Traditional Chinese medicine mask powder crushing equipment

A technology of traditional Chinese medicine mask and crushing equipment, which is used in solid separation, sieve, grid and other directions, can solve the problems of inability to separate waste and finished materials, and can not achieve blocking and screening at the same time, to achieve anti-blocking and screening. the effect of points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

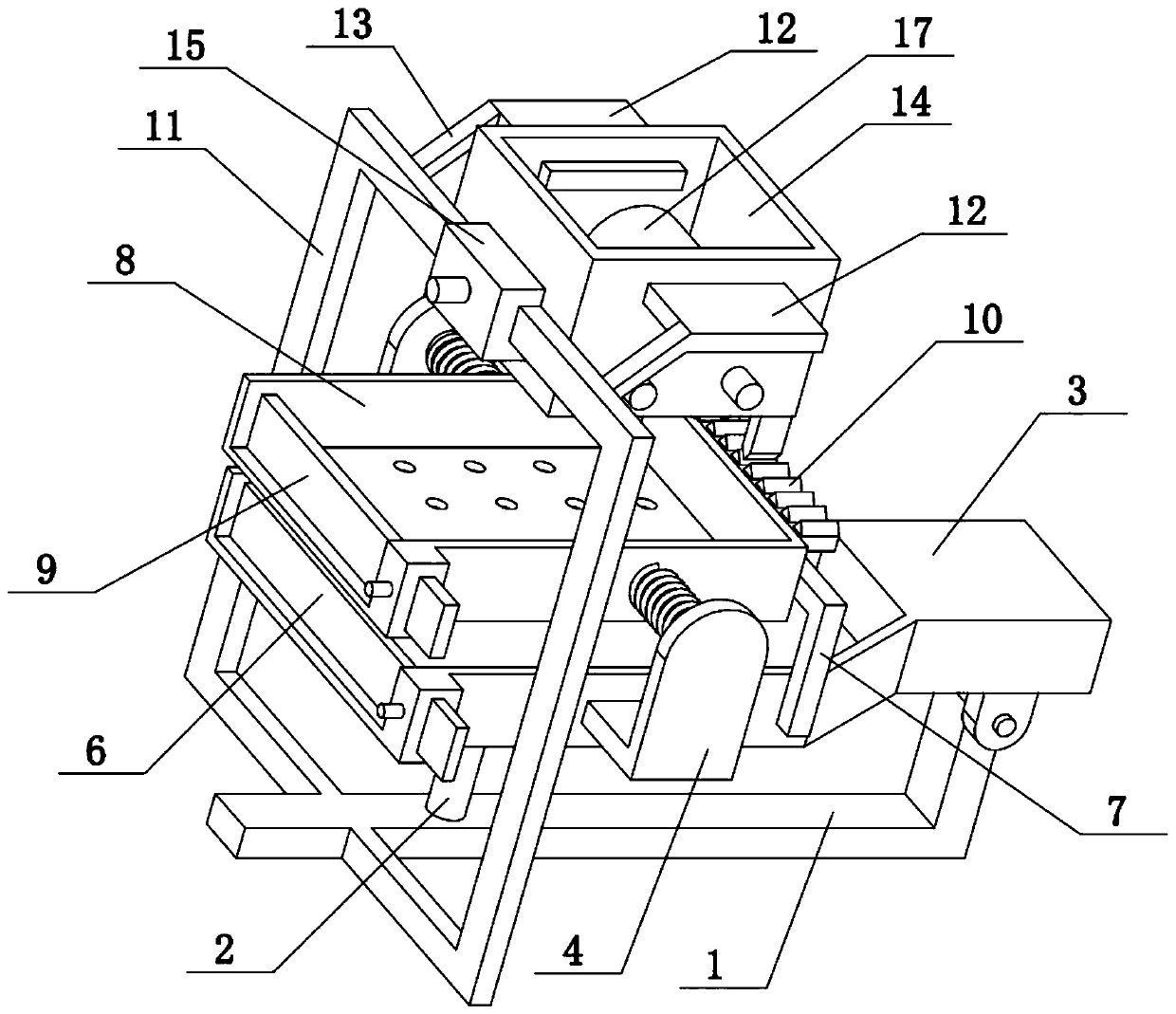

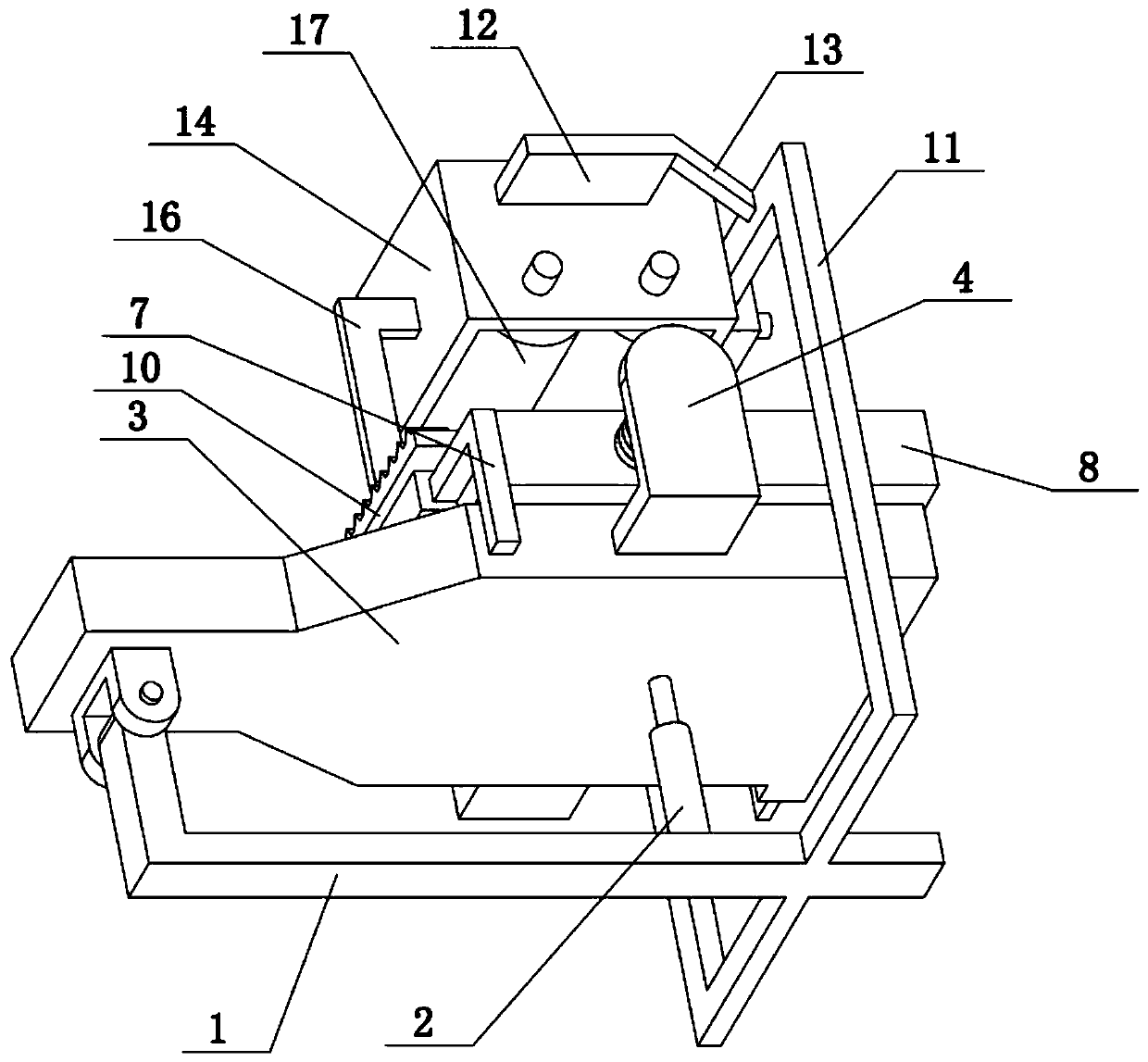

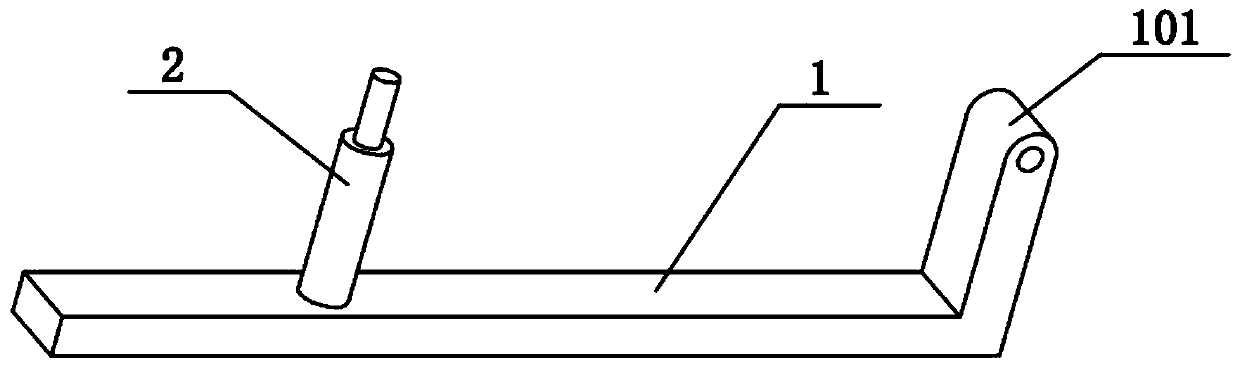

[0031] Combine below Figure 1-10 To illustrate this embodiment, the present invention relates to a crushing equipment, more specifically a crushing equipment for traditional Chinese medicine facial mask powder, including a bottom rod 1, an electric telescopic rod 2, a collection tray 3, a door frame 7, a sieve tray 8, a sieve Plate 801, clamping plate 10, rectangular support 11, rectangular cylinder 14, inserting rod 16 and crushing roller 17, sieve tray 8 and rectangular cylinder 14 can slide back and forth at the same time, and sieve tray 8 reciprocatingly slides back and forth to achieve the effect of screening. Rectangular cylinder 14 slides back and forth to achieve the anti-blocking effect, and at the same time realizes the effect of anti-blocking and screening; the collection pan 3 and the sieve pan 8 can be tilted at the same time, when the collection pan 3 is tilted, the powder is poured out, and the sieve pan 8 is tilted When pouring out the sieved sundries, the was...

specific Embodiment approach 2

[0034] Combine below Figure 1-10 To illustrate this embodiment, the crank-rocker mechanism drives the sieve tray 8 to reciprocate and slide back and forth, and when the sieve tray 8 reciprocates and slides back and forth, the insert rod 16 drives the rectangular cylinder 14 to reciprocate and slide back and forth. At this moment, the crank rocker mechanism is fixed on the rectangular support 11 .

specific Embodiment approach 3

[0036] Combine below Figure 1-10 To illustrate this embodiment, the crank and rocker mechanism is used to drive the rectangular cylinder 14 to reciprocate and slide back and forth. When the rectangular cylinder 14 reciprocates and slides back and forth, the insertion rod 16 drives the sieve tray 8 to reciprocate and slide back and forth. At this moment, the crank rocker mechanism is fixed on the collecting tray 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com