Gravel screening device for buildings

A screening device, a technology for construction, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of large amount of labor in screening sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example 1

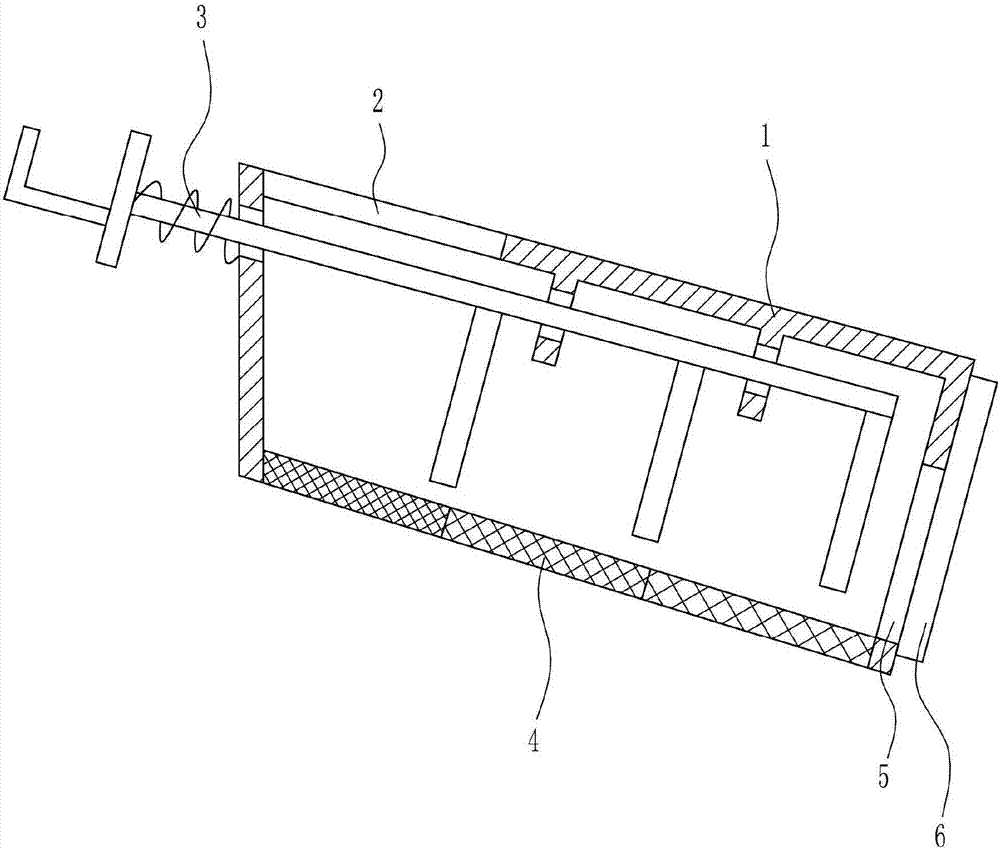

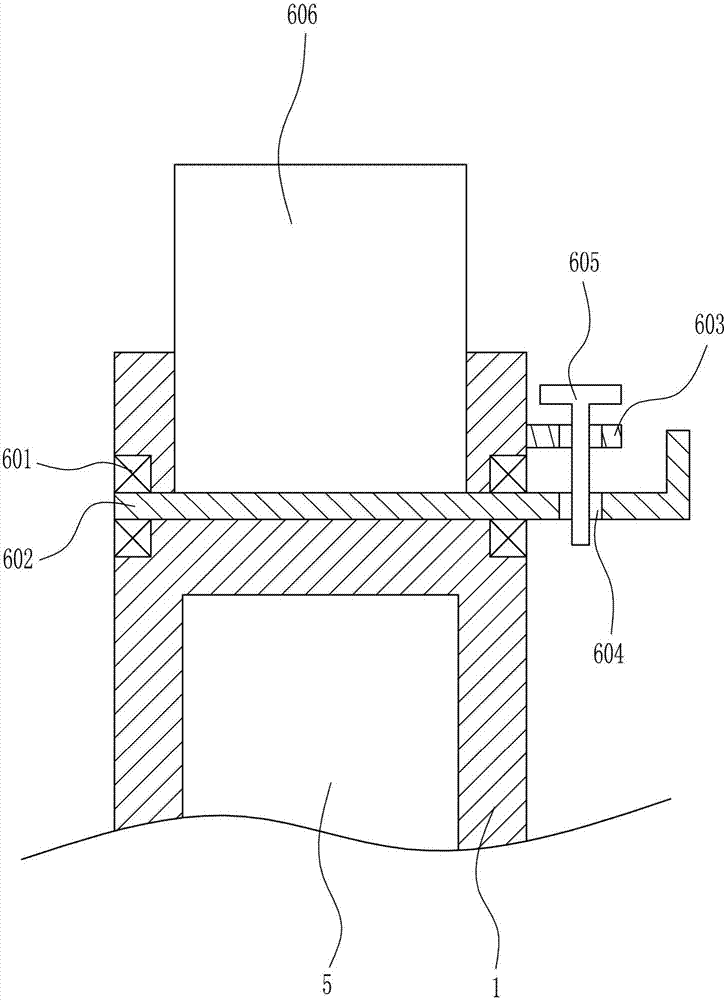

[0040] A construction grit screening device, such as Figure 1-7 As shown, it includes a screening box 1, a stirring mechanism 3, a screen 4 and a switch mechanism 6. The top left side of the screening box 1 is provided with a feeding port 2, and the screening box 1 is connected with a stirring mechanism 3. The bottom is evenly connected with a sieve 4, the aperture of the sieve 4 increases sequentially from left to right, a second through hole 5 is opened on the lower part of the right side of the screening box 1, and a switch mechanism 6 is connected to the right side of the screening box 1, The switch mechanism 6 is located on the right side of the second through hole 5 .

Example Embodiment

[0041] Example 2

[0042] A construction grit screening device, such as Figure 1-7 As shown, it includes a screening box 1, a stirring mechanism 3, a screen 4 and a switch mechanism 6. The top left side of the screening box 1 is provided with a feeding port 2, and the screening box 1 is connected with a stirring mechanism 3. The bottom is evenly connected with a sieve 4, the aperture of the sieve 4 increases sequentially from left to right, a second through hole 5 is opened on the lower part of the right side of the screening box 1, and a switch mechanism 6 is connected to the right side of the screening box 1, The switch mechanism 6 is located on the right side of the second through hole 5 .

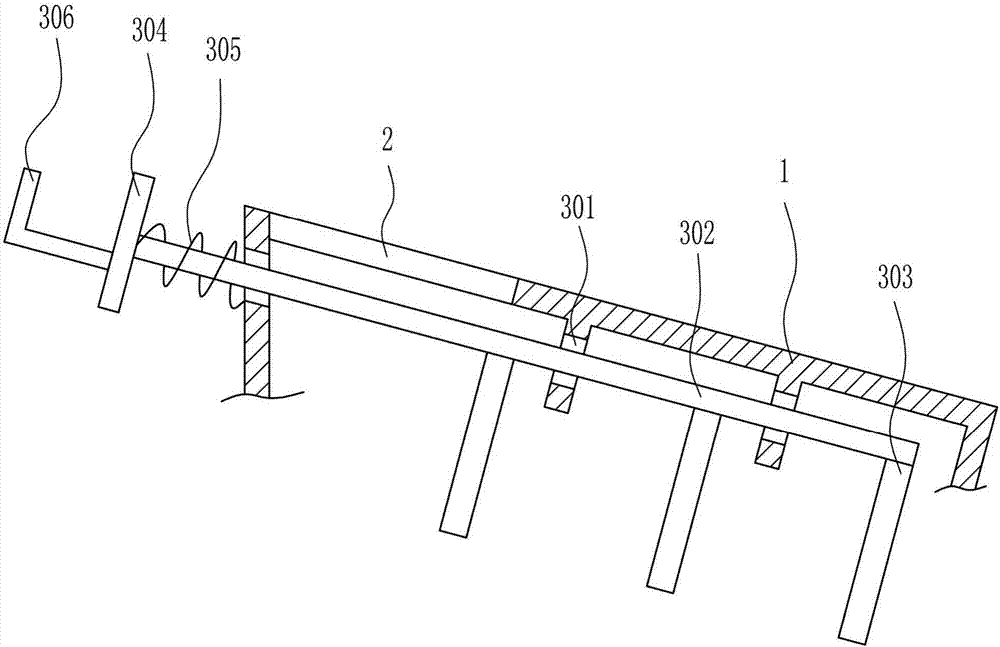

[0043] The stirring mechanism 3 includes a moving rod 302, a first stirring rod 303, a stop rod 304, a first spring 305 and a handle 306. The upper part of the screening box 1 is evenly opened with a first through hole 301, and the first through hole 301 is provided with a moving Rod...

Example Embodiment

[0044] Example 3

[0045] A construction grit screening device, such as Figure 1-7 As shown, it includes a screening box 1, a stirring mechanism 3, a screen 4 and a switch mechanism 6. The top left side of the screening box 1 is provided with a feeding port 2, and the screening box 1 is connected with a stirring mechanism 3. The bottom is evenly connected with a sieve 4, the aperture of the sieve 4 increases sequentially from left to right, a second through hole 5 is opened on the lower part of the right side of the screening box 1, and a switch mechanism 6 is connected to the right side of the screening box 1, The switch mechanism 6 is located on the right side of the second through hole 5 .

[0046] The stirring mechanism 3 includes a moving rod 302, a first stirring rod 303, a stop rod 304, a first spring 305 and a handle 306. The upper part of the screening box 1 is evenly opened with a first through hole 301, and the first through hole 301 is provided with a moving Rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com