pet solid food production

ActiveCN112354617AEasy to operateImprove work efficiencyPlastic recyclingGrain treatmentsEngineeringMechanical engineering

The invention relates to a screening device, in particular to a raw material screening device for pet solid food production. According to the raw material screening device for pet solid food production, operation is easy, the working efficiency can be improved, and manpower is saved. The raw material screening device for pet solid food production comprises a mounting plate, a connecting disc, a grinding disc mechanism, a crushing mechanism, a transmission mechanism and a material guide mechanism, wherein a supporting rod is connected to the bottom of the mounting plate; the connecting disc isconnected to one side of the top of the mounting plate; the grinding disc mechanism is arranged on the connecting disc; the crushing mechanism is arranged on the mounting plate; the transmission mechanism is arranged on the mounting plate, and the transmission mechanism is in transmission connection with the crushing mechanism and the grinding disc mechanism; and the material guide mechanism is arranged on the connecting disc. The grinding disc mechanism, the crushing mechanism, the transmission mechanism and the material guide mechanism are matched to operate to crush raw materials for makingdry pet materials.

Owner:吉安诺冠企业管理咨询有限公司

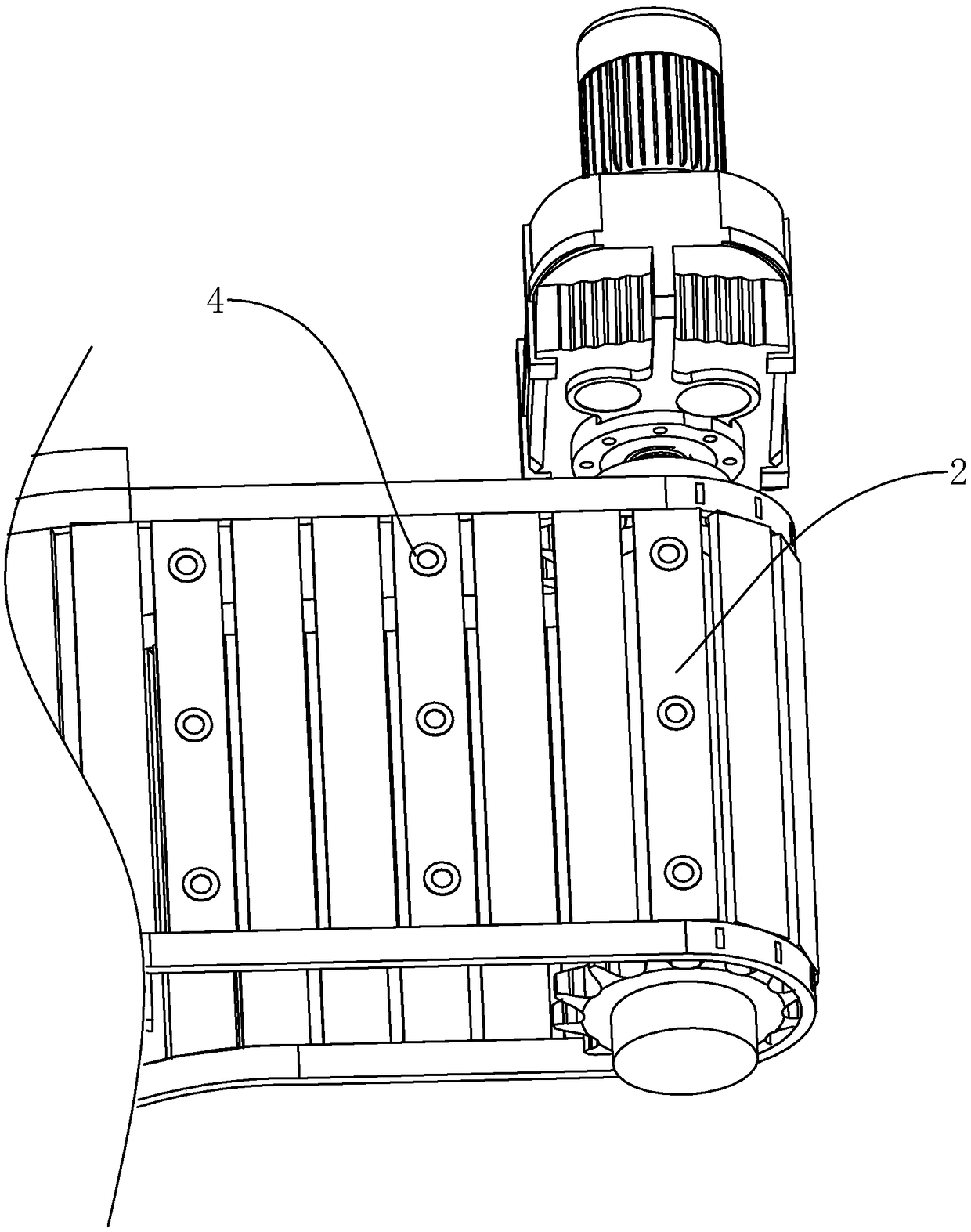

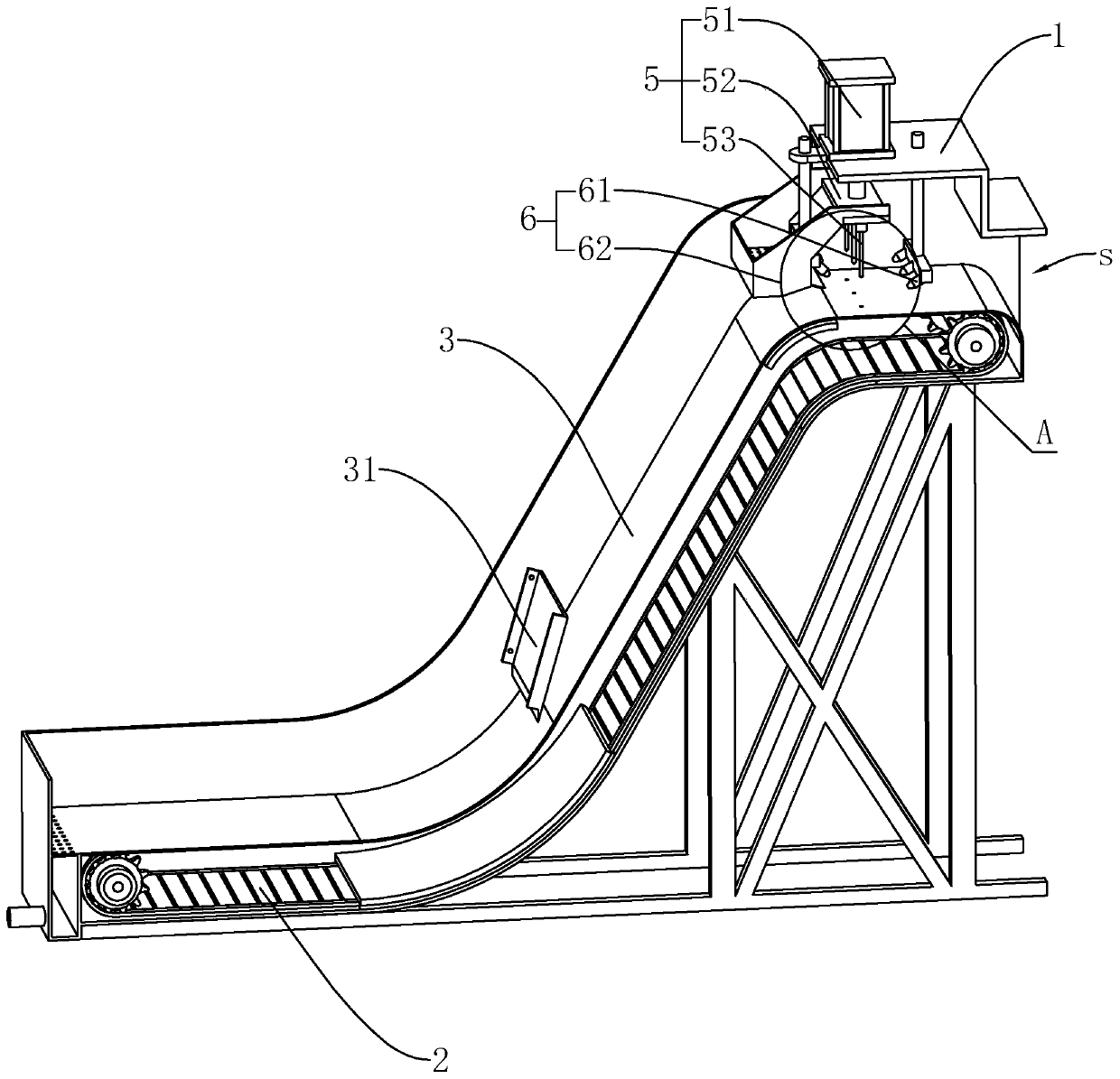

Feeding device used for cold header

ActiveCN109226656AWill not polluteWon't hinderCleaning using gasesMagnetic separationAir compressorMetal dust

The invention relates to the technical field of cold headers, and aims at providing a feeding device used for a cold header. The device comprises a rack, a conveying belt and a conveying groove; a plurality of magnets are arranged on the conveying belt at intervals; the conveying groove is formed in the upper portion of the conveying belt, and the bottom of the conveying groove fits the magnets onthe conveying belt; a limiting mechanism and a cleaning mechanism are arranged on the parts, above the discharging end, of the rack; the limiting mechanism comprises a downward pressing air cylinderand downward pressing members, and the positions of the downward pressing members correspond to the magnets; the cleaning mechanism comprises a cleaning nozzle connected with an air compressor. According to the feeding device, the conveying belt and conveyed fastening members are separated by using the conveying groove, the fastening members are driven to move by using the absorbing effect of themagnets separated by conveying groove so that metal dust and lubricating oil can completely fall in the conveying groove, the environment is not polluted, the cleaning of the conveying groove is convenient, the interior of the conveying groove has no gap and pit, the metal dust cannot be accumulated, the conveying of the fastening members is not blocked, and therefore the conveying is more stable.

Owner:ZHEJIANG QIANGLI FASTENER CO LTD

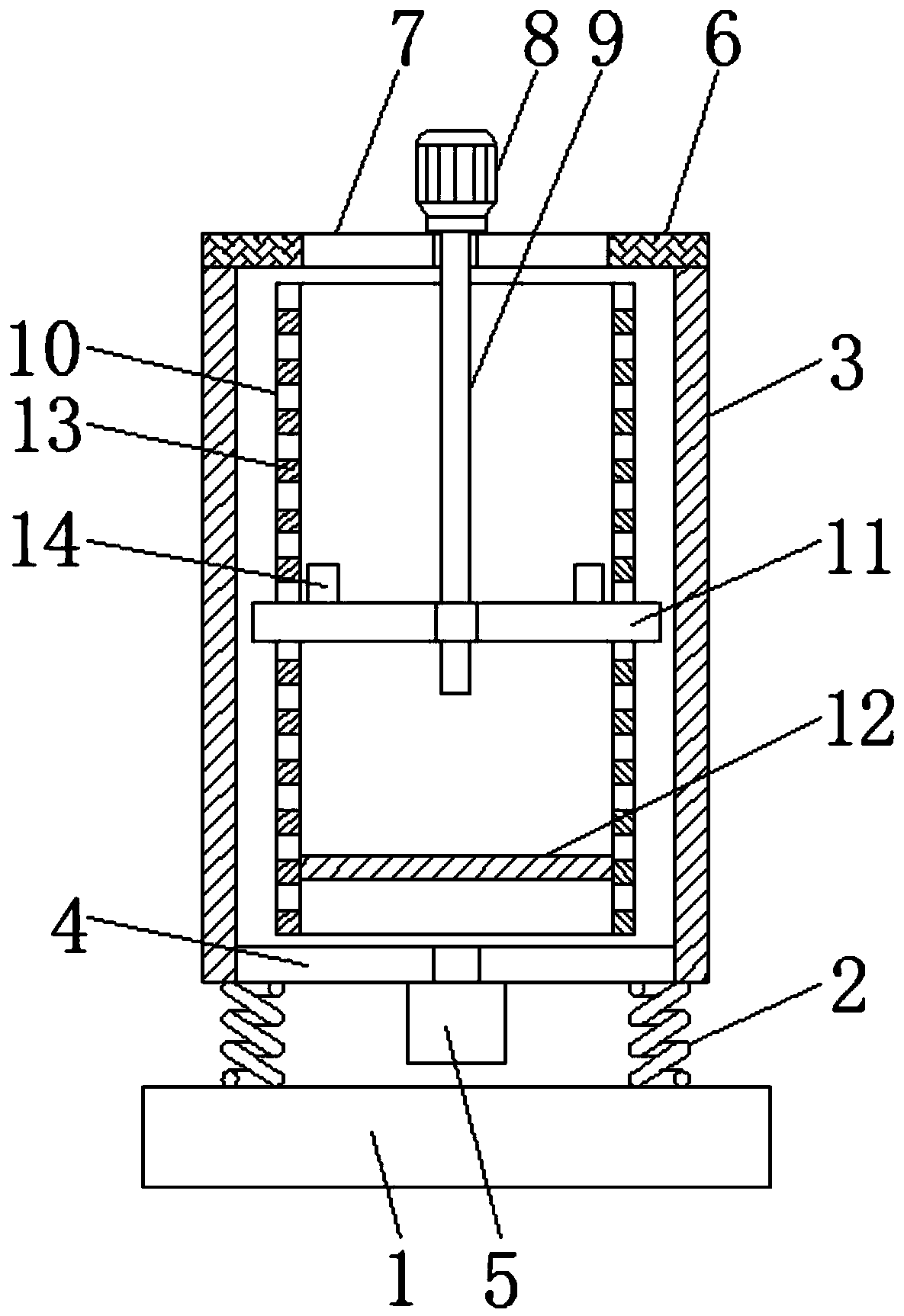

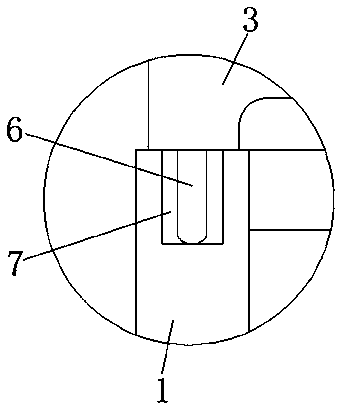

Traditional Chinese medicine mask powder crushing equipment

ActiveCN110124784ATo achieve the screening effectTo achieve anti-blocking effectSievingScreeningBiochemical engineeringWaste material

The invention relates to crushing equipment, in particular to traditional Chinese medicine mask powder crushing equipment. The crushing equipment is characterized in that a sieve tray and a rectangular barrel can slide back and forth at the same time, the sieve tray can slide back and forth in a reciprocating manner so as to achieve the screening effect, meanwhile, front-back reciprocating slidingof the rectangular barrel achieves the anti-blocking effect, and then the anti-blocking and screening effects are achieved at the same time; a collecting tray and the sieve tray can be inclined at the same time, powder can be poured out when the collecting tray is inclined, and screened impurities are poured out when the sieve tray is inclined, so that waste materials and finished products are discharged separately; and an electric telescopic rod is fixedly connected to a bottom rod, one end of the collecting tray is connected to one end of the bottom rod in a hinged mode, the electric telescopic rod is arranged on the lower side of the collecting tray, a door-shaped frame is fixedly connected to the collecting tray, the sieve tray can slide back and forth on the door-shaped frame in a reciprocating mode, a sieve plate is arranged on the sieve tray, a clamping plate is fixedly connected to the sieve tray, the sieve tray is positioned above the collecting tray, the lower end of a rectangular support is fixedly connected to the bottom rod, and the rectangular barrel can slide back and forth on the upper end of the rectangular support in a reciprocating manner.

Owner:滨州富创科技服务有限公司

Powder coal screening device

InactiveCN106824770ATo achieve the screening effectImprove screening efficiencySievingScreeningScreening effectEngineering

The invention discloses a powder coal screening device. The powder coal screening device comprises a frame. The upper end of the frame is provided with an air pipe for delivering coal. The upper end of the frame is provided with a screen. The coal in the air pipe falls onto the screen. A collection tank is arranged under the screen. The left and right ends of the screen are both provided with air cylinders. Guide rods of the air cylinders are connected with the two ends of the screen. The screen is driven by the air cylinders to do reciprocating movement. According to the powder coal screen device, the air cylinders are arranged to drive the screen to do reciprocating movement so as to achieve the screening effect. Small coal falls into the collection tank. Big coal is left on the screen and is pushed by a push plate to go into a recycling tank. The powder coal screening device is simple in structure, convenient to operate and low in screening cost, and the screening efficiency is improved.

Owner:何健

Riverway floating garbage clearing device

InactiveCN112144493ATo achieve the screening effectReduce areaWater cleaningRiver routingDielectric plate

The invention relates to the technical field of riverway garbage clearing, and discloses a riverway floating garbage clearing device. The riverway floating garbage clearing device comprises a shell, wherein the top of the shell is sleeved with a feeding pipe, a light object cavity is formed in the middle part of the shell, and a heavy object cavity is formed in the middle part of the shell; a classification disc is movably connected to the inner wall of the feeding pipe, electromagnets are fixedly connected to the inner wall of the middle part of the feeding pipe, reset springs are fixedly connected to the inner wall of the middle part of the feeding pipe, magnetic blocks are movably connected to the inner wall of the middle part of the feeding pipe, and partition blocks are fixedly connected to the inner sides of the magnetic blocks; and pressing rods are fixedly connected to the outer side of the classification disc, and compression springs are fixedly connected to the outer sides ofthe pressing rods. According to the riverway floating garbage clearing device, the compression springs are driven by the pressing rods to move, transmission rods are driven by the compression springsto move, and then trigger rods and dielectric plates are used in cooperation, so that the effect of screening garbage with different weights is achieved; and the transmission rods drive torsion rodsto move, the trigger rods drive the dielectric plates to move when being extruded by force so as to change the relative area between positive plates and negative plates.

Owner:李宣霖

Disused bandage crushing device

The invention discloses a disused bandage crushing device. The device comprises a machine body, the top of the right side of the machine body is fixedly connected with a first motor through a supportplate, an output shaft of the first motor is fixedly connected with a driving gear, the surface of the driving gear is meshed with a driven gear, and a first rotating rod is welded to the axle centerof the left side of the driving gear. The device achieves the effect of crushing disused bandages through the cooperation of the first motor, the driving gear, the driven gear, the first rotating rodand a second rotating rod, through the cooperation of a telescopic rod, a sieve plate, a screen, a spring, a transverse plate, a second motor, a swinging rod, a turntable, a movable belt, a rotating wheel, a rotating shaft and a vertical plate, the effect of screening the disused bandages is achieved, thereby performing the effect of secondary crushing and achieving the advantage of good crushingeffect on the bandages, and convenience is brought to the work of medical staff, which helps to improve the environment.

Owner:王绪武

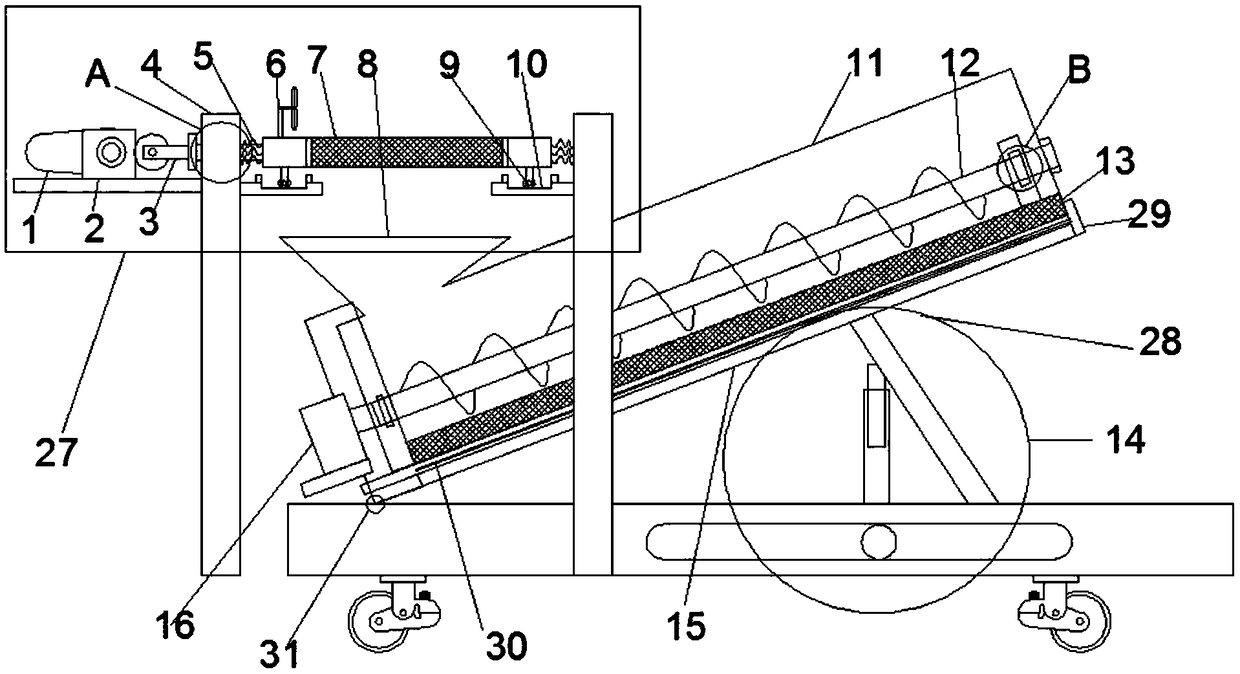

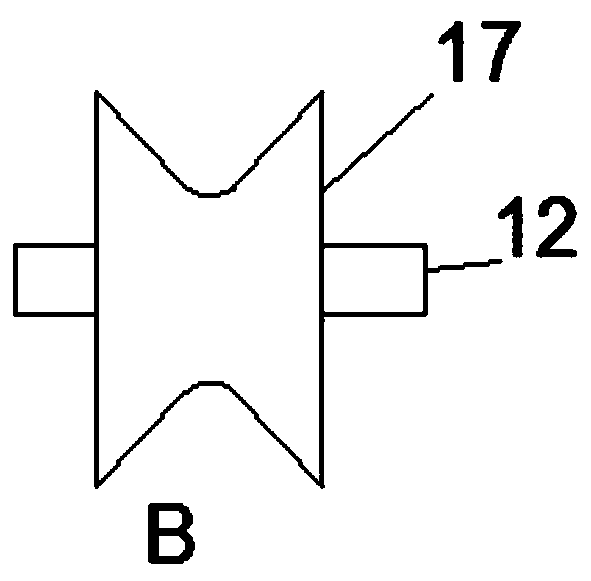

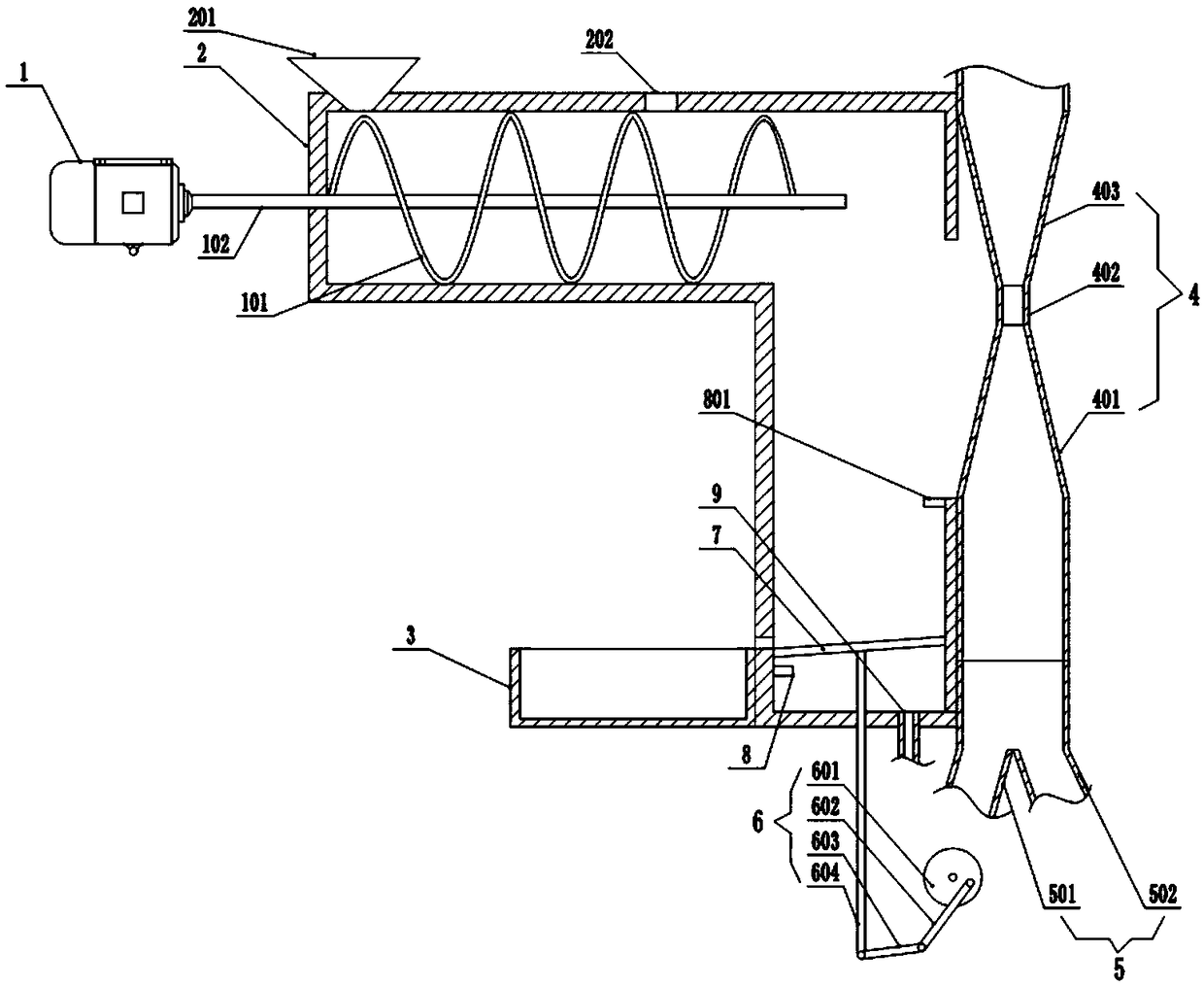

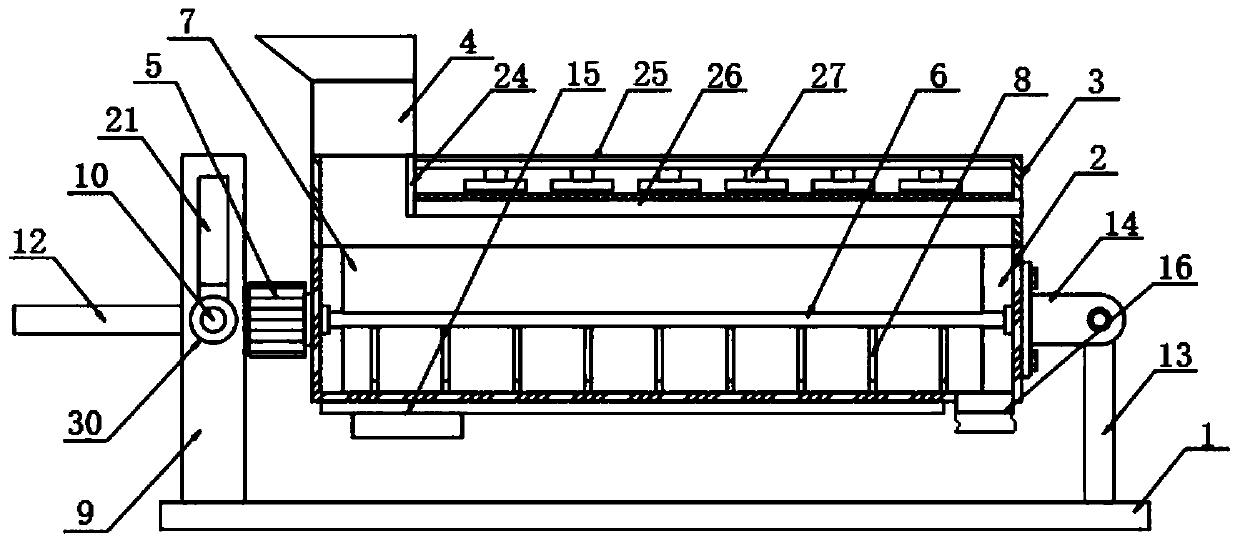

Conveying equipment for grain dryer

The invention discloses conveying equipment for a grain dryer. The conveying equipment for the grain dryer comprises screening equipment, conveying equipment and a lifting device, wherein a push rod is arranged in the middle of the left end of a first sieve plate; a cam is arranged on the left side of the push rod; a feed inlet is formed right under the first sieve plate; the conveying equipment is arranged under the feed inlet and comprises a transfer bin and a screw shaft; the screw shaft is arranged in the transfer bin; a second sieve plate is arranged under a screw blade; a screw rod is arranged in a cleaning door; a base is arranged at the lower end of the transfer bin; the transfer bin is rotatably connected with the base through a rotary shaft; and the lifting device is arranged atthe lower end of the transfer bin. In order to meet the requirements of different dryers, a designer designs the conveying device to be freely liftable, and a user can further horizontally place the device so as to maintain and clean the inner part of the transfer bin when sliding an outer cover; and in order to move conveniently, universal wheels are arranged on the base, so that the device is nolonger limited by a fixing form.

Owner:东莞穗丰粮食集团有限公司

Food raw material screening and drying device

InactiveCN108435526AAchieve the effect of putting in the filter trayDry evenlySievingScreeningEngineeringRaw material

The invention discloses a food raw material screening and drying device. The device comprises a main body box, a screening disc and a protective box; a feed port is mounted at the upper end of the main body box; the protective box is fixedly mounted on the end inner wall of the lower end of the main body box; an inclined plate is fixedly mounted at the upper end of the protective box; a stand column is fixedly mounted in the protective box; a driven gear is rotationally mounted at the upper end of the stand column through a rotating shaft; a motor is mounted in the motor box; an output shaft of the motor penetrates through the inner wall of the motor box, and a driving gear is rotationally mounted; a chute is formed in the inner wall of the main body box; slide blocks are fixedly mounted on the two sides of the screening disc; screen plates, symmetrically distributed about the screening disc, are rotationally mounted on the two sides of the bottom end of the screening disc; a limitingplate is fixedly mounted on the upper end surface of the screening disc; a heating pipe is fixedly mounted on the inner wall of the upper end of the main body box through a fixed block; and the heating pipe is positioned above the screening disc. The device has the advantage of capability of drying during screening.

Owner:海宁市立派商贸有限公司

Concrete recovery sand-stone separation device for constructional engineering

PendingCN112317123AAchieve dehydration effectImprove filtering effectMechanical material recoveryWet separationArchitectural engineeringElectric machinery

The invention discloses a concrete recovery sand-stone separation device for constructional engineering, and relates to the technical field of gravel separation. In order to solve the problem of finesand water removal, the device specifically comprises a base and a sedimentation tank, a box body is fixed to the top of the base through bolts, a water tank is fixed to the outer wall of one side ofthe box body through bolts, a feeding hopper is fixed to the top of the box body through threads, a stone outlet and a sand outlet are fixed to the outer wall of one side of the box body through threads, and a controller is fixed to the outer wall of one side of the box body through bolts; and an alarm is fixed to the outer wall of the top of the controller through bolts, a separation mechanism isarranged in the box body, a flushing mechanism is arranged on the inner wall of the top of the box body, and a discharging pipe is fixed to the outer wall of one side of the box body through threads.A second motor is started, so that the output end of the second motor drives a connecting rod to rotate, a rotary drum and a filtering frame can be driven to rotate through a fixing rod, mud enters the filtering frame through rotation of the rotary drum, and the mud is dewatered due to gravity.

Owner:魏雪

Screening and dedusting device for rapeseed oil production and processing

InactiveCN108940874AHigh efficiency in removing impuritiesHigh degree of automationSievingGas current separationMotor driveBiochemical engineering

The invention discloses a screening and dedusting device for rapeseed oil production and processing, and relates to the technical field of rapeseed oil production and processing. The screening and dedusting device for rapeseed oil production and processing comprises a base, wherein a spring is fixedly connected to the top end of the base; a protection barrel is arranged above the base; a support rod is fixedly arranged at the bottom end of the protection barrel; the top end of the spring is fixedly connected with the bottom part of one end, far away from the center of the protection barrel, ofthe support rod; and a vibrator is fixedly arranged in the middle of the bottom end of the support rod. According to the screening and dedusting device for rapeseed oil production and processing, through the cooperative arrangement of a fixed rod and a screening barrel, when a motor drives a rotary shaft to rotate, the fixed rod can drive the screening barrel to rotate, so that impurities with larger weight in rapeseeds are separated from through holes, the impurity removal efficiency is high, and the device is simple to operate and high in automation degree.

Owner:湖州金丰粮油有限公司

Environment-friendly agricultural screening equipment

InactiveCN108212753APromote environmental protectionEfficient collectionSievingDispersed particle filtrationScreening proceduresAgricultural engineering

The invention discloses environment-friendly agricultural screening equipment, and relates to the technical field of screening equipment. The environment-friendly agricultural screening equipment comprises a tank. Support legs are fixedly connected with the bottom of the tank, a tank cover is lapped on the top of the tank, a filter screen is embedded in the top of the tank cover, the bottom of thefilter screen penetrates the bottom of the tank cover, handles are fixedly connected with two sides of the top of the tank cover, four connecting blocks are fixedly connected with two sides of the bottom of the tank cover, and connecting grooves are formed in two sides of the top of the tank. The environment-friendly agricultural screening equipment has the advantages that a scrap collecting boxis arranged in the tank, screen cloth and a screening box are matched with each other, and accordingly scrap and dust which are generated in screening procedures can be effectively collected in the scrap collecting box; a motor is arranged at the bottom of the tank, a rotary rod, an eccentric turntable and a frame are matched with one another, and accordingly the motor can be operated to drive theeccentric turntable to rotate.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

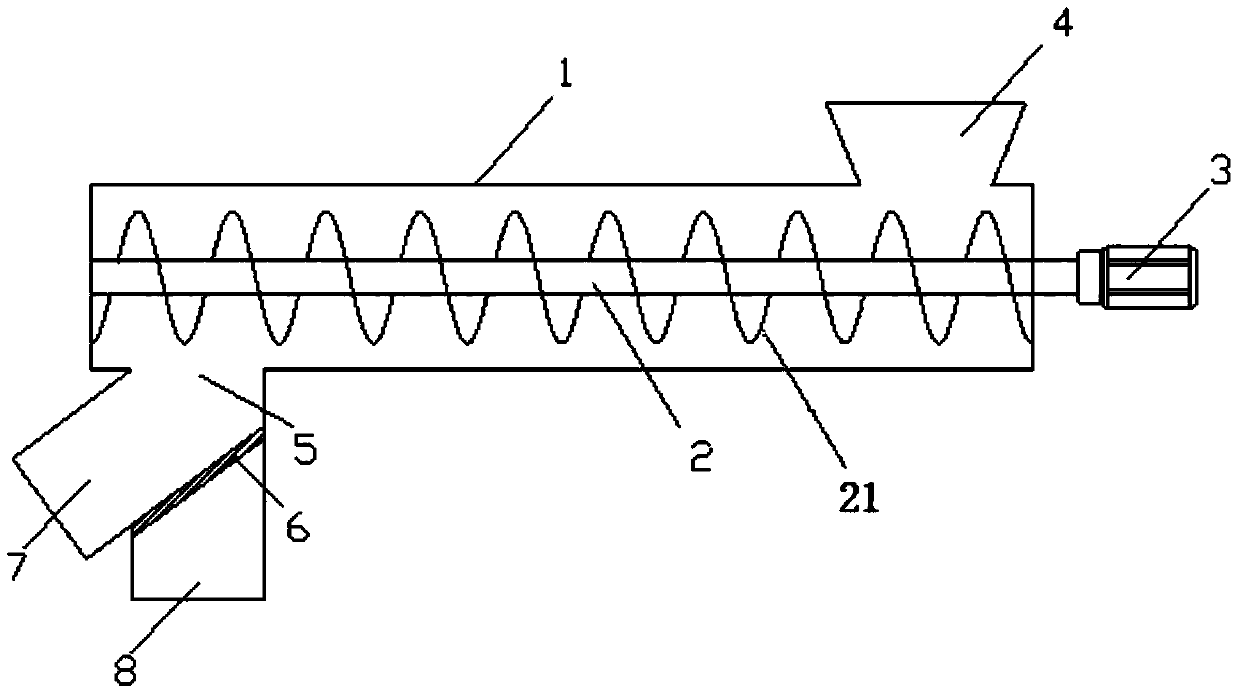

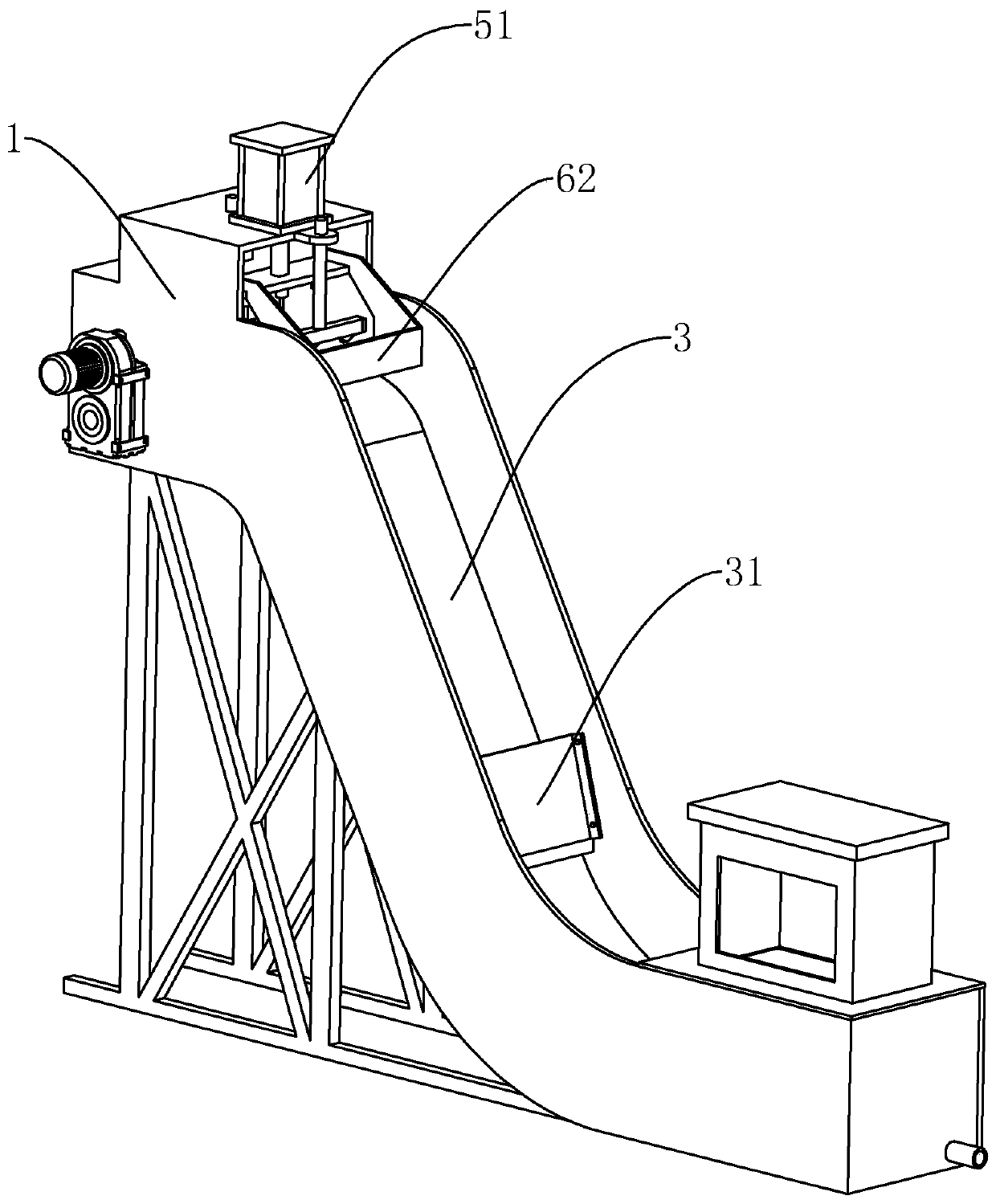

Expanding agent clinker granule sieving and conveying machine

InactiveCN104210814AReduce intermediate processEasy to processSievingScreeningElectric machineryProcess engineering

The invention discloses an expanding agent clinker granule sieving and conveying machine, which comprises a hollow tube housing, a spiral push shaft arranged inside the tube housing and a variable frequency motor for driving the spiral push shaft to rotate around the axis of the variable frequency motor, wherein the tube housing is overlapped with the axis line of the spiral push shaft, blades for pushing materials are arranged on the spiral push shaft and is of a spiral structure around the spiral push shaft, one end of the tube housing is provided with a feeding hole which is connected with a discharging hole of expanding agent clinker granule production equipment, and the other end of the tube housing is provided with a blanking hole; the bottom of the blanking hole is provided with a first discharging hole vertically downward and a second discharging hole obliquely downward, wherein the bifurcation of the first discharging hole and the second discharging hole is provided with an oblique sieve. The expanding agent clinker granule sieving and conveying machine can be arranged at the discharging hole of the expanding agent clinker granule production equipment and is used for directly sieving clinker granules, the sieved small-size clinker granules can be directly ground without being crushed, and thus the production efficiency is improved and the production cost of an expanding agent is lowered.

Owner:HUZHOU FENGSHENG NEW MATERIAL

Wind energy-based efficient wheat screening device capable of automatic feeding

InactiveCN111921851APrevents reduction in screening efficiencyLow costSievingGas current separationAgricultural engineeringMechanical engineering

The invention relates to the technical field of wind energy utilization and discloses a wind energy-based efficient wheat screening device capable of automatic feeding. The wind energy-based efficientwheat screening device capable of automatic feeding comprises a box body. Material-containing plates are fixedly connected to the inner top wall of the box body. A fixed plate is fixedly connected inside the box body. A movable plate is movably connected to the top of the fixed plate. A power box is fixedly connected to the left side of the box body. A spiral spring is arranged above the power box. A fourth rotary shaft is rotatably connected to the left side of the spiral spring. A big fan is fixedly connected to the left side of the fourth rotary shaft. A small fan is fixedly connected to the inner left wall of the box body. According to the wind energy-based efficient wheat screening device capable of automatic feeding, the big fan is driven to rotate through wind power; force accumulation is conducted on the spiral spring through the fourth rotary shaft by the big fan, and then stable power is generated when the spiral spring loosens gradually by utilizing the elastic force of thespiral spring; the movable plate is driven to slide in a sliding groove in the top of the fixed plate through a transmission mechanism, and thus wheat is conveyed onto a screen mesh intermittently; and the wind power source is utilized, and in addition, the screening cost is also lowered.

Owner:唐永辉

Rapeseed oil processing and screening equipment

ActiveCN108993901AScreening efficiency is efficient and sufficientTo achieve the screening effectGas current separationFatty-oils/fats productionOil processingRapeseed

The invention discloses rapeseed oil processing and screening equipment. The rapeseed oil processing and screening equipment comprises a box body and a filtering device. A feeding inlet is formed in the intermediate position of the upper end of the box body, and a passage tube is connected to the lower end of the feeding inlet. Air inlets are formed in the left and right sides of the passage tube,and the upper end of the right side of the passage tube is connected with a buckle through a drawstring. A blowing chamber is formed in the left end of the left side air inlet, and a fan is arrangedin the blowing chamber. An air vent is inlayed in the left side of the box body, and the filtering device is arranged directly below the passage tube. When a user uses the rapeseed oil processing andscreening equipment, in order to ensure that oil is cleaner when the rapeseed oil is processed, a cleaning function is added on the basis of screening, so that rapeseed can be thoroughly cleaned, andan agitator can be disassembled through an internal thread of a moving plate; and after cleaning, standing is performed for a period of time, the surface floating objects are removed and water is drained. The rapeseed oil processing and screening equipment is more thorough in screening.

Owner:安庆市望马楼生态农业发展有限公司

Method of inoculating Ustilago scitaminea to tissue culture seedlings of sugarcane

InactiveCN110199709AIncreased chance of infection with smut fungus cane whipInoculation results are stableHorticulture methodsDefective mutantSpore

The invention discloses a method of inoculating Ustilago scitaminea to tissue culture seedlings of sugarcane. The method includes: with an injector, injecting a mixed spore suspension of '+' and '-' mated wild strains of Ustilago scitaminea and a mixed spore suspension of '+' and '-' mated mutant strains of Ustilago scitaminea respectively to inner parts, near growth spots, of the tissue culture seedlings of sugarcane, wherein the mixed spore suspension of the '+' and '-' mated strains is 1*107 per mL, 1 mL of the spore suspension is injected per seedling, and the tissue culture seedlings of sugarcane to be tested are tissue culture seedlings 35-45 cm in height. After Ustilago scitaminea is inoculated, origination is evident, operability is high, and pathogenicity test cycle is shortened;therefore, efficiency of screening Ustilago scitaminea pathogenic defective mutants is improved; technical support is provided for the identification and mechanism research on pathogenicity associatedgenes of Ustilago scitaminea; the method has important significance.

Owner:SUGARCANE RES INST GUANGXI ACADEMY OF AGRI SCI

A screening and drying device for metal powder

ActiveCN108889608BTo achieve the screening effectRealize quantitative screeningSievingRotary stirring mixersElectric machineStructural engineering

The invention discloses a sieving and drying device for metal powder, which comprises a hot air blower, a powder sieving box, a material distribution box and a dispersion box. Conical mixing drum, the main shaft of the second motor is provided with a stirring shaft, the lower end of the conical mixing drum is provided with a feeding pipe, the lower end of the feeding pipe is connected with the distribution box, and the feeding pipe is provided with Control valve, a runner is provided in the distribution box, two grooves are symmetrically arranged on the runner, a mounting seat is provided on the side of the upper end of the powder sifting box, and a motor 1 is provided on the mounting seat. The main shaft of the motor is provided with an eccentric wheel, the powder sieving box is provided with a screen frame, the inside of the screen frame is provided with a screen, the bottom of the powder screening box is provided with a bracket, and the upper end of the bracket is provided with a Recycling box, this device realizes the quantitative screening of powder, ensures the screening effect and efficiency of the screen, the powder after processing by this device contains less impurities, and the powder has low water content.

Owner:芜湖市晨睿建材有限公司

Screening and spraying device for feed processing based on Bernoulli principle

PendingCN110961353ATo achieve the screening effectImprove screening efficiencyGas current separationFeeding-stuffBernoulli's principleOil and grease

The invention relates to the technical field of feed processing and discloses a screening and spraying device for feed processing based on the Bernoulli principle. The device comprises a base, whereina first fan blade is arranged at an upper part of the first rotating shaft, an upper part of the integral shell is connected with a screen, the upper side of an inclined plate is provided with a ventilation plate, a lower end of the first rotating shaft is fixedly connected with a centrifugal device, an upper part of the centrifugal device is surrounded by a third through hole, a lower end of thecentrifugal device is connected with a second rotating shaft, a lower end of the second rotating shaft is provided with a second leaf, the first rotating shaft drives the centrifugal device to rotate, the large particle feed enters into the centrifugal device through the first rotating shaft for centrifugal processing and then is thrown out through the third through hole, a second rotating shaftis driven by the centrifugal device to rotate, and the second rotating shaft drives the spraying liquid on an inner part of an outer side of a conical plate through a second blade to be included in the spraying liquid collection box. The device is advantaged in that problems of waste of feed spray liquid and excessive grease of feed in a feed screening and spraying device in the prior art are solved.

Owner:孙陆海

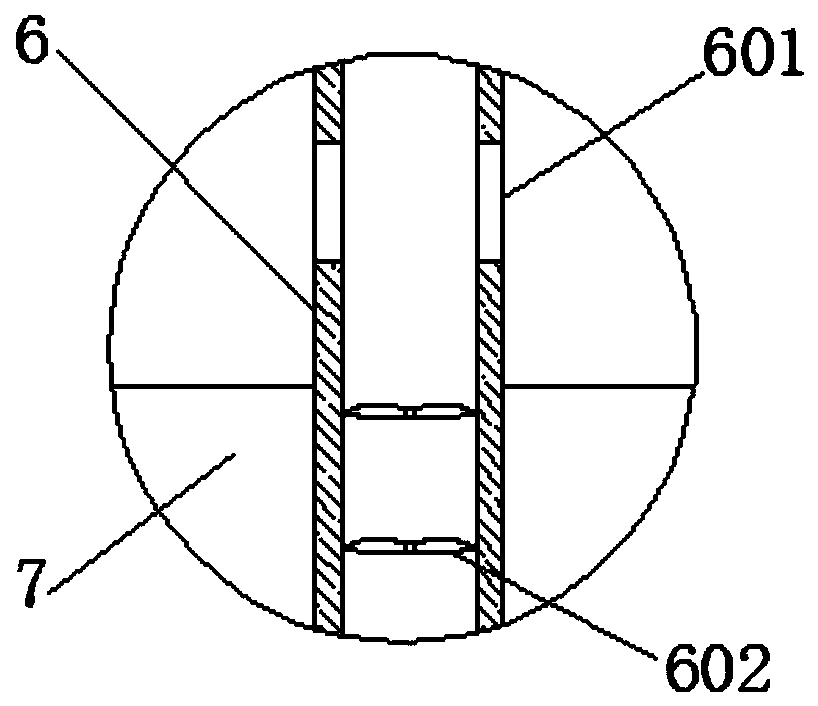

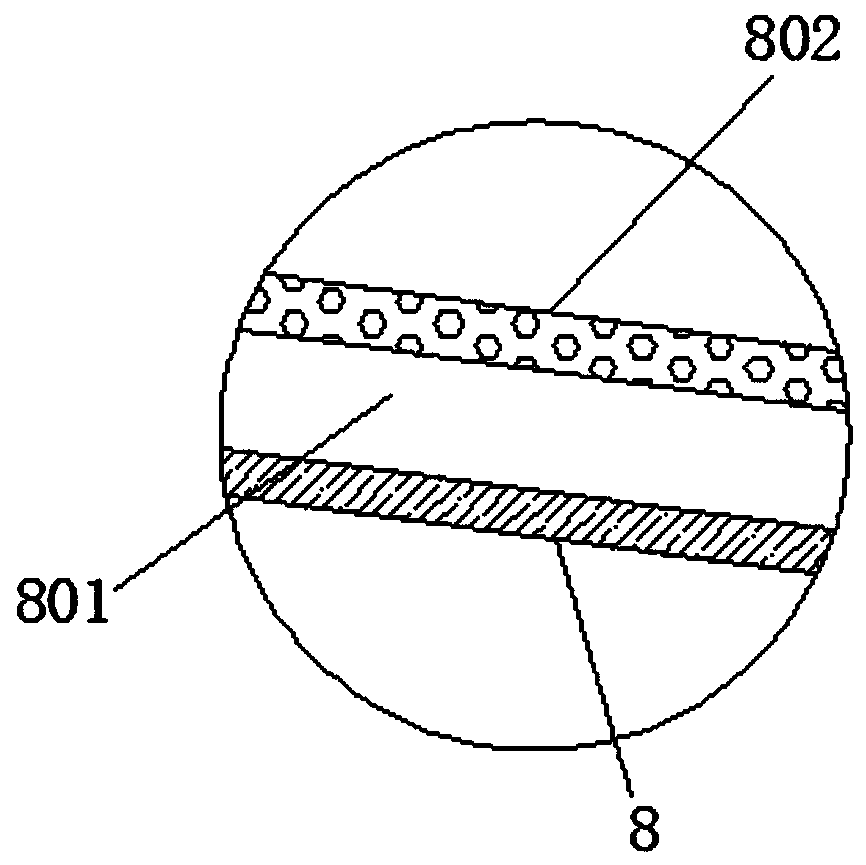

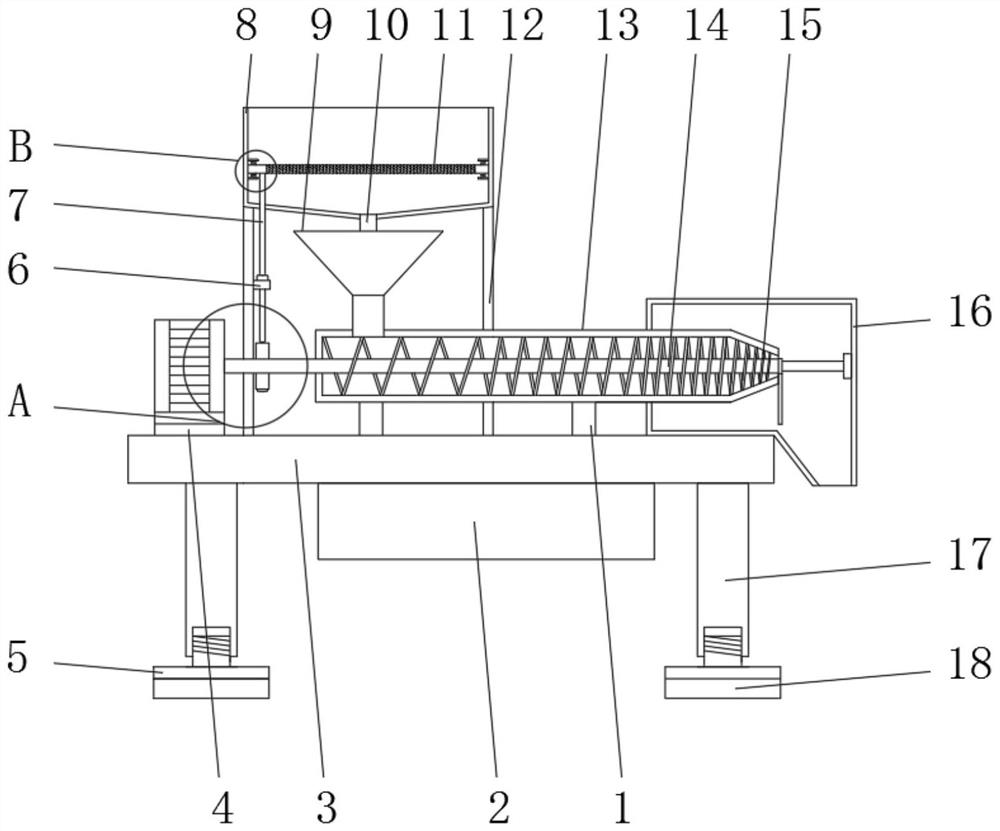

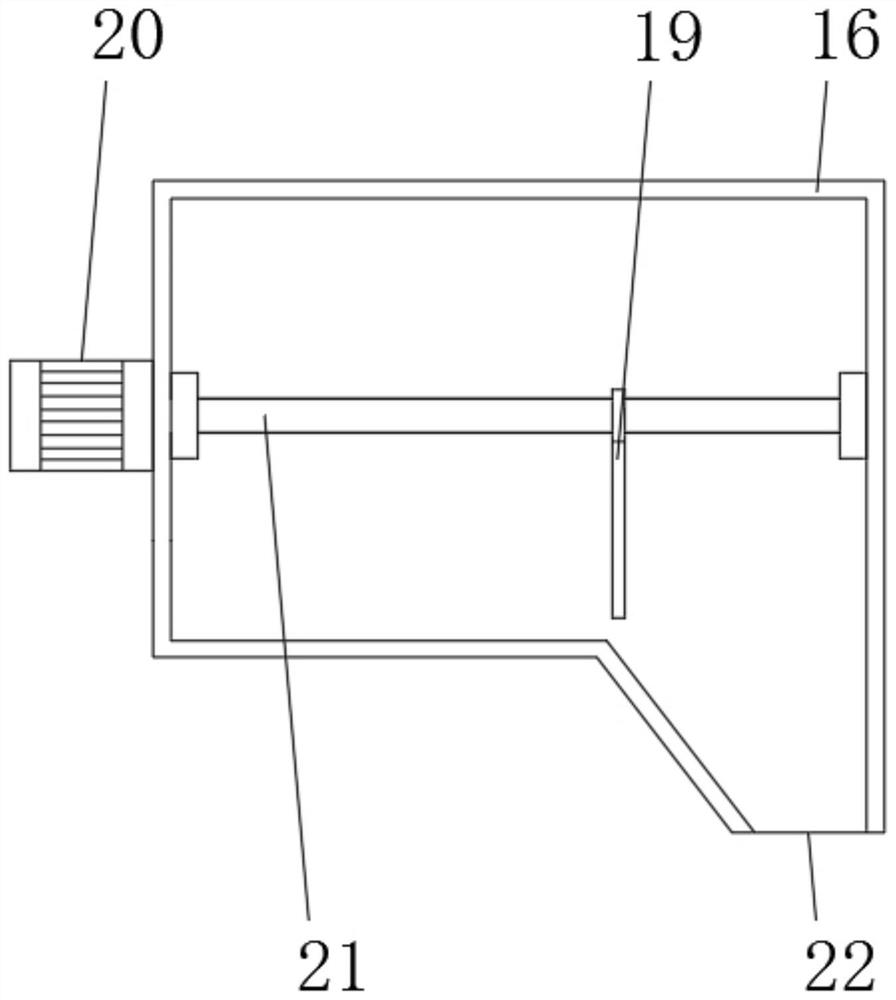

Small bulking machine driven by direct current motor

PendingCN112869219AImprove the use of environmental protectionPromote environmental protectionSievingBatteries circuit arrangementsDC - Direct currentElectric machine

The small bulking machine driven by the direct current motor comprises a workbench, a material screening box and a bulking device, the bulking device is installed in the middle of the top end of the workbench through a supporting table, a bulking shaft is installed in the middle of the interior of the bulking device, and bulking blades are installed on the portion, located in the bulking device, of the outer surface of the bulking shaft. A driving motor is installed at the position, located at one end of the bulking shaft, of one side of the top end of the workbench; a battery is installed at the middle position of the bottom end of the workbench, and screening boxes are installed at the positions, located at the four corners of one side of the driving motor, of the top end of the workbench through supporting columns. According to the invention, the problems of large occupied volume, high production noise, serious environmental pollution, need of manual product segmentation, high labor intensity and low use safety of the existing device which mostly adopts a diesel engine to drive a bulking device to perform bulking on a product are solved, and the environmental protection property and the use safety of the invention are improved.

Owner:天津市源美机电有限公司

Rice milling device

The invention provides a rice milling device with the better chaffhusk separating effect and the low rice broken rate. The rice milling device comprises a driving part and a rice milling box, a rice milling part connected to an output shaft of the driving part is arranged in the rice milling box, the rice milling box comprises a horizontal section and a vertical section, an opening is formed in the side wallof the side, away from the driving part, of the vertical section of the rice milling box, a venturi tube is arranged on the side, away from the driving part, of the rice milling box, the venturi tube abuts against the rice milling box, and a throat tube of the venturi tube faces toward the opening; the diffusion section of the venturi tube communicates with a pneumatic motor, an outputshaft of the pneumatic motor is connected with a crank sliding block mechanism, a piston plate located on the lower part of the opening is vertically and slidably connected into the vertical section of the rice milling box, filter holes are formed in the piston plate, and the piston plate is connected with the crank sliding block mechanism. According to the scheme, the rice milling device is usedfor rice milling, thus the obtained rice can contain little chaff husk, and the rice broken rate is low.

Owner:重庆诚阳农业发展有限公司

A feeding device for cold heading machine

ActiveCN109226656BWill not polluteWon't hinderMagnetic separationCleaning using gasesOil canTransmission belt

The invention relates to the technical field of cold headers, and aims at providing a feeding device used for a cold header. The device comprises a rack, a conveying belt and a conveying groove; a plurality of magnets are arranged on the conveying belt at intervals; the conveying groove is formed in the upper portion of the conveying belt, and the bottom of the conveying groove fits the magnets onthe conveying belt; a limiting mechanism and a cleaning mechanism are arranged on the parts, above the discharging end, of the rack; the limiting mechanism comprises a downward pressing air cylinderand downward pressing members, and the positions of the downward pressing members correspond to the magnets; the cleaning mechanism comprises a cleaning nozzle connected with an air compressor. According to the feeding device, the conveying belt and conveyed fastening members are separated by using the conveying groove, the fastening members are driven to move by using the absorbing effect of themagnets separated by conveying groove so that metal dust and lubricating oil can completely fall in the conveying groove, the environment is not polluted, the cleaning of the conveying groove is convenient, the interior of the conveying groove has no gap and pit, the metal dust cannot be accumulated, the conveying of the fastening members is not blocked, and therefore the conveying is more stable.

Owner:ZHEJIANG QIANGLI FASTENER CO LTD

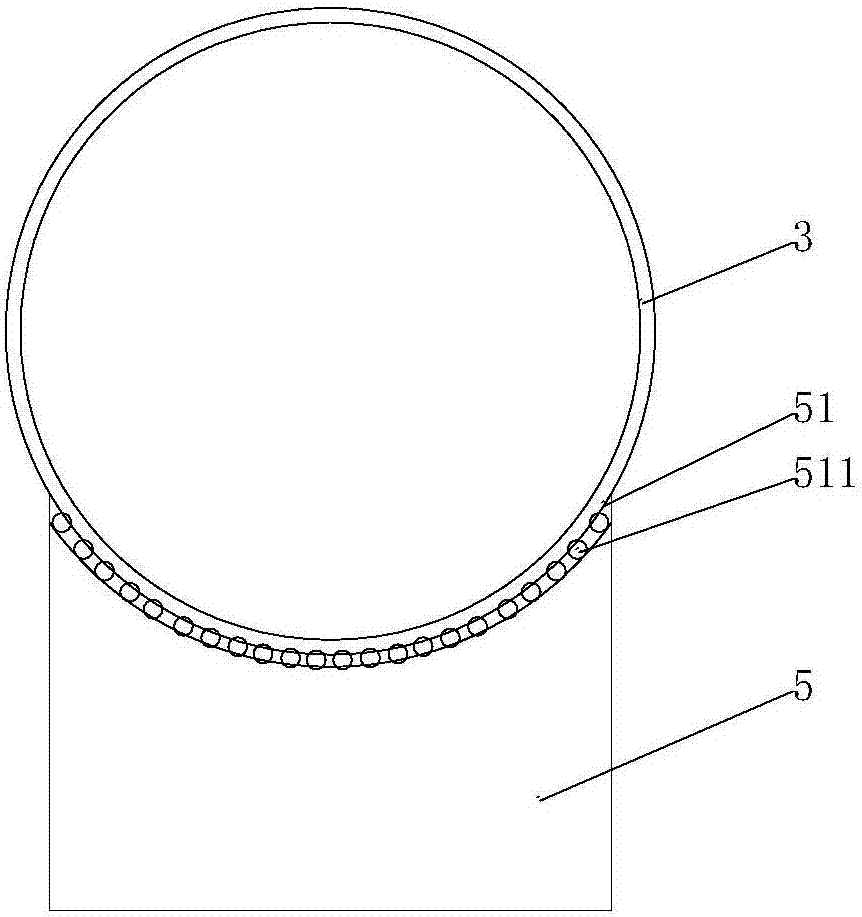

High-efficiency crop drying device

InactiveCN106931747AAvoid pollutionSmall footprintDrying gas arrangementsDrying chambers/containersDrive shaftElectric machine

The invention discloses a high-efficiency crop drying device, which comprises a base, a double-axis motor, a cylinder body, a hot air blower and a bearing seat; the double-axis motor is installed on the lower surface of a beam, and the transmission shaft of the double-axis motor is fixedly connected to both sides There are gears; the cylinder is located under the biaxial motor, and a rack ring is provided on the barrel surface of the cylinder corresponding to the gear, and the rack ring is fixedly connected to the cylinder and meshed with the gear; the bearing seat has two symmetrical It is located at the bottom of the barrel, and the bearing seat is rollingly connected with the barrel through balls; the hot air blower is fixed on the base, and the output end of the hot air blower is connected to the air duct, and the air duct extending into the barrel is vertically equipped with multiple rotating The air outlet is rotated and connected with the air duct by rotating the air outlet. The present invention enables the crops to be heated more evenly through the arrangement of the rotating air outlet, and improves the drying effect; meanwhile, the utility model has a compact structure and a small occupied area.

Owner:惠安县长捷机械科技有限公司

Seed screening equipment for agricultural production

ActiveCN108927331ATo achieve the screening effectImprove filtering effectGas current separationWet separationAgricultural engineeringAgriculture

The invention relates to seed screening equipment, in particular to the seed screening equipment for agricultural production. The invention aims to achieve the technical effect of providing the seed screening equipment performing multi-stage screening and improving the seed quality for agricultural production. The seed screening equipment for the agricultural production comprises a bottom plate, afirst collection frame, a second collection frame, a supporting rack, an annular sliding rail, a sliding block, a separating barrel, a screening barrel, an outer geared ring, a motor, a gear, a firstbaffle, a second baffle, a first insert slot, a guiding hole, a first elastic part, a first insert rod guiding block, a second elastic part and a first insert rod, and the annular sliding rail is fixedly connected to the top of the bottom plate through the supporting rack. By means of the seed screening equipment for the agricultural production, the effects of performing multi-stage screening andimproving the seed quality are achieved.

Owner:民乐县奥星农业科技有限公司

Drying device for rice processing

InactiveCN110833099AFully dryGuaranteed incomeGas current separationSeed preservation by dryingAgricultural scienceAgricultural engineering

The invention discloses a drying device for rice processing. The device comprises a bottom plate and a drying chamber, the drying chamber is arranged above the bottom plate, the top of the drying chamber is fixedly connected with an expansion chamber, the left side of the top of the expansion chamber communicates with a feeding hopper, and the middle of the left side of the drying chamber is fixedly connected with a power motor. The invention relates to the technical field of rice processing. The invention discloses the drying device for rice processing, the cylindrical drying chamber is matched with the windowing-type expansion chamber for drying, water vapor can be directly discharged out of the drying device; meanwhile, a stirring plate and a limiting plate are arranged in a matching manner, the rice can be continuously turned over and raised, the drying chamber can be obliquely adjusted through cooperation with the lifting mechanism, rice can be conveyed while the rice makes full contact with the inner wall of the drying chamber, the drying quality and the drying efficiency are guaranteed, under the condition that a water vapor treatment device is not used, the rice is fully dried, the manufacturing cost is reduced, and meanwhile the income of a manufacturer is guaranteed.

Owner:无为和泰农业科技有限公司

Jasmine tea clean production process

The invention discloses a clean production process of jasmine tea. The process mainly comprises the steps of curing fresh flowers, scenting, cleaning, holding out of scented flowers, baking, conveying while vibrating, and packaging. The jasmine tea prepared by adopting the process is long-lasting in aroma, fresh, rich and mellow in taste and clear, and yellow and bright in color of soup. The fresh flowers are cured, scented and cleaned on an operation platform, so that the cleanness of the jasmine tea can be ensured and the grade of the jasmine tea can not be influenced.

Owner:四川省炒花甘露茗茶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com