Rice milling device

A rice and rice milling technology, which is applied in application, grain degerming, grain processing, etc., can solve the problems of low work efficiency, extended time required for rice processing, etc., and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

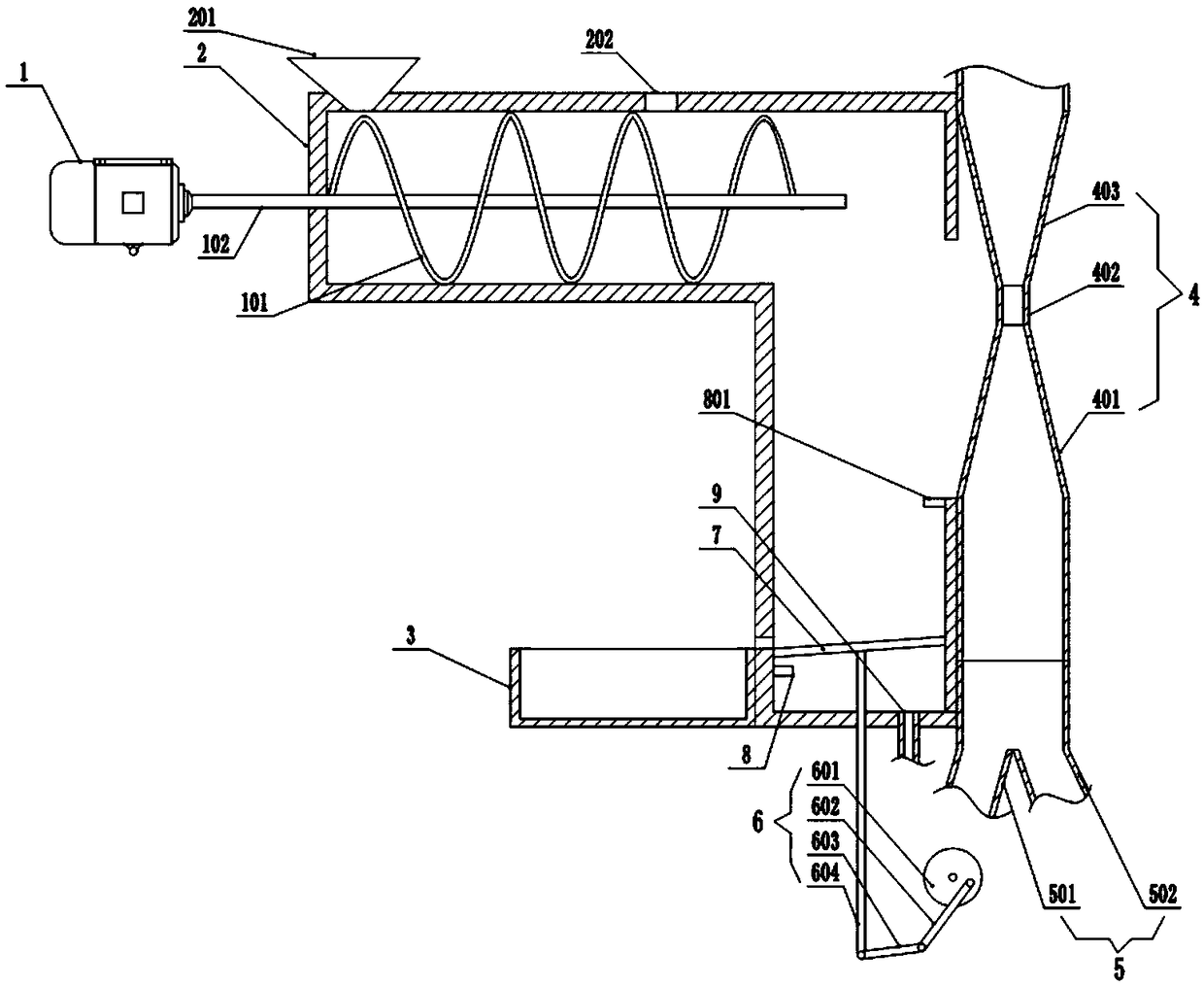

[0026] Rice milling apparatus, such as figure 1 Shown, comprise frame and the rice milling box 2 that is fixed on the frame, the left side of rice milling box 2 is provided with the driver that is fixed on the frame, and driver is motor 1 in the present embodiment. The rice milling box 2 is L-shaped, and the rice milling box 2 includes a horizontal section and a vertical section. The rice milling piece is provided in the horizontal section of the rice milling box 2. In this embodiment, the rice milling piece includes a rotating shaft 102 and a fixed connection The auger blade 101 on the rotating shaft 102, the output shaft of the motor 1 is coaxially connected with the rotating shaft 102, and the auger blade 101 is attached to the inner wall of the rice milling box 2 horizontal sections. Motor 1 output shaft and rice milling box 2 horizontal section sidewalls rotate and cooperate.

[0027] The top wall of the rice milling box 2 is provided with a feeding port 201 and a window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com